Toyota Prius: Electronically Controlled Brake System

- Precaution

- Definition Of Terms

- Parts Location

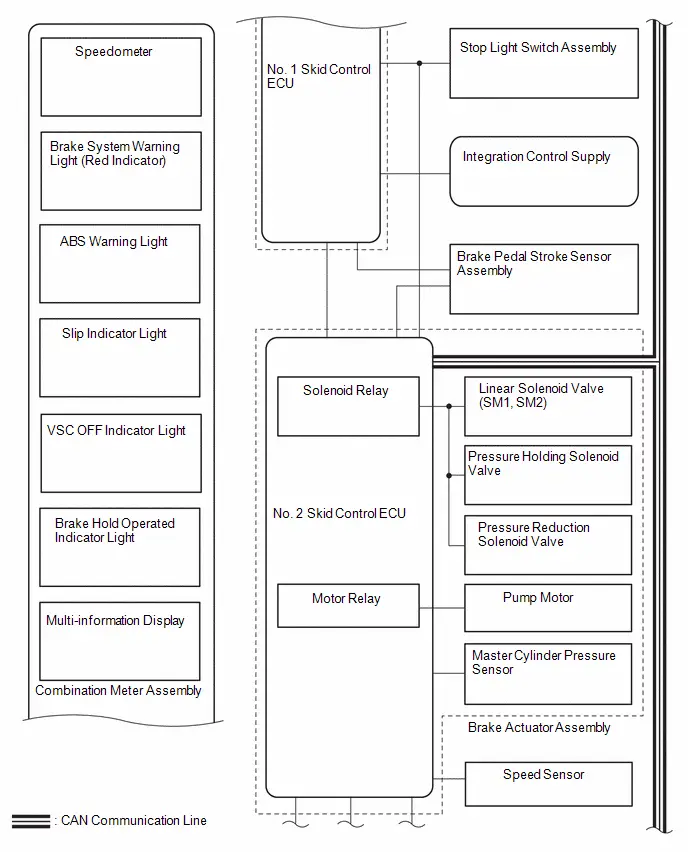

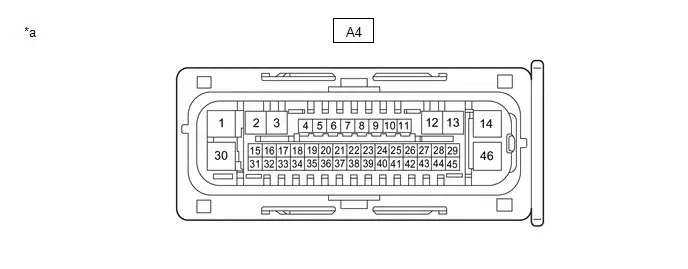

- System Diagram

- How To Proceed With Troubleshooting

- Problem Symptoms Table

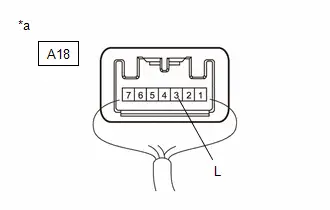

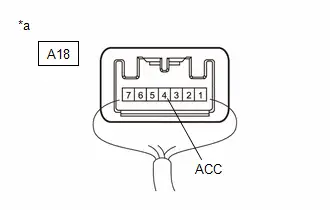

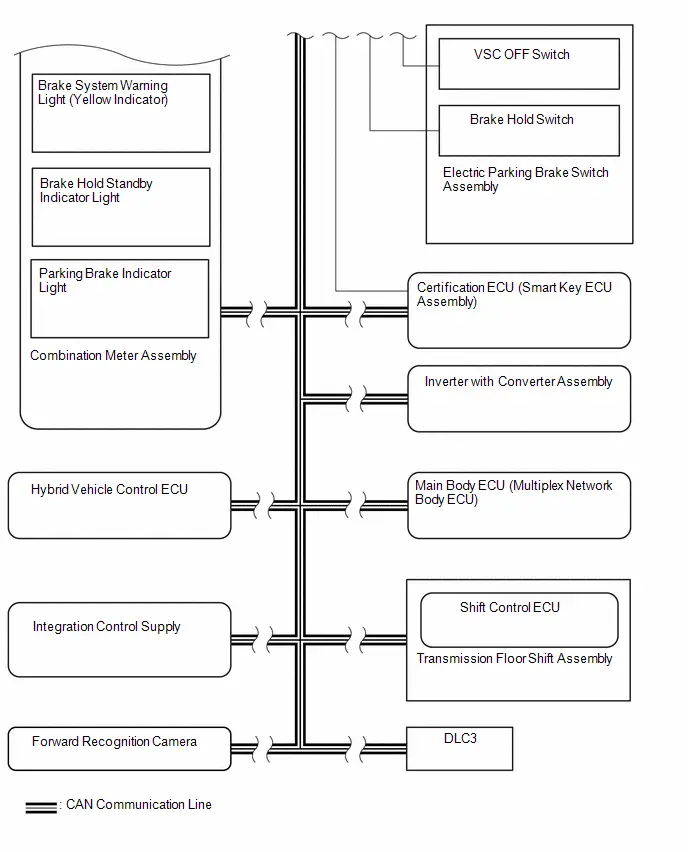

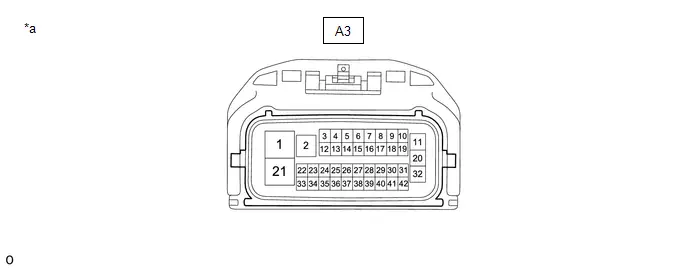

- Terminals Of Ecu

- Diagnosis System

- Dtc Check / Clear

- Freeze Frame Data

- Signal Check

- Fail-safe Chart

- Data List / Active Test

- On-vehicle Inspection

- Inspection

- VEHICLE CONTROL HISTORY (RoB)

- Yaw Rate Sensor Circuit Intermittent (C00631F,C05201F)

- Yaw Rate Sensor Signal Bias Level Out of Range / Zero Adjustment Failure (C006328,C006396)

- Yaw Rate Sensor Signal Stuck In Range (C00632A,C05201C,C05202A,C052096)

- Left Front Wheel Speed Sensor Circuit Short to Battery (C050012)

- Left Front Wheel Speed Sensor Circuit Short to Ground or Open (C050014)

- Left Front Wheel Speed Sensor Circuit Intermittent (C05001F)

- Left Front Wheel Speed Sensor Signal Stuck Low (C050023)

- Left Front Wheel Speed Sensor Signal Has Too Many Pulses (C05003A,C05063A)

- Left Front Wheel Speed Sensor Signal Compare Failure (C050062)

- Right Front Wheel Speed Sensor Circuit Short to Battery (C050612)

- Right Front Wheel Speed Sensor Circuit Short to Ground or Open (C050614)

- Right Front Wheel Speed Sensor Circuit Intermittent (C05061F)

- Right Front Wheel Speed Sensor Signal Stuck Low (C050623)

- Right Front Wheel Speed Sensor Signal Compare Failure (C050662)

