Toyota Prius: Panoramic View Monitor System

- Precaution

- System Diagram

- System Description

- How To Proceed With Troubleshooting

- Customize Parameters

- Calibration

- Utility

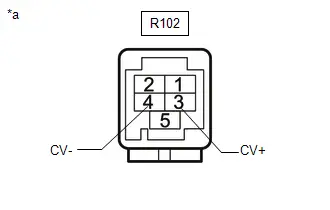

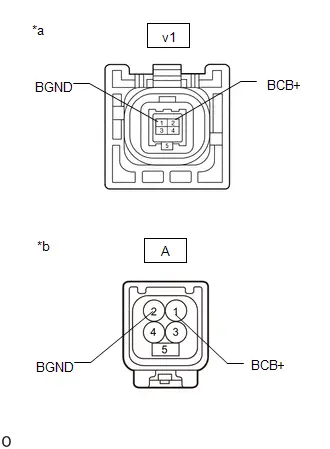

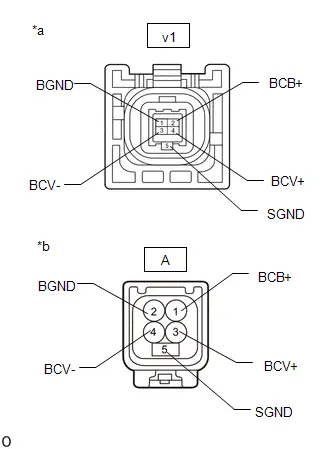

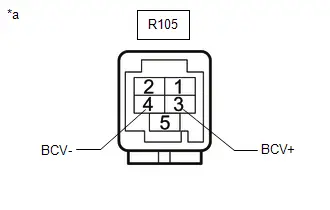

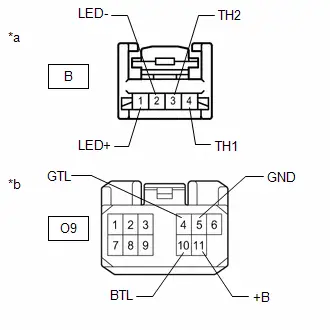

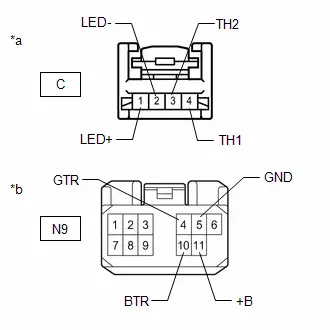

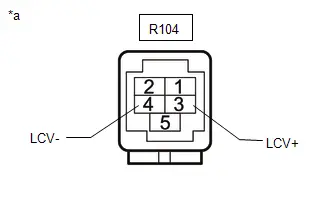

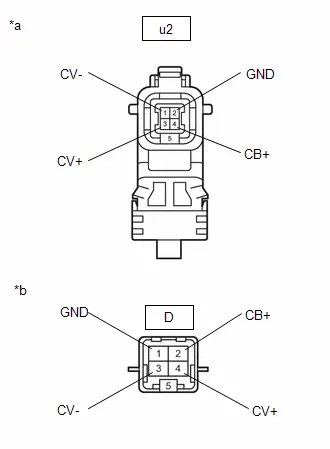

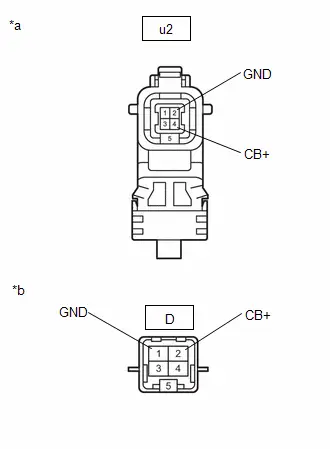

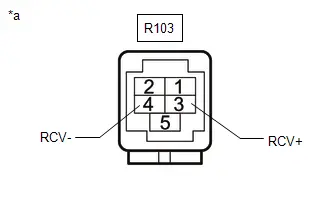

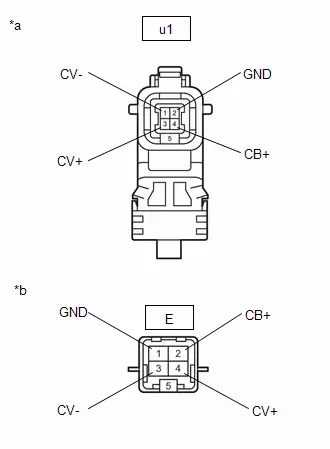

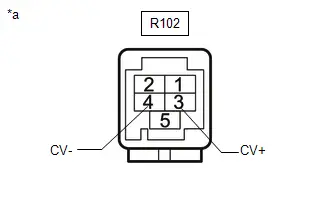

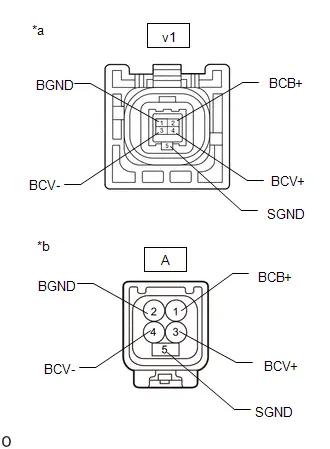

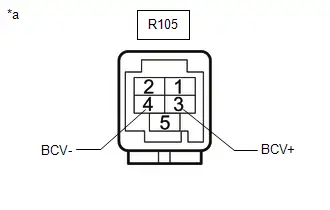

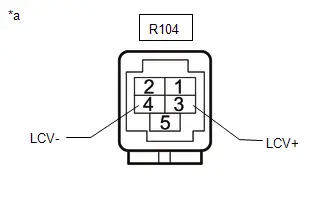

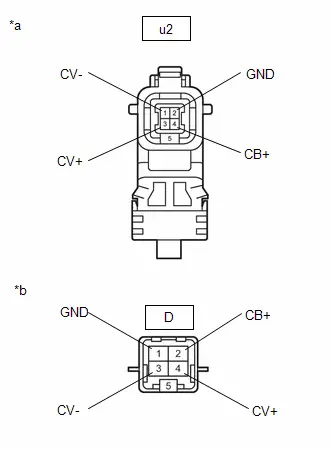

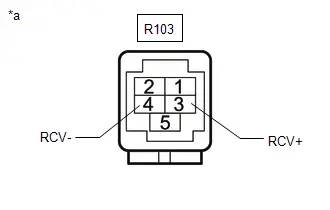

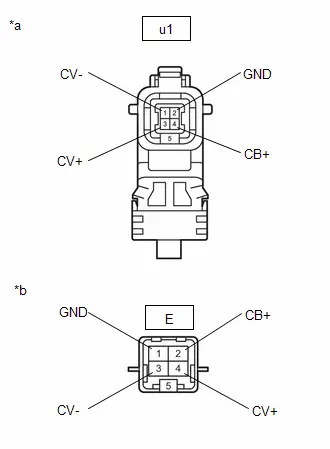

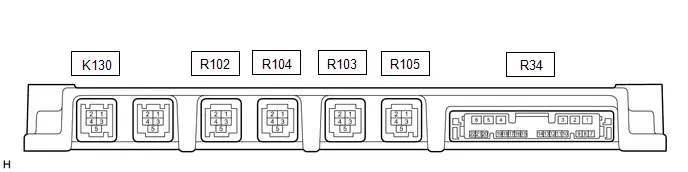

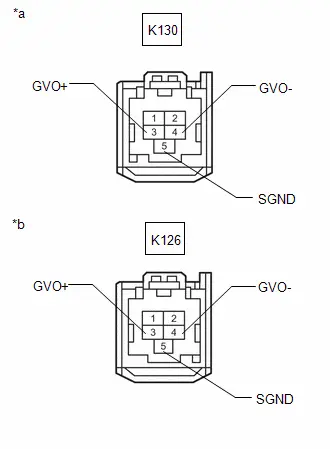

- Terminals Of Ecu

- Diagnosis System

- Freeze Frame Data

- Fail-safe Chart

- VEHICLE CONTROL HISTORY (RoB)

- Circumference Monitoring Camera Control Module System Internal Failure (C161404,C161B04)

- Rear Camera Circuit Short to Ground (C162011)

- Rear Camera Image Signal Missing Message (C162287)

- Front Camera Circuit Short to Ground (C168011)

- Front Camera Image Signal Missing Message (C168187)

- IR Floodlight Circuit Resistance Out of Range (C16891E)

- Side Camera (Left) Image Signal Missing Message (C168E87)

- Side Camera (Left) Circuit Short to Ground (C168F11)

- Side Camera (Right) Image Signal Missing Message (C169D87)

- Lost Communication with Steering Angle Sensor Module Missing Message (U012687,...,U111087)

- Lost Communication with Clearance Sonar Module (ch2) Missing Message (U11B687)

- "CHK" message(s) are displayed on the SIGNAL CHECK screen.

- ECU Power Source Circuit

- Image from Camera for Panoramic View Monitor is Abnormal

Precaution

PRECAUTION

PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL

NOTICE:

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

SENSOR EXPRESSIONS

(a) The descriptions for the blind spot monitor sensors differ depending on the system. The expressions listed in the table below are used in this Repair Manual.

| Part Name | Actual Part Name |

|---|---|

| Blind spot monitor sensor LH (B) | Blind spot monitor sensor LH |

| Blind spot monitor sensor RH (A) | Blind spot monitor sensor RH |

POINTS TO NOTE WHEN SERVICING

(a) Pay attention to the following points when servicing.

(1) Depending on the parts that are replaced or operations that are performed during Toyota Prius vehicle inspection or maintenance, calibration of other systems as well as the panoramic view monitor system may be needed.

Click here

HINT:

Each adjusted value for the calibration of the panoramic view monitor system will be stored in the parking assist ECU.

(2) When the lens of the television camera assembly is dirty, wash the lens with water and wipe it off with a soft cloth to obtain clear images. For heavy dirt, use neutral detergent to clean the lens.

PRECAUTIONS FOR PANORAMIC VIEW MONITOR SYSTEM

(a) In the following situations, the panoramic view monitor system may not operate correctly:

(1) When driving on icy, slippery or snowy roads

(2) When using tire chains or a spare tire

(3) When a door is not fully closed

(4) When driving on a slope or rough roads

(5) When using tires other than specified

(6) When the suspension of the Toyota Prius vehicle has been modified

(b) As the panoramic view monitor system generates the panoramic image by combining images received from the front television camera assembly, rear television camera assembly and side camera assemblies, the following phenomenon may occur:

(1) A three dimensional object may appear tilted

(2) An object above the road surface may appear farther away than it actually is, or may not be displayed at all

(3) A tall object may look as if it is coming out from between 2 combined images

(4) Depending on the brightness of the area surrounding each camera, there may be a significant difference in the brightness of the images that are used to generate the panoramic image.

(c) The image quality at the four corners of the panoramic image may be low as this is where the individual images are combined.

(d) Objects a certain height above the camera assemblies will not be displayed.

(e) Objects extremely close to the Toyota Prius vehicle may not be displayed on the panoramic view monitor.

(f) The panoramic image may not be displayed correctly if a front door, rear door or the back door is open.

(g) The panoramic image may not be displayed correctly if the height or inclination of the vehicle changes due to loading from passengers, luggage, etc.

(h) As the size and shape of the Toyota Prius vehicle icon may differ from that of the actual vehicle, the position of an object relative to the vehicle icon may appear different to its actual position.

PRECAUTION FOR MOVING OBJECT DETECTION (w/ Advanced Park)

(a) In the following situations, the camera may not be able to correctly detect moving objects.

(1) Pedestrians who are running.

(2) Pedestrians who suddenly appear from the shadow of the Toyota Prius vehicle or a building.

(3) Pedestrians who are riding moving objects such as a skateboard.

(4) Pedestrians whose clothing appears to be nearly the same color or brightness as their surroundings.

(5) Pedestrians behind an object such as a cart or luggage that hides part of their body.

(6) At night (after sunset).

(7) During bad weather (rain, snow, fog, etc.).

(8) When the lens is damaged or dirty (dirt, snow-melting agent, etc.).

(9) When water drops are moving over the camera lens.

(10) When a very bright light is shining directly into the camera sensor.

(11) When there is a difference in brightness (near open shutters in a garage or underground parking area, etc.).

(b) When objects such as the following are detected, the system may operate even without possibility of collision.

(1) Moving objects (such as flags, exhaust gas, large drops of rain, large snowflakes, rainwater on roads, etc.).

(2) When there are patterns on the road (white lines, pedestrian crossings, stones, streetcar rails, repaired areas, fallen leaves, gravel, standing water, etc.).

(3) A metal cover (grating) or drainage ditch.

(4) When there is a shoulder or an uneven surface.

(5) Objects reflected off puddles or wet road surfaces.

(6) Shadows.

(7) Elongated structures (columns, triangular cones, fire hydrants, etc.).

(8) Stationary pedestrians, motorcycles, Toyota Prius vehicles.

(c) In conditions such as the following, the system may operate even without possibility of collision.

(1) When driving over an uneven surface.

(2) When the vehicle is extremely tilted (loaded, suddenly braking, etc.).

(3) When there are changes in gradient.

(4) A lowered suspension or tire with a different diameter than a genuine tire, etc. is installed.

(5) When there is an extreme change in Toyota Prius vehicle height (nose up, nose down, etc.).

(6) When an aftermarket accessory (backlit license plate, fog light, etc.) is installed near the rear camera.

(7) When an aftermarket protective part is installed to the rear bumper (bumper trim, etc.).

(8) When an arm is held outside of a window.

(9) When a camera is mispositioned or misaligned.

(10) When a tow hook is installed to the Toyota Prius vehicle.

(11) When the camera lens is dirty (mud, snow-melting agent, etc.).

(12) When water drops are moving over the camera lens.

(13) When there is a flashing light source (hazard lights, etc.).

NOTES FOR EACH TELEVISION CAMERA ASSEMBLY

(a) Notes for each television camera assembly

(1) The panoramic view monitor system may not function properly if subjected to a severe blow by any hard object.

(2) Do not scrub the cover part of the camera (resin made). Scrubbing may scratch the cover and affect the image. Prevent organic solvents, waxes, bond removing solvents or glass coating from adhering to the cover. If such material adheres to the cover, clean it off immediately and wash it with water.

(3) Exposing the camera to a sudden temperature change may affect proper functioning of the camera.

(4) A clear image may not appear if the camera is dirty with snow, mud, etc. In that case, wash it with water and wipe off the lens. Use a detergent to remove dirt if necessary.

(5) When washing the Toyota Prius vehicle with a high-pressure washer, do not spray water on the television camera assembly or surrounding area. High-pressure water can damage the camera.

(b) Images may be unclear even in normal conditions if:

(1) The outer mirror switch assembly is operated (noise may occur in the image).

(2) Electrical devices are used in the cabin (noise may occur in the image).

(3) Accessories that generate radio waves have been installed (noise may occur in the image).

(4) The camera lens is frosted over (the image immediately after turning the ignition switch to ON may be blurred or darker than normal).

(5) The camera lens is dirty with snow, mud, etc.

(6) The lens of a camera is covered with foreign matter.

(7) A strong beam of light, such as a sunbeam or headlight, hits the camera.

(8) It is too dark around the camera (at night, etc.).

(9) The ambient temperature around the camera is either too high or too low.

(10) The Toyota Prius vehicle is tilted at a steep angle.

(11) The area around the vehicle is not sufficiently bright.

(12) The television camera assembly lens is scratched.

(13) The television camera assembly lens has drops of water on it or the humidity is high.

(14) When the camera is used under fluorescent lights, sodium lights or mercury lights, etc., the lights and the illuminated area may appear to flicker.

(15) The side outer mirror is equipped with a parking assist light and the side camera reacts even to infrared rays. Therefore, the camera image may differ from how objects look under visible light, because the infrared rays in sunlight or halogen lights, or the light emitted from the parking assist light may lighten the color of the camera image or change the color shade.

PRECAUTIONS FOR USING REAR CAMERA DETECTION FUNCTION (w/ Rear Camera Detection Function)

(a) a. The rear camera detection function may not be able to detect pedestrians correctly in the following situations:

(1) Pedestrians who are bending forward or squatting

(2) Pedestrians who are laying down

(3) Pedestrians who are running

(4) Pedestrians who suddenly appear from the shadow of the Toyota Prius vehicle or a building

(5) Pedestrians who are riding moving objects such as a bicycle, skateboard, etc.

(6) Pedestrians wearing oversized clothing such as a rain coat, long skirt, etc., making their silhouette obscure

(7) Pedestrians at night or whose clothing appears to be nearly the same color or brightness as their surroundings.

(8) Pedestrians behind an object such as a cart or luggage that hides part of their body

(9) At night (after sunset)

(10) During bad weather (rain, snow, fog, etc.)

(11) Damaged or dirty lens (dirt, snow-melting agent, etc.)

(12) Backlight (direct sunlight, sunlight reflected off the road surface, headlights of other Toyota Prius vehicles, etc.)

(13) Difference in brightness (near open shutters in a garage or underground parking area)

(b) The rear camera detection function may not perform valid detection in the following conditions:

(1) Solid objects (pillars, pylons, fences, parked vehicles, etc.)

(2) Moving objects (passing Toyota Prius vehicle, motorcycle, etc.)

(3) Moving objects (such as flags, exhaust gas, large drops of rain, large snowflakes, rainwater on roads, etc.)

(4) Patterns on roads (white lines, pedestrian crossings, stones, streetcar rails, repaired areas, fallen leaves, gravel, etc.)

(5) A metal cover (grating) or drainage ditch

(6) Shoulders and ridges

(7) Surrounding objects reflected off puddles or wet road surfaces

(8) Shadows

(9) When driving over an uneven surface

(10) The Toyota Prius vehicle is extremely tilted (loaded, suddenly braking, etc.)

(11) There are changes in gradient

(12) A lowered suspension or tire with a different diameter than a genuine tire, etc. is installed

(13) An extreme change in vehicle height (such as nose up, nose down, etc.)

(14) An aftermarket accessory (backlit license plate, fog light, etc.) is installed near the rear camera

(15) An aftermarket protective part is installed to the rear bumper (bumper trim, etc.)

(16) The axis of the camera is misaligned (due to reinstallation, collision, etc.)

(17) A towing hook is installed

(18) The camera lens is dirty (mud, snow-melting agent, etc.)

(19) Water drops are moving over the camera lens

(20) There is a flashing light source (hazard lights, etc.)

(c) Regarding the visibility of the radio and display receiver assembly

(1) When the temperature inside the Toyota Prius vehicle is extremely high or extremely low, the radio and display receiver assembly may not correctly display detection.

(d) Regarding the audibility of the buzzer sound

(1) If the volume setting of the audio system is high, it may be difficult to hear the buzzer.

PRECAUTION FOR PARKING ASSIST LIGHT

(a) Precautions

- Do not apply excessive force to the camera lens of the parking assist lights or subject them to a strong impact as it may affect proper functioning of the parking assist lights.

- Do not scrub the camera lens of the parking assist lights as scrubbing may scratch the lens and affect the quality of the image.

- The cover parts of the parking assist lights are made of resin. If any organic solvent, degreaser, wax or glass coating contacts a cover, immediately wipe it off and wash the cover with water or cracks may develop.

- Do not expose the parking assist lights to sudden temperature changes (such as pouring hot water in cold weather) as it may affect proper functioning of the panoramic view monitor system.

- If there is foreign matter such as water drops, snow or mud on the camera lenses of the parking assist lights, wash the cameras with a large amount of water and then wipe the lenses with a soft wet cloth. Do not scrub the camera lenses as scrubbing may scratch them and may adversely affect operation.

- When washing the Toyota Prius vehicle with a high-pressure washer, do not spray water on the parking assist lights or surrounding area. High-pressure water can damage the parking assist lights.

(b) If the quality of the image is poor even when the system is operating normally.

(1) A foreign object is attached to a camera lens

(2) A camera lens is covered with foreign matter, etc.

(3) The temperature around a camera lens is excessively high or low

(4) The Toyota Prius vehicle or road is on an incline

(5) A camera lens is scratched

(6) A camera lens has water droplets on it or the humidity is high

PRECAUTIONS FOR RECORDED DATA

(a) The panoramic view monitor system records data related to vehicle control and operation. Make sure to clear the data if requested by the customer.

Click here

PRECAUTIONS FOR REPLACEMENT OF COMPONENTS

(a) After replacing certain components, it may be necessary to send the Toyota Prius vehicle information.

