Toyota Prius: Plug-in Charge Control System (for Phev Model)

- Precaution

- Definition Of Terms

- Parts Location

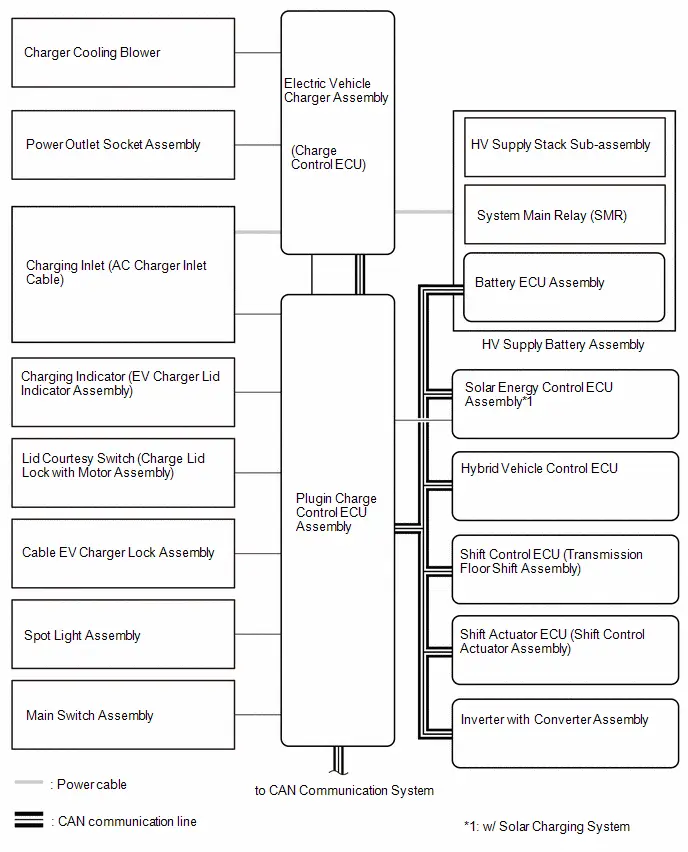

- System Diagram

- How To Proceed With Troubleshooting

- Customize Parameters

- Utility

- Problem Symptoms Table

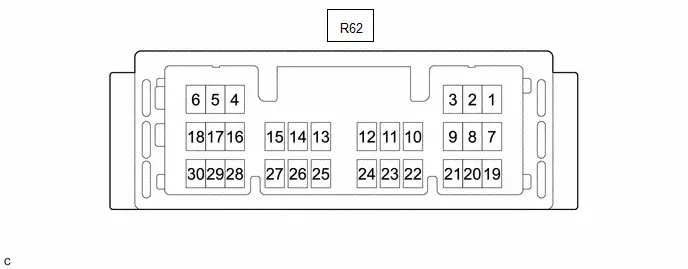

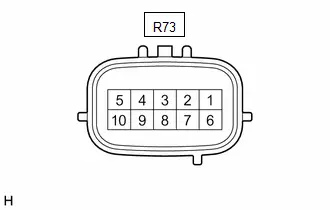

- Terminals Of Ecu

- Diagnosis System

- Dtc Check / Clear

- Freeze Frame Data

- System Voltage (BATT) Circuit Short to Ground or Open (P056014)

- Hybrid/EV Battery Charging System Positive Contactor Stuck Closed (P0D0700)

- Hybrid/EV Battery Charging System Positive/Negative Contactor Actuator Stuck Closed (P0D0773)

- Hybrid/EV Battery Charging System Negative Contactor Control Actuator Stuck Closed (P0D0E73)

- Hybrid/EV Battery Charger Input Current Sensor Circuit Circuit Current Above Threshold (P0D2A19)

- Charging Connector Proximity Detection Circuit Short to Ground (P0D5611)

- Charging Connector Proximity Detection Circuit Short to Auxiliary Battery or Open (P0D5615)

- Hybrid/EV Battery Charger Hybrid/EV Battery Output Current (ICHG) High Circuit Current Above Threshold (P19CC19)

- Charger Cooling Fan Revolution Sensor Component Internal Failure (P1CE996)

- High Voltage Charging Circuit Consumption Circuit Short (P309F49)

- Lost Communication with ECM/PCM "A" Missing Message (U010087,U015587,U029387)

- Lost Communication with Battery Charger Control Module "B" Missing Message (U01BB87)

- Lost Communication with Solar Charging Control Module Missing Message (U113A87)

- Lost Communication with Hybrid/EV Powertrain Control Module (ch3) Missing Message (U115187)

- Lost Communication with Hybrid/EV Battery Energy Control Module "A" (ch2) Missing Message (U117B87)

- Open in AC Line

- AC Line Insulation Malfunction

- Cannot Set or Change Charge Schedule Setting

- Charging Starts Immediately Despite Charge Schedule Setting

- Cannot Lock Charging Connector

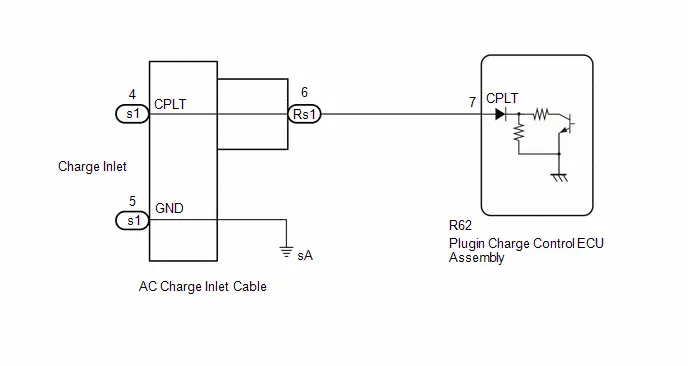

- Control Pilot Signal Circuit

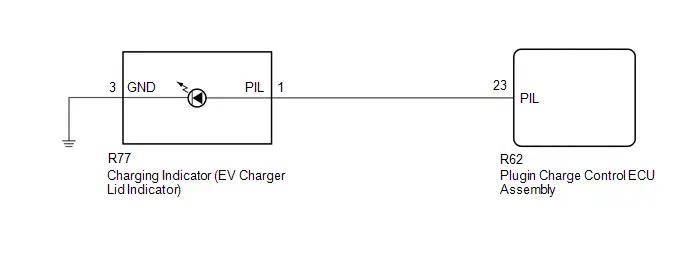

- Charging Indicator Circuit

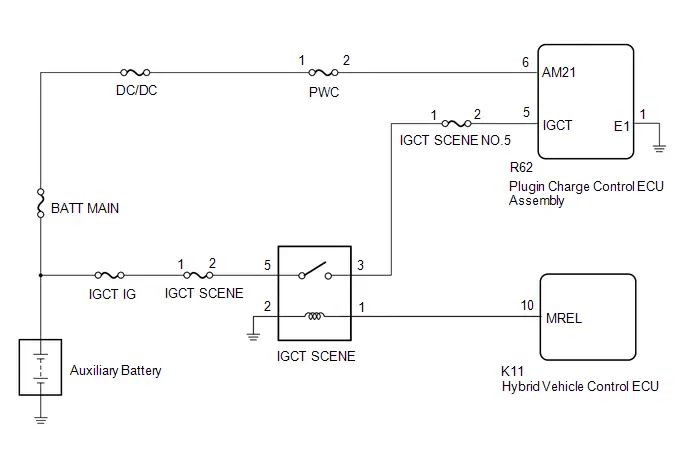

- ECU Power Source Circuit

Precaution

PRECAUTION

PRECAUTIONS FOR INSPECTING PLUG-IN CHARGE CONTROL SYSTEM

CAUTION:

-

During inspection work, to prevent the auxiliary power supply control system from activating and causing operation of electrical devices such as the radiator fan and water pump to start at unintended timing, press and hold the ignition switch (push start switch) for 5 seconds to prohibit auxiliary power supply control system and solar charging control (traction battery output control).

HINT:

- When the ignition switch (push start switch) is pressed and held for 5 seconds, messages about auxiliary power supply control system and solar charging control (traction battery output control) are displayed in the meter.

- After the inspections in the motor/engine compartment are completed, turning the ignition switch ON (READY) will restore the prohibited controls.

-

Before the following operations are conducted, take precautions to prevent electric shock by turning the ignition switch off, wearing insulated gloves, and removing the service plug grip from HV battery.

-

To prevent electric shock, make sure to remove the service plug grip to cut off the high voltage circuit before servicing the Toyota Prius vehicle.

-

After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

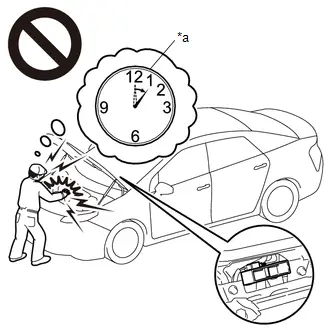

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals.

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

*a

Without waiting for 10 minutes

-

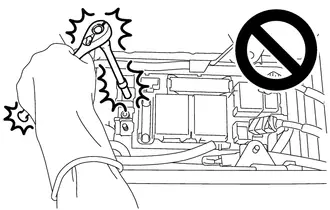

When troubleshooting high voltage circuit, use either a tool wrapped with vinyl insulation tape or an insulated tool. (It is extremely dangerous when a high-voltage charge passes through a non-insulated tool causing a short.)

-

When turning the ignition switch ON during an inspection, do not press the ignition switch while depressing the brake pedal.

Pressing the ignition switch with the brake pedal depressed causes the system to enter the READY-on state. This is very dangerous because high voltage may be applied to the inspection area.

NOTICE:

- After removing the service plug grip, turning the ignition switch to ON (READY) may cause a malfunction. Do not turn the ignition switch to ON (READY) unless instructed by the repair manual.

- Turn the ignition switch off before performing any resistance checks.

- Turn the ignition switch off before disconnecting or reconnecting any connectors.

- When high-voltage connectors are removed, wrap the connectors with insulation tape to prevent them from contacting foreign matter.

HINT:

-

Removing the service plug grip

Click here

-

Checking the terminal voltage

Click here

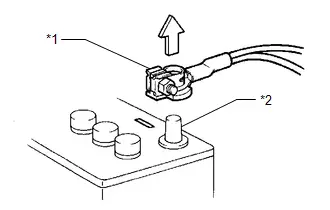

PRECAUTIONS FOR DISCONNECTING AMD TERMINAL

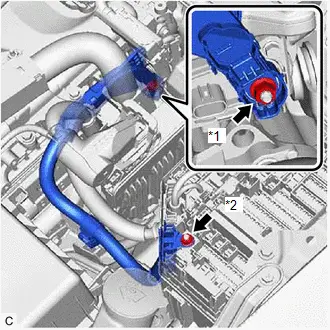

The AMD terminal is connected to the positive terminal of the auxiliary battery.

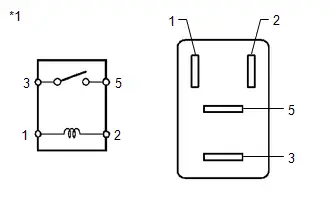

| *1 | AMD Terminal (Inverter with Converter Assembly Side) |

| *2 | AMD Terminal (No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly Side) |

NOTICE:

- Be sure to disconnect the cable from the negative (-) auxiliary battery terminal before disconnecting the AMD terminal from the No. 1 engine room relay block and No. 1 junction block assembly.

- A short circuit to ground may occur if the AMD terminal is disconnected before the cable is disconnected from the negative (-) auxiliary battery terminal. If a short circuit to ground occurs, a fusible link or fuse may break.

-

Do not disconnect the AMD terminal except when replacing the inverter with converter assembly.

When disconnection is necessary, be careful not to apply excessive force to the terminal.

- After disconnecting the AMD terminal, wrap it with vinyl insulating tape.

- Be sure to reconnect the AMD terminal to the No. 1 engine room relay block and No. 1 junction block assembly before reconnecting the cable to the negative (-) terminal of the auxiliary battery.

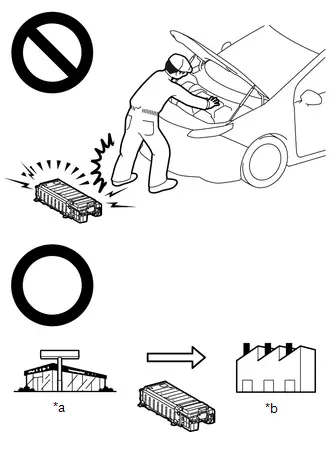

DISPOSING OF HV BATTERY

When disposing of HV battery, make sure to return them through an authorized collection agent who is capable of handling them safely. If they are returned via the manufacturer specified route, they will be returned properly and in a safe manner by an authorized collection agent.

CAUTION:

-

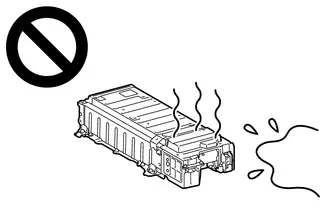

After removing the HV battery, keep it away from water. Exposure to water may cause the HV battery to produce heat, resulting in a fire.

-

Accidents such as electric shock may result if the HV battery is disposed of improperly or abandoned.

Therefore, make sure to return HV battery through an authorized collection agent.

*a

Dealer

*b

Battery Collection Agent

- To reduce the risk of fire, HV battery must not be stored in an area where they will be exposed to fire or high temperatures.

- If the temperature of the HV battery is high, leave the Toyota Prius vehicle until the temperature drops.

-

Make sure to insulate the high-voltage connectors and terminals of the HV battery with insulating tape after removing them.