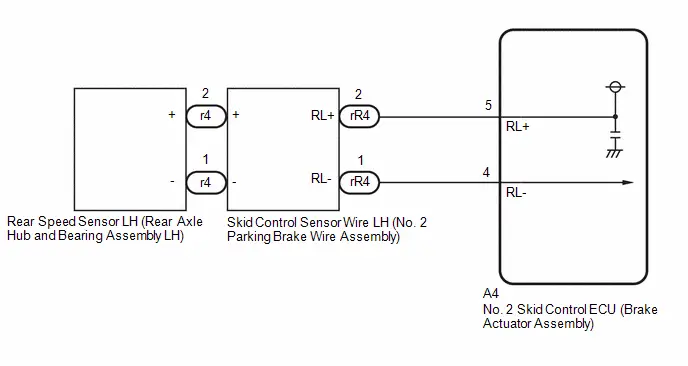

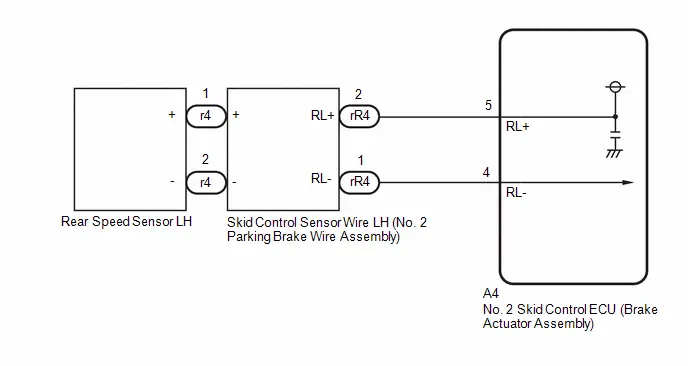

- Left Rear Wheel Speed Sensor Circuit Short to Battery (C050C12)

- Left Rear Wheel Speed Sensor Circuit Short to Ground or Open (C050C14)

- Left Rear Wheel Speed Sensor Signal Stuck Low (C050C23)

- Left Rear Wheel Speed Sensor Signal Has Too Many Pulses (C050C3A,C05123A)

- Left Rear Wheel Speed Sensor Signal Compare Failure (C050C62)

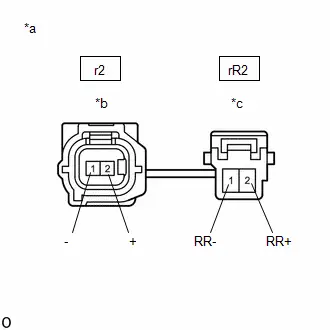

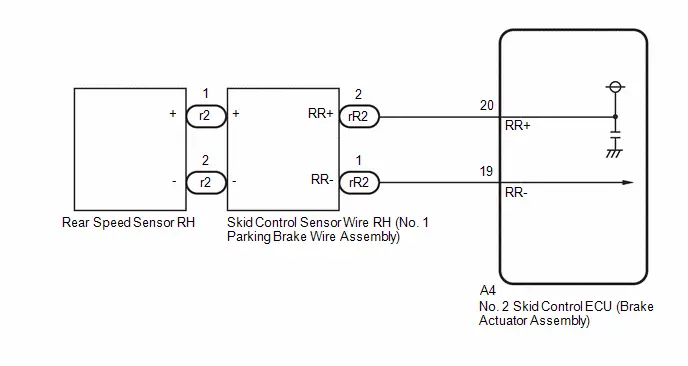

- Right Rear Wheel Speed Sensor Circuit Short to Battery (C051212)

- Right Rear Wheel Speed Sensor Circuit Short to Ground or Open (C051214)

- Right Rear Wheel Speed Sensor Circuit Intermittent (C05121F)

- Right Rear Wheel Speed Sensor Signal Stuck Low (C051223)

- Right Rear Wheel Speed Sensor Signal Compare Failure (C051262)

- Multi-axis Acceleration Sensor Module "A" (C051D00)

- Steering Angle Sensor Module Signal Stuck In Range (C05262A)

- Steering Angle Sensor Module Component Internal Failure (C052696)

- ABS Pump Motor Control Circuit Short to Ground or Open (C052C14,C052C16,C052C17,C052C49,C052F14)

- Brake Pressure Sensor "A" Circuit Voltage Below Threshold (C054016,...,C122D17)