Click here

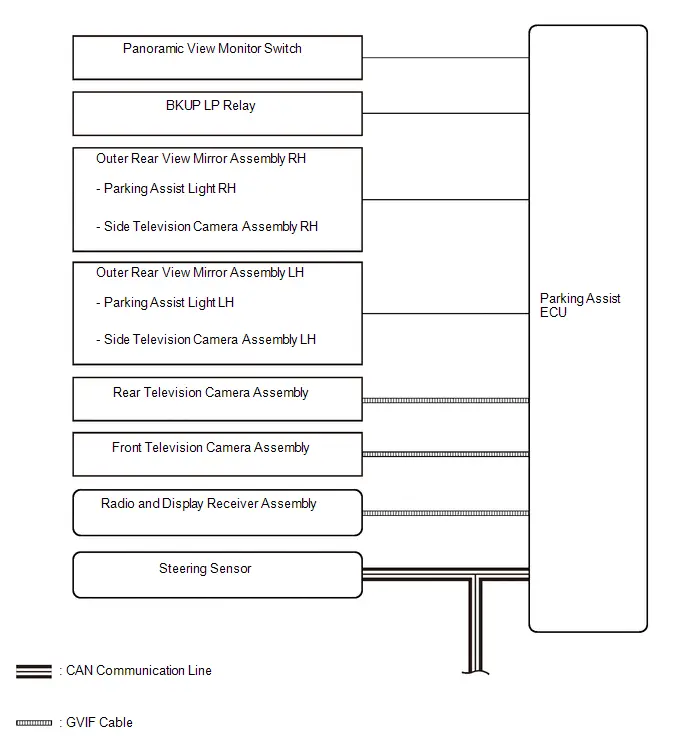

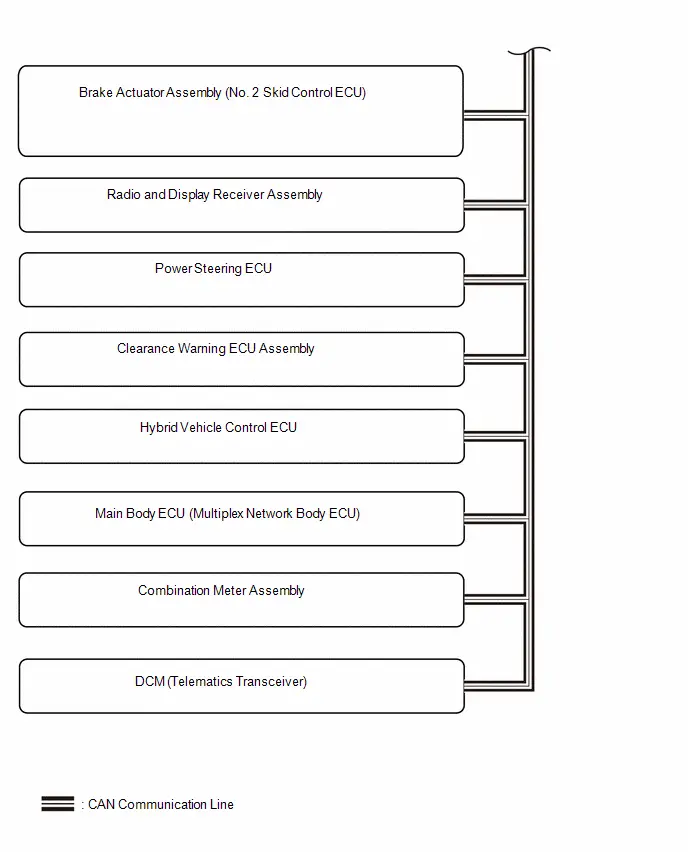

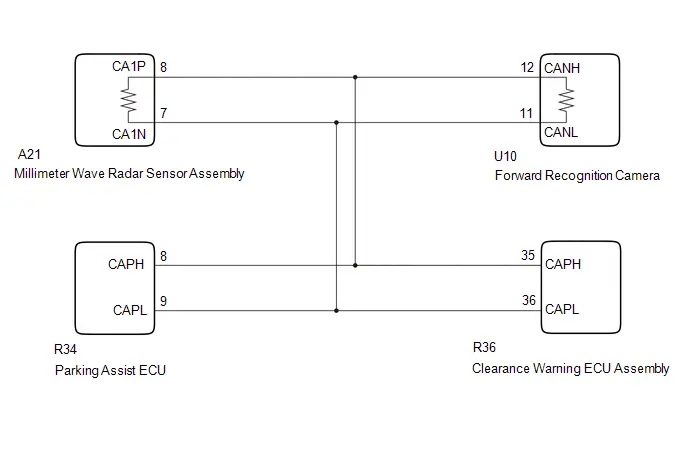

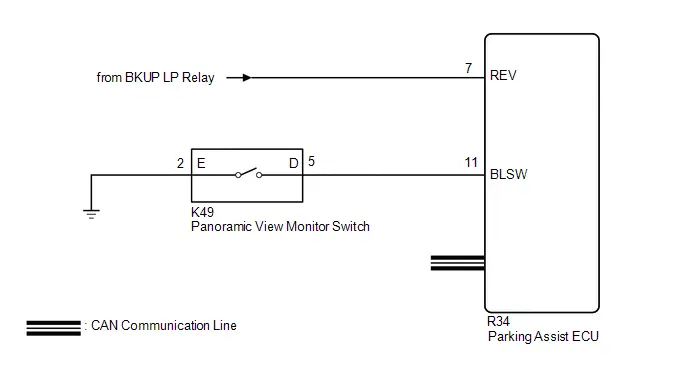

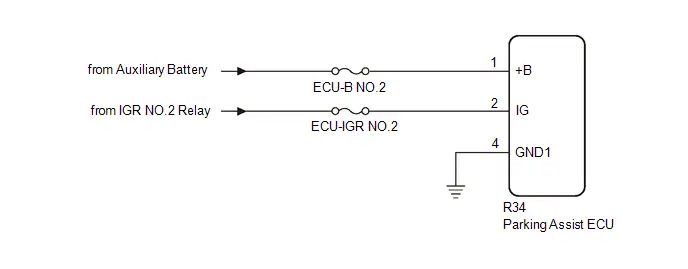

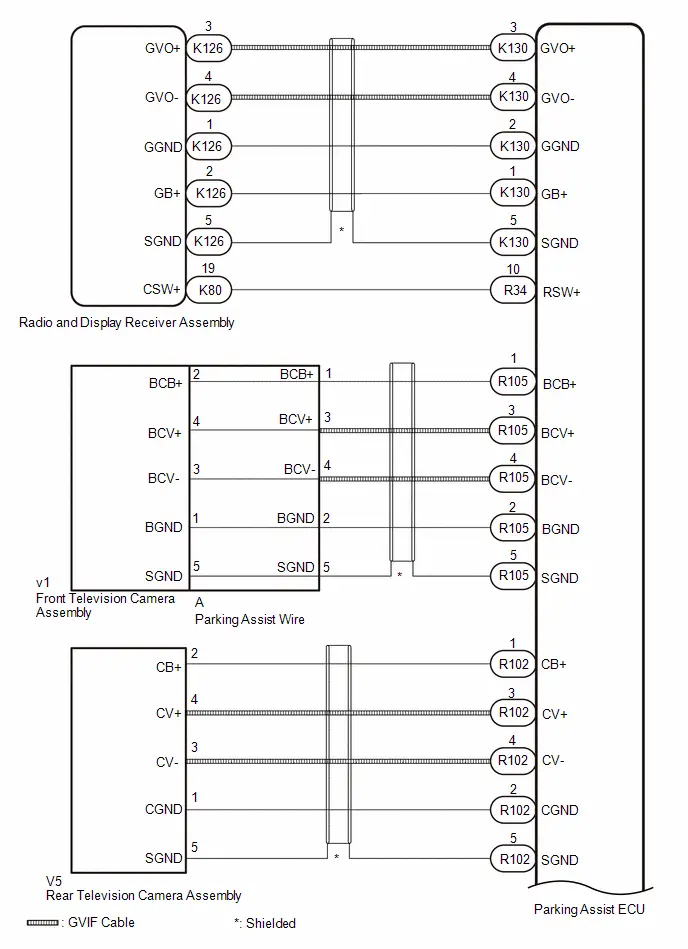

System Diagram

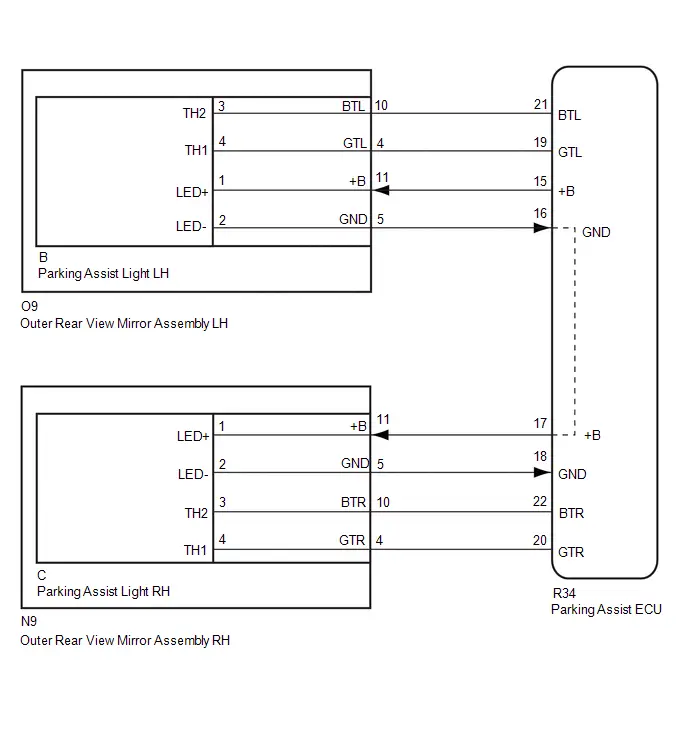

SYSTEM DIAGRAM

System Description

SYSTEM DESCRIPTION

COMMUNICATION SYSTEM OUTLINE

(a) CAN communication system

(1) The panoramic view monitor system uses CAN communication for data communications between the parking assist ECU and each ECU.

(2) If a problem occurs in the CAN communication line, the parking assist ECU outputs a CAN communication malfunction DTC. (To check, use the GTS.)

(3) When there is a problem with the CAN communication line, the parking assist ECU stores a CAN communication malfunction DTC. (Perform a check of the radio and display receiver assembly using the diagnosis screen)

Click here

(4) If a CAN communication line malfunction DTC is output, repair the malfunction in the communication line and troubleshoot the panoramic view monitor system when data communication is normal.

(5) Since the CAN communication line has its own length and route, it cannot be repaired temporarily with a bypass wire, etc.

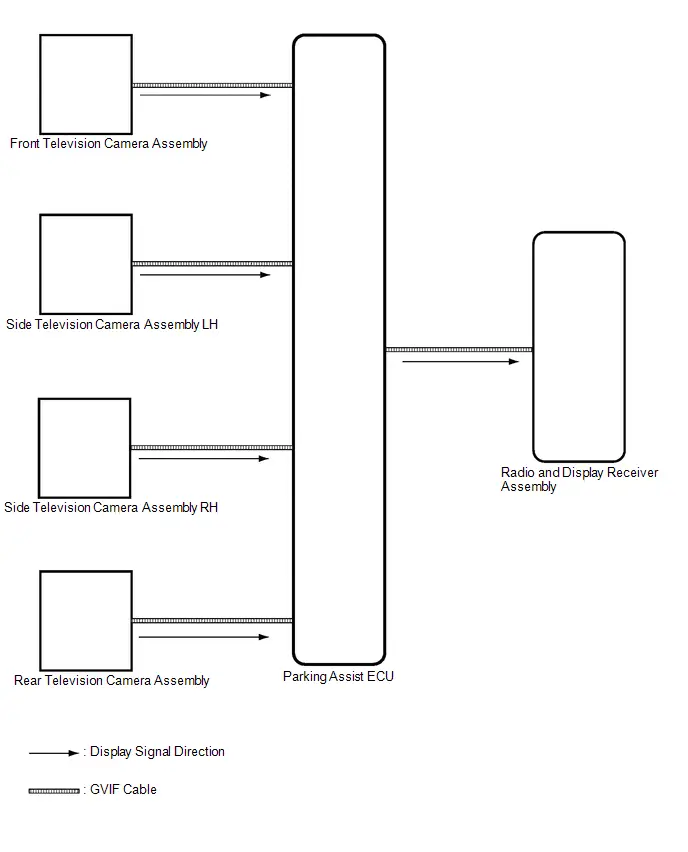

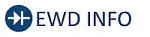

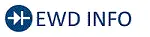

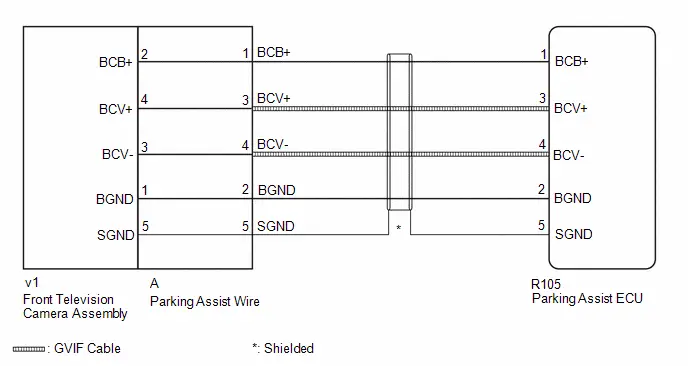

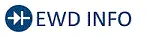

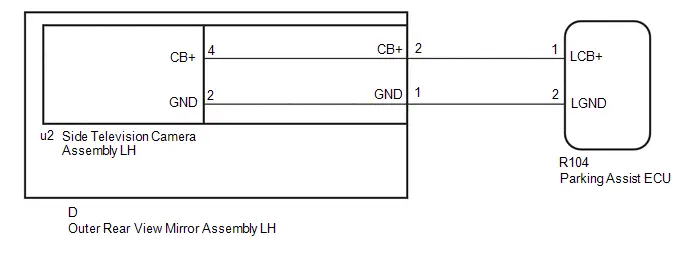

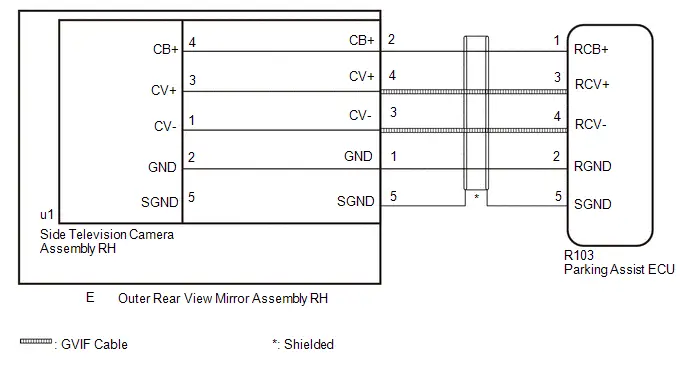

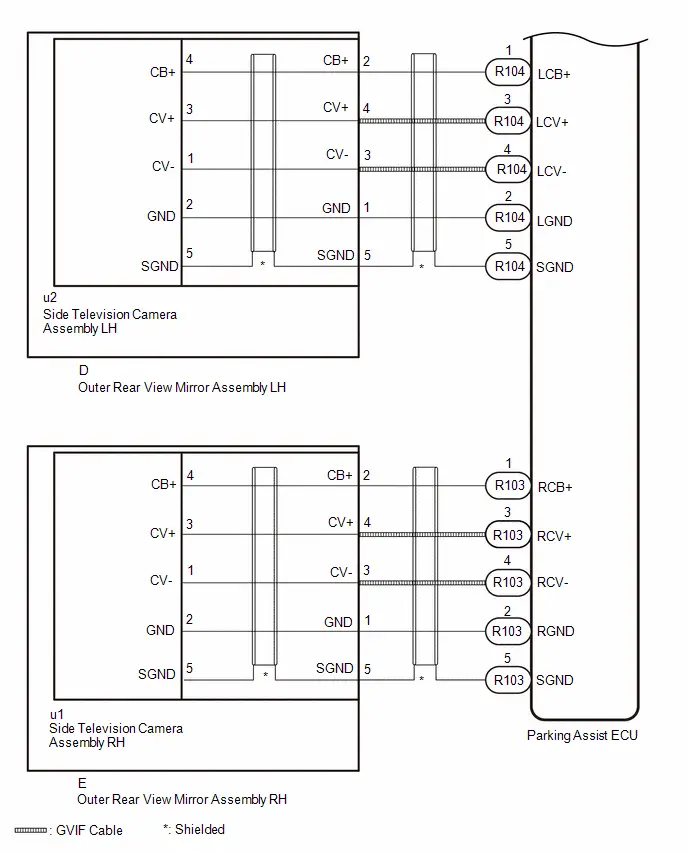

VIDEO SIGNALS

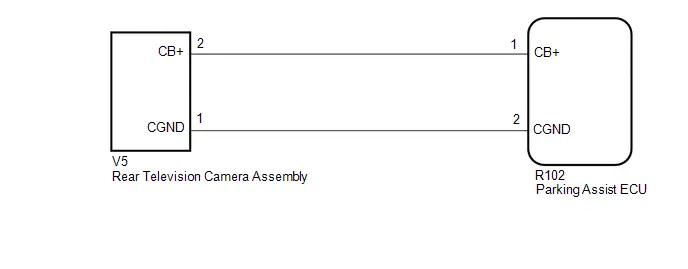

(a) Video signal circuit

(1) Video signals from each camera are input into the parking assist ECU via GVIF cable.

(2) Video signals from the parking assist ECU are input into the radio and display receiver assembly via GVIF cable.

(b) Screen display

(1) Video signals input from each camera are processed in the parking assist ECU and displayed on the radio and display receiver assembly as the panoramic view monitor system screen.

DIAGNOSTIC FUNCTION OUTLINE

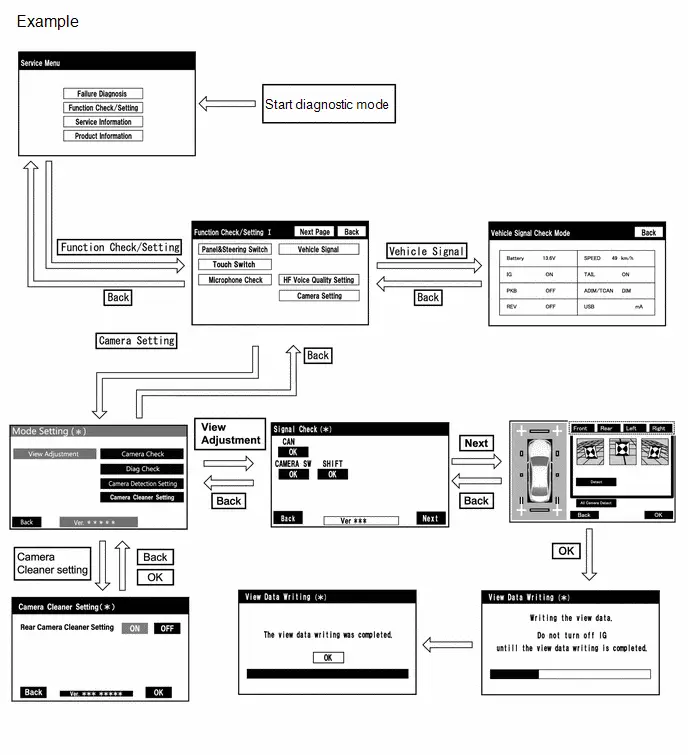

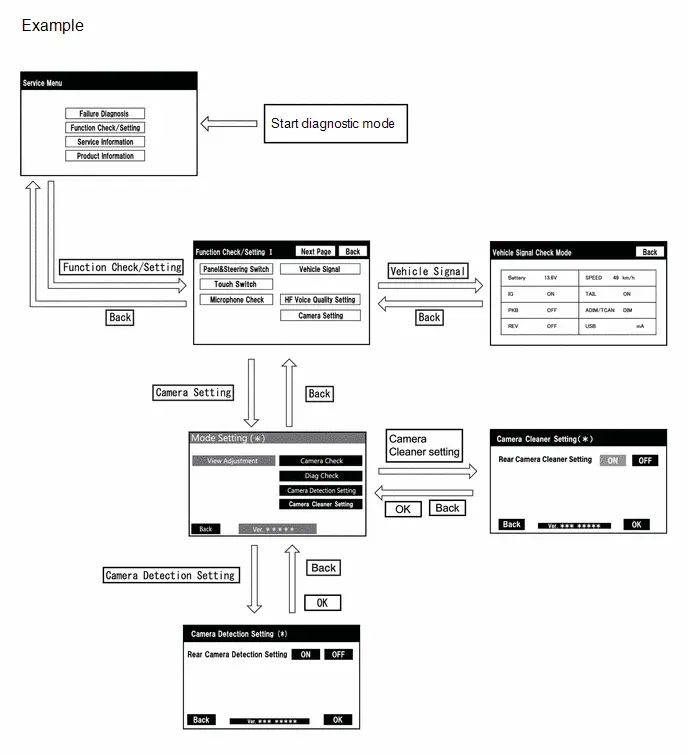

(a) This panoramic view monitor system has a diagnostic function displayed in the radio and display receiver assembly. This function enables the calibration (adjustment and verification) of the panoramic view monitor system.

Click here

HINT:

The panoramic view monitor system has a diagnosis function which can check each signal input to the parking assist ECU and adjust and monitor the panoramic view monitor system.

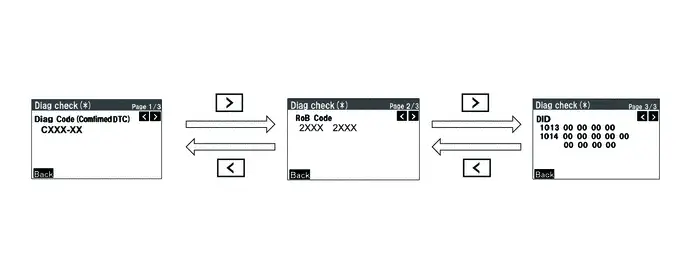

(b) The panoramic view monitor system can check the following items by using the GTS.

| Item | Proceed to |

|---|---|

| DTC | - |

| RoB | - |

| Data List / Active Test |

|

| SSR | - |

CALIBRATION

(a) Use the panoramic view monitor system diagnosis screen for calibration and checking of the panoramic view monitor system.

Click here

NOTICE:

Part replacement and work performed during servicing may require calibration of the panoramic view monitor system and other systems.

Click here

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

- Use the following procedure to troubleshoot the panoramic view monitor system.

- *: Use the GTS.

PROCEDURE

| 1. | Toyota Prius Vehicle BROUGHT TO WORKSHOP |

|

| 2. | CUSTOMER PROBLEM ANALYSIS |

(a) Ask the customer about the problems and the conditions at the time the malfunction occurred to make sure the problem symptom was not temporarily caused by radio waves in the surrounding environment.

HINT:

The panoramic view monitor display may be temporarily distorted due to radio waves around the Toyota Prius vehicle.

| Problem Symptom | Cause |

|---|---|

| The problem symptom indicates a panoramic view monitor display malfunction and the problem symptom cannot be reproduced. | The display may be temporarily distorted when the Toyota Prius vehicle is close to an object that transmits radio waves, such as a telecommunication tower, an airport or a truck equipped with a transceiver. |

|

| 3. | INSPECT AUXILIARY BATTERY VOLTAGE |

(a) Measure the auxiliary battery voltage with the ignition switch off.

Standard voltage:

11 to 14 V

If the voltage is below 11 V, replace or recharge the auxiliary battery before proceeding.

|

| 4. | CHECK AUDIO AND VISUAL SYSTEM |

(a) Refer to Audio and Visual System.

Click here

| Result | Proceed to |

|---|---|

| Audio and visual system is normal | A |

| Audio and visual system is abnormal | B |

| B |

| GO TO AUDIO AND VISUAL SYSTEM |

|

| 5. | CHECK COMMUNICATION FUNCTION OF CAN COMMUNICATION SYSTEM* |

(a) Use the GTS to check if the CAN communication system is functioning normally.

Click here

| Result | Proceed to |

|---|---|

| CAN DTCs are not output | A |

| CAN DTCs are output | B |

| B |

| GO TO CAN COMMUNICATION SYSTEM |

|

| 6. | CHECK FOR DTC* |

(a) Check for DTCs and note any codes that are output.

Chassis > Circumference Monitoring Camera Control Module > Trouble Codes(b) Clear the DTCs.

Chassis > Circumference Monitoring Camera Control Module > Trouble Codes(c) Recheck for DTCs. Try to prompt the DTC by simulating the original activity that the DTC suggests.

Chassis > Circumference Monitoring Camera Control Module > Trouble Codes| Result | Proceed to |

|---|---|

| DTC is not output | A |

| DTC is output | B |

| B |

| GO TO DIAGNOSTIC TROUBLE CODE CHART |

|

| 7. | CHECK FOR Toyota Prius Vehicle CONTROL HISTORY* |

HINT:

Refer to Vehicle Control History.

Click here

(a) Check for vehicle control history and note any codes that are output.