If the HV battery is stored without insulating the connectors and terminals, electric shock or fire may result.

NOTICE:

Before returning the HV battery, make sure to perform a recovery inspection.

Click here

PRECAUTIONS WHEN REPLACING HYBRID Toyota Prius Vehicle CONTROL ECU

NOTICE:

-

Before replacing the hybrid vehicle control ECU, refer to Registration.

Click here

-

When the hybrid vehicle control ECU is replaced, perform ECU configuration.

Click here

-

When the hybrid Toyota Prius vehicle control ECU is replaced, update the ECU security key.

Click here

-

After replacing the hybrid vehicle control ECU, it is necessary to perform the vehicle specification information procedure for the ECU.

Click here

- If the Toyota Prius vehicle specification information procedure has not been performed, vehicle control history (RoB) will be stored.

- After performing the vehicle specification information procedure, perform a health check using the GTS and confirm that there are no DTCs stored.

PRECAUTIONS FOR DISCONNECTING AND RECONNECTING CABLE TO NEGATIVE (-) AUXILIARY BATTERY TERMINAL

(a) Before performing work on electronic components, disconnect the cable from the negative (-) auxiliary battery terminal to prevent damage to the electrical system or electrical components.

| *1 | Cable |

| *2 | Negative (-) Battery Terminal |

(b) Before disconnecting and reconnecting the auxiliary battery cable, turn the ignition switch off and the headlight switch off. Then loosen the terminal nut completely. Do not damage the cable or terminal.

(c) When the auxiliary battery cable is disconnected, the clock and radio settings and stored DTCs are cleared. Therefore, before disconnecting the auxiliary battery cable, make a note of them.

NOTICE:

- To prevent damage to electronic components, disconnect the cable from the negative (-) auxiliary battery terminal before performing work.

- Be sure to turn the ignition switch off before disconnecting the cable from the negative (-) auxiliary battery terminal.

- Be careful not to damage the cable or terminal.

- When the negative (-) auxiliary battery terminal is disconnected, the clock and radio settings, etc., as well as any stored DTCs, will be cleared.

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

Definition Of Terms

DEFINITION OF TERMS

| Term | Definition |

|---|---|

| Monitor Description | Description of what the plugin charge control ECU monitors and how to detect malfunctions (monitoring purpose and its details). |

| Related DTCs | A group of diagnostic trouble codes that are output by the plugin charge control ECU based on the same malfunction detection logic. |

| Typical Enabling Conditions | Preconditions that allow the plugin charge control ECU to detect malfunctions. With all preconditions satisfied, the plugin charge control ECU stores DTCs when the monitored value(s) exceeds malfunction threshold(s). |

| Sequence of Operation | Order of monitor priority, applied if multiple sensors and components are involved in a single malfunction detection process. Each sensor and component are monitored in turn and subsequent items are not monitored until the previous detection operation completes. |

| Required Sensors/Components | Sensors and components used by the plugin charge control ECU to detect each malfunction. |

| Frequency of Operation | Number of times the plugin charge control ECU checks for each malfunction during each driving cycle. "Once per driving cycle" means that the plugin charge control ECU only checks for malfunctions once during a single driving cycle. "Continuous" means that the plugin charge control ECU checks for malfunctions whenever enabling conditions are met. |

| Duration | Minimum time for which the plugin charge control ECU must detect continuous deviation in monitored value(s) in order to store a DTC. Timing begins when typical enabling conditions are met. |

| Malfunction Thresholds | Value beyond which the plugin charge control ECU determines malfunctions exist and stores DTCs. |

| MIL Operation | Timing of MIL illumination after a malfunction is detected. "Immediate" means that the plugin charge control ECU illuminates the MIL as soon as a malfunction is detected. "2 driving cycles" means that the plugin charge control ECU illuminates the MIL if the same malfunction is detected again during the next driving cycle. |

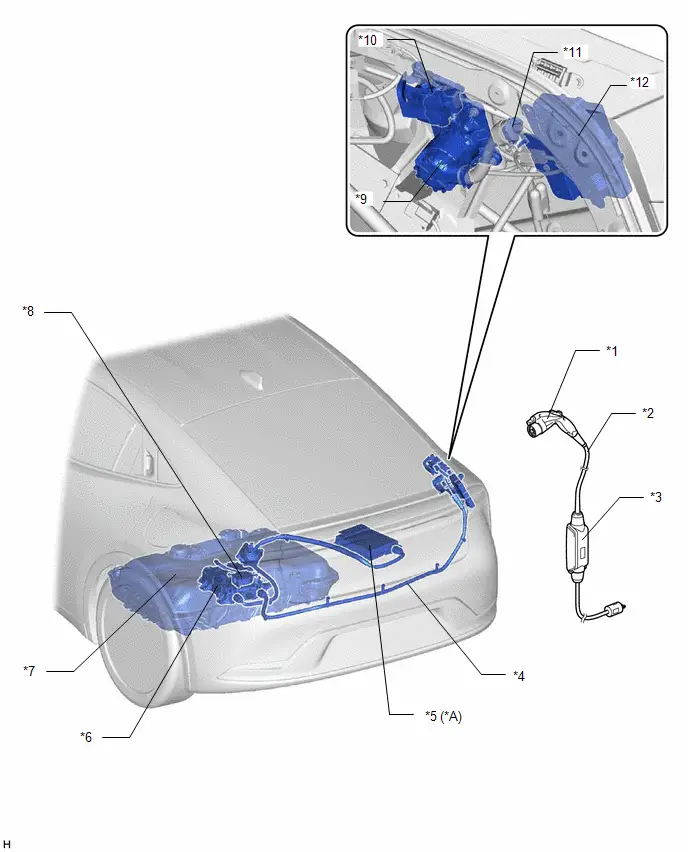

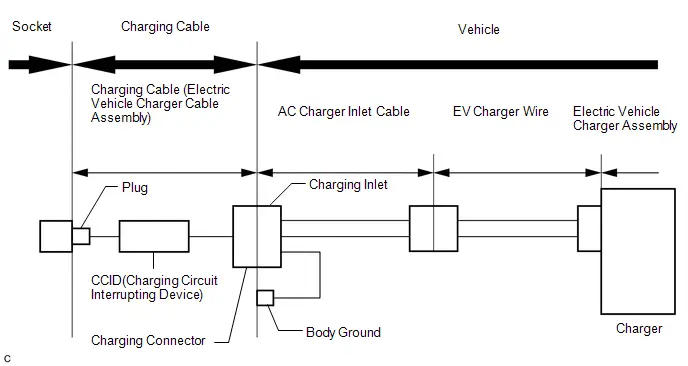

Parts Location

PARTS LOCATION

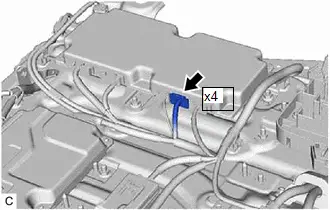

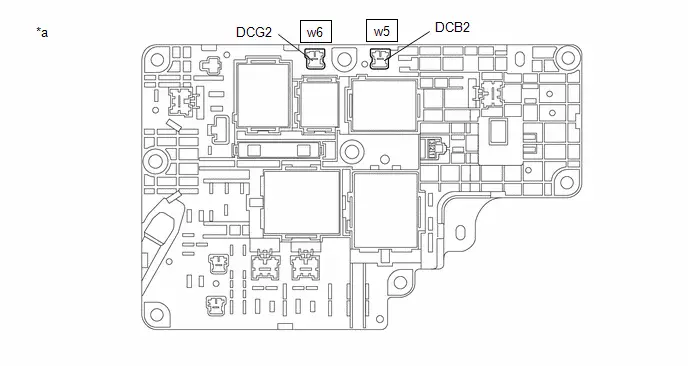

ILLUSTRATION

| *A | w/ SOLAR CHARGING SYSTEM | - | - |

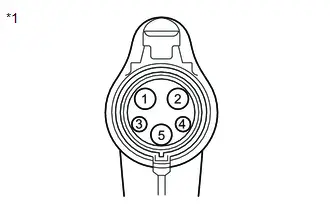

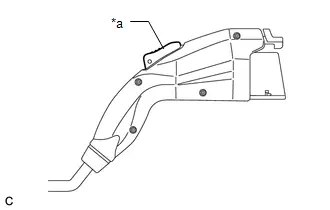

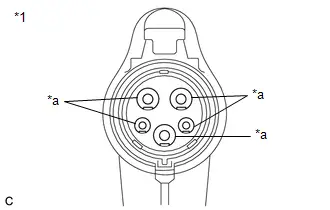

| *1 | CHARGING CONNECTOR | *2 | CHARGING CABLE (ELECTRIC Toyota Prius Vehicle CHARGER CABLE ASSEMBLY) |

| *3 | CCID (CHARGING CIRCUIT INTERRUPTING DEVICE) | *4 | EV CHARGER WIRE |

| *5 | SOLAR ENERGY CONTROL ECU ASSEMBLY | *6 | ELECTRIC Toyota Prius Vehicle CHARGER ASSEMBLY - CHARGE CONTROL ECU - VOLTAGE INVERTER ASSEMBLY |