- Brake Pressure Sensor "A" Circuit Voltage Above Threshold (C054017)

- Left Front Wheel Speed Sensor Incorrect Component Installed (C055595)

- Brake System Control Module "A" Internal Electronic Failure (C059749,C12F662,C12F762,C13BF62)

- Brake Pressure Sensor "E" Malfunction (C05A100,...,C14C017)

- Brake Pressure Sensor "E" Signal Bias Level Out of Range / Zero Adjustment Failure (C05A128)

- Brake Pedal Position Sensor "A" (C05C000)

- Brake Pressure Sensor "H" Signal Bias Level Out of Range / Zero Adjustment Failure (C063928)

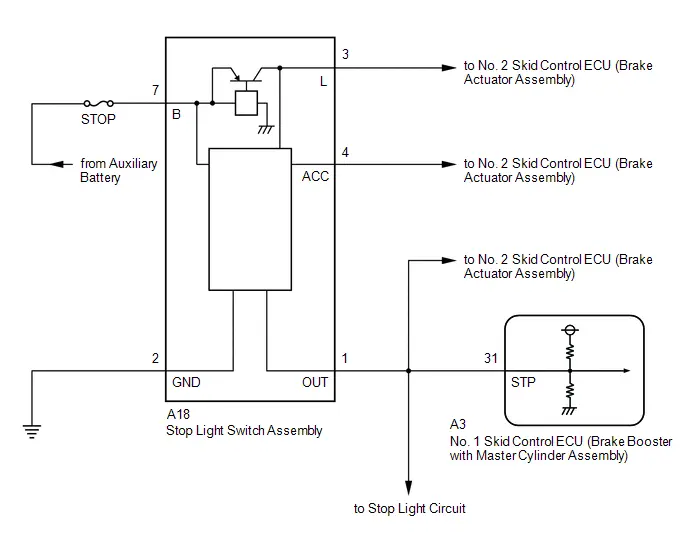

- Ignition Switch On/Start Position Malfunction (C102000)

- Brake Pedal Position Sensor "A" Supply Voltage Malfunction (C110000)

- Brake Pedal Position Sensor "A" Supply Voltage Malfunction (C110000)

- Brake Pedal Position Sensor "A" Supply Voltage Circuit Voltage Out of Range (C11001C)

- Brake Pedal Position Sensor "B" Supply Voltage Circuit Voltage Out of Range (C11031C)

- Brake Pressure Sensor "H" / Brake Pedal Position Sensor Signal Compare Failure (C116C62)

- Brake Servo Pressure Sensor Pressure Increase Malfunction (C116D00)

- Electronic Brake Booster Motor Supply Voltage Circuit Short to Ground or Open (C117514)

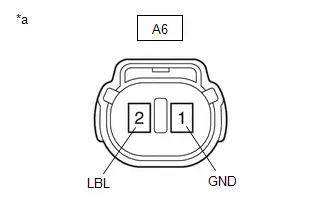

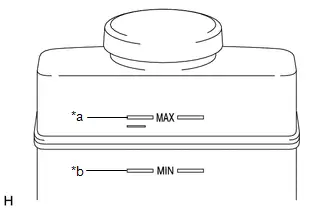

- Master Reservoir Level Malfunction (C120200)

- Yaw Rate Sensor / Multi-axis Acceleration Sensor Module "A" (C124000)

- Braking System information System Programming Failure (C124A05)

- Electronic Brake Booster Control Module "A" Backup Power Supply Voltage Circuit Open (C125D13,C14C949,C14DD49)

- Electronic Brake Booster Control Module "A" Backup Power Supply Voltage System Voltage Low (C125DA2,C125DA3)

- Reservoir Level Switch Circuit Short to Battery or Open (C126E15)

- Electronic Brake Booster Motor "A" Position Sensor Signal Cross Coupled (C129A2B)