Chassis > Circumference Monitoring Camera Control Module > Utility| Tester Display |

|---|

| Toyota Prius Vehicle Control History (RoB) |

| Result | Proceed to |

|---|---|

| No vehicle control history is output | A |

| Toyota Prius Vehicle control history is output | B |

| B |

| GO TO VEHICLE CONTROL HISTORY |

|

| 8. | PROBLEM SYMPTOMS TABLE |

(a) Refer to the Problem Symptoms Table.

Click here

| Result | Proceed to |

|---|---|

| Fault is not listed in Problem Symptoms Table | A |

| Fault is listed in Problem Symptoms Table | B |

| B |

| GO TO STEP 10 |

|

| 9. | OVERALL ANALYSIS AND TROUBLESHOOTING* |

(a) Data List / Active Test

Click here

(b) Terminals of ECU

Click here

|

| 10. | ADJUST, REPAIR OR REPLACE |

|

| 11. | CONFIRMATION TEST |

| NEXT |

| END |

Customize Parameters

CUSTOMIZE PARAMETERS

CUSTOMIZE PANORAMIC VIEW MONITOR SYSTEM

(a) Customize using multi-display.

NOTICE:

- When the customer requests a change in a function, first make sure that the function can be customized.

- Be sure to make a note of the current settings before customizing.

- When troubleshooting a function, first make sure that the function is set to the default setting.

| Display | Measurement Item | Default | Setting | ECU |

|---|---|---|---|---|

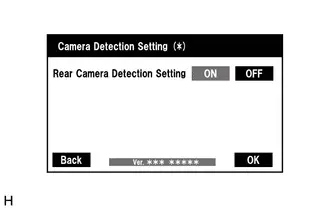

| RCD | Switches the rear camera detection function on and off. | ON | ON or OFF | Parking assist ECU |

Calibration

CALIBRATION

ADJUST PANORAMIC VIEW MONITOR SYSTEM

NOTICE:

-

If any of the following components are removed and installed, the adjustment procedure may be omitted by performing the simple inspection.

- Front television camera assembly, radiator grille assembly or front bumper

- Rear television camera assembly

- Side television camera assembly RH, parking assist light RH, or outer rear view mirror assembly RH

- Side television camera assembly LH, parking assist light LH, or outer rear view mirror assembly LH

(a) This panoramic view monitor system can be set from the diagnostic screen of the radio and display receiver assembly.

(b) If the following operations are performed, it is necessary to perform adjustments and checks on the diagnostic screen.

| Part Name | Operation | Adjustment Item | Proceed to |

|---|---|---|---|

|

*1: At the time of SST (marker tool set) non-use

*2: At the time of use SST (marker tool set) *3: If the camera assembly has been replaced, it is not possible to perform the simple inspection. | |||

| Parking assist ECU | Replacement | Parking assist ECU initialization | Procedure 2 |

| Procedure 3 | |||

| Procedure 12*1 | |||

| Procedure 13*2 | |||

| Procedure 14 | |||

| Procedure 15 | |||

| Suspension, tires, etc. | The Toyota Prius vehicle height changes because of suspension or tire replacement | Parking assist ECU initialization | Procedure 2 |

| Procedure 3 | |||

| Procedure 12*1 | |||

| Procedure 13*2 | |||

| Procedure 14 | |||

| Procedure 15 | |||

| Rear television camera assembly |

| Rear television camera view adjustment | Procedure 1*3 |

| Procedure 2 | |||

| Procedure 3 | |||

| Procedure 6*1 | |||

| Procedure 13*2 | |||

| Procedure 7 | |||

| Procedure 15 | |||

|

| Front television camera view adjustment | Procedure 1*3 |

| Procedure 2 | |||

| Procedure 3 | |||

| Procedure 4*1 | |||

| Procedure 13*2 | |||

| Procedure 5 | |||

| Procedure 15 | |||

|

| Side television camera view adjustment | Procedure 1*3 |

| Procedure 2 | |||

| Procedure 3 | |||

| Procedure 8*1 | |||

| Procedure 13*2 | |||

| Procedure 9 | |||

| Procedure 15 | |||

| Procedure 16 | |||

|

| Side television camera view adjustment | Procedure 1*3 |

| Procedure 2 | |||

| Procedure 3 | |||

| Procedure 10*1 | |||

| Procedure 13*2 | |||

| Procedure 11 | |||

| Procedure 15 | |||

| Procedure 16 | |||

| Replacement or removal and installation of 2 or more parts | Television camera view adjustment | Procedure 2 |

| Procedure 3 | |||

| Procedure 12*1 | |||

| Procedure 13*2 | |||

| Procedure 14 | |||

| Procedure 15 | |||

| Procedure 16 | |||

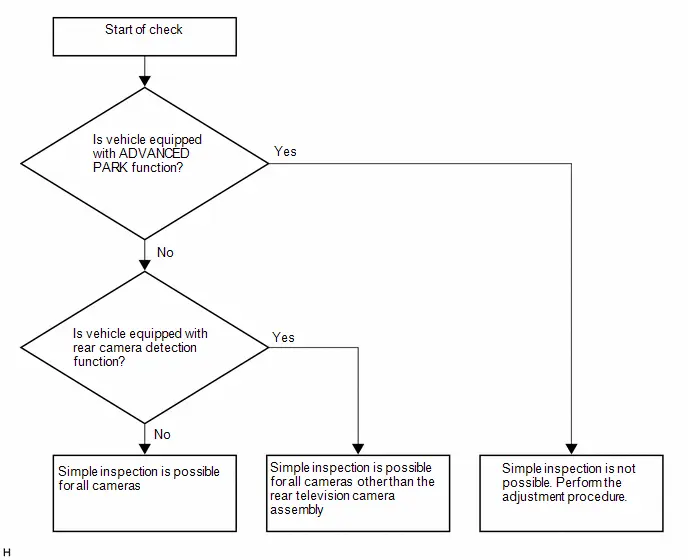

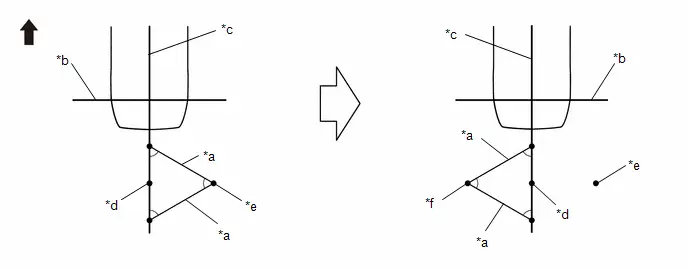

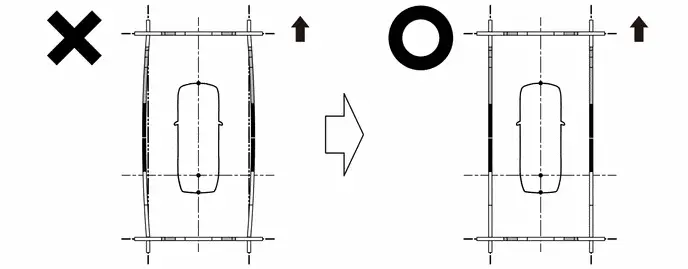

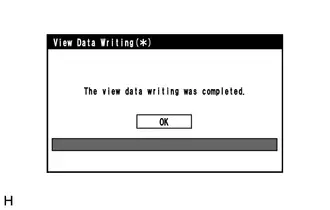

PROCEDURE 1: SIMPLE INSPECTION

(a) Pre-check:

(1) Check that the Toyota Prius vehicle is compatible with the simple inspection.

NOTICE:

- Perform the inspection at a location with white lines (parking space, etc.) with a width of approximately 100 mm to 150 mm between the white lines.

- The white lines must be straight, uniform, and without extreme damage. (Do not use dotted lines or lines where the paint is peeling.)

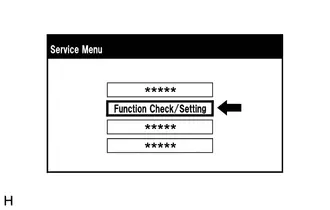

(b) Display the screen adjustment screen in order to perform a screen adjustment.

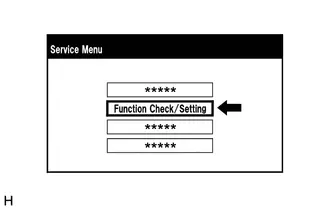

(1) Start diagnosis

HINT:

Click here

CAUTION:

The adjustment must be performed with the ignition switch ON (READY). Therefore, make sure that the parking brake is engaged, the brake pedal is depressed, the shift lever is in P, and that sufficient precautions are taken to ensure that the Toyota Prius vehicle does not start off.

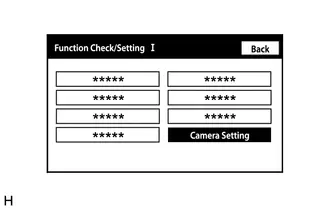

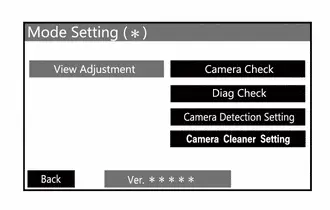

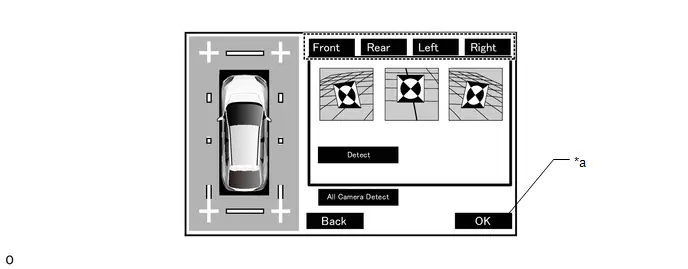

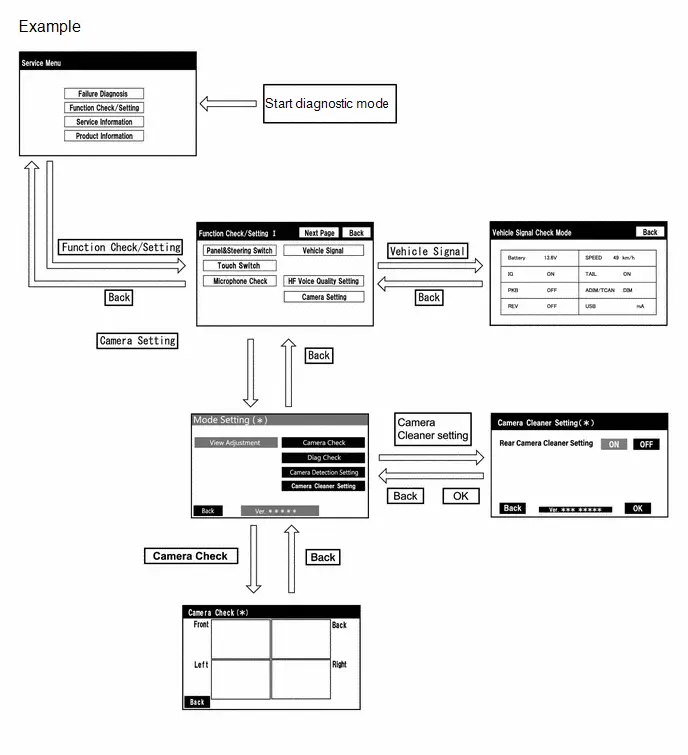

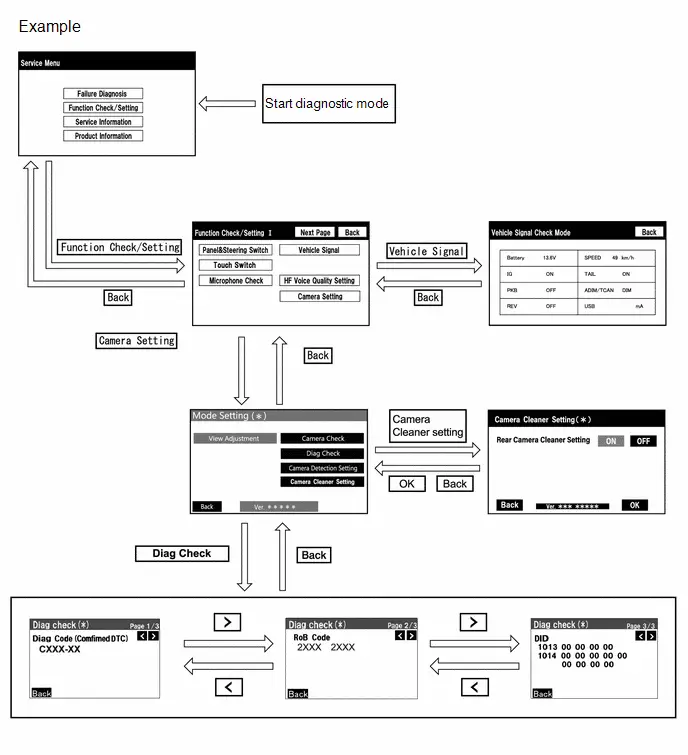

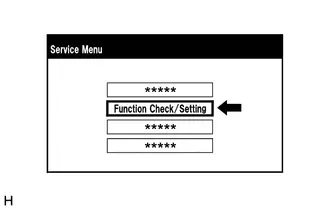

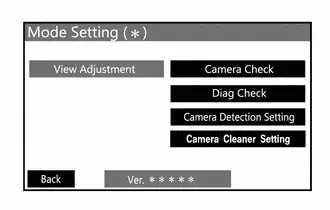

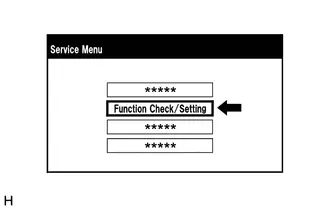

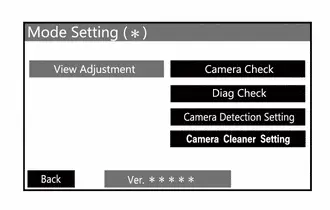

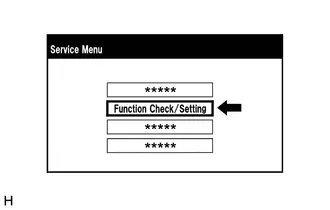

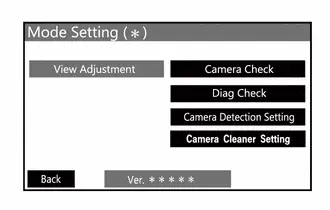

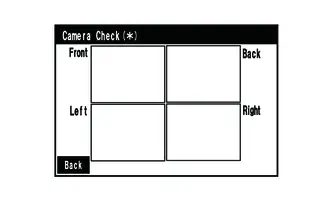

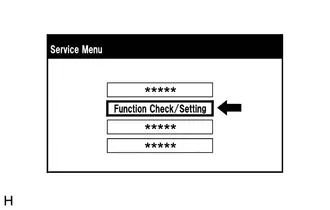

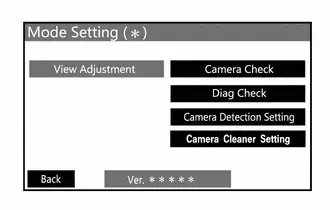

(2) Select "Function Check/Setting" from the "Service Menu" screen.

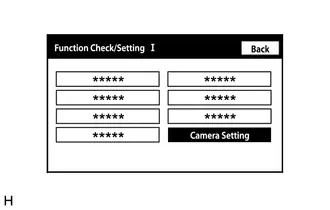

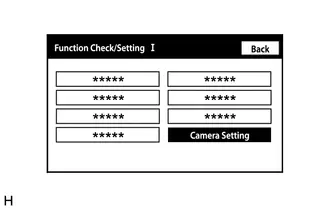

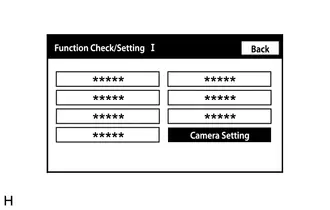

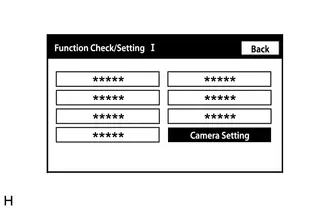

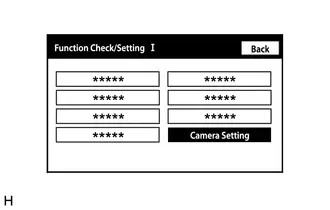

(3) Select "Camera Setting" on the "Function Check/Setting I" screen.

NOTICE:

If the "Camera Setting" selection screen is not displayed, turn the ignition switch off and enter the diagnosis screen after turning the ignition switch to ON once again.

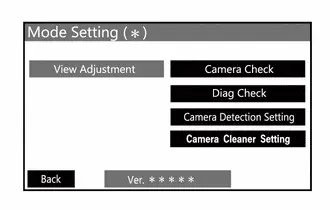

(4) Select "View Adjustment" on the "Mode Setting (*)" screen to display the adjustment screen.

HINT:

To select a grayed out item, select and hold the item for 2 seconds or more.

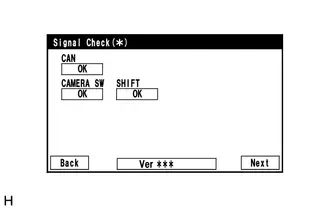

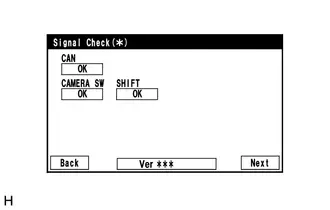

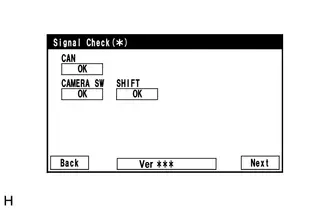

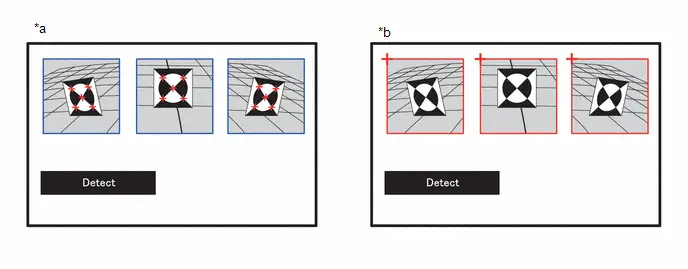

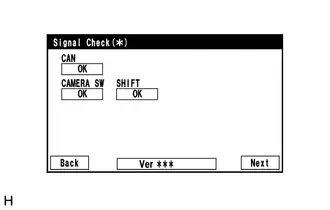

(5) After checking the screen, press the "Next" button on the "Signal Check (*)" screen.

HINT:

- When "CHK" (red) is displayed, perform the inspections.

- If performing the adjustment after proceeding to the next screen, confirm that all items display "OK" (blue) before selecting "Next".

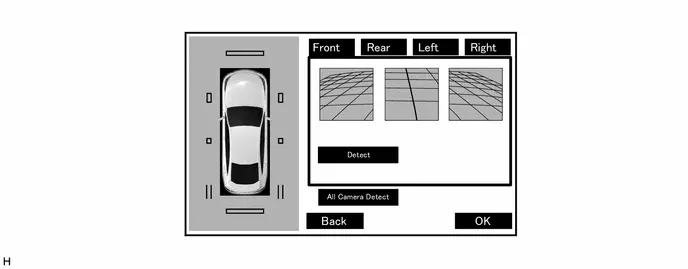

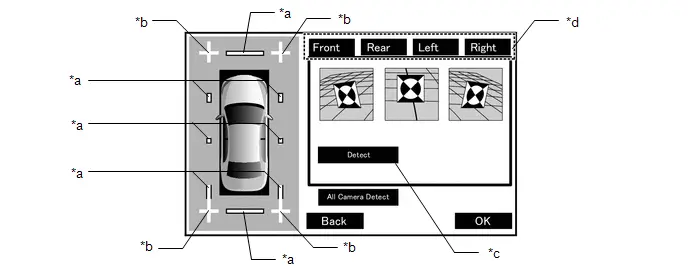

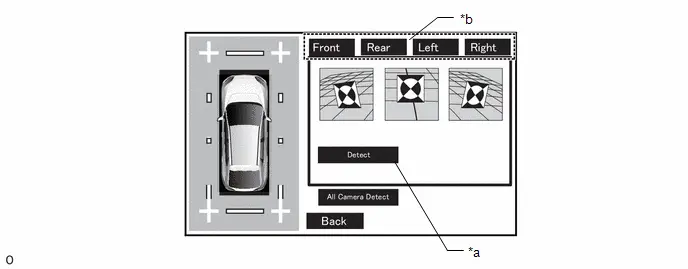

(6) When the adjustment screen is displayed, perform a simple inspection of related systems.

NOTICE:

Do not push "Detect" or "All Camera Detect" on the adjustment screen as this will cause the adjustment procedure to be performed again.

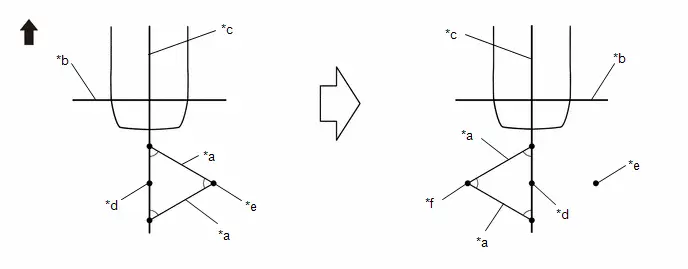

(c) Simple inspection after removal and installation of the front television camera assembly, radiator grille assembly, or front bumper.

NOTICE:

If a camera assembly has been replaced, it is not possible to perform the simple inspection.

HINT:

It is possible to inspect either the side television camera assembly RH or side television camera assembly LH.