| *7 | HV SUPPLY BATTERY ASSEMBLY | *8 | CHARGER COOLING BLOWER |

| *9 | AC CHARGER INLET CABLE - CHARGING INLET | *10 | CABLE EV CHARGER LOCK ASSEMBLY |

| *11 | CHARGING INDICATOR (EV CHARGER LID INDICATOR) | *12 | PLUGIN CHARGE CONTROL ECU ASSEMBLY |

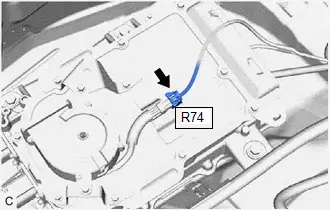

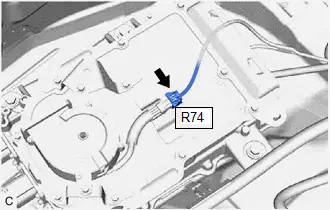

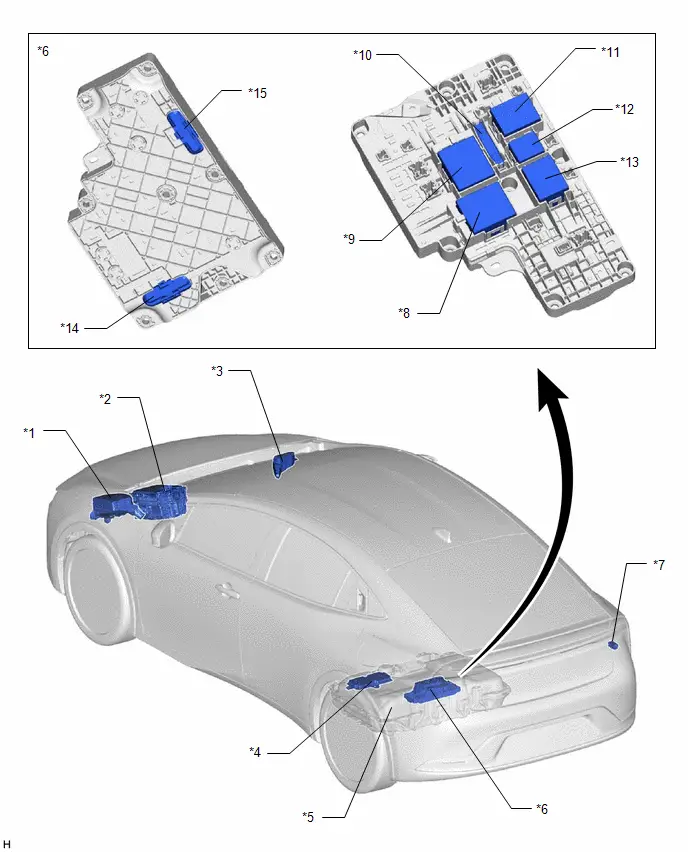

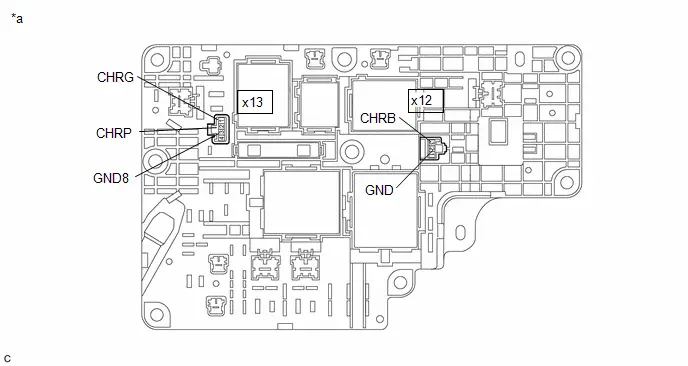

ILLUSTRATION

| *1 | NO. 1 ENGINE ROOM RELAY BLOCK AND NO. 1 JUNCTION BLOCK ASSEMBLY | *2 | INVERTER WITH CONVERTER ASSEMBLY |

| *3 | NO. 2 ENGINE ROOM RELAY BLOCK AND NO. 2 JUNCTION BLOCK ASSEMBLY | *4 | BATTERY ECU ASSEMBLY |

| *5 | HV SUPPLY BATTERY ASSEMBLY | *6 | NO. 1 TRACTION BATTERY DEVICE BOX |

| *7 | FUSE BLOCK ASSEMBLY | *8 | SMRB RELAY |

| *9 | SMRG RELAY | *10 | SYSTEM MAIN RESISTOR |

| *11 | CHRG RELAY | *12 | CHRP RELAY |

| *13 | CHRB RELAY | *14 | AC CHARGING FUSE (HIGH VOLTAGE FUSE) |

| *15 | SOLAR CHARGING FUSE (HIGH VOLTAGE FUSE) | - | - |

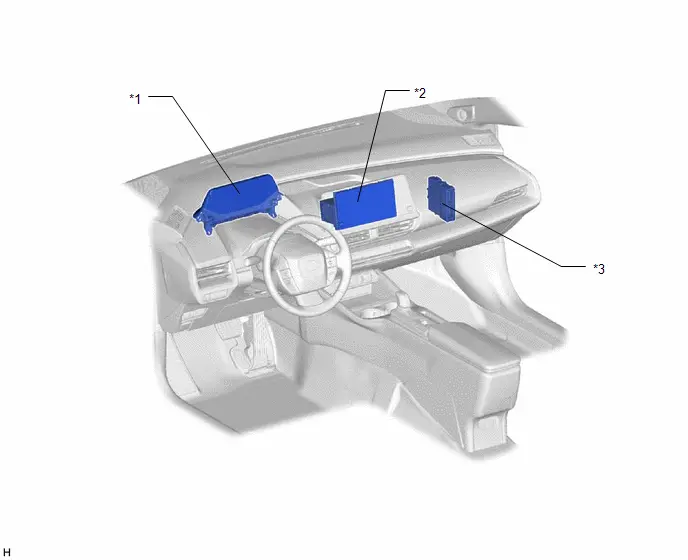

ILLUSTRATION

| *1 | COMBINATION METER ASSEMBLY | *2 | RADIO AND DISPLAY RECEIVER ASSEMBLY |

| *3 | HYBRID Toyota Prius Vehicle CONTROL ECU | - | - |

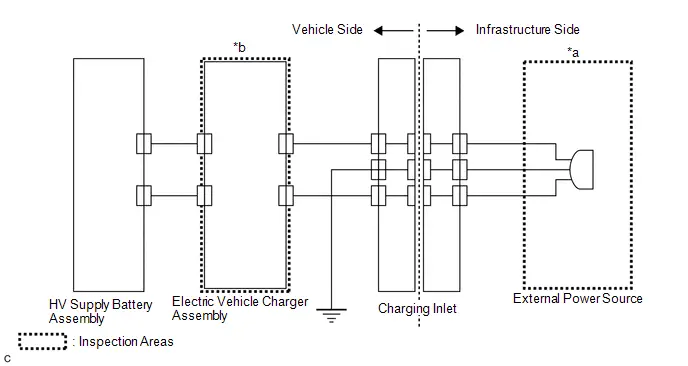

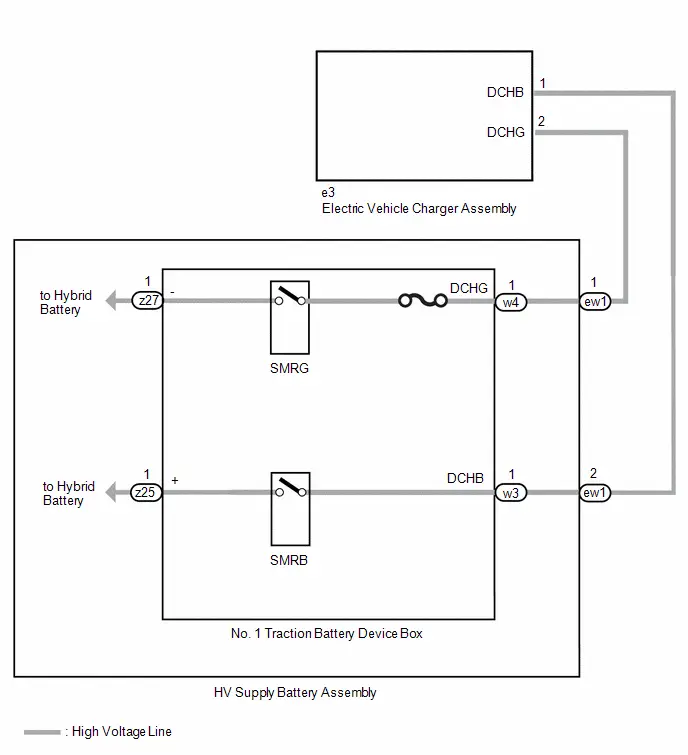

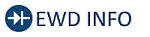

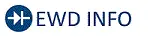

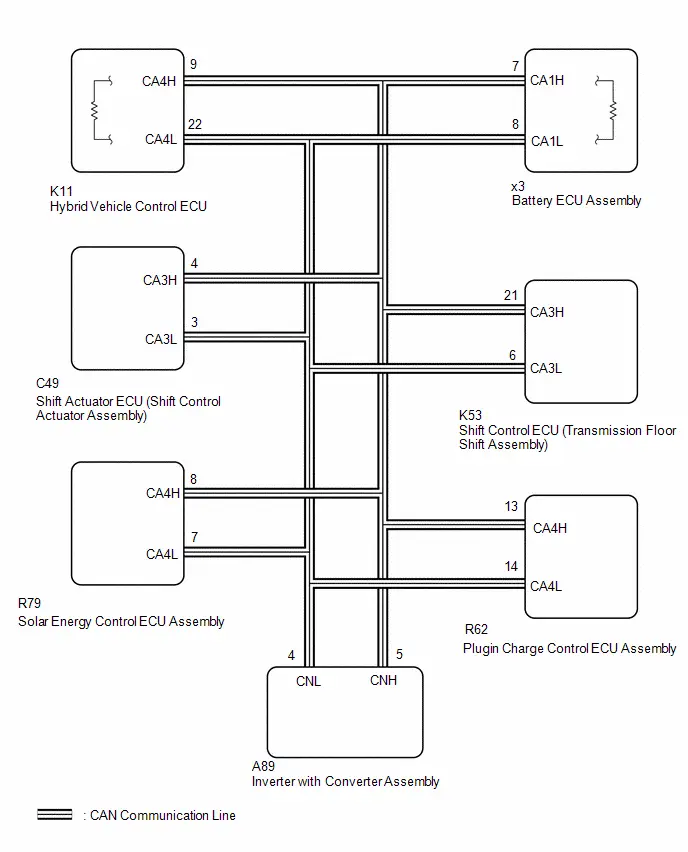

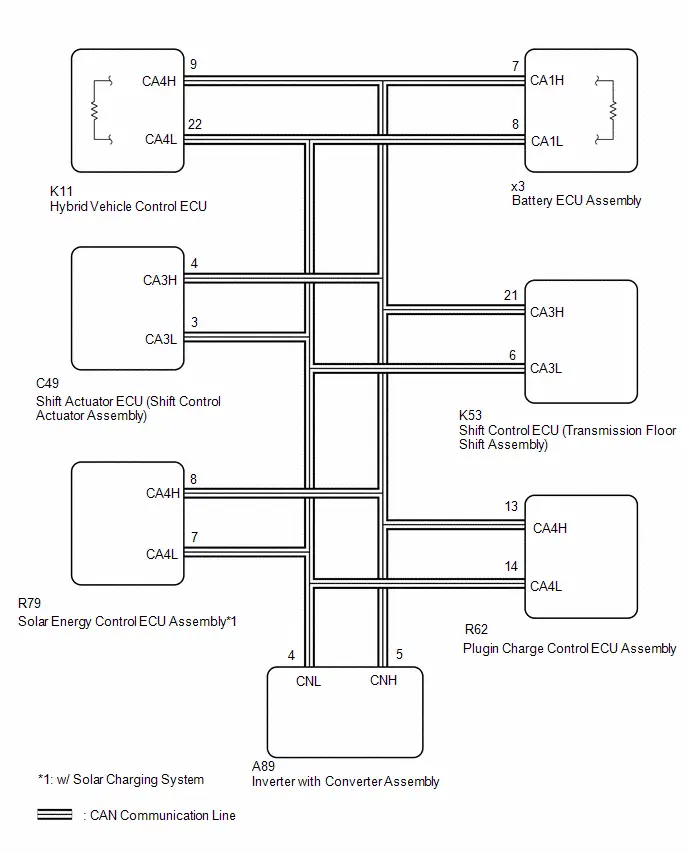

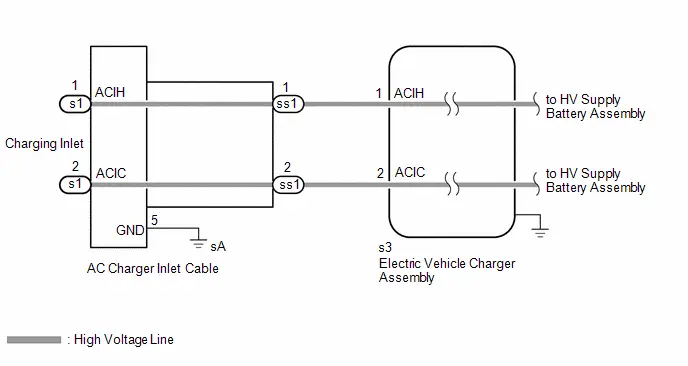

System Diagram

SYSTEM DIAGRAM

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

- *: Use the GTS

- Use the following procedure to troubleshoot the hybrid control system.

PROCEDURE

| 1. | Toyota Prius Vehicle BROUGHT TO WORKSHOP |

|

| 2. | CUSTOMER PROBLEM ANALYSIS |

Click here

|

| 3. | CONNECT GTS TO THE DLC3* |

HINT:

If the display on the tester indicates a communication error, inspect the DLC3.

|

| 4. | CHECK DTC AND FREEZE FRAME DATA* |

Click here

HINT:

If the Freeze Frame Data item "AC Input Voltage for Monitoring" shows 270 V or more, there is a possibility that the charging voltage was higher than standard voltage, causing a DTC to be output. When performing a reproduction test, normal charge the Toyota Prius vehicle at the standard voltage, then check for DTCs.

| Result | Proceed to |

|---|---|

| No DTCs are output | A |

| CAN communication system DTCs are output | B |

| Other than above | C |

| B |

| PROCEED TO CAN COMMUNICATION SYSTEM |

| C |

| GO TO STEP 12 |

|

| 5. | CHECK FOR Toyota Prius Vehicle CONTROL HISTORY (RoB) |

(a) Check for Vehicle Control History (RoB).

Click here

| Result | Proceed to |

|---|---|

| Toyota Prius Vehicle Control History (RoB) stored | A |

| Vehicle Control History (RoB) not stored | B |

| B |

| GO TO STEP 9 |

|

| 6. | CHECK FOR Toyota Prius Vehicle CONTROL HISTORY (RoB) (VEHICLE RELATED CAUSE) |

(a) On the customer's vehicle, perform charging using a known good charging cable and a known good power source.

| Result | Proceed to |

|---|---|

| Charging is possible | A |

| Charging is not possible | B |

| B |

| GO TO STEP 18 |

|

| 7. | CHECK FOR Toyota Prius Vehicle CONTROL HISTORY (RoB) (CHARGING CABLE RELATED CAUSE) |

(a) On a known good vehicle, perform charging using the customer's charging cable and a known good power source.

| Result | Proceed to |

|---|---|

| Charging is possible | A |

| Charging is not possible | B |

| B |

| GO TO STEP 18 |

|

| 8. | CHECK FOR Toyota Prius Vehicle CONTROL HISTORY (RoB) (USER, ENVIRONMENT, EXTERNAL POWER SOURCE/CHARGING STAND RELATED CAUSE) |

(a) Based on the output vehicle control history and the results of the customer interview, narrow down the suspected cause according to the contributing factors.

| Result | Proceed to |

|---|---|

| Applicable for user | A |

| Applicable for environment | B |

| Applicable for external power source/charging stand | C |

| A |

| GO TO STEP 18 |

| B |

| GO TO STEP 18 |

| C |

| GO TO STEP 18 |

| 9. | PERFORM MALFUNCTION SIMULATION TEST |

(a) Based on the results of the customer problem analysis, try to reproduce the problem.

| Result | Proceed to |

|---|---|

| Problem can be reproduced | A |

| Problem cannot be reproduced | B |

| B |

| GO TO STEP 11 |

|

| 10. | PROBLEM SYMPTOMS TABLE |

Click here

| NEXT |

| GO TO STEP 18 |

| 11. | CHECK FOR INTERMITTENT PROBLEMS |

Click here

| NEXT |

| GO TO STEP 18 |

| 12. | CHECK DTC AND FREEZE FRAME DATA* |

Click here

HINT:

- Make sure to save freeze frame data because the data is necessary for performing simulation tests.

- For the hybrid control system, there are many DTCs, many of which can be stored due to a single malfunction. As a result, in some of the diagnosis procedures an instruction is provided to check for other DTCs. By following the diagnosis path based on the combination of output DTCs, it is possible to narrow down the problem early and avoid unnecessary diagnosis.

|

| 13. | PERFORM MALFUNCTION SIMULATION TEST |

(a) Based on the results of the customer problem analysis, try to reproduce the problem.

| Result | Proceed to |

|---|---|

| Problem can be reproduced | A |

| Problem cannot be reproduced | B |

| B |

| GO TO STEP 17 |

|

| 14. | REFER TO DTC CHART OR PERFORM CODE-SPECIFIC TROUBLESHOOTING |

(a) Refer to the DTC chart or conduct code-specific troubleshooting.