- Left Front Wheel ABS Hold Solenoid Control Circuit Short to Battery (C12A512,...,C12B014)

- Electronic Brake Booster Motor "A" Circuit Current Above Threshold (C12B419)

- Electronic Brake Booster Motor "A" Actuator Stuck (C12B471)

- Electronic Brake Booster Motor "A" Drive Circuit Missing Message (C12BF87)

- Left Rear Wheel ABS Hold Solenoid Control Circuit Short to Battery (C12D112,...,C12DC14)

- ECB Solenoid Control "A" Circuit Short to Battery (C12F812,C12F814)

- Linear Solenoid Valve Offset Learning (C134500)

- Linear Solenoid Valve Offset Learning Missing Calibration (C134554)

- Brake System Control Module "A" System Voltage System Voltage Low (C137BA2)

- Brake System Control Module "A" System Voltage System Voltage High (C137BA3)

- Stop Lamp Relay Actuator Stuck On (C13807E)

- Stop Lamp Relay Actuator Stuck Off (C13807F)

- Electronic Brake Booster Motor "A" Current Sensor Signal Cross Coupled (C13BA2B)

- Brake Pressure Too Low (Brake Booster) (C13D900)

- Brake Pressure Leak Malfunction (C140000,C140A00)

- ABS Pump Motor Actuator Stuck (C142771)

- ABS Solenoid Control Actuator Stuck On (C143A7E,C143A7F)

- Electronic Brake Booster Control Module "A" Supply Voltage Circuit Voltage Below Threshold (C14C616)

- Electronic Brake Booster Control Module "A" Supply Voltage Circuit Voltage Above Threshold (C14C617)

- Electronic Brake Booster Control Module "A" System Voltage Low (C14C9A2)

- Brake Fluid Air Bleeding Not Programmed (C14CE51)

- Brake Pressure Control solenoid Supply Voltage Circuit Short to Ground or Open (C14DD14)

- Left Front Wheel Speed Sensor Supply Voltage Circuit Short to Ground or Open (C14E014,C14E314)

- Steering Angle Sensor Supply Voltage Circuit Short to Ground or Open (C14FE14)

- Brake Switch "A" (P057100)

- Brake Pedal Position Sensor "A" (P057A00,P05E062)

- Brake Pedal Position Sensor "A" Circuit Short to Battery (P057A12,P057A14,P057A1F)

- Lost Communication with Drive Motor Control Module "A" (U011000,U012987,U029300,U110600,U114A00,U115000,U117D87)

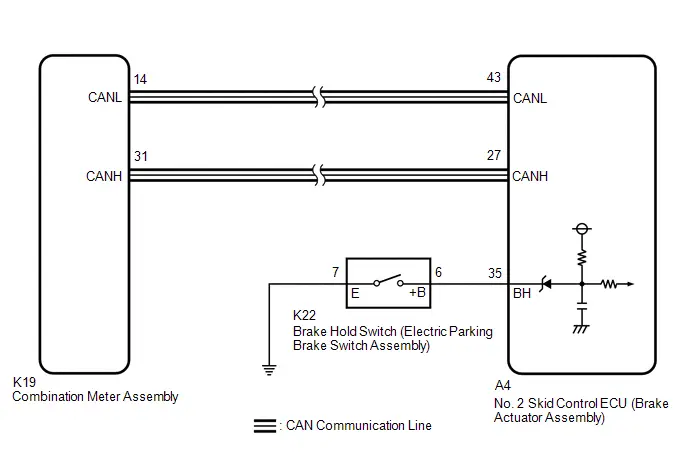

- Brake Hold Standby Indicator Light Circuit

- Brake Hold Operated Indicator Light Circuit

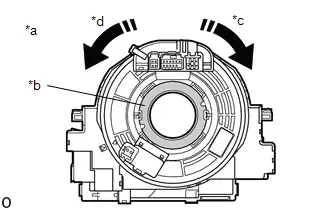

- Steering Angle Sensor Wrong Installation (X0455)