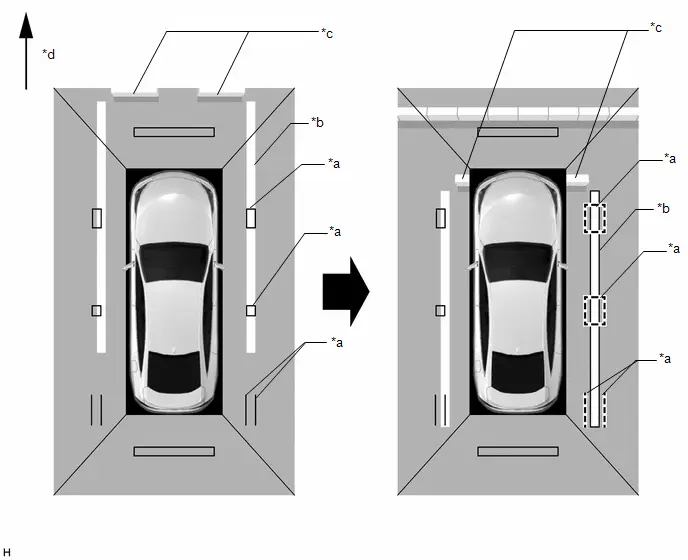

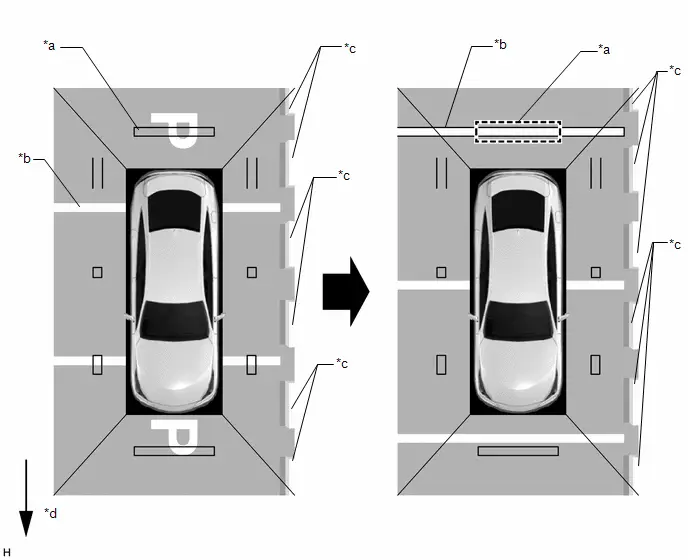

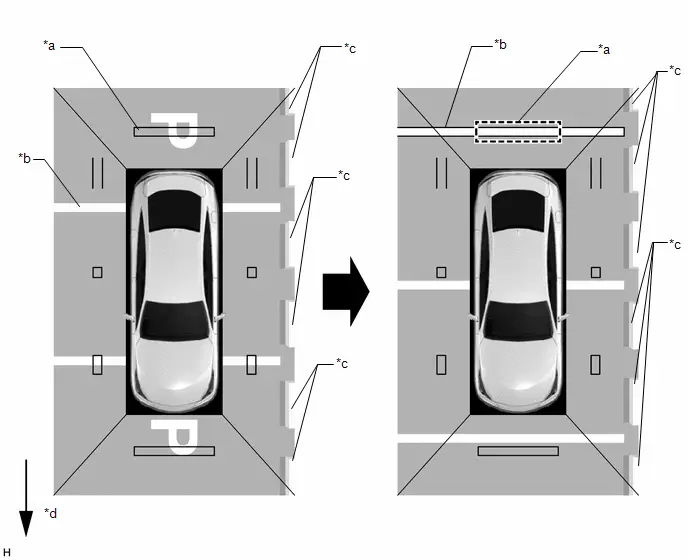

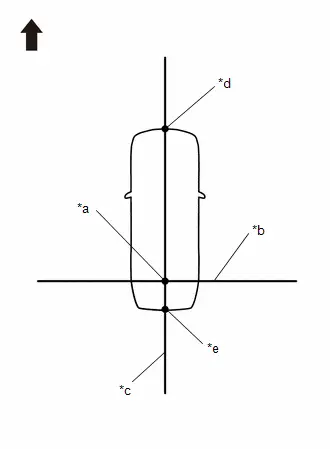

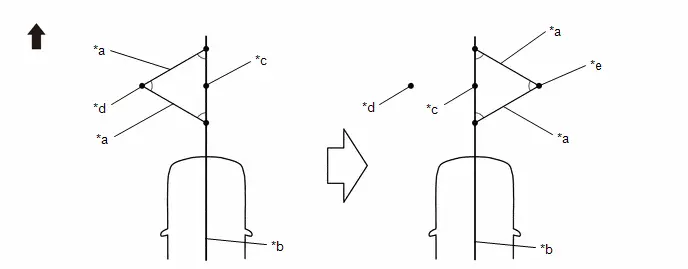

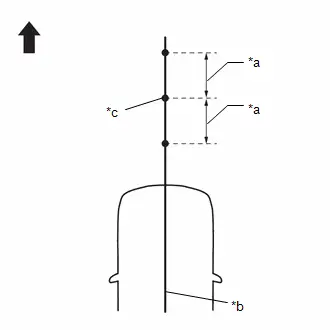

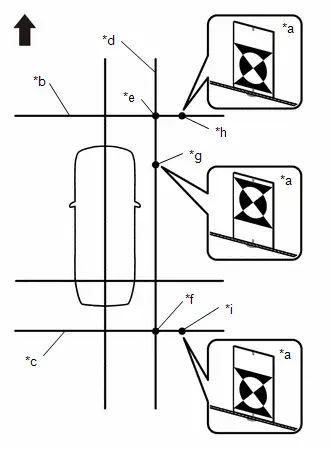

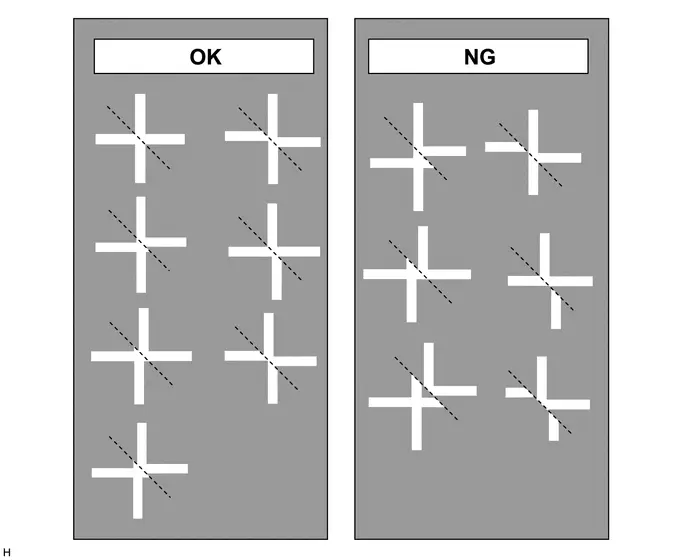

(1) As shown in the illustration, move the Toyota Prius vehicle forward and longitudinally align all the red frames on the image of the side television camera assembly RH or side television camera assembly LH with the white line (parking space).

Inspection using image of side television camera assembly RH

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

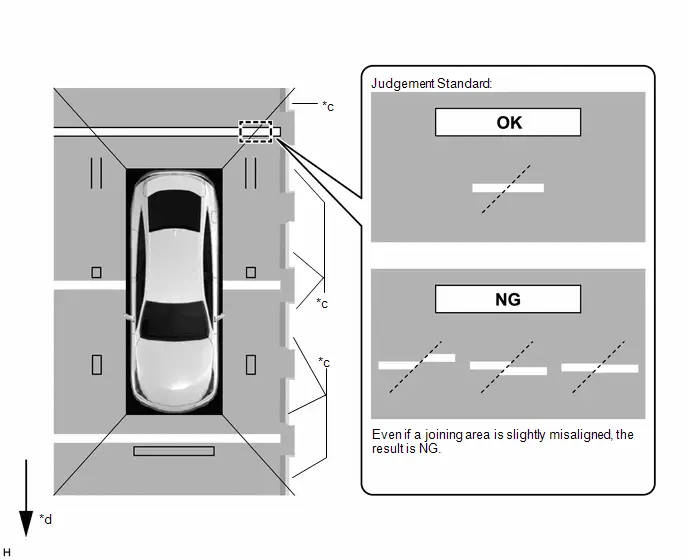

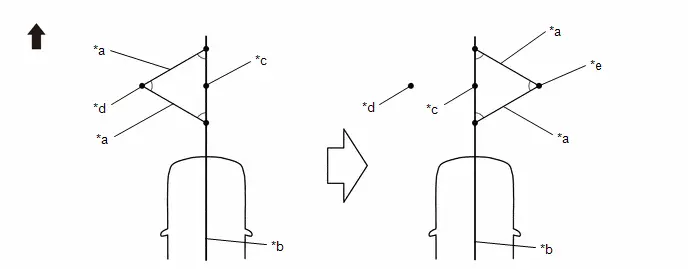

(2) While aligning the two red frames (adjustment screen) with the white line (parking space), move the vehicle rearward and check the white line (parking space) at the joining area (inside the frame) of the front television camera assembly image and side television camera assembly RH image or side television camera assembly LH image.

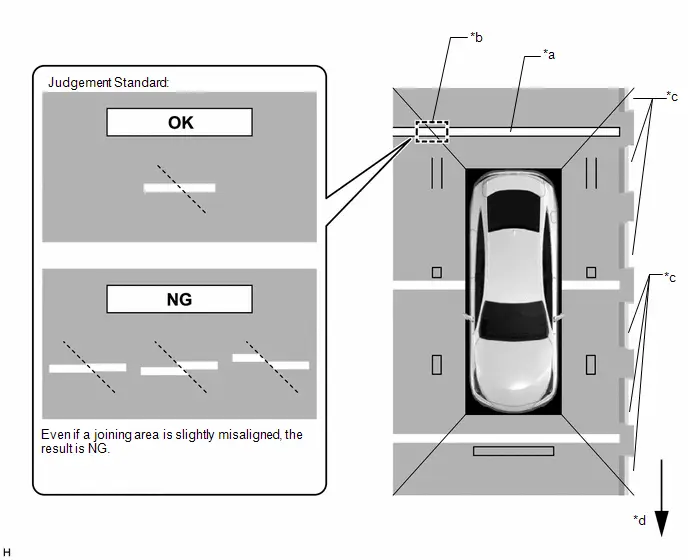

If the line is aligned straight as shown in the illustration, the result is OK. Otherwise, perform camera adjustment.

Inspection using image of side television camera assembly RH

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Joining Area (Inside the frame) | *d | Parking Stop |

| *e | Front of Toyota Prius Vehicle | - | - |

(d) Simple inspection after removal and installation of the side television camera assembly RH, parking assist light RH, or outer rear view mirror assembly RH.

NOTICE:

If a camera assembly has been replaced, it is not possible to perform the simple inspection.

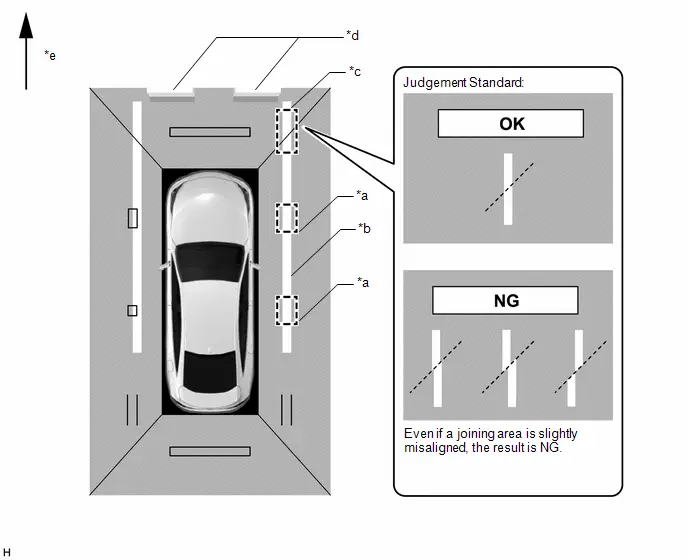

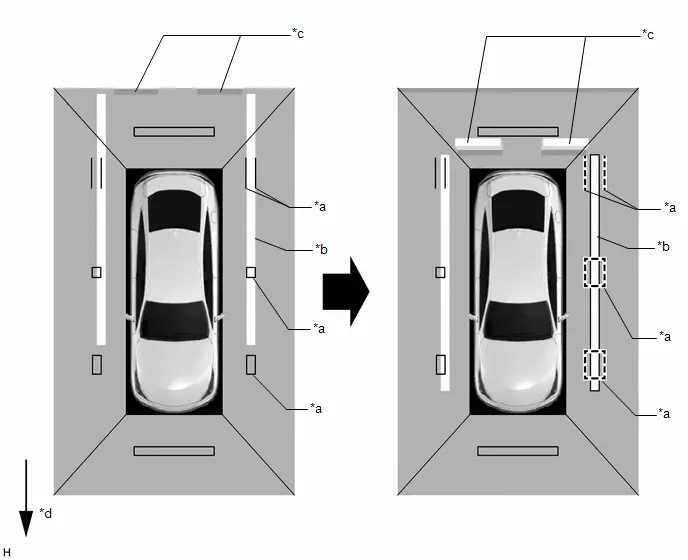

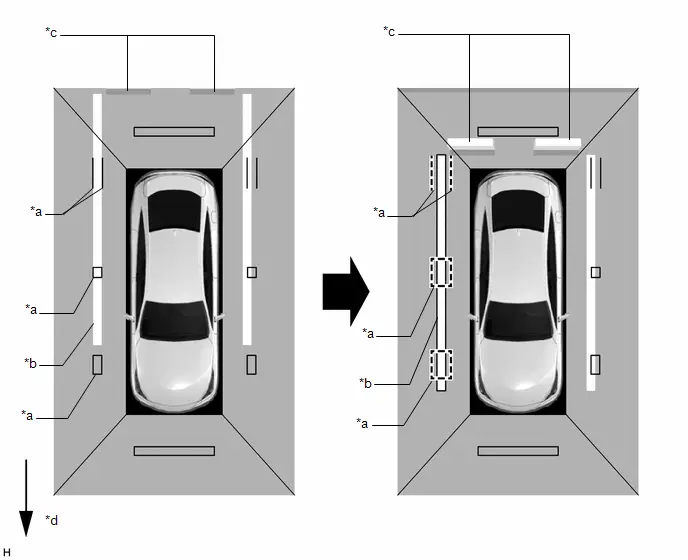

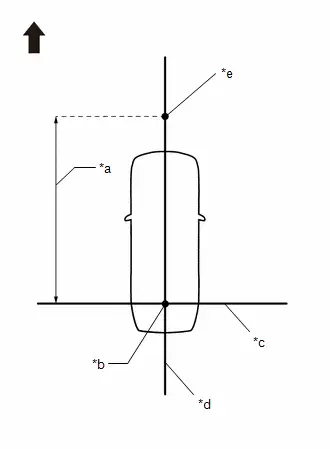

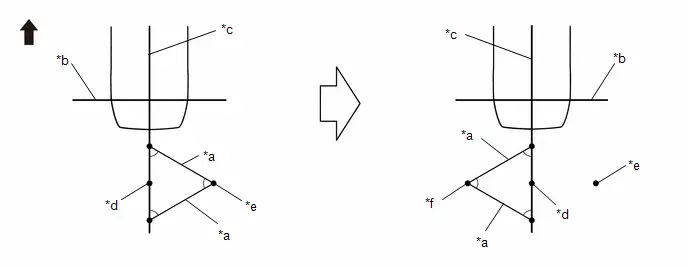

(1) As shown in the illustration, move the Toyota Prius vehicle rearward and align all the red frames (adjustment screen) on the image of the side television camera assembly RH with the white line (parking space).

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

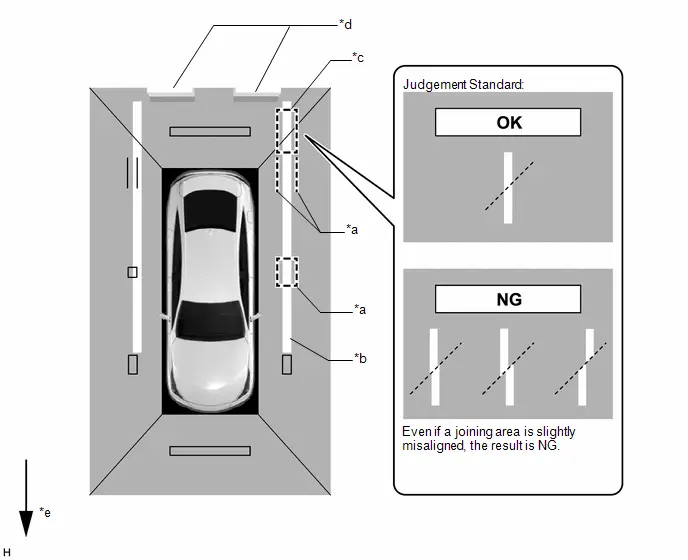

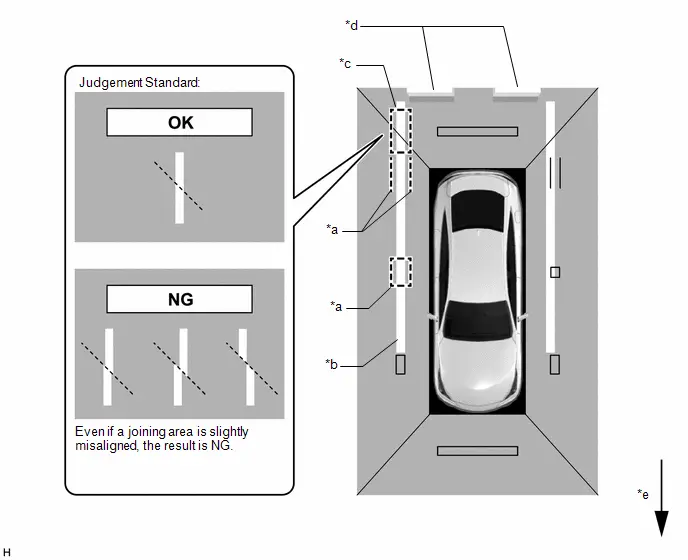

(2) While aligning the two red frames (adjustment screen) with the white line (parking space), move the vehicle forward and check the white line at the joining area (inside the frame) of the rear television camera assembly image and side television camera assembly RH image.

If the line is aligned straight as shown in the illustration, the result is OK. Otherwise, perform camera adjustment.

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Joining Area (Inside the frame) | *d | Parking Stop |

| *e | Front of Toyota Prius Vehicle | - | - |

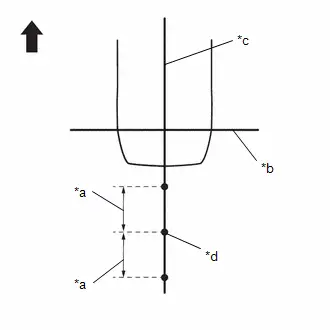

(3) As shown in the illustration, move the vehicle so that it is 90 degrees to the white lines (parking space) and align the red frame (adjustment screen) on the image of the rear television camera assembly with the white line (parking space).

Inspection when moving forward and aligning the red frame (adjustment screen) with the white line (parking space)

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

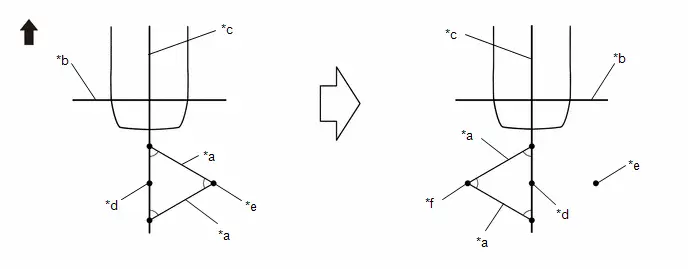

(4) Check the white line (parking space) at the joining area (inside the frame) of the rear television camera assembly image and side television camera assembly RH image.

If the line is aligned straight as shown in the illustration, the result is OK. Otherwise, perform camera adjustment.

| *a | White Line (Parking Space) | *b | Joining Area (Inside the frame) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

(e) Simple inspection after removal and installation of the side television camera assembly LH, parking assist light LH, or outer rear view mirror assembly LH.

NOTICE:

If a camera assembly has been replaced, it is not possible to perform the simple inspection.

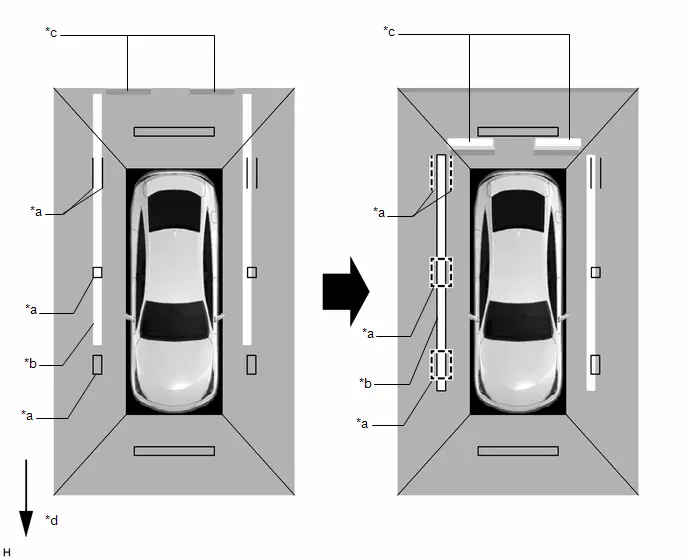

(1) As shown in the illustration, move the Toyota Prius vehicle rearward and align all the red frames (adjustment screen) on the image of the side television camera assembly LH with the white line (parking space).

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

(2) While aligning the two red frames (adjustment screen) with the white line (parking space), move the vehicle forward and check the white line at the joining area (inside the frame) of the rear television camera assembly image and side television camera assembly LH image.

If the line is aligned straight as shown in the illustration, the result is OK. Otherwise, perform camera adjustment.

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Joining Area (Inside the frame) | *d | Parking Stop |

| *e | Front of Toyota Prius Vehicle | - | - |

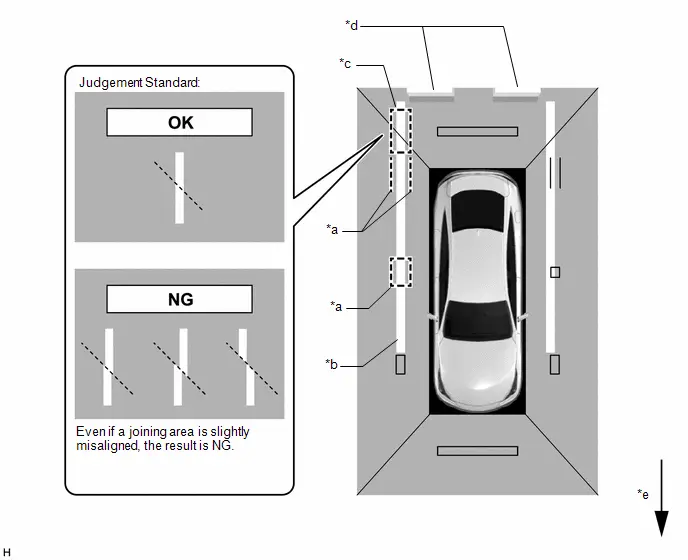

(3) As shown in the illustration, move the vehicle so that it is 90 degrees to the white lines (parking space) and align the red frame (adjustment screen) on the image of the rear television camera assembly with the white line (parking space).

Inspection when moving forward and aligning the red frame (adjustment screen) with the white line (parking space)

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

(4) Check the white line (parking space) at the joining area (inside the frame) of the rear television camera assembly image and side television camera assembly LH image.