Click here

|

| 15. | REPAIR OR REPLACE MALFUNCTIONING PARTS, COMPONENT AND AREA |

|

| 16. | CHECK FOR DTCS* |

Click here

| NEXT |

| END |

| 17. | CHECK FOR INTERMITTENT PROBLEMS |

Click here

|

| 18. | REPAIR OR REPLACE MALFUNCTIONING PARTS, COMPONENT AND AREA |

|

| 19. | CONFIRMATION TEST |

(a) Conduct plug-in charging, and referring to the results of the customer problem analysis, check to see if the malfunction reoccurs.

| NEXT |

| END |

Customize Parameters

CUSTOMIZE PARAMETERS

CUSTOMIZE PLUG-IN CHARGE CONTROL SYSTEM

The following items can be customized.

NOTICE:

- When the customer requests a change in a function, first make sure that the function can be customized.

- Be sure to make a note of the current settings before customizing.

- When troubleshooting a function, first make sure that the function is set to the default setting.

(a) Customizing with the multi-information display

(1) Select the setting tab in the multi-information display.

(2) Enter the following menus: Toyota Prius Vehicle Settings / Charging Settings.

(3) Select the setting by referring to the table below.

| Display | Description | Default | Setting | Relevant ECU |

|---|---|---|---|---|

| Charging Schedule | Setting the charge schedule. | - | Charge schedule

| Plugin charge control ECU assembly |

| Charging Current | Changing the upper limit of the charging current. | MAX | MAX / 8 A | |

| Connector Lock | Charging connector lock setting can be changed. | Auto Lock | Auto Lock / Auto Lock & Unlock / OFF | |

| Battery Cooler | Setting "HV Supply Battery Cooler" on/off. | On | On / Off | Battery ECU assembly |

| Battery Heater | Setting "HV Supply Battery Heater" on/off. | On | On / Off |

(b) Customizing with the multimedia display

(1) In the multimedia display, enter the following menus: Toyota Prius Vehicle / Charging Schedule

(2) Change the charging schedule, or select "Charge Now" setting.

(3) In the multimedia display, enter the following menus: Vehicle Settings / Vehicle customize / Charging.

(4) Select the setting by referring to the table below.

| Display | Description | Default | Setting | Relevant ECU |

|---|---|---|---|---|

| Charging Schedule | Setting the charge schedule. | - | Charge schedule

| Plugin charge control ECU assembly |

| Charging Current | Changing the upper limit of the charging current. | Max | Max / 8 A | |

| Connector Lock | Charging connector lock setting can be changed. | Auto Lock | Auto Lock / Auto Lock & Unlock / OFF |

SETTING "Charge Now"

HINT:

- When "Charge Now" is set to on, the registered charging schedule is temporarily canceled and plug-in AC charging started immediately after connecting AC charging cable.

- If charging schedules are registered and "Charge Now" is on and AC charging cable is disconnected, "Charge Now" will be off.

(a) Setting with the multi-information display

(1) Turn the ignition switch to ON.

(2) Select the setting tab in the multi-information display.

(3) Enter the following menus: Toyota Prius Vehicle Settings / Charging Schedule.

(4) Turn "Charge Now" to on.

(b) Setting with the multimedia display

(1) Turn the ignition switch to ON.

(2) Select the setting tab in the multimedia display.

(3) Enter the following menus: Vehicle / Charging schedule.

(4) Turn "Charge now" button to on.

Utility

UTILITY

ALL READINESS

HINT:

- With "All Readiness", you can check whether or not the DTC judgment has been completed by using the GTS.

- You should check "All Readiness" after simulating malfunction symptoms or for validation after finishing repairs.

(a) Clear the DTCs even if no DTCs are stored.

Powertrain > Plug-in Control > Clear DTCs(b) Turn the ignition switch off and wait for 2 minutes or more.

(c) Perform the DTC judgment driving pattern to run the DTC judgment.

(d) Enter the following menus.

Powertrain > Plug-in Control > Utility| Tester Display |

|---|

| All Readiness |

(e) Input the DTCs to be confirmed.

(f) Check the DTC judgment result.

| GTS Display | Description |

|---|---|

| If the judgment result shows Incomplete or N/A, perform the DTC confirmation driving pattern again. | |

| Normal |

|

| Abnormal |

|

| Incomplete |

|

| N/A |

|

(g) Turn the ignition switch off.

Toyota Prius Vehicle CONTROL HISTORY (RoB)

(a) Connect the GTS to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the GTS on.

(d) Enter the following menus: Powertrain / Plug-in Control / Utility / Vehicle Control History (RoB).

Powertrain > Plug-in Control > Utility| Tester Display |

|---|

| Toyota Prius Vehicle Control History (RoB) |

Click here

(e) Turn the ignition switch off.

CHARGER COOLING FAN (CHG WAKE UP)

NOTICE:

If the ignition switch is turned off, the connector between the GTS and vehicle is disconnected, or a communication error occurs when "Charger Cooling Fan (CHG Wake Up)" is being performed, perform "Charger Cooling Fan (CHG Wake Up)" again and make sure to terminate it normally.

(a) Select "Charger Cooling Fan (CHG Wake Up)".

Powertrain > Plug-in Control > Utility| Tester Display |

|---|

| Charger Cooling Fan (CHG Wake Up) |

(b) On the next screen, select "CHG 1 Side Fan Drive".

(c) Enter the drive duty value (0/20/40/60/80/100).

(d) Press "Next" to operate the cooling fan.

(e) Press "Next", then on the next screen select "Exit" to complete "Charger Cooling Fan (CHG Wake Up)".

NOTICE:

Make sure to press the "Exit" button to terminate the operation.

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Plug-in Charge Control System| Symptom | Suspected Area | Link |

|---|---|---|

| Plug-in charging does not start | AC Charging Does not Start |

|

| Charging stops during plug-in charging | Charging Stops during AC Charging |

|

| Plug-in charging time is too long | AC Charging Time is Too Long |

|

| Cannot set or change charge schedule setting | Cannot Set or Change Charge Schedule Setting |

|

| Charging starts immediately despite charge schedule setting (After connecting charging connector, charging indicator (EV charger lid indicator) illuminates) | Charging Starts Immediately Despite Charge Schedule Setting |

|

| Charging does not start at scheduled start time | Charging Does Not Start at Scheduled Start Time |

|

| Charging stops before scheduled stop time | Charging Stops before Scheduled Stop Time |

|

| Charging continues despite reaching scheduled stop time | Charging Continues despite Reaching Scheduled Stop Time |

|

| Cannot lock charging connector | PLUG LOCK fuse | - |

| Cannot Lock Charging Connector |

| |

| Cannot unlock charging connector | PLUG LOCK fuse | - |

| Cannot Unlock Charging Connector |

| |

| Charging indicator does not come ON | Charging Indicator Circuit |

|

| Charging indicator remains ON |

CUSTOMER PROBLEM ANALYSIS

Symptom Detail Confirmation List| Confirmation item | Description |

|---|---|

| Toyota Prius Vehicle Specifications | Vehicle Model / Vehicle Frame No. / Vehicle Registration Date / Installed Optional Components / Date and Time of Malfunction / Date and Time When Vehicle Brought to Workshop / Driving Distance

|

| Symptoms | Information about the symptoms is useful for determining the malfunctioning area.

|

| Date/Time Charging Connector Connected Date/Time Symptom Was Noticed | Useful for determining the order in which problem symptoms and malfunctions occurred. |

| Frequency of Occurrence | Useful for performing troubleshooting. |

| Weather | Conditions such as if it was sunny, cloudy or rainy, existence of thunder/lightning, temperature, etc.

|

| Repair History | History of previous repairs can be useful for troubleshooting. |

| Conditions before malfunction occurred | Information such as if the user performed any unusual operations before the malfunction occurred, if any conditions were different than normal, etc. can be helpful for performing problem analysis. |

| Charging Location |

|

| Charging Cable Used |

|

| Charging Cable Storage Condition | The charging cable may be damaged if it has been improperly stored.

|

| Electrical Outlet Voltage and Type | Useful for performing troubleshooting. NOTICE: Using the following is not recommended:

|

| Existence of Electrical Power Management Function on Power Source (Charging Station) Side | If the charging power source is controlled by an electrical power management function which turns the power source on and off, charging may be interrupted or may take longer than advertised. |

| History of Work Performed on Electrical System | If work has been performed on the electrical system of the charging power source, it may have caused a malfunction. |

| Charging Indicator Light State | Abnormal conditions can be identified by the state of the charging indicator.

|

| HV Supply Battery Assembly Status | When the service plug grip is fully charged, charging will not begin when the charge connector is connected. Either of the following methods can be used to check the SOC (State of Charge) of the service plug grip:

|

| Charging Cable Indicator Light State | Abnormal conditions can be identified by the state of the indicators on the charging cable. |

| Existence of Power Outage or Breaker Trip During Plug-in Charging | If a power outage or breaker tripping causes charging to be suspended, it may be mistaken as a malfunction. |

| Existence of Charging Schedule | Charging schedule not set / Charging schedule set (charging start time) / Charging schedule set (departure time/air conditioning cooperative control setting) / Charging schedule set (departure time/air conditioning cooperative control not set) / difference between actual current time and set current time

|

| Charging Station Display | If a message was displayed on the charging station when the malfunction occurred, the malfunction may be on the charging power source side. |

| DTCs, Toyota Prius Vehicle Control History | DTCs and vehicle control history data are useful for determining the location or cause of malfunctions. |

Terminals Of Ecu

TERMINALS OF ECU

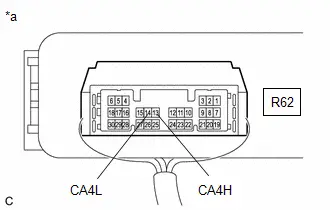

PLUGIN CHARGE CONTROL ECU ASSEMBLY

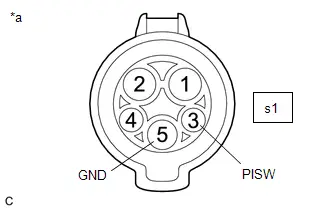

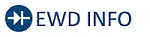

| Connector Code | Terminal No. | Symbol | Terminal Description |

|---|---|---|---|

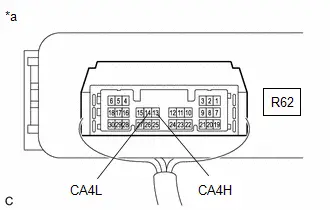

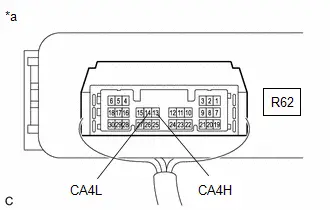

| R62 | 1 | E1 | Earth ground |

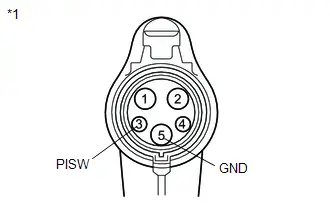

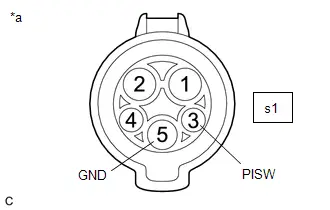

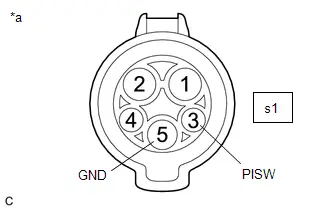

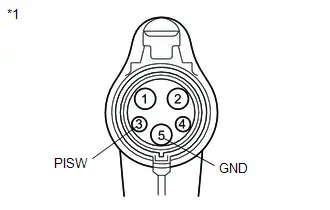

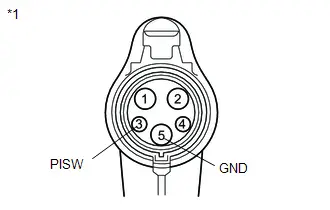

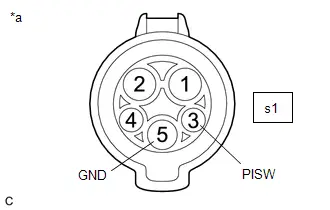

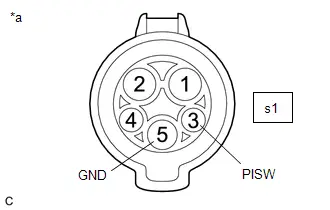

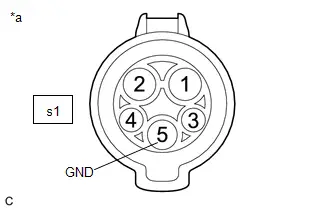

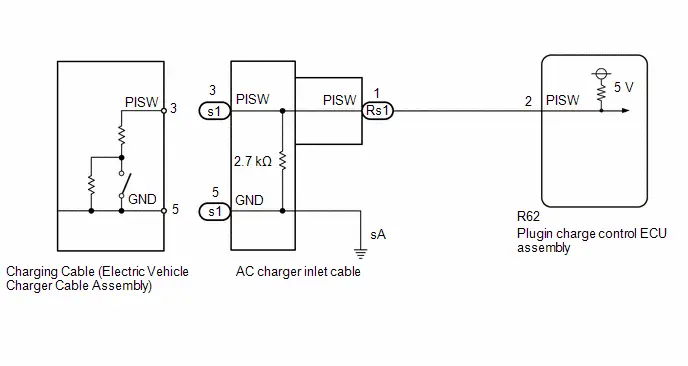

| 2 | PISW | Charging connector connection signal | |

| 3 | - | - | |

| 4 | - | - | |

| 5 | IGCT | IGCT power source | |

| 6 | AM21 | Power source | |

| 7 | CPLT | Charge voltage judgment and allowable amperage recognition signals | |