- Zero Point Calibration of Yaw Rate Sensor Undone (X204C)

- Zero Point Calibration of Steering Angle Sensor Malfunction (X20D7)

- Zero Point Calibration of Steering Angle Sensor Not Acquired (X20D8)

- Excessive Brake Pedal Travel (No Fluid Leaks and No Air in System)

- ABS does not Operate

- ABS Operates Before Necessary When Braking

- Abnormal Brake Pedal Response on First Depression

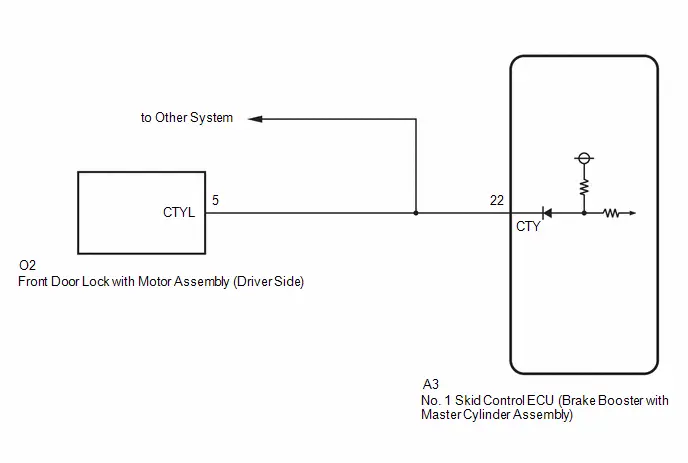

- VSC OFF Switch Circuit

Precaution

PRECAUTION

PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL

NOTICE:

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

TROUBLESHOOTING PRECAUTIONS

(a) When there is a malfunction with terminal contact points or part installation problems, removal and installation of the suspected problem parts may return the system to the normal condition either completely or temporarily.

(b) Before disconnecting a connector or removing and installing a component in order to narrow down the malfunctioning part, make sure to perform the following procedure.

- Check for and record any DTCs and Freeze Frame Data that were stored around the time that the malfunction occurred.

-

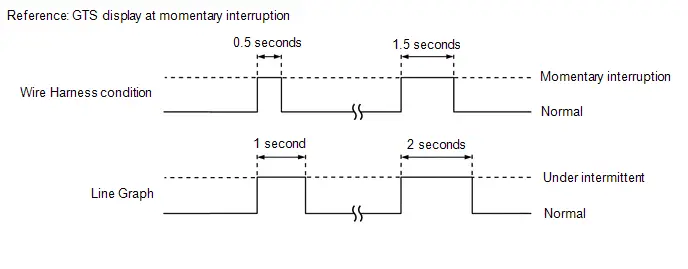

If any open circuit DTCs related to intermittent (momentary interruptions) malfunctions are output, check the intermittent monitor.

Click here

NOTICE:

When disconnecting a connector or removing a fuse or relay, make sure that the ignition switch is off, the brake pedal is not depressed, and the driver door has been closed for 4 minutes or more*.

*: Differs according to Toyota Prius vehicle conditions

(c) Since the system may be influenced by malfunctions in systems other than the brake control system, be sure to check for DTCs in other systems.

HANDLING PRECAUTIONS

(a) Do not remove or install electronically controlled brake system parts such as the steering angle sensor, yaw rate and acceleration sensor (airbag ECU assembly) or brake pedal stroke sensor assembly except when required, as they need to be adjusted correctly after removal and installation.

(b) Be sure to perform preparation before work and confirmation after work is completed by following the directions in the repair manual when working on the electronically controlled brake system.

(c) When removing/installing or replacing an electronically controlled brake system related component, disconnect the cable from the negative (-) auxiliary battery terminal before performing the procedure.

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notice before proceeding with work.