If the line is aligned straight as shown in the illustration, the result is OK. Otherwise, perform camera adjustment.

| *a | White Line (Parking Space) | *b | Joining Area (Inside the frame) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

(f) Simple inspection after removal and installation of the rear television camera assembly.

NOTICE:

If a camera assembly has been replaced, it is not possible to perform the simple inspection.

(1) As shown in the illustration, move the vehicle rearward and align all the red frames (adjustment screen) on the image of the side television camera assembly RH with the white line (parking space).

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Parking Stop | *d | Front of Toyota Prius Vehicle |

(2) While aligning the two red frames (adjustment screen) with the white line (parking space), move the vehicle forward and check the white line at the joining area (inside the frame) of the rear television camera assembly image and side television camera assembly RH image.

If the line is aligned straight as shown in the illustration, the result is OK. Otherwise, perform camera adjustment.

| *a | Red Frame (Adjustment Screen) | *b | White Line (Parking Space) |

| *c | Joining Area (Inside the frame) | *d | Parking Stop |

| *e | Front of Toyota Prius Vehicle | - | - |

PROCEDURE 2: PRE-WORK CHECKS

(a) Preliminary checks

NOTICE:

- Provide shadow to prevent backlight from hitting the camera.

- Use string that does not stretch.

- Apply pieces of adhesive tape to serve as check markers. When placing the markers, make them 100 mm (3.94 in.) wide.

- SST may also be used for the recognition markers and the positioning and check markers used in optical axis adjustment.

(1) Perform the work in a wide, level location (L direction approximately 6.5 m x W direction approximately 3.5 m).

- Forward/rearward of the Toyota Prius vehicle: Approximately 1.3 m each end

- Left/right of the vehicle: Approximately 1.2 m each side

(2) Park the vehicle on a flat surface with the steering wheel centered.

NOTICE:

Before stopping the vehicle, move the vehicle backward and forward to ensure that both the steering wheel and the tires point straight ahead.

(3) Adjust the tire pressure to the specified value(s).

(4) Remove all luggage from the Toyota Prius vehicle and place the markers before starting work.

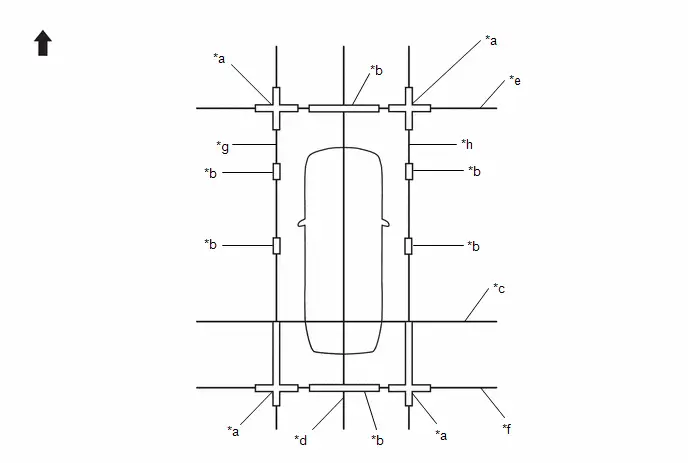

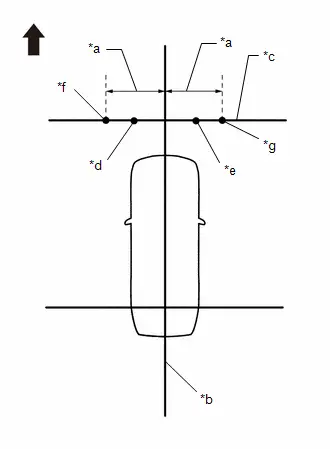

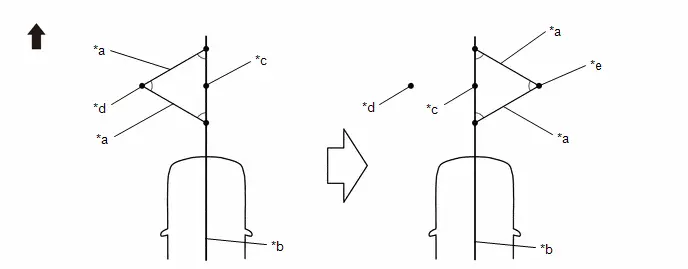

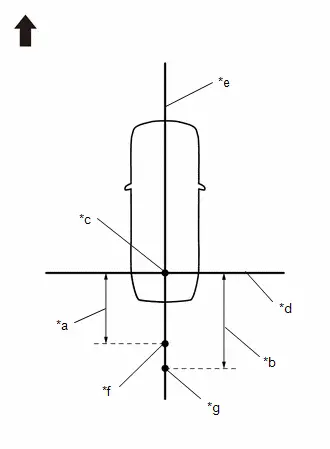

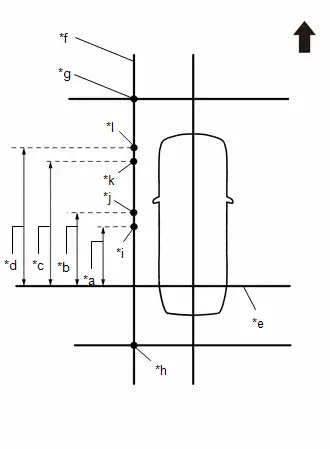

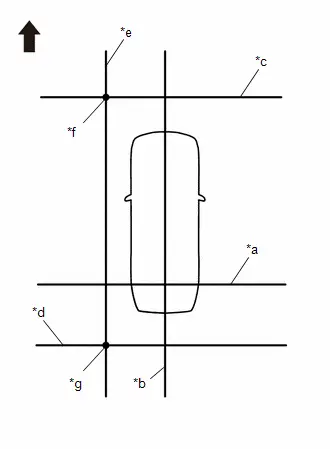

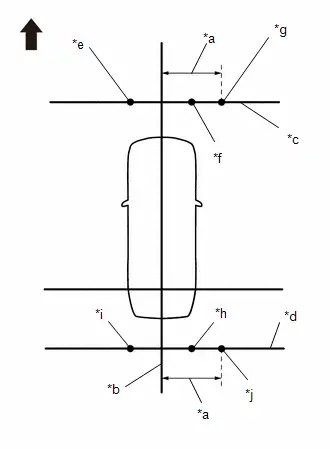

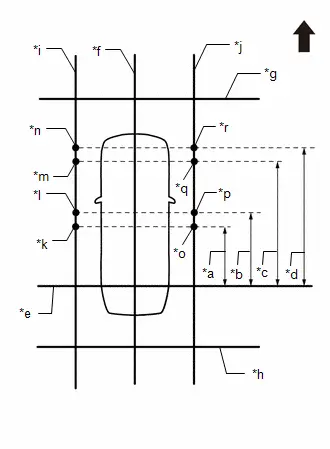

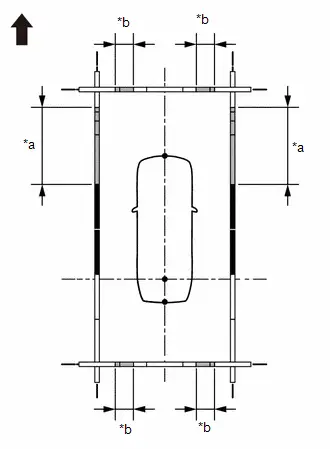

(b) Marker locations (check marker)

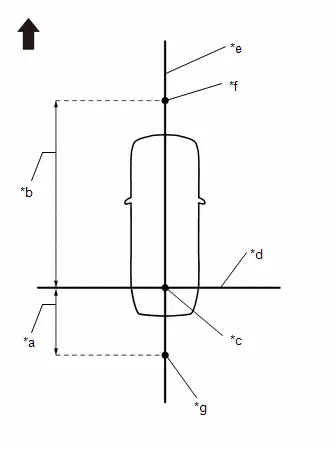

(1) Secure the string to the locations required to make the checks and set markers as shown in the illustration.

-

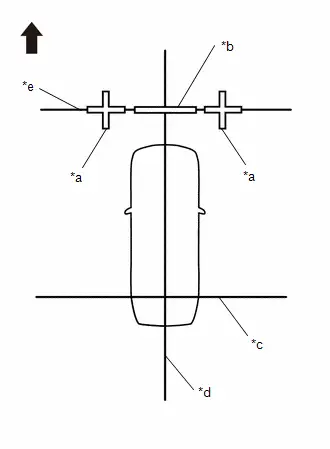

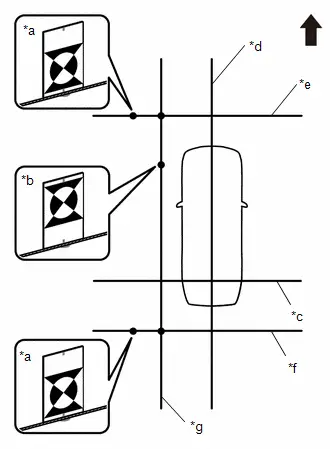

Front camera adjustment only

*a

Cross Check Marker

*b

Check Marker

*c

String 1

*d

String 2

*e

String 3

Front of Toyota Prius Vehicle

-

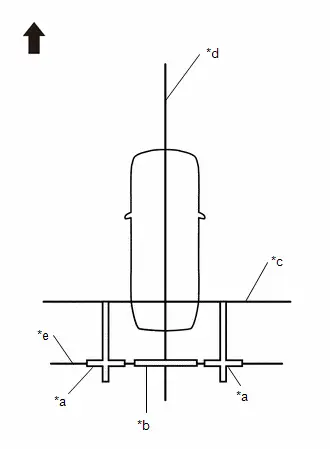

Rear camera adjustment only

*a

Cross Check Marker

*b

Check Marker

*c

String 1

*d

String 2

*e

String 4

Front of Toyota Prius Vehicle

-

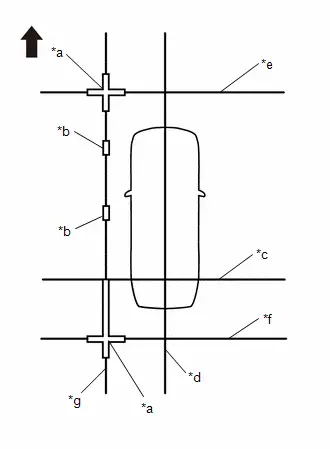

Left camera adjustment only

*a

Cross Check Marker

*b

Check Marker

*c

String 1

*d

String 2

*e

String 3

*f

String 4

*g

String 5

Front of Toyota Prius Vehicle

-

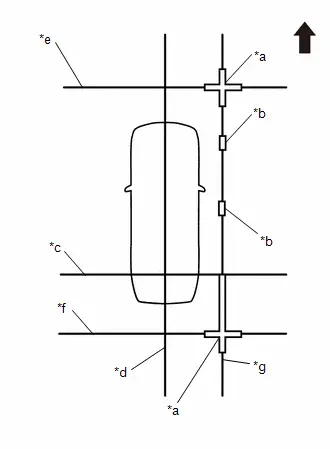

Right camera adjustment only

*a

Cross Check Marker

*b

Check Marker

*c

String 1

*d

String 2

*e

String 3

*f

String 4

*g

String 6

Front of Toyota Prius Vehicle

-

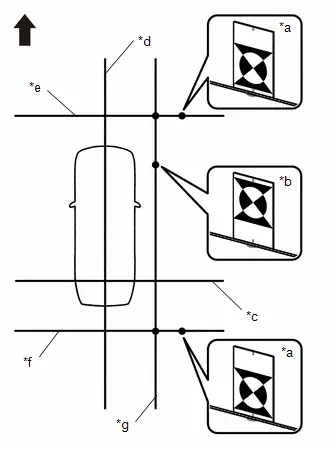

Adjustment of 4 cameras

*a

Cross Check Marker

*b

Check Marker

*c

String 1

*d

String 2

*e

String 3

*f

String 4

*g

String 5

*h

String 6

Front of Toyota Prius Vehicle

-

-

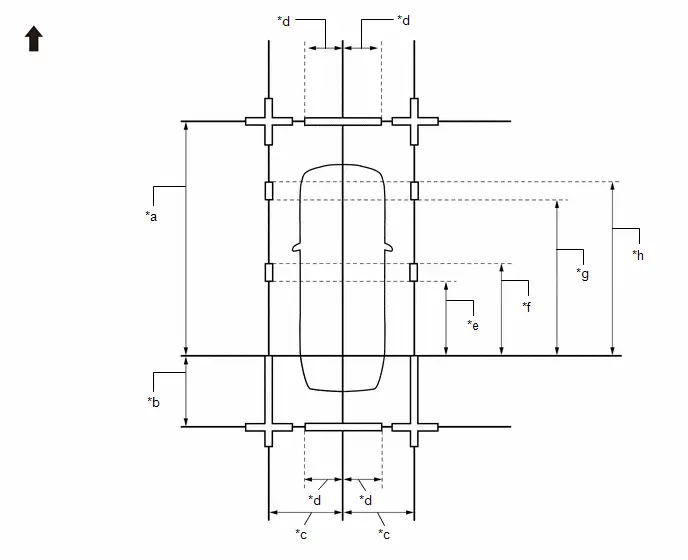

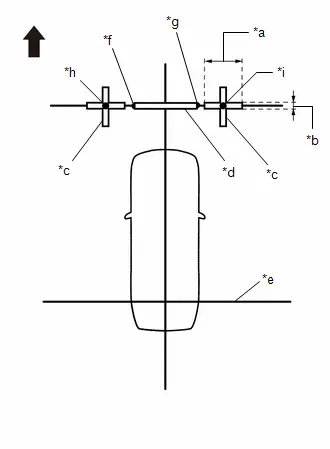

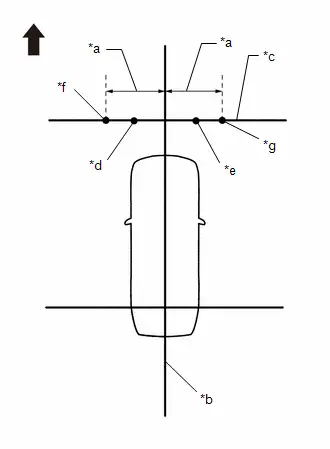

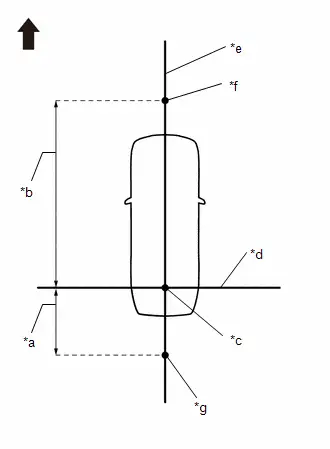

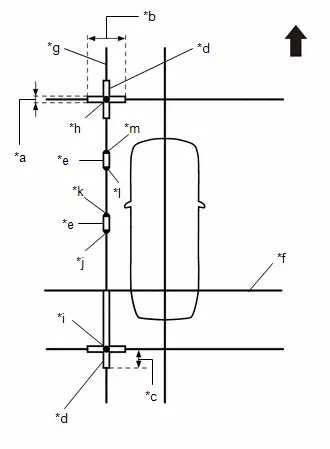

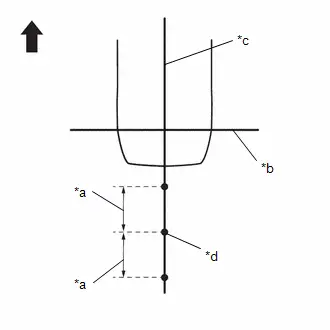

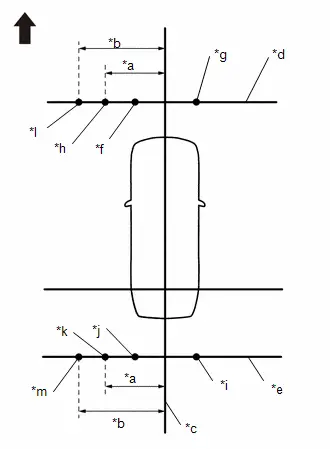

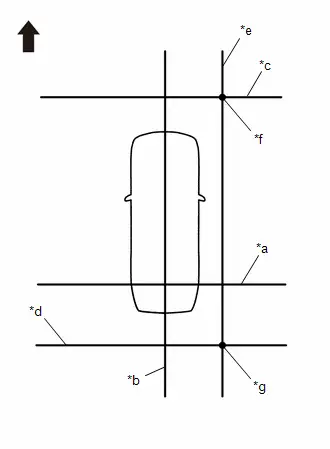

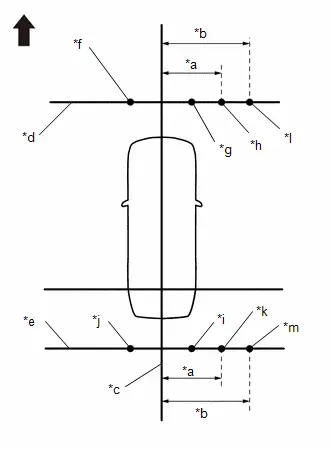

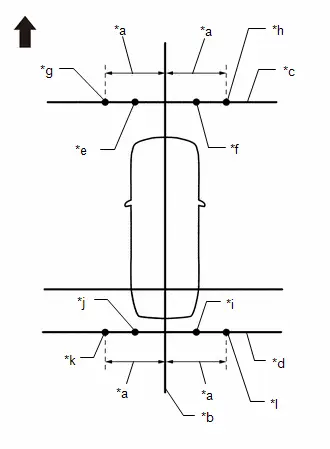

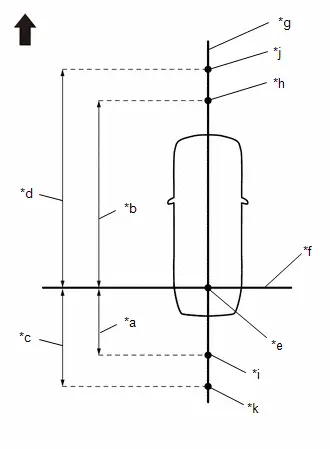

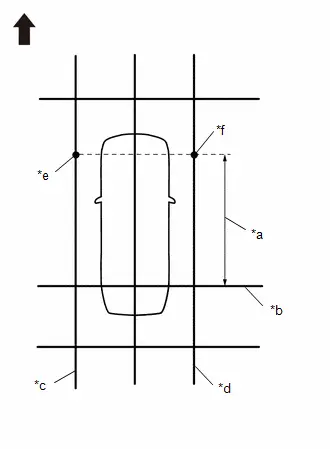

(c) Marker positions

(1) Set the check markers at the positions shown in the illustration.

| *a | 4600 mm (15.09 ft.) | *b | 1000 mm (3.28 ft.) |

| *c | 1200 mm (3.94 ft.) | *d | 693 mm (2.27 ft.) |

| *e | 1400 mm (4.59 ft.) | *f | 1600 mm (5.25 ft.) |

| *g | 3000 mm (9.84 ft.) | *h | 3200 mm (10.50 ft.) |

| Front of Toyota Prius Vehicle | - | - |

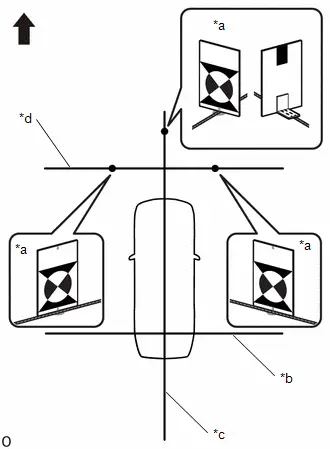

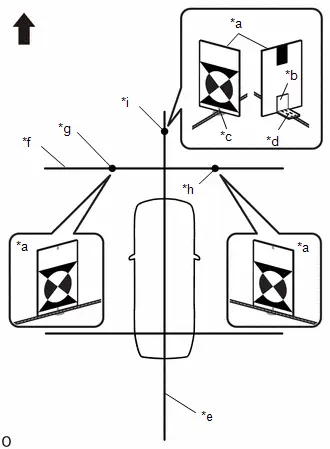

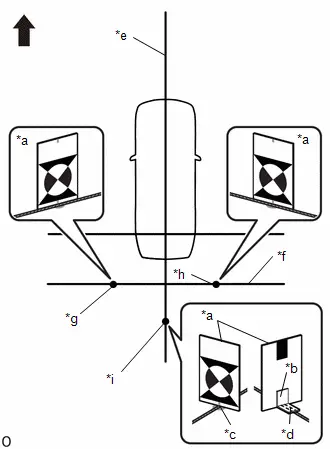

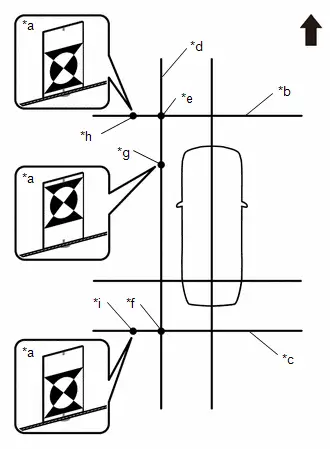

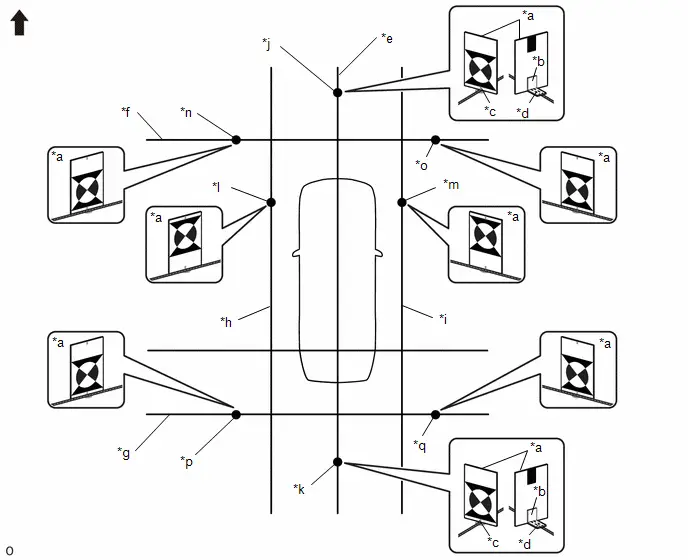

(d) Marker locations (SST)

SST: 09870-52010

SST: 09870-52020

(1) Secure the strings to the location required to make the checks and set SST as shown in the illustration.