| 8 | - | - | |

| 9 | - | - | |

| 10 | SSEN | HV battery charging permission signal | |

| 11 | CA1H | CAN communication signal | |

| 12 | CA1L | CAN communication signal | |

| 13 | CA4H | CAN communication signal | |

| 14 | CA4L | CAN communication signal | |

| 15 | - | - | |

| 16 | - | - | |

| 17 | LDSW | Charging lid switch signal | |

| 18 | LDLP | Charging inlet light | |

| 19 | - | - | |

| 20 | - | - | |

| 21 | - | - | |

| 22 | - | - | |

| 23 | PIL | Charging indicator light | |

| 24 | ACLP | AC inverter indicator light | |

| 25 | CA5H | CAN communication signal | |

| 26 | CA5L | CAN communication signal | |

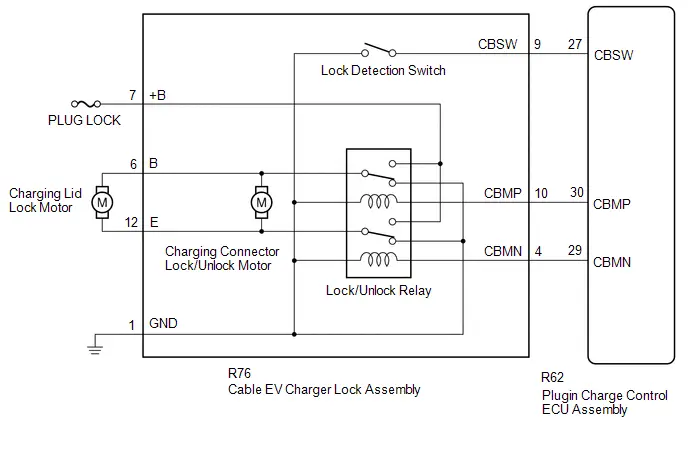

| 27 | CBSW | Charging connector lock detection switch signal | |

| 28 | ACRL | Charger wake up signal | |

| 29 | CBMN | Charging connector lock motor reverse operation | |

| 30 | CBMP | Charging connector lock motor forward operation |

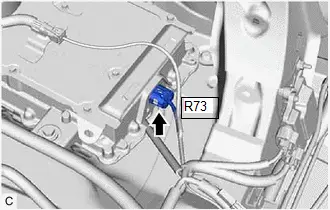

| Connector Code | Terminal No. | Symbol | Terminal Description |

|---|---|---|---|

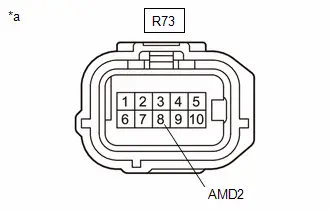

| R73 | 1 | - | - |

| 2 | CA5H | CAN communication signal | |

| 3 | CA5L | CAN communication signal | |

| 4 | FTLS | Charger cooling blower speed signal | |

| 5 | FANG | Cooling fan body ground | |

| 6 | ACRL | Charger wake up signal | |

| 7 | FANB | Cooling fan power source | |

| 8 | AMD2 | Power source | |

| 9 | - | - | |

| 10 | FCTL | Charger cooling blower operation signal |

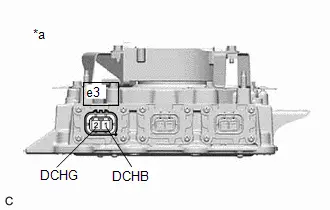

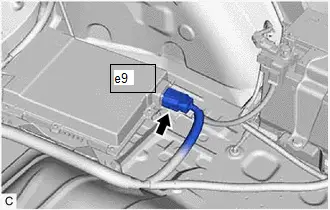

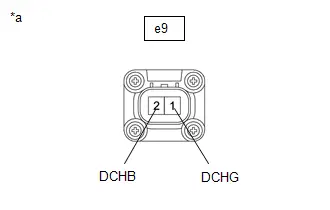

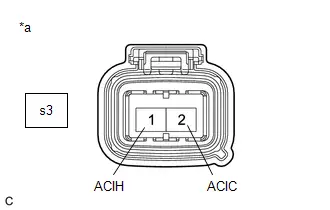

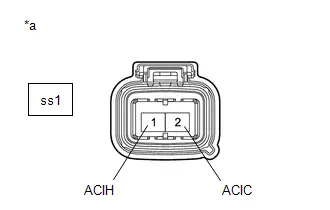

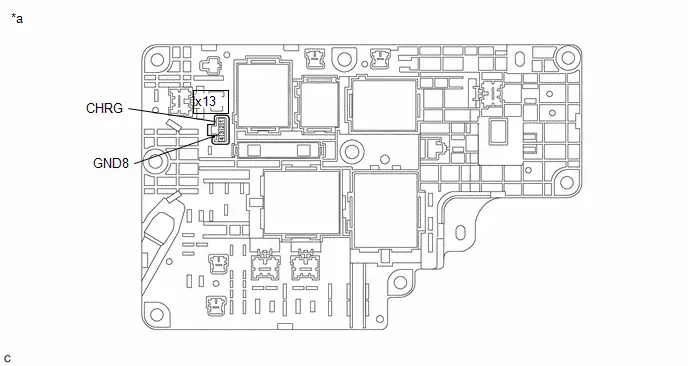

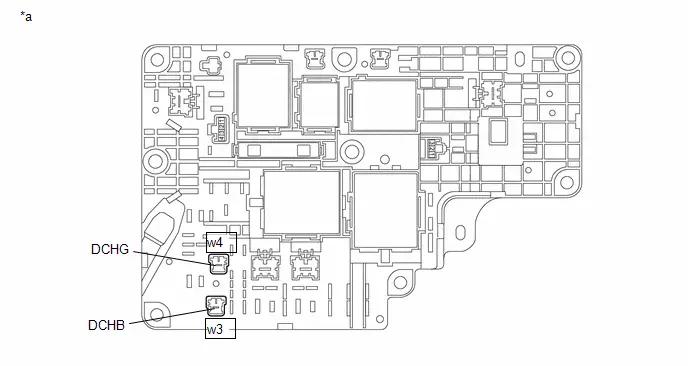

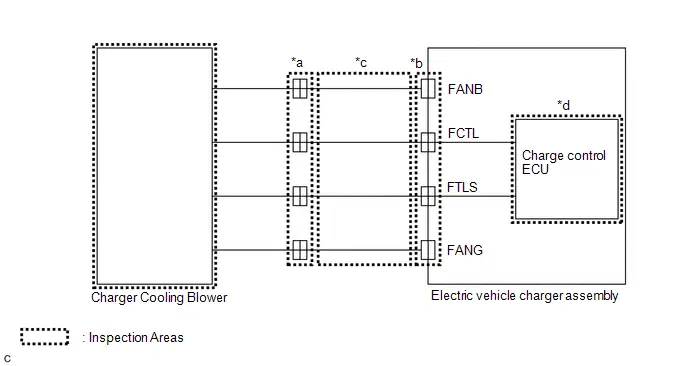

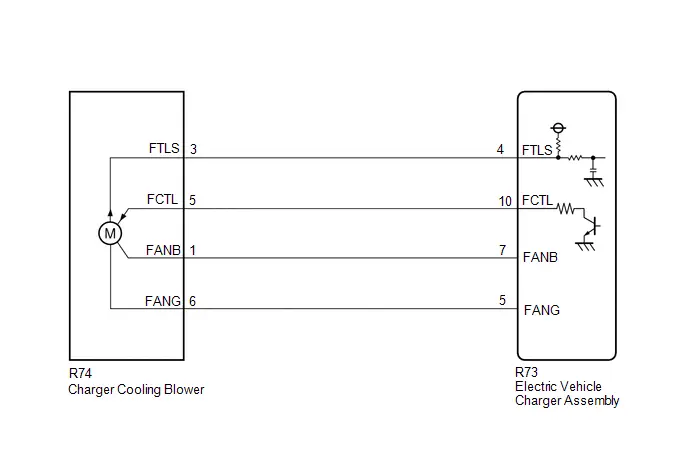

ELECTRIC Toyota Prius Vehicle CHARGER ASSEMBLY

Diagnosis System

DIAGNOSIS SYSTEM

DESCRIPTION

(a) The plugin charge control ECU assembly has a self-diagnosis system. If the computer, plug-in charge control system, or a component is not working properly, the ECU records the conditions that relate to the fault. The ECU also illuminates the master warning in the combination meter assembly and provides other appropriate messages on the multi-information display, such as the plug-in charge control system warning message.

- When troubleshooting OBD II (On-Board Diagnostics) Toyota Prius vehicles, the GTS (complying with SAE J1978) must be connected to the DLC3 (Data Link Connector 3) of the vehicle. Various data in the vehicle plugin charge control ECU assembly can then be read.

-

OBD II regulations require that the vehicle's on-board computer illuminates the MIL (Malfunction Indicator Lamp) on the instrument panel when the computer detects a malfunction in:

- The emission control system components.

- The powertrain control components (which affect Toyota Prius vehicle emissions).

-

The computer itself.

In addition, the applicable DTCs prescribed by SAE J2012 are recorded in the plugin charge control ECU assembly memory. If the malfunction does not recur in 3 consecutive trips, the MIL turns off automatically but the DTCs remain recorded in the plugin charge control ECU assembly memory.

- To check for DTCs, connect the GTS to the DLC3. The GTS displays DTCs, Freeze Frame Data, and a variety of plug-in charge control system data. The DTCs and Freeze Frame Data can be cleared with the GTS. In order to enhance the OBD function on Toyota Prius vehicles and develop the off-board diagnosis system, Controller Area Network (CAN) communication is used in this system. CAN is a network which uses a pair of data transmission lines spanning multiple computers and sensors. It allows for high speed communications between the systems and simplification of the wire harness connections.

2 TRIP DETECTION LOGIC

- When a malfunction is first detected, the malfunction is temporarily stored in the plugin charge control ECU assembly memory (1st trip). If the same malfunction is detected during the next drive cycle, the MIL is illuminated (2nd trip).

FREEZE FRAME DATA

- The plugin charge control ECU assembly records Toyota Prius vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was moving or stationary, whether the engine was warmed up or not, as well as other data recorded at the time of a malfunction.

AUXILIARY BATTERY VOLTAGE

Standard Voltage:

| Switch Condition | Specified Condition |

|---|---|

| Ignition switch ON | 11 to 14 V |

-

If voltage is below 11 V, recharge or replace the auxiliary battery.

NOTICE:

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

MIL (Malfunction Indicator Lamp)

(a) The MIL is illuminated when the ignition switch is first turned to ON, before the READY indicator illuminates.

(b) When the READY indicator illuminates, the MIL should turn off. If the MIL remains illuminated, the diagnosis system has detected a malfunction or abnormality in a system.

HINT:

If the MIL is not illuminated when the ignition switch is first turned to ON, check the MIL circuit.

for SFI System: Click here

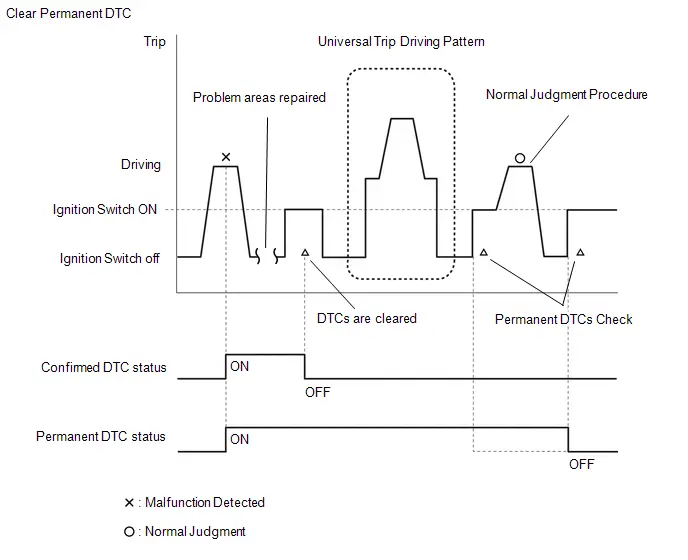

Dtc Check / Clear

DTC CHECK / CLEAR

- After clearing current DTCs using the GTS (or by disconnecting the cable from the negative (-) auxiliary battery terminal), permanent DTCs can be cleared when the universal trip is performed and then the system is determined to be normal for the relevant DTCs. The driving pattern to obtain a normal judgment is described under the "Confirmation Driving Pattern" for the respective DTC.

-

To clear permanent DTCs, all of the following conditions must be are met:

- There is a history that universal trip driving was performed.

- The Toyota Prius vehicle has been judged as normal for 1 trip.

- No malfunctions are detected.

CLEAR PERMANENT DTC

(a) Enter the following menus: Powertrain / Plug-in Control / Trouble Codes.

Powertrain > Plug-in Control > Trouble CodesHINT:

If "YES" is displayed for the value of "PERMANENT" at the top right of the GTS screen, permanent DTCs are stored.

(b) Select the "Generic" tab.

(c) Check if permanent DTCs are stored.

HINT:

If permanent DTCs are not output, it is not necessary to continue this procedure.

(d) Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

Powertrain > Plug-in Control > Clear DTCsNOTICE:

Do not clear the DTCs or disconnect the cable from the auxiliary battery terminal after performing this step.