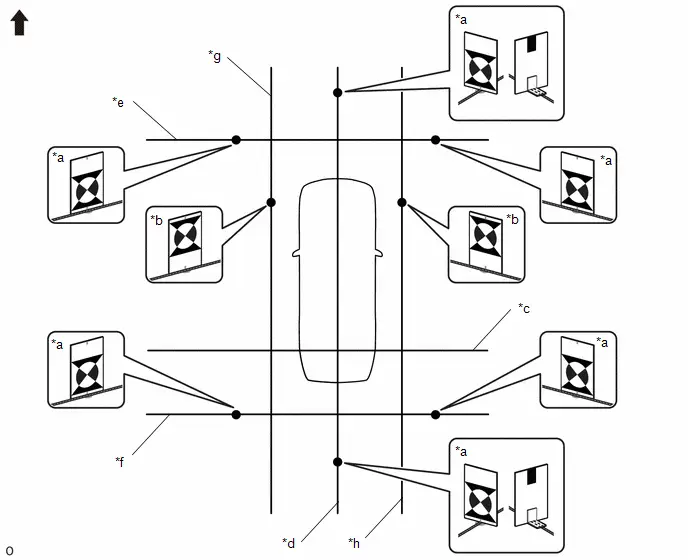

-

Front camera adjustment only

NOTICE:

Set SST (television camera adjustmenttarget) with its marker surface facingtoward the Toyota Prius vehicle.

*a

SST (Except Side Setting)

*b

String 1

*c

String 2

*d

String 3

Front of Toyota Prius Vehicle

-

Rear camera adjustment only

NOTICE:

Set SST (television camera adjustmenttarget) with its marker surface facingtoward the vehicle.

*a

SST (Except Side Setting)

*b

String 1

*c

String 2

*d

String 4

Front of Toyota Prius Vehicle

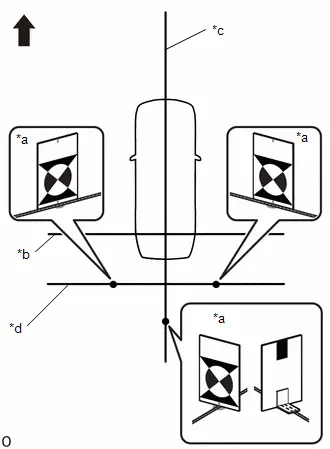

-

Left camera adjustment only

NOTICE:

- Set SST (television camera adjustment target) with its marker surface facing toward the vehicle.

- The vertical direction of SST (television camera adjustment target) differs depending on whether side setting or front, rear and corner setting is used.

*a

SST (Except Side Setting)

*b

SST (Side Setting)

*c

String 1

*d

String 2

*e

String 3

*f

String 4

*g

String 5

Front of Toyota Prius Vehicle

-

Right camera adjustment only

*a

SST (Except Side Setting)

*b

SST (Side Setting)

*c

String 1

*d

String 2

*e

String 3

*f

String 4

*g

String 6

Front of Toyota Prius Vehicle

NOTICE:

- Set SST (television camera adjustment target) with its marker surface facing toward the vehicle.

- The vertical direction of SST (television camera adjustment target) differs depending on whether side setting or front, rear and corner setting is used.

-

Adjustment of 4 cameras

NOTICE:

- Set SST (television camera adjustment target) with its marker surface facing toward the Toyota Prius vehicle.

- The vertical direction of SST (television camera adjustment target) differs depending on whether side setting or front, rear and corner setting is used.

*a

SST (Except Side Setting)

*b

SST (Side Setting)

*c

String 1

*d

String 2

*e

String 3

*f

String 4

*g

String 5

*h

String 6

Front of Toyota Prius Vehicle

-

-

(e) Marker positions

SST: 09870-52010

SST: 09870-52020

(1) Set SST in the positions shown in the illustration.

NOTICE:

- Set SST (television camera adjustment target) with its marker surface facing toward the Toyota Prius vehicle.

- The vertical direction of SST (television camera adjustment target) differs depending on whether side setting or front, rear and corner setting is used.

| *a | 5650 mm (18.53 ft.) | *b | 4650 mm (15.25 ft.) |

| *c | 2900 mm (9.51 ft.) | *d | 2050 mm (6.72 ft.) |

| *e | 1050 mm (3.44 ft.) | *f | 1350 mm (4.43 ft.) |

| *g | 1450 mm (4.76 ft.) | - | - |

| Front of Toyota Prius Vehicle | - | - |

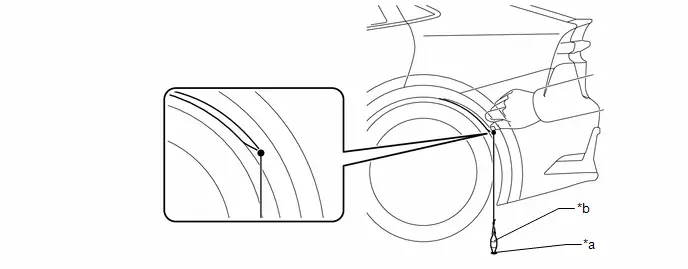

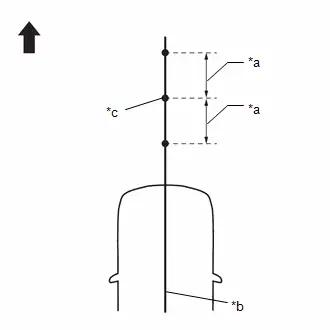

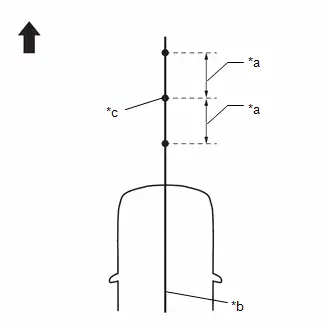

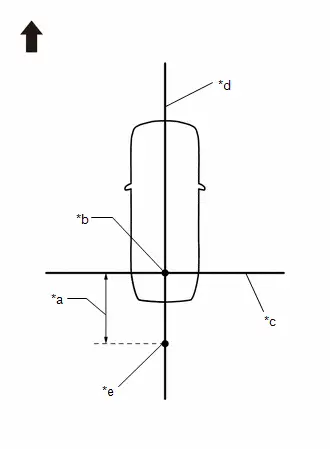

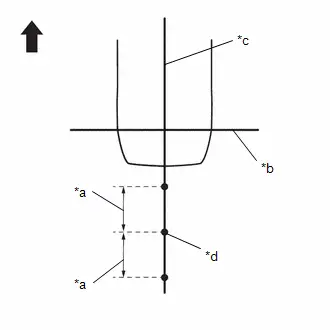

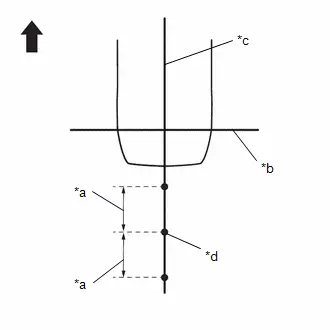

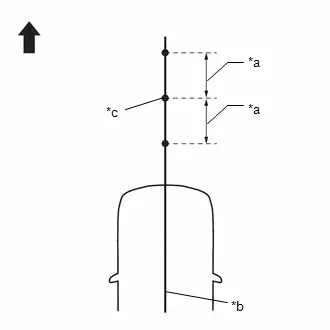

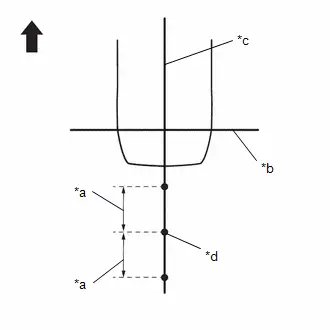

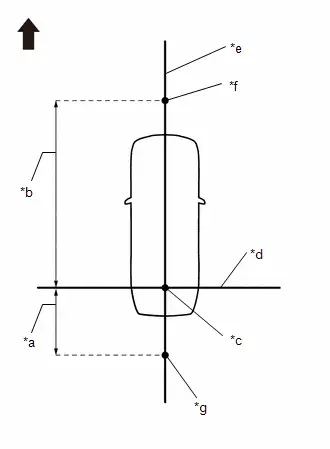

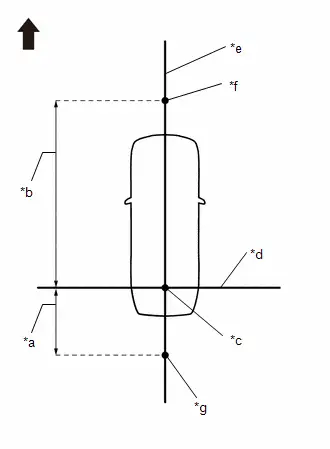

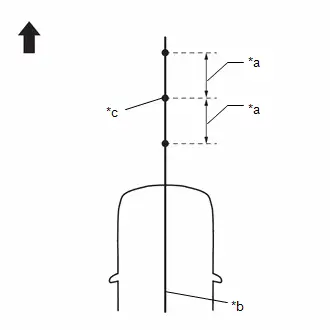

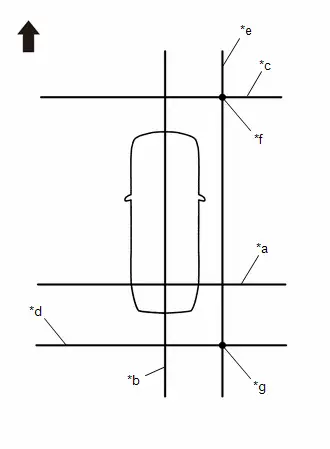

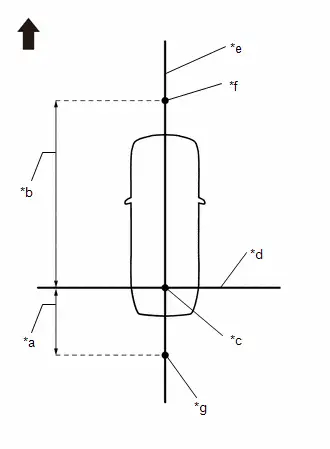

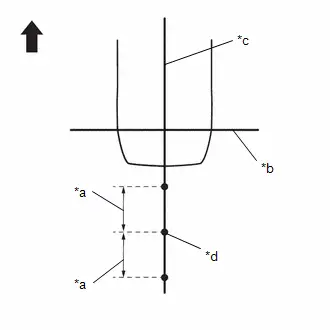

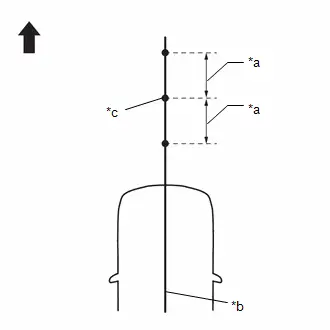

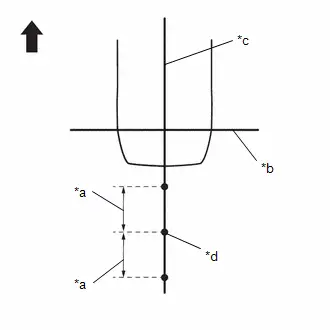

PROCEDURE 3: SET DATUM POINTS

(a) Extend the datum line (string 1).

(1) Hang a weight with a pointed tip and accurately mark the center position on the road surface. (Mark A)

NOTICE:

Make sure that the weight hangs straight down from the string.

| *a | Mark A |

| *b | Weight |

(2) Repeat the procedure to mark the right side. (Mark B)

(3) Secure string 1 so that it passes through marks A and B on the left and right sides.

| *a | String 1 |

| *b | Mark A |

| *c | Mark B |

| Front of Toyota Prius Vehicle |

NOTICE:

- When securing the string, check that there is no slack and the string is not twisted.

- Extend the line for approximately 0.4 m or more from the left/right side of the vehicle. (w/ Advanced Park or w/ Parking Support Brake System (Rear Pedestrians) Function)

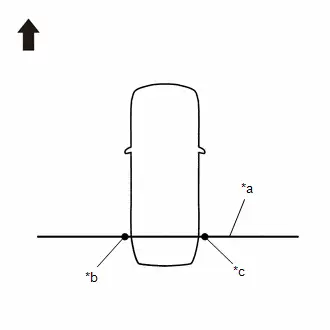

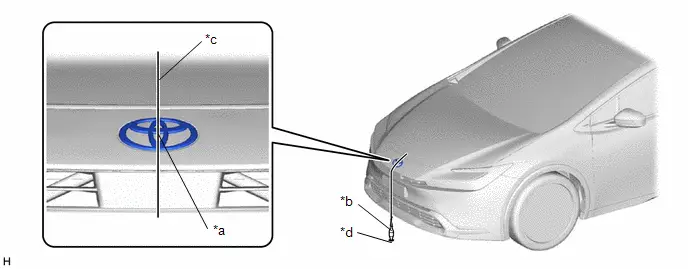

(b) Extend the Toyota Prius vehicle center line (string 2).

(1) Hang a weight with a pointed tip such that is passes through the center of the front emblem and accurately mark the center position on the road surface. (Mark C)

| *a | Center | *b | Weight |

| *c | String | *d | Mark C |

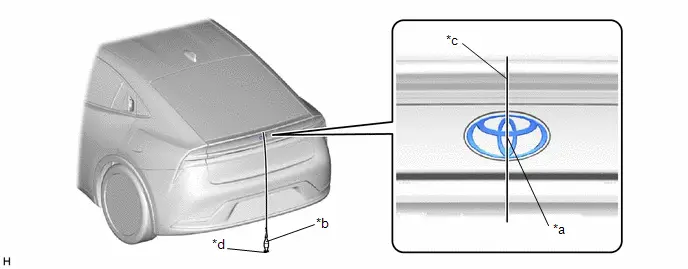

(2) Hang a weight with a pointed tip from the center of the rear emblem and accurately mark the center position on the road surface. (Mark D)

| *a | Center | *b | Weight |

| *c | String | *d | Mark D |

(3) Secure string 2 so that it passes through marks C and D at the front and rear of the Toyota Prius vehicle.

NOTICE:

When securing string, check that there is no slack and the string is not twisted.

HINT:

Set the point where strings 1 and 2 intersect as the datum point.

| *a | Datum Point |

| *b | String 1 |

| *c | String 2 |

| *d | Mark C |

| *e | Mark D |

| Front of Toyota Prius Vehicle |

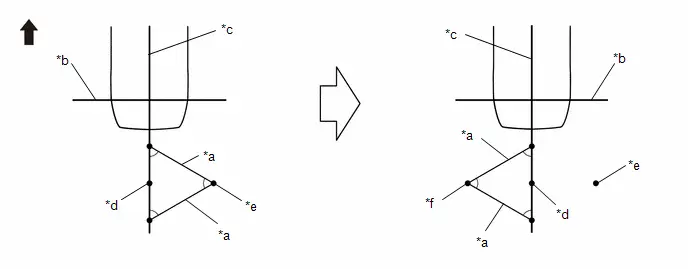

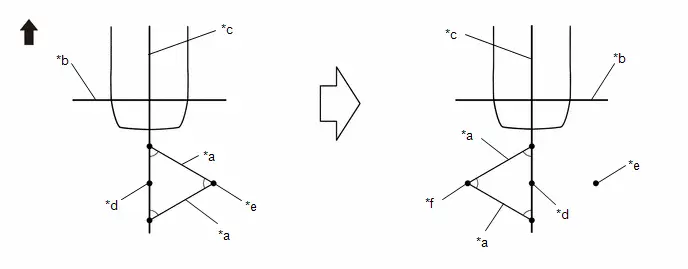

PROCEDURE 4: SET MARKERS (FRONT ADJUSTMENT)

| *a | 4600 mm (15.09 ft.) |

| *b | Datum Point |

| *c | String 1 |

| *d | String 2 |

| *e | Mark E |

| Front of Toyota Prius Vehicle |

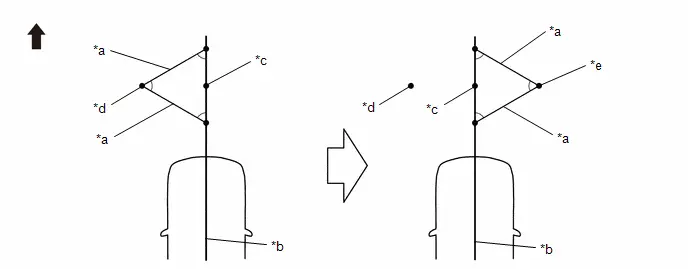

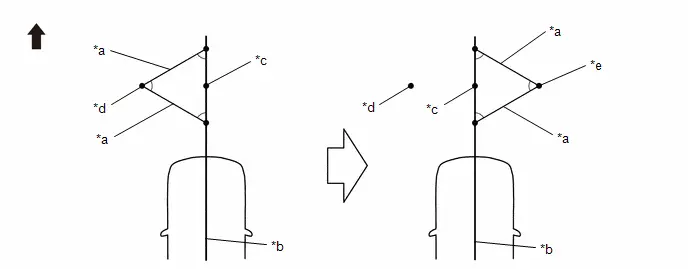

(a) In front of the vehicle, extend string (3) perpendicular to the vehicle center line (string (2)), and place a marker.

(1) Mark the position on string 2 in front of the vehicle, 4600 mm (15.09 ft.) from the datum point. (Mark E)

(2) Fix the ends of 2 strings (800 mm [2.62 ft.] long) at 2 positions 400 mm (1.31 ft.) from mark E as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 2 |

| *c | Mark E |

| Front of Toyota Prius Vehicle |

(3) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks F and G)

| *a | 800 mm (2.62 ft.) String | *b | String 2 |

| *c | Mark E | *d | Mark F |

| *e | Mark G | - | - |

| Front of Toyota Prius Vehicle | - | - |

(4) Secure string (3) so that it passes through marks F and G as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | 1200 mm (3.94 ft.) |

| *b | String 2 |

| *c | String 3 |

| *d | Mark F |

| *e | Mark G |

| *f | Mark H |

| *g | Mark I |

| Front of Toyota Prius Vehicle |

(5) Mark positions on string (3), 1200 mm (3.94 ft.) to the left and right of the vehicle center line (string 2). (Marks H and I).

(6) Place and secure the cross check markers, centered on marks H and I.

| *a | 800 mm (2.62 ft.) |

| *b | 100 mm (0.33 ft.) |

| *c | Cross Check Marker |

| *d | Check Marker |

| *e | String 1 |

| *f | Mark F |

| *g | Mark G |

| *h | Mark H |

| *i | Mark I |

| Front of Toyota Prius Vehicle |

NOTICE:

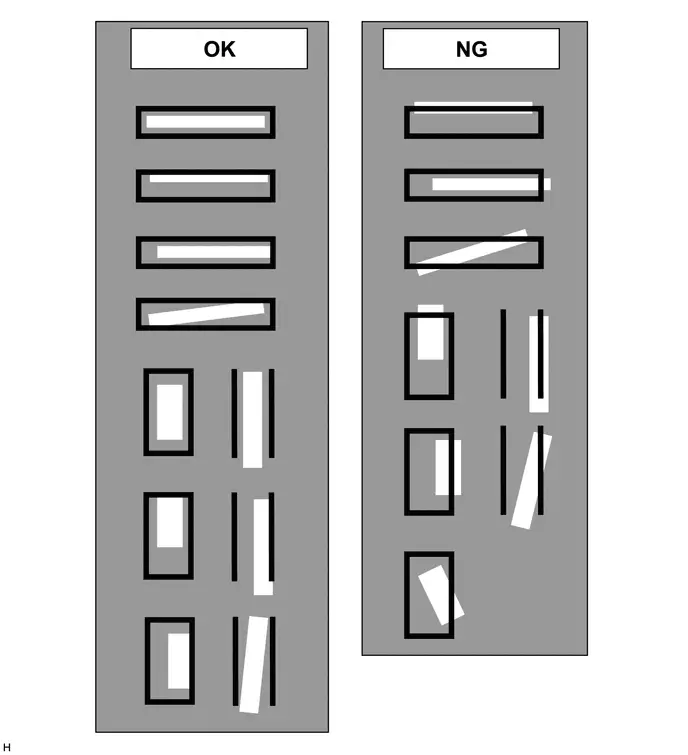

- Align the cross check markers perpendicular to the string.

- Make each arm of the cross check markers 800 mm (2.62 ft.) long and 100 mm (0.33 ft.) wide.

(7) Place the check marker between marks F and G.

(8) Perform the set SST (front adjustment) (procedure 5).

PROCEDURE 5: SET SST (FRONT ADJUSTMENT)

| *a | 4650 mm (15.25 ft.) |

| *b | 5650 mm (18.53 ft.) |

| *c | Datum Point |

| *d | String 1 |

| *e | String 2 |

| *f | Mark E |

| *g | Mark W |

| Front of Toyota Prius Vehicle |

(a) In front of the vehicle, extend string (3) perpendicular to the vehicle center line (string (2)), and place SST.

SST: 09870-52010

SST: 09870-52020

(1) Mark the position on string (2) in front of the vehicle, 4650 mm (15.25 ft.) from the datum point. (Mark E)

(2) Mark the position on string (2) in front of the Toyota Prius vehicle, 5650 mm (18.53 ft.) from the datum point. (Mark W)

(3) Fix the ends of 2 strings (800 mm [2.62 ft.] long) at 2 positions 400 mm (1.31 ft.) from mark E as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 2 |

| *c | Mark E |

| Front of Toyota Prius Vehicle |

(4) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks F and G)

| *a | 800 mm (2.62 ft.) String | *b | String 2 |

| *c | Mark E | *d | Mark F |

| *e | Mark G | - | - |

| Front of Toyota Prius Vehicle | - | - |

(5) Secure string (3) so that it passes through marks F and G as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | 1450 mm (4.76 ft.) |

| *b | String 2 |

| *c | String 3 |

| *d | Mark F |

| *e | Mark G |

| *f | Mark AA |

| *g | Mark AB |

| Front of Toyota Prius Vehicle |

(6) Mark positions on string (3), 1450 mm (4.76 ft.) to the left and right of the vehicle center line (string (2)). (Marks AA and AB).

(7) While the center line of SST (television camera adjustment target) is aligned with mark W, place string (2) so that it overlaps the center line of SST (L type stand) as shown in the illustration.

| *a | SST (Television Camera Adjustment Target) |

| *b | SST (L Type Stand) |

| *c | SST (Television Camera Adjustment Target) Center Line |

| *d | SST (L Type Stand) Center Line |

| *e | String 2 |

| *f | String 3 |

| *g | Mark AA |

| *h | Mark AB |

| *i | Mark W |

| Front of Toyota Prius Vehicle |

(8) Align the center line of SST (television camera adjustment target) with marks AA and AB and place it parallel with string (3) as shown in the illustration.

(9) Perform the screen adjustment procedure (procedure 15).

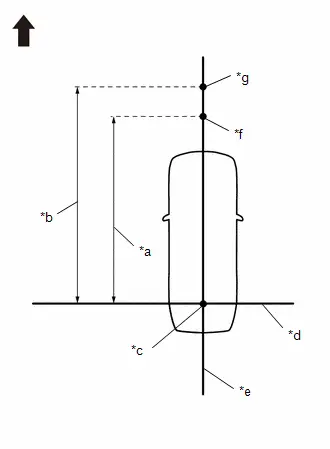

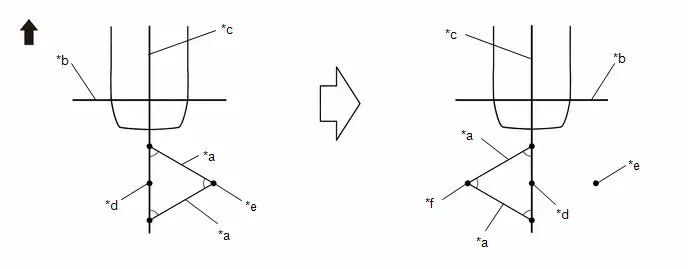

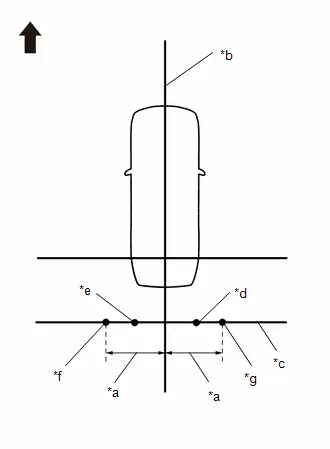

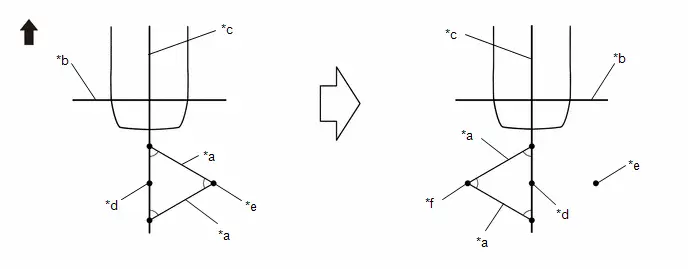

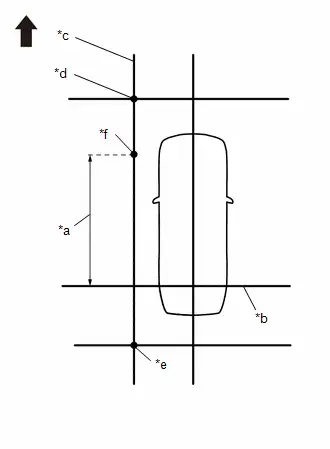

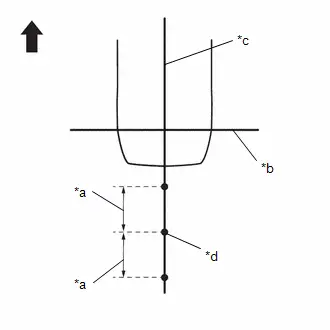

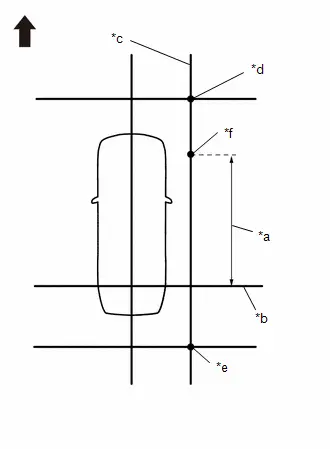

PROCEDURE 6: SET MARKERS (REAR ADJUSTMENT)

(a) To the rear of the Toyota Prius vehicle, extend string (4) perpendicular to the vehicle center line (string (2)), and place a check marker.

(1) Mark a position on string 2 to the rear of the vehicle, 1000 mm (3.28 ft.) from the datum point. (Mark J)

| *a | 1000 mm (3.28 ft.) |

| *b | Datum Point |

| *c | String 1 |

| *d | String 2 |

| *e | Mark J |

| Front of Toyota Prius Vehicle |

(2) Fix the ends of 2 strings (800 mm [2.62 ft.]) at 2 positions 400 mm (1.31 ft.) from mark J as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 1 |

| *c | String 2 |

| *d | Mark J |

| Front of Toyota Prius Vehicle |

(3) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks K and L)

| *a | 800 mm (2.62 ft.) String | *b | String 1 |

| *c | String 2 | *d | Mark J |

| *e | Mark K | *f | Mark L |

| Front of Toyota Prius Vehicle | - | - |

(4) Secure string (4) so that it passes through marks K and L as shown in the illustration.

| *a | 1200 mm (3.94 ft.) |

| *b | String 2 |

| *c | String 4 |

| *d | Mark K |

| *e | Mark L |

| *f | Mark M |

| *g | Mark N |

| Front of Toyota Prius Vehicle |

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

(5) Mark positions on string (4), 1200 mm (3.94 ft.) to the left and right of the vehicle center line (string 2). (Marks M and N)

(6) Place and secure the cross check markers, centered on marks M and N.

| *a | 800 mm (2.62 ft.) |

| *b | 100 mm (0.33 ft.) |

| *c | 400 mm (1.31 ft.) |

| *d | Cross Check Marker |

| *e | Check Marker |

| *f | String 1 |

| *g | Mark K |

| *h | Mark L |

| *i | Mark M |

| *j | Mark N |

| Front of Toyota Prius Vehicle |

NOTICE:

- Align the cross check markers perpendicular to the string.

- Make each arm of the cross check markers 800 mm (2.62 ft.) long and 100 mm (0.33 ft.) wide.

- Extend the rear cross check markers to string 1.

(7) Place the check marker between marks K and L.

(8) Perform the set SST (rear adjustment) (procedure 7).

PROCEDURE 7: SET SST (REAR ADJUSTMENT)

(a) To the rear of the Toyota Prius vehicle, extend string (4) perpendicular to the vehicle center line (string (2)), and place SST.

SST: 09870-52010

SST: 09870-52020

(1) Mark a position on string (2) to the rear of the vehicle, 1050 mm (3.44 ft.) from the datum point. (Mark J)

| *a | 1050 mm (3.44 ft.) |

| *b | 2050 mm (6.72 ft.) |

| *c | Datum Point |

| *d | String 1 |

| *e | String 2 |

| *f | Mark J |

| *g | Mark X |

| Front of Toyota Prius Vehicle |

(2) Mark a position on string (2) to the rear of the vehicle, 2050 mm (6.72 ft.) from the datum point. (Mark X)

(3) Fix the ends of 2 strings (800 mm [2.62 ft.]) at 2 positions 400 mm (1.31 ft.) from mark J as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 1 |

| *c | String 2 |

| *d | Mark J |

| Front of Toyota Prius Vehicle |

(4) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks K and L)

| *a | 800 mm (2.62 ft.) String | *b | String 1 |

| *c | String 2 | *d | Mark J |

| *e | Mark K | *f | Mark L |

| Front of Toyota Prius Vehicle | - | - |

(5) Secure string (4) so that it passes through marks K and L as shown in the illustration.

| *a | 1450 mm (4.76 ft.) |

| *b | String 2 |

| *c | String 4 |

| *d | Mark K |

| *e | Mark L |

| *f | Mark AC |

| *g | Mark AD |

| Front of Toyota Prius Vehicle |

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

(6) Mark positions on string (4), 1450 mm (4.76 ft.) to the left and right of the vehicle center line (string (2)). (Marks AC and AD)

(7) While the center line of SST (television camera adjustment target) is aligned with mark X, place string (2) so that it overlaps the center line of SST (L type stand) as shown in the illustration.

| *a | SST (Television Camera Adjustment Target) |

| *b | SST (L Type Stand) |

| *c | SST (Television Camera Adjustment Target) Center Line |

| *d | SST (L Type Stand) Center Line |

| *e | String 2 |

| *f | String 4 |

| *g | Mark AC |

| *h | Mark AD |

| *i | Mark X |

| Front of Toyota Prius Vehicle |

(8) Align the center line of SST (television camera adjustment target) with marks AC and AD and place it parallel with string (4) as shown in the illustration

(9) Perform the screen adjustment procedure (procedure 15).

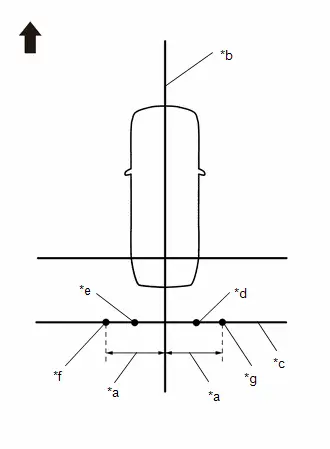

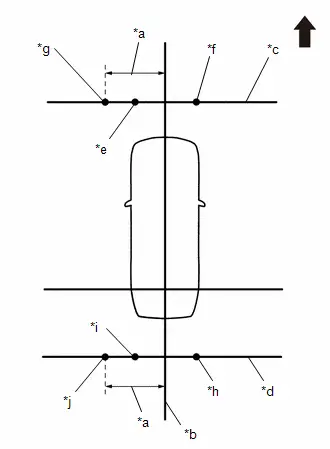

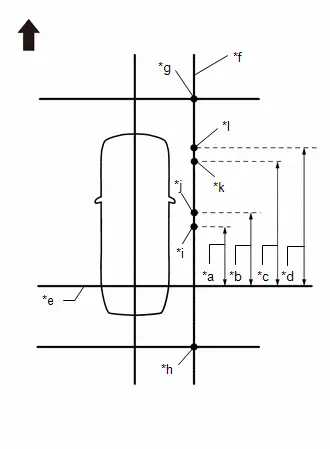

PROCEDURE 8: SET MARKERS (LEFT-SIDE ADJUSTMENT)

(a) At the left side of the Toyota Prius vehicle, extend string (5) parallel to the vehicle center line (string (2)), and place a marker

(1) Mark the position on string (2) in front of the vehicle, 4600 mm (15.09 ft.) from the datum point. (Mark E)

| *a | 1000 mm (3.28 ft.) |

| *b | 4600 mm (15.09 ft.) |

| *c | Datum Point |

| *d | String 1 |

| *e | String 2 |

| *f | Mark E |

| *g | Mark J |

| Front of Toyota Prius Vehicle |

(2) Mark the position on string (2) to the rear of the vehicle, 1000 mm (3.28 ft.) from the datum point. (Mark J)

(3) Fix the ends of 2 strings (800 mm [2.62 ft.] long) at 2 positions 400 mm (1.31 ft.) from mark E as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 2 |

| *c | Mark E |

| Front of Toyota Prius Vehicle |

(4) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks F and G)

| *a | 800 mm (2.62 ft.) String | *b | String 2 |

| *c | Mark E | *d | Mark F |

| *e | Mark G | - | - |

| Front of Toyota Prius Vehicle | - | - |

(5) Fix the ends of 2 strings (800 mm [2.62 ft.]) at 2 positions 400 mm (1.31 ft.) from mark J as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 1 |

| *c | String 2 |

| *d | Mark J |

| Front of Toyota Prius Vehicle |

(6) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks K and L)

| *a | 800 mm (2.62 ft.) String | *b | String 1 |

| *c | String 2 | *d | Mark J |

| *e | Mark K | *f | Mark L |

| Front of Toyota Prius Vehicle | - | - |

(7) Secure strings (3) and (4) so that they pass through marks F and G, marks K and L as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | 1200 mm (3.94 ft.) |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | Mark F |

| *f | Mark G |

| *g | Mark H |

| *h | Mark K |

| *i | Mark L |

| *j | Mark M |

| Front of Toyota Prius Vehicle |

(8) Mark strings (3) and (4), 1200 mm (3.94 ft.) to the left of the vehicle center line (string 2). (Marks H and M)

(9) Secure string (5) so that it passes through marks H and M as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | String 1 |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | String 5 |

| *f | Mark H |

| *g | Mark M |

| Front of Toyota Prius Vehicle |

| *a | 1400 mm (4.59 ft.) |

| *b | 1600 mm (5.25 ft.) |

| *c | 3000 mm (9.84 ft.) |

| *d | 3200 mm (10.50 ft.) |

| *e | String 1 |

| *f | String 5 |

| *g | Mark H |

| *h | Mark M |

| *i | Mark O |

| *j | Mark P |

| *k | Mark Q |

| *l | Mark R |

| Front of Toyota Prius Vehicle |

(10) Make marks on string (5) that are 1400 mm (4.59 ft.), 1600 mm (5.25 ft.), 3000 mm (9.84 ft.) and 3200 mm (10.50 ft.) from the datum line (string 1) as shown in the illustration. (Marks O, P, Q and R)

(11) Place and secure the cross check markers, centered on marks H and M.

| *a | 100 mm (0.33 ft.) |

| *b | 800 mm (2.62 ft.) |

| *c | 400 mm (1.31 ft.) |

| *d | Cross Check Marker |

| *e | Check Marker |

| *f | String 1 |

| *g | String 5 |

| *h | Mark H |

| *i | Mark M |

| *j | Mark O |

| *k | Mark P |

| *l | Mark Q |

| *m | Mark R |

| Front of Toyota Prius Vehicle |

NOTICE:

- Align the cross check markers perpendicular to the string.

- Make each arm of the cross check markers 800 mm (2.62 ft.) long and 100 mm (0.33 ft.) wide.

- Extend the rear cross check markers to string 1.

(12) Place check markers between marks O and P, and marks Q and R.

(13) Perform the set SST (left-side adjustment) (procedure 9).

PROCEDURE 9: SET SST (LEFT-SIDE ADJUSTMENT)

(a) At the left side of the Toyota Prius vehicle, extend string (5) parallel to the vehicle center line (string (2)), and place SST.

SST: 09870-52010

SST: 09870-52020

(1) Mark the position on string (2) in front of the vehicle, 4650 mm (15.25 ft.) from the datum point. (Mark E)

| *a | 1050 mm (3.44 ft.) |

| *b | 4650 mm (15.25 ft.) |

| *c | Datum Point |

| *d | String 1 |

| *e | String 2 |

| *f | Mark E |

| *g | Mark J |

| Front of Toyota Prius Vehicle |

(2) Mark the position on string (2) to the rear of the vehicle, 1050 mm (3.44 ft.) from the datum point. (Mark J)

(3) Fix the ends of 2 strings (800 mm [2.62 ft.] long) at 2 positions 400 mm (1.31 ft.) from mark E as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 2 |

| *c | Mark E |

| Front of Toyota Prius Vehicle |

(4) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks F and G)

| *a | 800 mm (2.62 ft.) String | *b | String 2 |

| *c | Mark E | *d | Mark F |

| *e | Mark G | - | - |

| Front of Toyota Prius Vehicle | - | - |

(5) Fix the ends of 2 strings (800 mm [2.62 ft.]) at 2 positions 400 mm (1.31 ft.) from mark J as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 1 |

| *c | String 2 |

| *d | Mark J |

| Front of Toyota Prius Vehicle |

(6) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks K and L)

| *a | 800 mm (2.62 ft.) String | *b | String 1 |

| *c | String 2 | *d | Mark J |

| *e | Mark K | *f | Mark L |

| Front of Toyota Prius Vehicle | - | - |

(7) Secure strings (3) and (4) so that they pass through marks F and G, marks K and L as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | 1350 mm (4.43 ft.) |

| *b | 1450 mm (4.76 ft.) |

| *c | String 2 |

| *d | String 3 |

| *e | String 4 |

| *f | Mark F |

| *g | Mark G |

| *h | Mark H |

| *i | Mark K |

| *j | Mark L |

| *k | Mark M |

| *l | Mark AA |

| *m | Mark AC |

| Front of Toyota Prius Vehicle |

(8) Mark strings (3) and (4), 1350 mm (4.43 ft.) to the left of the vehicle center line (string 2). (Marks H and M)

(9) Mark strings (3) and (4), 1450 mm (4.76 ft.) to the left of the vehicle center line (string 2). (Marks AA and AC)

(10) Secure string (5) so that it passes through marks H and M as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | String 1 |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | String 5 |

| *f | Mark H |

| *g | Mark M |

| Front of Toyota Prius Vehicle |

(11) Make a mark on string (5) that is 2900 mm (9.51 ft.) from the reference line (string (1)) as shown in the illustration. (Mark Y)

| *a | 2900 mm (9.51 ft.) |

| *b | String 1 |

| *c | String 5 |

| *d | Mark H |

| *e | Mark M |

| *f | Mark Y |

| Front of Toyota Prius Vehicle |

(12) Align the center line of SST (television camera adjustment target) with mark AA and place it parallel with string (3) as shown in the illustration.

| *a | SST (Television Camera Adjustment Target) |

| *b | String 3 |

| *c | String 4 |

| *d | String 5 |

| *e | Mark H |

| *f | Mark M |

| *g | Mark Y |

| *h | Mark AA |

| *i | Mark AC |

| Front of Toyota Prius Vehicle |

(13) Align the center line of SST (television camera adjustment target) with mark AC and place it parallel with string (4) as shown in the illustration.

(14) Align the center line of SST (television camera adjustment target) with mark Y and place it parallel with string (5) as shown in the illustration.

NOTICE:

The vertical direction of SST (television camera adjustment target) differs depending on whether corner setting or side setting is used.

(15) Perform the screen adjustment procedure (procedure 15).

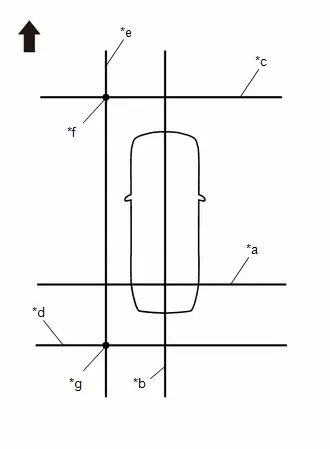

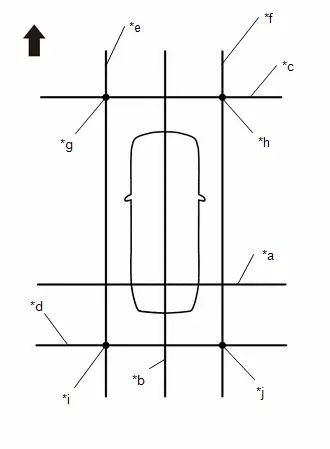

PROCEDURE 10: SET MARKERS (RIGHT-SIDE ADJUSTMENT)

(a) At the right side of the Toyota Prius vehicle, extend string (6) parallel to the vehicle center line (string (2)), and place a marker.

(1) Mark the position on string (2) in front of the vehicle, 4600 mm (15.09 ft.) from the datum point. (Mark E)

| *a | 1000 mm (3.28 ft.) |

| *b | 4600 mm (15.09 ft.) |

| *c | Datum Point |

| *d | String 1 |

| *e | String 2 |

| *f | Mark E |

| *g | Mark J |

| Front of Toyota Prius Vehicle |

(2) Mark the position on string (2) to the rear of the vehicle, 1000 mm (3.28 ft.) from the datum point. (Mark J)

(3) Fix the ends of 2 strings (800 mm [2.62 ft.] long) at 2 positions 400 mm (1.31 ft.) from mark E as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 2 |

| *c | Mark E |

| Front of Toyota Prius Vehicle |

(4) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks F and G)

| *a | 800 mm (2.62 ft.) String | *b | String 2 |

| *c | Mark E | *d | Mark F |

| *e | Mark G | - | - |

| Front of Toyota Prius Vehicle | - | - |

(5) Fix the ends of 2 strings (800 mm [2.62 ft.]) at 2 positions 400 mm (1.31 ft.) from mark J as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 1 |

| *c | String 2 |

| *d | Mark J |

| Front of Toyota Prius Vehicle |

(6) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks K and L)

| *a | 800 mm (2.62 ft.) String | *b | String 1 |

| *c | String 2 | *d | Mark J |

| *e | Mark K | *f | Mark L |

| Front of Toyota Prius Vehicle | - | - |

(7) Secure strings (3) and (4) so that they pass through marks F and G and marks K and L as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | 1200 mm (3.94 ft.) |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | Mark F |

| *f | Mark G |

| *g | Mark I |

| *h | Mark K |

| *i | Mark L |

| *j | Mark N |

| Front of Toyota Prius Vehicle |

(8) Mark strings (3) and (4), 1200 mm (3.94 ft.) to the right of the vehicle center line (string 2). (Marks I and N)

(9) Secure string (6) so that it passes through marks I and N as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | String 1 |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | String 6 |

| *f | Mark I |

| *g | Mark N |

| Front of Toyota Prius Vehicle |

(10) Make marks on string (6) that are 1400 mm (4.59 ft.), 1600 mm (5.25 ft.), 3000 mm (9.84 ft.) and 3200 mm (10.50 ft.) from the datum line (string 1) as shown in the illustration. (Marks S, T, U and V)

| *a | 1400 mm (4.59 ft.) |

| *b | 1600 mm (5.25 ft.) |

| *c | 3000 mm (9.84 ft.) |

| *d | 3200 mm (10.50 ft.) |

| *e | String 1 |

| *f | String 6 |

| *g | Mark I |

| *h | Mark N |

| *i | Mark S |

| *j | Mark T |

| *k | Mark U |

| *l | Mark V |

| Front of Toyota Prius Vehicle |

(11) Place and secure the cross check markers, centered on marks I and N.

| *a | 100 mm (0.33 ft.) |

| *b | 800 mm (2.62 ft.) |

| *c | 400 mm (1.31 ft.) |

| *d | Cross Check Marker |

| *e | Check Marker |

| *f | String 1 |

| *g | String 6 |

| *h | Mark I |

| *i | Mark N |

| *j | Mark S |

| *k | Mark T |

| *l | Mark U |

| *m | Mark V |

| Front of Toyota Prius Vehicle |

NOTICE:

- Align the cross check markers perpendicular to the string.

- Make each arm of the cross check markers 800 mm (2.62 ft.) long and 100 mm (0.33 ft.) wide.

- Extend the rear cross check markers to string 1.

(12) Place check markers between marks S and T, and marks U and V.

(13) Perform the set SST (right-side adjustment) (procedure 11).

PROCEDURE 11: SET SST (RIGHT-SIDE ADJUSTMENT)

(a) At the left side of the Toyota Prius vehicle, extend string (6) parallel to the vehicle center line (string (2)), and place SST.