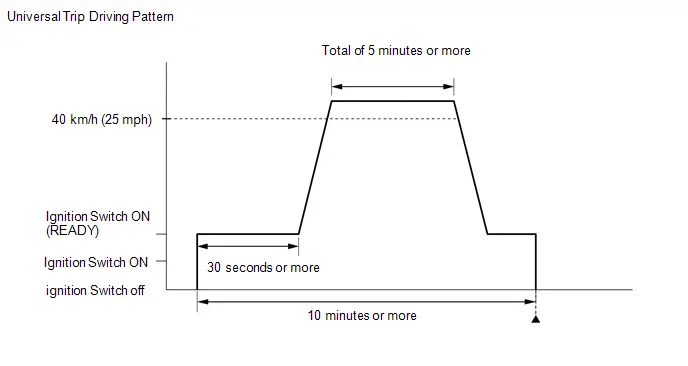

(e) Perform the universal trip.

CAUTION:

When performing the driving pattern, obey all speed limits and traffic laws.

HINT:

The universal trip driving pattern and normal judgment procedure can be performed consecutively in the same driving cycle.

(1) Turn the ignition switch to ON (READY) and wait for 30 seconds or more.

(2) Drive the Toyota Prius vehicle at 40 km/h (25 mph) or more for a total of 5 minutes or more.

HINT:

It is possible to complete the drive pattern even if the vehicle decelerates to less than 40 km/h (25 mph) during the driving cycle provided that the vehicle is driven at 40 km/h (25 mph) or more for a total of 5 minutes.

(3) Allow 10 minutes or more to elapse from the time the ignition switch turned ON (READY).

(f) Turn the ignition switch off and wait for 2 minutes or more.

(g) Turn the ignition switch to ON.

(h) Enter the following menus: Powertrain / Plug-in Control / Trouble Codes.

Powertrain > Plug-in Control > Trouble Codes(i) Check that the permanent DTCs have been cleared.

HINT:

If permanent DTCs are not output, it is not necessary to continue this procedure.

(j) Perform the normal judgment procedure in the respective confirmation driving pattern of each output DTC.

HINT:

Do not turn the ignition switch off by mistake during this step.

(k) With ignition switch ON (READY) and wait for 5 seconds or more.

(l) Turn the ignition switch off and wait for 2 minutes or more.

(m) Turn the ignition switch to ON.

(n) Enter the following menus: Powertrain / Plug-in Control / Trouble Codes.

Powertrain > Plug-in Control > Trouble Codes(o) Check that the permanent DTCs have been cleared.

Freeze Frame Data

FREEZE FRAME DATA

FREEZE FRAME DATA

The plugin charge control ECU records vehicle and plug-in charging condition information as Freeze Frame Data the moment a DTC is stored.

It can be used for estimating or duplicating the vehicle conditions that were present when the malfunction occurred.

Powertrain > Plug-in Control| Tester Display |

|---|

| Toyota Prius Vehicle Speed |

| Engine Speed |

| Calculate Load |

| Coolant Temperature |

| Engine Run Time |

| Throttle Position Sensor No.1 Voltage % |

| Smoothed Value of BATT Voltage |

| Warmup Cycle Cleared DTC |

| Distance from DTC Cleared |

| Time after DTC Cleared |

| Running Time from MIL ON |

| Total Distance Traveled |

| Total Distance Traveled - Unit |

| MIL ON Run Distance |

| PISW Status |

| My Room Operation |

| ACRL Drive Request |

| Frequency Switching Signal |

| IGB Signal |

| IGB ON Request |

| IGCT Signal Status |

| IGCT Keeping Request |

| IG2 Signal Status |

| Charging Control Signal Status |

| A/C Useable Power |

| A/C Consumption Power |

| Remote Air Control System |

| Hybrid/EV Control System Control Mode |

| Hybrid/EV Output Temperature Sensor |

| Solar Available Information |

| Solar Diagnosis Prohibition Notification |

| Solar Charging Control Mode |

| Solar Charging Permission Signal by Main CPU |

| Solar Charging Boosting DC/DC Converter Voltage |

| Solar Charging Boosting DC/DC Converter Input Power |

| Solar Boosting DC/DC Converter Drive Request |

| HV/EV Battery Total Voltage |

| Charging Voltage for Hybrid/EV Battery |

| Hybrid/EV Battery Local Bus Communication |

| Hybrid/EV Battery Temperature when Charging Start |

| Hybrid/EV Battery Maximum Temperature |

| Hybrid/EV Battery Minimum Temperature |

| Hybrid/EV Battery Charging/Power Feeding Permission Status with Hybrid/EV Battery Thermal Keep |

| Hybrid/EV Battery Charging Power |

| Hybrid/EV Battery Control Status on Thermal Keeping and Charging |

| Hybrid/EV Battery Current for Driving Control |

| Hybrid/EV Battery Current for Hybrid/EV Battery Control |

| Auxiliary Battery Voltage Low Status |

| Auxiliary Battery Voltage Low Status from Hybrid/EV |

| Auxiliary Battery Voltage Low Status from Hybrid/EV Battery |

| Hybrid/EV Communication Enable Information (Hybrid/EV Battery Local Bus) |

| SOC of Immediately after Wake Up |

| ICHG Current (Instantaneous Value) |

| Charging Lid Switch Status |

| Charging Lid Lamp Status |

| Hood Courtesy Switch Signal |

| Charging Indicator lighting Request |

| Charging Connector Connect Status |

| Charging Connector Connect Status Voltage |

| Charging Connector Lock Pin Status |

| Charging Connector Lock Motor Unlock Direction Revolution Request Current |

| Charging Connector Lock Motor Lock Direction Revolution Request Current |

| AC Charging Positive Inlet Temperature Sensor Voltage |

| AC Charging Negative Inlet Temperature Sensor Voltage |

| AC Charging Positive Inlet Temperature |

| AC Charging Negative Inlet Temperature |

| AC Charging Inlet Insert Status |

| Power Feeding Connecter Power Supply Switch |

| Interlock Operation Status |

| Charger Power Supply Voltage Type |

| Charger Operation Status |

| Charger Operation Request |

| Charger Input Power |

| Charger Output Power |

| Charger Cooling Fan Drive Request |

| Charger Cooling Fan Driving Duty |

| Charger Cooling Fan Revolution |

| Charger Drive Permission Signal |

| AC Power Supply Rated Current |

| AC Power Supply Rated Power |

| Charging Control Information |

| Charging History Information |

| DC Operation Mode |

| System Impedance Increase Abnormal |

| Total Number of AC Charging |

| AC Charging Total Time |

| AC Charging |

| AC Charging Operation Status |

| AC Charging Input Minimum Voltage History |

| Target Charging Power |

| Target Charging Power from Charger |

| Charging Required Time Calculation Status |

| Charging Required Time |

| Charging Elapsed Time |

| Charging State Elapsed Time |

| AC Input Voltage for Monitoring |

| Target AC Input Voltage for Control |

| AC Input Voltage Instantaneous Value 1 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 2 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 3 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 4 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 5 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 6 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 7 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 8 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 9 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 10 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 11 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 12 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 13 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 14 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 15 for Waveform Monitoring |

| AC Input Voltage Instantaneous Value 16 for Waveform Monitoring |

| Time Cycle of Charging Voltage Zero Crossing Point |

| Plug-in Control ECU Voltage Request (SMP5) |

| Plug-in Control ECU Voltage (VOMS5) |

| Plug-in Control Module System Voltage (Plus) |

| Plug-in Control Module System Voltage (Minus) |

| AC Power Feeding Control Mode |

| AC Input Current |

| Charging Current Upper Limit |

| Charging Current Duty from Charger |

| Time Cycle of Charging Current Duty from Charger |

| Charging Current Limit Status from Charger |

| Charging Power Limit (Charging Voltage Low) |

| Timer Wait Request |

| Power Supply Voltage (SMP5) |

| PFC Boosting Circuit Driver Drive Status |

| Voltage after Boosting by PFC Boosting Circuit |

| PFC Boosting Circuit Current Amplitude |

| PFC Temperature |

| High Voltage Circuit Shutdown Signal |

| DC/DC Converter Operation Status |

| DC/DC Converter Driver Drive Status (for Charging) |

| DC/DC Converter Temperature (for Charging) |

| AC 100V Switch Indicator Lighting Request |

| Power Feeding Isolation Fault Detection |

| Power Feeding Inverter Operation Status |

| Power Feeding INV Activate Request |

| Power Feeding INV Activate Status |

| Power Feeding INV Output Frequency Setting |

| Power Feeding INV Output Voltage Setting |

| Charging/Power Feeding Switching Switch Status |

| Charging/Power Feeding Switching Switch Request |

| AC Charging Negative Relay Status |

| AC Charging Positive Relay Status |

| AC Charging Negative Relay Drive Request |

| AC Charging Positive Relay Drive Request |

| AC Charging Precharge Relay Status |

| AC Charging Precharge Relay Drive Request |

| Charging Relay Connect Request in CCID Box from CCID Box |

| Rush Current Prevention Resistance Relay Activate Request |

| SMRB Control Status |

| SMRG Control Status |

| VAI |

| VAO |

| B Voltage |

System Voltage (BATT) Circuit Short to Ground or Open (P056014)

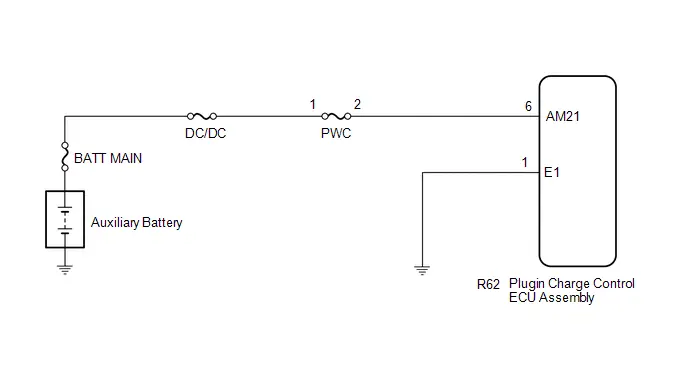

DESCRIPTION

Auxiliary battery power source is always supplied to the AM21 terminal of the plugin charge control ECU assembly for storage of diagnostic codes and freeze frame data. Back-up power source is supplied even after the ignition switch off.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Warning Indicate | DTC Output from | Priority | Note |

|---|---|---|---|---|---|---|---|---|

| P056014 | System Voltage (BATT) Circuit Short to Ground or Open | Malfunction in the plugin charge control ECU assembly back-up power source circuit (1 trip detection logic) |

| Comes on | Master Warning: Comes on | Plug-in Control | A | SAE Code: P0562 |

MONITOR DESCRIPTION

If a period of time has elapsed with a low voltage at the AM21 terminal of the plugin charge control ECU assembly, the plugin charge control ECU assembly will determine that a malfunction has occurred in the back-up power supply system, and it will store a DTC. The MIL will illuminate the next time the engine is started.

MONITOR STRATEGY

| Related DTCs | P0562: System voltage (plug-in charge control module) |

| Required sensors/components | Plug-in charge control ECU |

| Frequency of operation | Continuous |

| Duration | TMC's intellectual property |

| MIL operation | Immediately |

| Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

| The monitor will run whenever the following DTCs are not stored | TMC's intellectual property |

| Other conditions belong to TMC's intellectual property | - |

TYPICAL MALFUNCTION THRESHOLDS

| TMC's intellectual property | - |

COMPONENT OPERATING RANGE

| Plugin charge control ECU | DTC P056014 is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

-

After repair has been completed, clear the DTC and then check that the Toyota Prius vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

-

When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

-

Turn the ignition switch to ON and wait for 5 seconds or more.[*1]

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / Plug-in Control / Utility / All Readiness.

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

Click here

NOTICE:

- Be sure to check that the applicable DTC is output from the Plug-in Charge Control System.

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

PROCEDURE

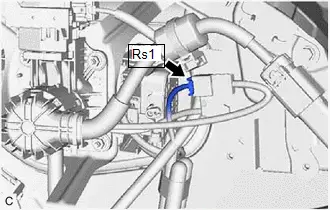

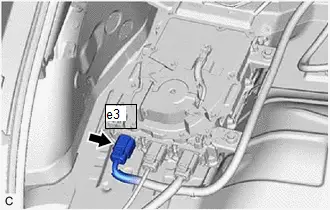

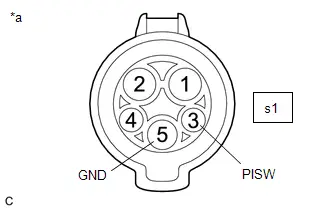

| 1. | CHECK CONNECTOR CONNECTION CONDITION (PLUGIN CHARGE CONTROL ECU ASSEMBLY CONNECTOR) |

| (a) Check the connections of the plugin charge control ECU assembly connector. HINT: Click here

OK: The connectors are connected securely and there are no contact pressure problems. Result:

|

|

| NG |

| CONNECT SECURELY |

|

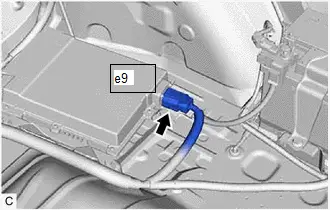

| 2. | CHECK HARNESS AND CONNECTOR (PLUGIN CHARGE CONTROL ECU ASSEMBLY - PWC FUSE) |

Pre-procedure1

(a) Disconnect the R62 plugin charge control ECU assembly connector.

(b) Connect the cable to the negative (-) auxiliary battery terminal.

Procedure1

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:  Click Location & Routing(R62) Click Connector(R62) Click Location & Routing(R62) Click Connector(R62)

Result:

|

|

Post-procedure1

(d) Disconnect the cable from the negative (-) auxiliary battery terminal.

(e) Reconnect the plugin charge control ECU assembly connector.

| OK |

| REPLACE PLUGIN CHARGE CONTROL ECU ASSEMBLY |

|

| 3. | CHECK FUSE (PWC) |

Pre-procedure1

(a) Remove the PWC fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

Procedure1

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition | Result |

|---|---|---|---|

| PWC fuse terminals | Always | Below 1 Ω | Ω |

Post-procedure1

(c) Install the PWC fuse.

| OK |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (PLUGIN CHARGE CONTROL ECU ASSEMBLY - PWC FUSE) |

| NG |

| REPLACE FUSE (PWC) |

Hybrid/EV Battery Charging System Positive Contactor Stuck Closed (P0D0700)

DTC SUMMARY

MALFUNCTION DESCRIPTION

The plugin charge control ECU assembly detects a stuck closed malfunction of a charge relay on the HV battery positive ( ) terminal side.

The cause of this malfunction may be one of the following:

- Voltage sensor (VSOL) malfunction

- Solar energy control ECU assembly malfunction

- Communication (wire harness) malfunction

- No. 1 traction battery device box malfunction

- Plugin charge control ECU assembly malfunction

- No. 1 traction battery device box malfunction

- Battery ECU assembly malfunction

- Low voltage wire harness malfunction

- Low voltage connector malfunction

- Solar energy control ECU assembly discharge resistance malfunction

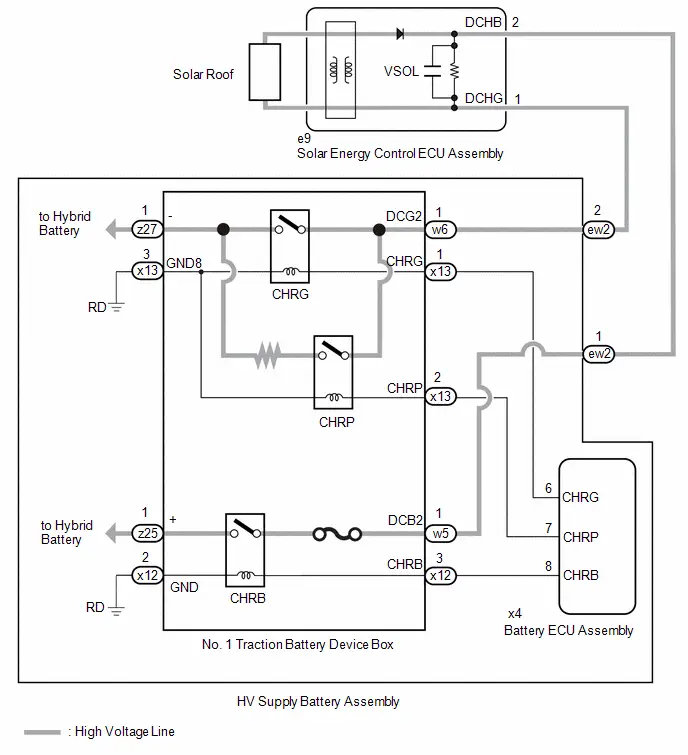

DESCRIPTION

The CHRs (Charge Relays) are the relays that connect or disconnect the high-voltage system in accordance with commands from the battery ECU assembly.

There are 3 CHRs and 1 system main resistor. CHRB, CHRP, CHRG and the system main resistor are located in the traction battery device box.

To connect to the high voltage power system, the Toyota Prius vehicle will first turn on CHRP and CHRB to charge the vehicle through the system main resistor. Then, CHRP will be turned off after CHRG is turned on. To shut off the high voltage power system, CHRB and CHRG are turned off.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Warning Indicate | DTC Output from | Priority | Note |

|---|---|---|---|---|---|---|---|---|

| P0D0700 | Hybrid/EV Battery Charging System Positive Contactor Stuck Closed | The voltage in the solar energy control ECU assembly does not drop even though the CHRB relay is turned off. (1 trip detection logic) |

| Comes on | Master Warning: Comes on | Plug-in Control | B | SAE Code: P0D08 |

MONITOR DESCRIPTION

The plugin charge control ECU assembly monitors the operating state of the CHR relay. If the voltage of the solar energy control ECU assembly does not decrease even though the CHRB relay is turned off, the plugin charge control ECU assembly judges that there is a malfunction and illuminates the MIL and stores a DTC.

MONITOR STRATEGY

| Related DTCs | P0D08: Battery Charger Hybrid/EV Battery Output Voltage Sensor Circuit Range/Performance |

| Required sensors/components | No. 1 traction battery device box Battery ECU assembly Solar energy control ECU assembly |

| Frequency of operation | - |

| Duration | TMC's intellectual property |

| MIL operation | 1 driving cycle |

| Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

| The monitor will run whenever the following DTCs are not stored | TMC's intellectual property |

| Other conditions belong to TMC's intellectual property | - |

TYPICAL MALFUNCTION THRESHOLDS

| TMC's intellectual property | - |

COMPONENT OPERATING RANGE

| Plug-in charge control ECU | DTC P0D0700 is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

-

After repair has been completed, clear the DTC and then check that the Toyota Prius vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

-

When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch on (READY) and wait for 5 seconds or more. [*1]

- Turn the ignition switch off and wait for 2 minutes or more. [*2]

-

Confirm to start solar charging and wait for 2 minutes or more. [*3]

HINT:

[*1] to [*3]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / Plug-in Control / Utility / All Readiness.

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

Click here

NOTICE:

- After clearing the DTCs (or after disconnecting the cable from the auxiliary battery terminal) before repairs are performed, do not park the Toyota Prius vehicle in direct sunlight, etc., as solar charging may be performed which may cause a malfunction of other components.

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

PROCEDURE

| 1. | CHECK DTC OUTPUT (HYBRID CONTROL, HV BATTERY, PLUG-IN CONTROL, SOLAR CHARGING CONTROL) |

Pre-procedure1

(a) Enter the following menus:

Powertrain > Hybrid Control > Trouble Codes Powertrain > HV Battery > Trouble Codes Powertrain > Plug-in Control > Trouble Codes Powertrain > Solar Charging Control > Trouble CodesProcedure1

(b) Check for DTCs.

| Result | Proceed to |

|---|---|

| P0D0700 only is output, or DTCs except the ones in the table below are also output. | A |

| DTCs of Hybrid Control System in the tables below are output. | B |

| DTCs of Hybrid Battery System in the tables below are output. | C |

| DTCs of Plug-in Charge Control System in the tables below are output. | D |

| DTCs of Solar Charging System in the tables below are output. | E |

| Malfunction Content | System | Relevant DTC | |

|---|---|---|---|

| Microcomputer malfunction | Plug-in Charge Control System | P060B49 | Plug-in Control Module A/D Processing Internal Electronic Failure |

| P0E5E87 | Plug-in Control Module Processor from Hybrid/EV Battery Charger Control Module Processor Missing Message | ||

| P1C1F49 | Hybrid/EV Battery Charger Control Module A/D Processing Internal Electronic Failure | ||

| Solar Charging System | P1EDB49 | Solar Charger Control Module A/D Processing Internal Electronic Failure | |

| Communication system malfunction | Plug-in Charge Control System | U01BB87 | Lost Communication with Battery Charger Control Module "B" Missing Message |

| U113A87 | Lost Communication with Solar Charging Control Module Missing Message | ||

| U117B87 | Lost Communication with Hybrid/EV Battery Energy Control Module "A" (ch2) Missing Message | ||

| Solar Charging System | U115087 | Lost Communication with Hybrid Powertrain Control Module (Hybrid/EV Battery Local Bus) Missing Message | |

| U115387 | Lost Communication with Battery Charger Control Module "A" (ch2) Missing Message | ||

| U117B87 | Lost Communication with Battery Energy Control Module "A" (ch2) Missing Message | ||

| Sensor and actuator circuit malfunction | Hybrid Battery System | P0D0A11 | Hybrid/EV Battery Charging System Positive Contactor Control Circuit Short to Ground |

| P0D0A15 | Hybrid/EV Battery Charging System Positive Contactor Control Circuit Short to Auxiliary Battery or Open | ||

| P0D1111 | Hybrid/EV Battery Charging System Negative Contactor Control Circuit Short to Ground | ||

| P0D1115 | Hybrid/EV Battery Charging System Negative Contactor Control Circuit Short to Auxiliary Battery or Open | ||

| P0E6D11 | Hybrid/EV Battery Charging System Precharge Contactor Control Circuit Short to Ground | ||

| P0E6D15 | Hybrid/EV Battery Charging System Precharge Contactor Control Circuit Short to Auxiliary Battery or Open | ||

| Plug-in Charge Control System | P0D4C12 | Hybrid/EV Battery Charger Hybrid/EV Battery Input Voltage Sensor Circuit Short to Auxiliary Battery | |

| P0D4C14 | Hybrid/EV Battery Charger Hybrid/EV Battery Input Voltage Sensor Circuit Short to Ground or Open | ||

| P0D4C1C | Hybrid/EV Battery Charger Hybrid/EV Battery Input Voltage Sensor Voltage Out of Range | ||

| P1EA41C | Hybrid/EV Control Battery Voltage Sensor / Solar Charging Voltage Sensor Voltage Out of Range | ||

| Solar Charging System | P1EA412 | Solar Charging Voltage Sensor Circuit Short to Auxiliary Battery | |

| P1EA414 | Solar Charging Voltage Sensor Circuit Short to Ground or Open | ||

| System malfunction | Hybrid Control System | P0A1F94 | Hybrid/EV Battery Energy Control Module Unexpected Operation |

| P1BAC1C | Hybrid/EV Battery Charging System Positive/Negative Contactor Enable Circuit Circuit Voltage Out of Range | ||

| Plug-in Charge Control System | P0D0E73 | Hybrid/EV Battery Charging System Negative Contactor Control Actuator Stuck Closed | |

| P0E6A73 | Hybrid/EV Battery Charging System Precharge Contactor Control Actuator Stuck Closed | ||

| P1EA41C | Hybrid/EV Control Battery Voltage Sensor / Solar Charging Voltage Sensor Voltage Out of Range | ||

HINT:

-

P0D0700 may be output as a result of the malfunction indicated by the DTCs above.

- The chart above is listed in inspection order of priority.

- Check DTCs that are output at the same time by following the listed order. (The main cause of the malfunction can be determined without performing unnecessary inspections.)

Post-procedure1

(c) None

| B |

| GO TO DTC CHART (HYBRID CONTROL SYSTEM) |

| C |

| GO TO DTC CHART (HYBRID BATTERY SYSTEM) |

| D |

| GO TO DTC CHART (PLUG-IN CHARGE CONTROL SYSTEM) |

| E |

| GO TO DTC CHART (SOLAR CHARGING SYSTEM) |

|

| 2. | CHECK FREEZE FRAME DATA (P0D0700) |

(a) Read the freeze frame data of DTC P0D0700.

Powertrain > Plug-in Control > DTC(P0D0700) > Freeze Frame Data| Tester Display |

|---|

| Solar Charging Boosting DC/DC Converter Voltage |

| HV/EV Battery Total Voltage |

NOTICE:

In this step, read only the values of "0(s)", which means the moment the DTC has been confirmed, although other information before and after the moment is also displayed when reading the freeze frame data.

| Result | Proceed to |

|---|---|

| Difference between "Hybrid/EV Battery Total Voltage" and "Solar Charging Boosting DC/DC Converter Voltage" is always less than 100 V. | A |

| Difference between "Hybrid/EV Battery Total Voltage" and "Solar Charging Boosting DC/DC Converter Voltage" is 100 V or more. | B |

HINT:

When the difference between "Solar Charging Boosting DC/DC Converter Voltage" and "Hybrid/EV Battery Total Voltage" is large even though the charge relay of HV battery positive ( ) terminal side is OFF, the solar energy control ECU assembly has a malfunction.

| B |

| REPLACE SOLAR ENERGY CONTROL ECU ASSEMBLY |

|

| 3. | CHECK CONNECTOR CONNECTION CONDITION (BATTERY ECU CONNECTOR) |

CAUTION:

Be sure to wear insulated gloves.

Pre-procedure1

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

Procedure1

| (b) Check the connector connections and contact pressure of the relevant terminals of the battery ECU connector. Click here

OK: The connectors are connected securely and there are no contact pressure problems. Result:

|

|

Post-procedure1

(c) None.

| OK |

| GO TO STEP 5 |

|

| 4. | CONNECT SECURELY |

|

| 5. | CHECK CONNECTOR CONNECTION CONDITION (NO. 1 TRACTION BATTERY DEVICE BOX CONNECTOR) |

CAUTION:

Be sure to wear insulated gloves.

Pre-procedure1

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

Procedure1

| (b) Check the connector connections and contact pressure of the relevant terminals of the No. 1 traction battery device box connector. Click here

OK: The connectors are connected securely and there are no contact pressure problems. Result:

|

|

Post-procedure1

(c) None.

| OK |

| GO TO STEP 7 |

|

| 6. | CONNECT SECURELY |

|

| 7. | CHECK GROUND WIRE CONNECTION CONDITION (CHR ACTIVATION LOW-VOLTAGE CIRCUIT) |

(a) Check the installation condition of the ground wire RD.

OK:

The ground wire RD is securely installed.

| OK |

| GO TO STEP 9 |

|

| 8. | CONNECT SECURELY |

|

| 9. | CHECK HARNESS AND CONNECTOR (BATTERY ECU ASSEMBLY - NO. 1 TRACTION BATTERY DEVICE BOX) |

CAUTION:

Be sure to wear insulated gloves.

Pre-procedure1

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the No. 1 traction battery device box connector.