SST: 09870-52010

SST: 09870-52020

(1) Mark the position on string (2) in front of the vehicle, 4650 mm (15.25 ft.) from the datum point. (Mark E)

| *a | 1050 mm (3.44 ft.) |

| *b | 4650 mm (15.25 ft.) |

| *c | Datum Point |

| *d | String 1 |

| *e | String 2 |

| *f | Mark E |

| *g | Mark J |

| Front of Toyota Prius Vehicle |

(2) Mark the position on string (2) to the rear of the vehicle, 1050 mm (3.44 ft.) from the datum point. (Mark J)

(3) Fix the ends of 2 strings (800 mm [2.62 ft.] long) at 2 positions 400 mm (1.31 ft.) from mark E as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 2 |

| *c | Mark E |

| Front of Toyota Prius Vehicle |

(4) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks F and G)

| *a | 800 mm (2.62 ft.) String | *b | String 2 |

| *c | Mark E | *d | Mark F |

| *e | Mark G | - | - |

| Front of Toyota Prius Vehicle | - | - |

(5) Fix the ends of 2 strings (800 mm [2.62 ft.]) at 2 positions 400 mm (1.31 ft.) from mark J as shown in the illustration.

| *a | 400 mm (1.31 ft.) |

| *b | String 1 |

| *c | String 2 |

| *d | Mark J |

| Front of Toyota Prius Vehicle |

(6) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks K and L)

| *a | 800 mm (2.62 ft.) String | *b | String 1 |

| *c | String 2 | *d | Mark J |

| *e | Mark K | *f | Mark L |

| Front of Toyota Prius Vehicle | - | - |

(7) Secure strings (3) and (4) so that they pass through marks F and G and marks K and L as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | 1350 mm (4.43 ft.) |

| *b | 1450 mm (4.76 ft.) |

| *c | String 2 |

| *d | String 3 |

| *e | String 4 |

| *f | Mark F |

| *g | Mark G |

| *h | Mark I |

| *i | Mark K |

| *j | Mark L |

| *k | Mark N |

| *l | Mark AB |

| *m | Mark AD |

| Front of Toyota Prius Vehicle |

(8) Mark strings (3) and (4), 1350 mm (4.43 ft.) to the right of the vehicle center line (string 2). (Marks I and N)

(9) Mark strings (3) and (4), 1450 mm (4.76 ft.) to the right of the vehicle center line (string 2). (Marks AB and AD)

(10) Secure string (6) so that it passes through marks I and N as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | String 1 |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | String 6 |

| *f | Mark I |

| *g | Mark N |

| Front of Toyota Prius Vehicle |

(11) Make a mark on string (6) that is 2900 mm (9.51 ft.) from the reference line (string (1)) as shown in the illustration. (Mark Z)

| *a | 2900 mm (9.51 ft.) |

| *b | String 1 |

| *c | String 6 |

| *d | Mark I |

| *e | Mark N |

| *f | Mark Z |

| Front of Toyota Prius Vehicle |

(12) Align the center line of SST (television camera adjustment target) with mark AB and place it parallel with string (3) as shown in the illustration.

| *a | SST (Television Camera Adjustment Target) |

| *b | String 3 |

| *c | String 4 |

| *d | String 6 |

| *e | Mark I |

| *f | Mark N |

| *g | Mark Z |

| *h | Mark AB |

| *i | Mark AD |

| Front of Toyota Prius Vehicle |

(13) Align the center line of SST (television camera adjustment target) with mark AD and place it parallel with string (4) as shown in the illustration.

(14) Align the center line of SST (television camera adjustment target) with mark Z and place it parallel with string (6) as shown in the illustration.

NOTICE:

The vertical direction of SST (television camera adjustment target) differs depending on whether corner setting or side setting is used

(15) Perform the screen adjustment procedure (procedure 15).

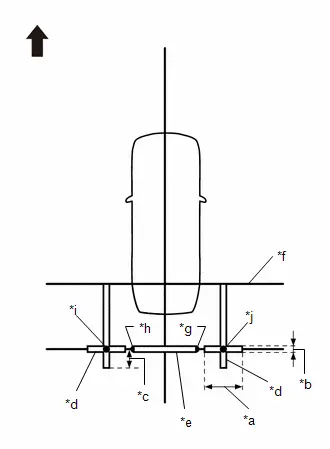

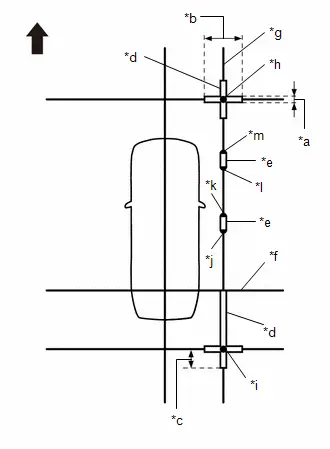

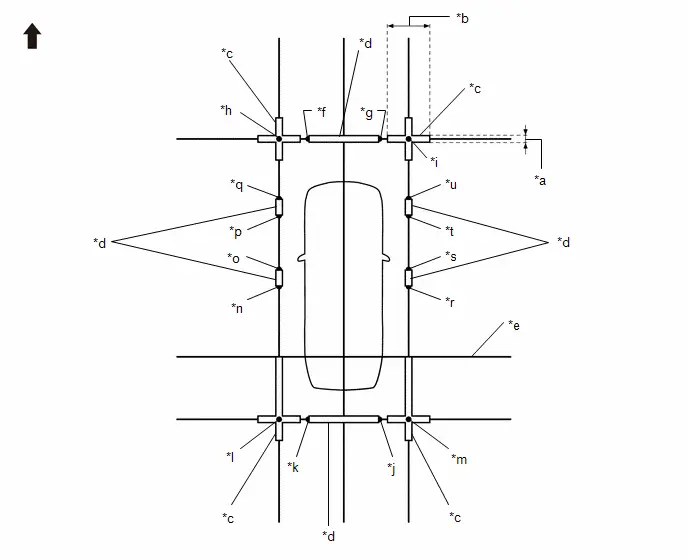

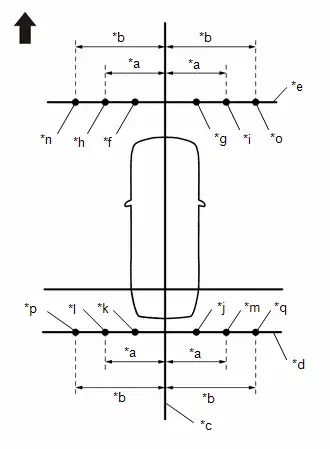

PROCEDURE 12: SET MARKERS (ADJUSTMENT OF ALL CAMERAS)

(a) At the right and left sides of the Toyota Prius vehicle, extend strings (5) and (6) parallel to the vehicle center line (string 2), and place markers.

| *a | 1000 mm (3.28 ft.) |

| *b | 4600 mm (15.09 ft.) |

| *c | Datum Point |

| *d | String 1 |

| *e | String 2 |

| *f | Mark E |

| *g | Mark J |

| Front of Toyota Prius Vehicle |

(1) Mark the position on string (2) in front of the vehicle, 4600 mm (15.09 ft.) from the datum point. (Mark E)

(2) Mark the position on string (2) to the rear of the vehicle, 1000 mm (3.28 ft.) from the datum point. (Mark J)

| *a | 400 mm (1.31 ft.) |

| *b | String 2 |

| *c | Mark E |

| Front of Toyota Prius Vehicle |

(3) Fix the ends of 2 strings (800 mm [2.62 ft.] long) at 2 positions 400 mm (1.31 ft.) from mark E as shown in the illustration.

(4) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks F and G)

| *a | 800 mm (2.62 ft.) String | *b | String 2 |

| *c | Mark E | *d | Mark F |

| *e | Mark G | - | - |

| Front of Toyota Prius Vehicle | - | - |

| *a | 400 mm (1.31 ft.) |

| *b | String 1 |

| *c | String 2 |

| *d | Mark J |

| Front of Toyota Prius Vehicle |

(5) Fix the ends of 2 strings (800 mm [2.62 ft.]) at 2 positions 400 mm (1.31 ft.) from mark J as shown in the illustration.

(6) Move the free ends of the 2 strings and mark the point where the ends meet. (Marks K and L)

| *a | 800 mm (2.62 ft.) String | *b | String 1 |

| *c | String 2 | *d | Mark J |

| *e | Mark K | *f | Mark L |

| Front of Toyota Prius Vehicle | - | - |

(7) Secure strings (3) and (4) so that they pass through marks F, G, K and L as shown in the illustration.

| *a | 1200 mm (3.94 ft.) |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | Mark F |

| *f | Mark G |

| *g | Mark H |

| *h | Mark I |

| *i | Mark K |

| *j | Mark L |

| *k | Mark M |

| *l | Mark N |

| Front of Toyota Prius Vehicle |

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

(8) Mark string (3), 1200 mm (3.94 ft.) to the left and right of the vehicle center line (string 2). (Marks H and I)

(9) Mark string (4), 1200 mm (3.94 ft.) to the left and right of the Toyota Prius vehicle center line (string 2). (Marks M and N)

(10) Secure strings (5) and (6) so that they pass through marks H, M, I and N as shown in the illustration.

NOTICE:

When securing the string, check that there is no slack and the string is not twisted.

| *a | String 1 |

| *b | String 2 |

| *c | String 3 |

| *d | String 4 |

| *e | String 5 |

| *f | String 6 |

| *g | Mark H |

| *h | Mark I |

| *i | Mark M |

| *j | Mark N |

| Front of Toyota Prius Vehicle |

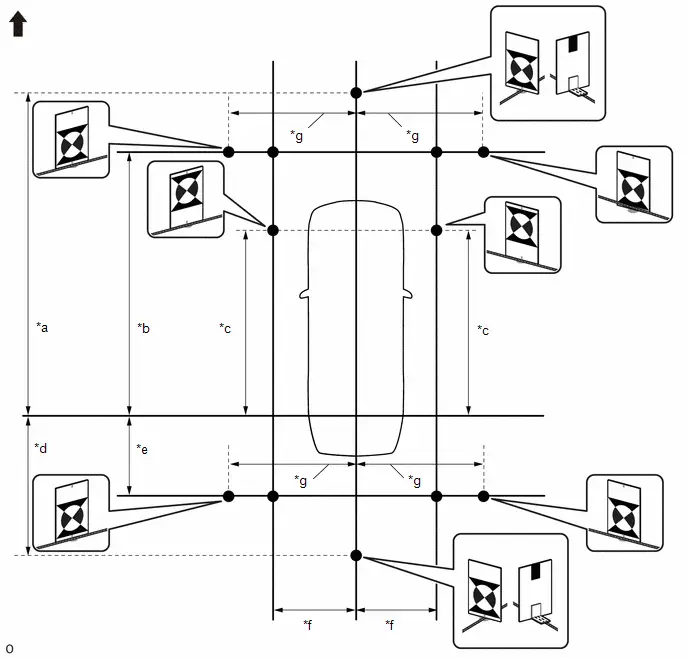

| *a | 1400 mm (4.59 ft.) |

| *b | 1600 mm (5.25 ft.) |

| *c | 3000 mm (9.84 ft.) |

| *d | 3200 mm (10.50 ft.) |

| *e | String 1 |

| *f | String 2 |

| *g | String 3 |

| *h | String 4 |

| *i | String 5 |

| *j | String 6 |

| *k | Mark O |

| *l | Mark P |

| *m | Mark Q |

| *n | Mark R |

| *o | Mark S |

| *p | Mark T |

| *q | Mark U |

| *r | Mark V |

| Front of Toyota Prius Vehicle |

(11) Make marks on string (5) that are 1400 mm (4.59 ft.), 1600 mm (5.25 ft.), 3000 mm (9.84 ft.) and 3200 mm (10.50 ft.) from the datum line (string 1) as shown in the illustration. (Marks O, P, Q and R)

(12) Make marks on string (6) that are 1400 mm (4.59 ft.), 1600 mm (5.25 ft.), 3000 mm (9.84 ft.) and 3200 mm (10.50 ft.) from the datum line (string 1) as shown in the illustration. (Marks S, T, U and V)

(13) Place and secure the cross check markers, centered on marks H, I, M and N.

NOTICE:

- Align the cross check markers perpendicular to the string.

- Make each arm of the cross check markers 800 mm (2.62 ft.) long and 100 mm (0.33 ft.) wide.

- Extend the rear cross check markers to string 1.

| *a | 100 mm (0.33 ft.) | *b | 800 mm (2.62 ft.) |

| *c | Cross Check Marker | *d | Check Marker |

| *e | String 1 | *f | Mark F |

| *g | Mark G | *h | Mark H |

| *i | Mark I | *j | Mark K |

| *k | Mark L | *l | Mark M |

| *m | Mark N | *n | Mark O |

| *o | Mark P | *p | Mark Q |

| *q | Mark R | *r | Mark S |

| *s | Mark T | *t | Mark U |

| *u | Mark V | - | - |

| Front of Toyota Prius Vehicle | - | - |

(14) Place check markers between marks F and G, marks K and L, marks O and P, marks Q and R, marks S and T, and marks U and V.

(15) Perform the set SST (adjustment of all cameras) (procedure 14).

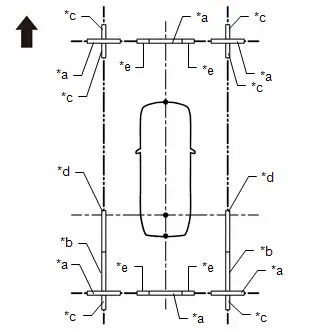

PROCEDURE 13: SET MARKERS (SST ADJUSTMENT)

(a) Using SST (marker tool set), place the markers.

SST: 09870-30010

Markers and Spacers Used| Part Name | Color | Length | Qty |

|---|---|---|---|

| Marker A | White | 800 mm (31.5 in.) | 6 |

| Marker B | White | 950 mm (37.4 in.) | 2 |

| Marker E | White | 350 mm (13.8 in.) | 6 |

| Marker F | White | 1000 mm (39.4 in.) | 2 |

| Marker G | White | 293 mm (11.5 in.) | 4 |

| Marker H | White | 200 mm (7.87 in.) | 4 |

| Spacer J | Black | 1000 mm (39.4 in.) | 6 |

| Spacer N | Black | 200 mm (7.87 in.) | 2 |

| Spacer P | Black | 107 mm (4.21 in.) | 4 |

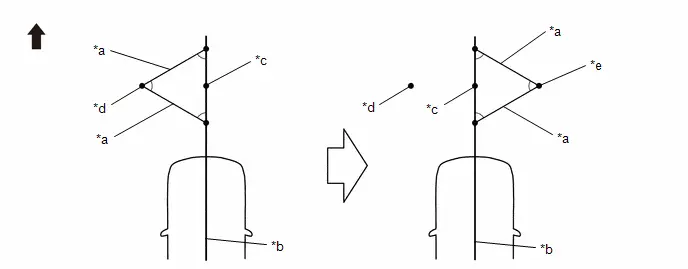

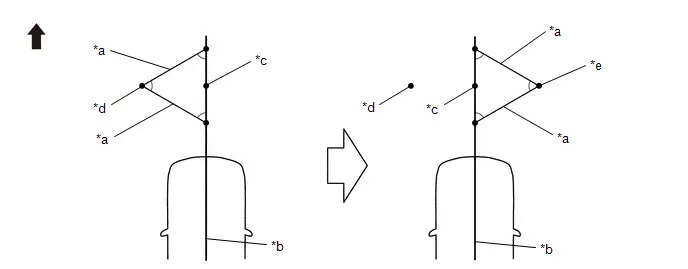

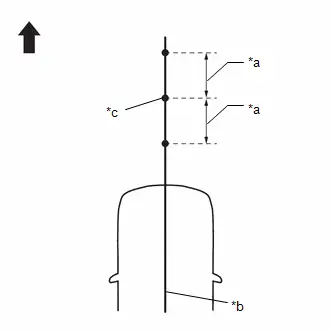

(1) Set the marker A, marker B, marker E, marker F and marker G so as to surround the Toyota Prius vehicle as shown in the illustration.

| *a | Marker A |

| *b | Marker B |

| *c | Marker E |

| *d | Marker F |

| *e | Marker G |

| Front of Toyota Prius Vehicle |

| Part Name | Color | Length | Qty |

|---|---|---|---|

| Marker A | White | 800 mm (31.5 in.) | 6 |

| Marker B | White | 950 mm (37.4 in.) | 2 |

| Marker E | White | 350 mm (13.8 in.) | 6 |

| Marker F | White | 1000 mm (39.4 in.) | 2 |

| Marker G | White | 293 mm (11.5 in.) | 4 |

(2) Set the spacer J as shown in the illustration.

| *a | Spacer J |

| Front of Toyota Prius Vehicle |

| Part Name | Color | Length | Qty |

|---|---|---|---|

| Spacer J | Black | 1000 mm (39.4 in.) | 4 |

(3) Combine with spacers and set at positions A and B to assemble the marker tool set.

| *a | A |

| *b | B |

| Front of Toyota Prius Vehicle |

| Part Name | Color | Length | Qty |

|---|---|---|---|

| Spacer J | Black | 1000 mm (39.4 in.) | 1 |

| Spacer N | Black | 200 mm (7.87 in.) | 1 |

HINT:

Create 2 sets and combine together.

B| Part Name | Color | Length | Qty |

|---|---|---|---|

| Spacer P | Black | 107 mm (4.21 in.) | 1 |

HINT:

Create 4 sets and combine together.

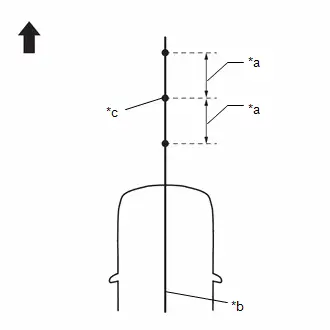

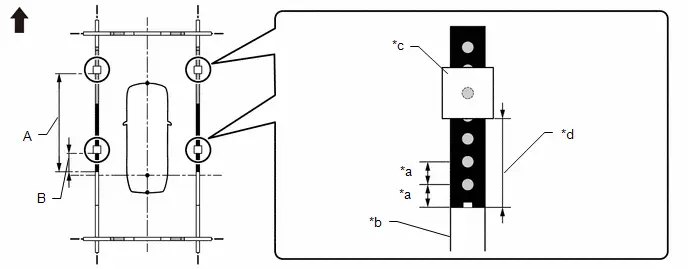

(4) Set the marker H.

| *a | 100 mm (3.94 in.) | *b | Marker F |

| *c | Marker H | *d | Distance from the front end of the marker F to the rear end of the marker H |

| Front of Toyota Prius Vehicle | - | - |

| Marker H Setting Positions | Distance from the front end of the marker F to the rear end of the marker H |

|---|---|

| A | 2000 mm (6.56 ft.) |

| B | 400 mm (1.31 ft.) |

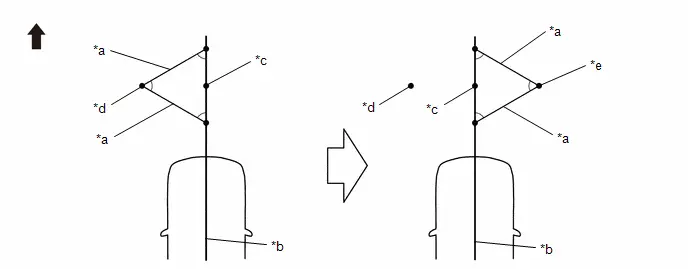

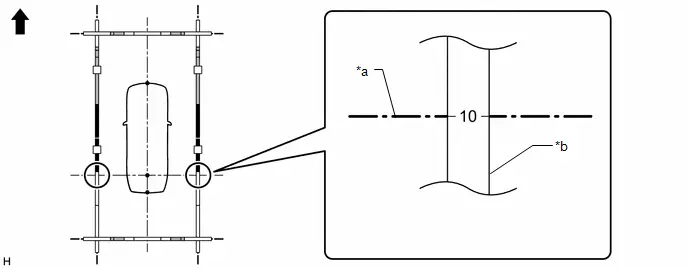

(5) Align the position number on the marker F with the datum line as shown in the illustration.

NOTICE:

When aligning the marker F with the datum line, check that the string used for the datum line is not twisted or bent.

| *a | Datum line | *b | Marker F |

| Front of Toyota Prius Vehicle | - | - |

| Marker F Position |

|---|

| 10 |

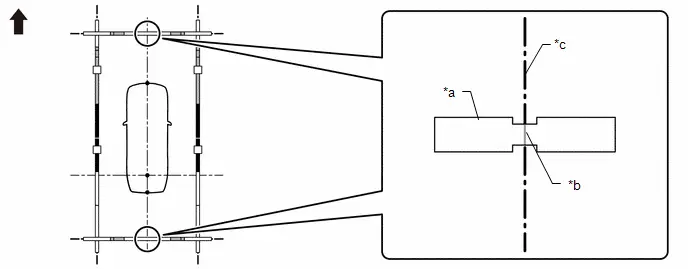

(6) Align the mark-off line of the marker A set at the front and back with the Toyota Prius vehicle center line as shown in the illustration.

NOTICE:

When aligning the marker A with the vehicle center line, check that the string used for the vehicle center line is not twisted or bent.

| *a | Marker A | *b | Mark-off line |

| *c | Toyota Prius Vehicle center line | - | - |

| Front of Vehicle | - | - |

(7) Check that the entire marker tool set is not distorted after the setting is completed. If there is any distortion, perform corrections so that it is straightened.

| Front of Toyota Prius Vehicle | - | - |

(8) Perform the set SST.

| Adjustment point | Proceed to |

|---|---|

| Front camera adjustment only | Set SST (front adjustment) (procedure 5) |

| Rear camera adjustment only | Set SST (rear adjustment) (procedure 7) |

| Left camera adjustment only | Set SST (left-side adjustment) (procedure 9) |

| Right camera adjustment only | Set SST (right-side adjustment) (procedure 11) |

| Adjustment of 4 cameras | Set SST (adjustment of cameras) (procedure 14) |

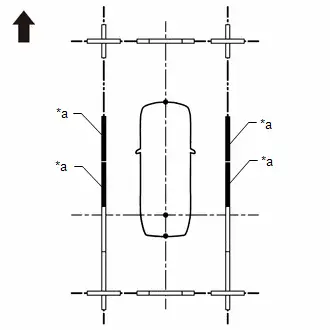

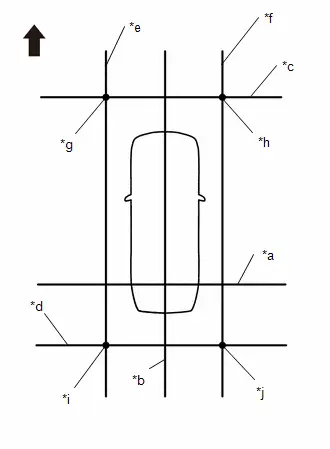

PROCEDURE 14: SET SST (ADJUSTMENT OF ALL CAMERA)

(a) At the right and left sides of the Toyota Prius vehicle, extend strings (5) and (6) parallel to the vehicle center line (string (2)), and place SST.

SST: 09870-52010

SST: 09870-52020

| *a | 1050 mm (3.44 ft.) |

| *b | 4650 mm (15.25 ft.) |

| *c | 2050 mm (6.72 ft.) |

| *d | 5650 mm (18.53 ft.) |

| *e | Datum Point |

| *f | String 1 |

| *g | String 2 |

| *h | Mark E |

| *i | Mark J |

| *j | Mark W |

| *k | Mark X |

| Front of Toyota Prius Vehicle |

(1) Mark the position on string (2) in front of the vehicle, 4650 mm (15.25 ft.) from the datum point. (Mark E)