(c) Disconnect the battery ECU assembly connector.

Procedure1

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

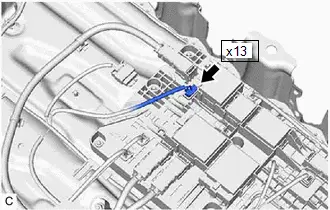

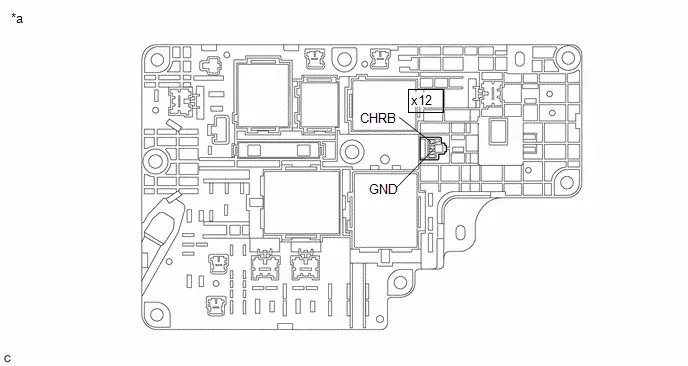

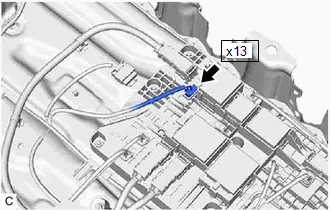

Click Location & Routing(x4,x12) Click Connector(x4) Click Connector(x12)

Click Location & Routing(x4,x12) Click Connector(x4) Click Connector(x12) | Tester Connection | Condition | Specified Condition |

|---|---|---|

| x4-8 (CHRB) - x12-3 (CHRB) | Ignition switch off | Below 1 Ω |

Standard Resistance (Check for Short):

Click Location & Routing(x4,x12) Click Connector(x4) Click Connector(x12)

Click Location & Routing(x4,x12) Click Connector(x4) Click Connector(x12) | Tester Connection | Condition | Specified Condition |

|---|---|---|

| x4-8 (CHRB) or x12-3 (CHRB) - Body ground and other terminals | Ignition switch off | 10 kΩ or higher |

Post-procedure1

(e) Reconnect the battery ECU assembly connector.

(f) Reconnect the No. 1 traction battery device box connector.

| OK |

| GO TO STEP 11 |

|

| 10. | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 11. | CHECK HARNESS AND CONNECTOR (NO. 1 TRACTION BATTERY DEVICE BOX - BODY GROUND) |

CAUTION:

Be sure to wear insulated gloves.

Pre-procedure1

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the No. 1 traction battery device box connector.

(c) Connect the SST.

HINT:

Click here

Procedure1

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Click Location & Routing(x12) Click Connector(x12)

Click Location & Routing(x12) Click Connector(x12) | Tester Connection | Condition | Specified Condition |

|---|---|---|

| x12-2 (GND) - Body ground | Ignition switch off | Below 1 Ω |

Post-procedure1

(e) Disconnect the SST.

(f) Reconnect the No. 1 traction battery device box connector.

| OK |

| GO TO STEP 13 |

|

| 12. | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 13. | INSPECT NO. 1 TRACTION BATTERY DEVICE BOX (CHRB) |

CAUTION:

Be sure to wear insulated gloves.

Pre-procedure1

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the No. 1 traction battery device box connector.

Procedure1

(c) Measure the resistance according to the value(s) in the table below.

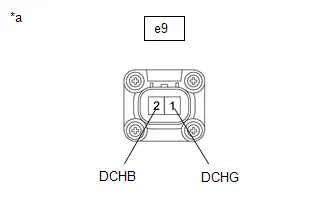

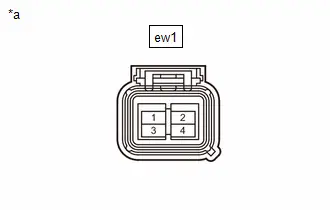

| *a | Component without harness connected (No. 1 Traction Battery Device Box) | - | - |

Standard Resistance:

Click Location & Routing(x12) Click Connector(x12)

Click Location & Routing(x12) Click Connector(x12) | Tester Connection | Condition | Specified Condition |

|---|---|---|

| x12-3 (CHRB) - x12-2 (GND) | -40 to 80°C (-40 to 176°F) | 20.6 to 40.8 Ω |

HINT:

If the CHR relay is welded, there is a possibility that the welding may release with a little vibration.

Post-procedure1

(d) Reconnect the No. 1 traction battery device box connector.

| NG |

| GO TO STEP 16 |

|

| 14. | CHECK NO. 1 TRACTION BATTERY DEVICE BOX |

CAUTION:

Be sure to wear insulated gloves.

Pre-procedure1

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

| (b) Disconnect the HV battery high voltage connector from the No. 1 traction battery device box. NOTICE: Insulate each disconnected high-voltage connector with insulating tape. Wrap the connector from the wire harness side to the end of the connector. |

|

| (c) Disconnect the HV battery high voltage connector from the No. 1 traction battery device box. NOTICE: Insulate each disconnected high-voltage connector with insulating tape. Wrap the connector from the wire harness side to the end of the connector. |

|

Procedure1

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

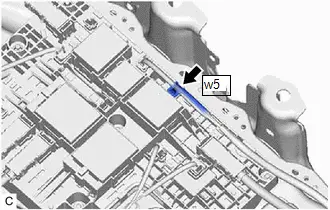

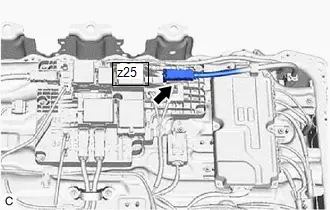

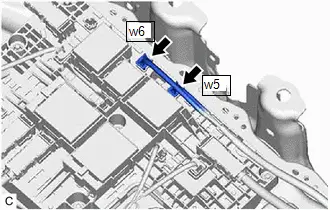

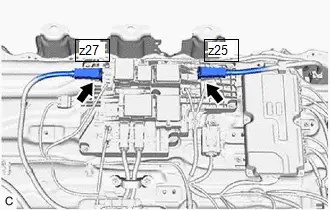

Click Location & Routing(z25,w5) Click Connector(z25) Click Connector(w5)

Click Location & Routing(z25,w5) Click Connector(z25) Click Connector(w5) | Tester Connection | Condition | Specified Condition |

|---|---|---|

| z25-1 ( ) - w5-1 (DCB2) | Ignition switch off | 10 kΩ or higher |

HINT:

If the CHR relay is welded, there is a possibility that the welding may release with a little vibration.

| Result | Judgment | Proceed to |

|---|---|---|

| OK | Past malfunction | A |

| NG | Present malfunction | B |

Post-procedure1

(e) Reconnect the HV battery high voltage connectors.

| B |

| GO TO STEP 17 |

|

| 15. | REPLACE NO. 1 TRACTION BATTERY DEVICE BOX |

HINT:

Click here

| NEXT |

| GO TO STEP 18 |

| 16. | REPLACE NO. 1 TRACTION BATTERY DEVICE BOX |

HINT:

Click here

| NEXT |

| GO TO STEP 18 |

| 17. | REPLACE NO. 1 TRACTION BATTERY DEVICE BOX |

HINT:

Click here

|

| 18. | READ VALUE USING GTS (CHECK FOR NORMAL OPERATION) |

Pre-procedure1

(a) Clear the DTCs.

Powertrain > Plug-in Control > Clear DTCs(b) Turn the ignition switch off and wait for 2 minutes or more.

(c) Confirm to start solar charging and wait for 2 minutes or more.

Procedure1

(d) According to the display on the GTS, read the Data List and monitor the values of "Hybrid/EV Battery Total Voltage" and "Solar Charging Boosting DC/DC Converter Voltage" for 3 minutes.

Powertrain > Plug-in Control > Data List| Tester Display |

|---|

| Solar Charging Boosting DC/DC Converter Voltage |

| HV/EV Battery Total Voltage |

| Result | Proceed to |

|---|---|

| Difference between "Hybrid/EV Battery Total Voltage" and "Solar Charging Boosting DC/DC Converter Voltage" is always less than 100 V. | A |

| Difference between "Hybrid/EV Battery Total Voltage" and "Solar Charging Boosting DC/DC Converter Voltage" is 100 V or more. | B |

Post-procedure1

(e) Turn the ignition switch off.

| A |

| END |

|

| 19. | REPLACE NO. 1 TRACTION BATTERY DEVICE BOX |

HINT:

Click here

| NEXT |

| REPLACE BATTERY ECU ASSEMBLY |

Hybrid/EV Battery Charging System Positive/Negative Contactor Actuator Stuck Closed (P0D0773)

DTC SUMMARY

MALFUNCTION DESCRIPTION

The plugin charge control ECU detects a stuck closed malfunction of a charge relay on the negative (-) terminal side of the HV battery.

The cause of this malfunction may be one of the following:

- Voltage sensor (VSOL) malfunction

- Solar energy control ECU assembly malfunction

- Communication (wire harness) malfunction

- No. 1 traction battery device box malfunction

- Plugin charge control ECU assembly malfunction

- Traction battery device box malfunction

- Battery ECU assembly malfunction

- Low voltage wire harness malfunction

- Low voltage connector malfunction

- Solar energy control ECU assembly discharge resistance malfunction

DESCRIPTION

Refer to the description for DTC P0D0700.

Click here

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Warning Indicate | DTC Output from | Priority | Note |

|---|---|---|---|---|---|---|---|---|

| P0D0773 | Hybrid/EV Battery Charging System Positive/Negative Contactor Actuator Stuck Closed | The voltage in the solar energy control ECU assembly does not drop even though the CHRB and CHRG relays are turned off. (1 trip detection logic) |

| Comes on | Master Warning: Comes on | Plug-in Control | B | SAE Code: P0D08 |

MONITOR DESCRIPTION

The plugin charge control ECU assembly monitors the operating state of the charge relay. If the voltage of the solar energy control ECU assembly does not decrease even though the CHRB relay and the CHRG relay are turned off, the plugin charge control ECU assembly judges that there is a malfunction and illuminates the MIL and stores a DTC.

MONITOR STRATEGY

| Related DTCs | P0D08: Battery Charging System Positive Contactor Stuck Closed |

| Required sensors/components | No. 1 traction battery device box Battery ECU assembly Solar energy control ECU assembly |

| Frequency of operation | - |

| Duration | TMC's intellectual property |

| MIL operation | 1 driving cycle |

| Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

| The monitor will run whenever the following DTCs are not stored | TMC's intellectual property |

| Other conditions belong to TMC's intellectual property | - |

TYPICAL MALFUNCTION THRESHOLDS

| TMC's intellectual property | - |

COMPONENT OPERATING RANGE

| Plug-in charge control ECU | DTC P0D0773 is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

-

After repair has been completed, clear the DTC and then check that the Toyota Prius vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

-

When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch on (READY) and wait for 5 seconds or more. [*1]

- Turn the ignition switch off and wait for 2 minutes or more. [*2]

-

Confirm to start solar charging and wait for 2 minutes or more. [*3]

HINT:

[*1] to [*3]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / Plug-in Control / Utility / All Readiness.

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to the wiring diagram for the P0D0700.

Click here

CAUTION / NOTICE / HINT

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

Click here

NOTICE:

- After clearing the DTCs (or after disconnecting the cable from the auxiliary battery terminal) before repairs are performed, do not park the Toyota Prius vehicle in direct sunlight, etc., as solar charging may be performed which may cause a malfunction of other components.

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

PROCEDURE

| 1. | CHECK DTC OUTPUT (HYBRID CONTROL, HV BATTERY, PLUG-IN CONTROL, SOLAR CHARGING CONTROL) |

Pre-procedure1

(a) Enter the following menus:

Powertrain > Hybrid Control > Trouble Codes Powertrain > HV Battery > Trouble Codes Powertrain > Plug-in Control > Trouble Codes Powertrain > Solar Charging Control > Trouble CodesProcedure1

(b) Check for DTCs.

| Result | Proceed to |

|---|---|

| P0D0773 only is output, or DTCs except the ones in the table below are also output. | A |

| DTCs of Hybrid Control System in the tables below are output. | B |

| DTCs of Hybrid Battery System in the tables below are output. | C |

| DTCs of Plug-in Charge Control System in the tables below are output. | D |

| DTCs of Solar Charging System in the tables below are output. | E |

| Malfunction Content | System | Relevant DTC | |

|---|---|---|---|

| Microcomputer malfunction | Plug-in Charge Control System | P060B49 | Plug-in Control Module A/D Processing Internal Electronic Failure |

| P0E5E87 | Plug-in Control Module Processor from Hybrid/EV Battery Charger Control Module Processor Missing Message | ||

| P1C1F49 | Hybrid/EV Battery Charger Control Module A/D Processing Internal Electronic Failure | ||

| Solar Charging System | P1EDB49 | Solar Charger Control Module A/D Processing Internal Electronic Failure | |

| Communication system malfunction | Plug-in Charge Control System | U01BB87 | Lost Communication with Battery Charger Control Module "B" Missing Message |

| U113A87 | Lost Communication with Solar Charging Control Module Missing Message | ||

| U117B87 | Lost Communication with Hybrid/EV Battery Energy Control Module "A" (ch2) Missing Message | ||

| Solar Charging System | U115087 | Lost Communication with Hybrid Powertrain Control Module (Hybrid/EV Battery Local Bus) Missing Message | |

| U115387 | Lost Communication with Battery Charger Control Module "A" (ch2) Missing Message | ||