Click here

(d) This system is equipped with 2 skid control ECUs; the No. 1 skid control ECU (brake booster with master cylinder assembly) and No. 2 skid control ECU (brake actuator assembly). For this reason, it is necessary to follow the specified procedure when reading DTCs, Freeze Frame Data, the Data List, etc.

The respective menus for each ECU are as follows:- No. 1 skid control ECU: Chassis / Brake Booster

-

No. 2 skid control ECU: Chassis / Brake/EPB*

*: Electric Parking Brake System

(e) If the No. 1 skid control ECU (brake booster with master cylinder assembly), No. 2 skid control ECU (brake actuator assembly) or a sensor has been removed and installed, it is necessary to check the system for problems after the parts have been reassembled. Check for DTCs using the GTS. Also check that the system functions and signals received by the ECU are normal using Dealer Mode (Signal Check).

HINT:

If a Dealer Mode (Signal Check) inspection is not performed, a sensor not calibrated malfunction DTC may be stored even if the No. 1 skid control ECU (brake booster with master cylinder assembly), No. 2 skid control ECU (brake actuator assembly) and all sensors are normal.

(f) If the brake pedal is depressed before the brake control system is prepared to operate, the pedal stroke may seem unusually long or short. This is due to the fact the stroke simulator cut solenoid has not yet operated and is not a malfunction.

After the ignition switch is turned to ON or the brake pedal is depressed twice or more, the stroke simulator will operate and the brake pedal stroke will remain consistent.

DTC PRECAUTION

(a) Warnings for some DTCs cannot be cleared by only repairing the malfunctioning parts. If the warning is displayed even after repair work, the DTC should be cleared after turning the ignition switch off.

NOTICE:

If a DTC for a malfunctioning part reappears after it is cleared, then it has been stored again.

PRECAUTIONS FOR REMOVAL, INSTALLATION AND REPLACEMENT OF COMPONENTS

(a) After replacing certain components, it may be necessary to update the ECU security key.

Click here

(b) Perform "Calibration" after removal, installation or replacement of any of the following components:

Click here

- No. 1 skid control ECU (brake booster with master cylinder assembly)

- No. 2 skid control ECU (brake actuator assembly)

- Brake pedal stroke sensor assembly (including when performing an adjustment)

- Brake pedal

- Yaw rate and acceleration sensor (airbag ECU assembly)

(c) Perform Dealer Mode (Signal Check) inspection after removal, installation or replacement of any of the following components:

Click here

- Speed sensor

- Speed sensor rotor

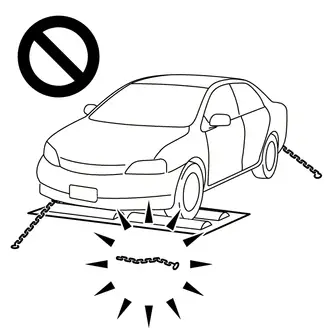

CHASSIS DYNAMOMETER PRECAUTION

(a) Enter Inspection Mode to disable TRAC and VSC operation when using a chassis dynamometer.

Refer to Inspection Mode Procedure: Click here

CAUTION:

-

Do not use the drum tester with any of the lock chains disconnected.

- Using the drum tester with a lock chain disconnected could cause the Toyota Prius vehicle to begin moving unexpectedly.

-

Do not use the drum tester while the TRAC or VSC is able to operate.

- TRAC or VSC operation could cause the vehicle to begin moving unexpectedly.

CAN COMMUNICATION SYSTEM PRECAUTIONS

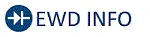

(a) The CAN communication system is used for communication between the No. 1 skid control ECU (brake booster with master cylinder assembly), No. 2 skid control ECU (brake actuator assembly), steering angle sensor, yaw rate and acceleration sensor (airbag ECU assembly) and other ECUs. If there is a malfunction in a CAN communication line, corresponding DTCs for the communication line are output.

(b) If any CAN communication DTCs are output, repair the malfunction, then troubleshoot the electronically controlled brake system while communication is normal.

(c) In order to enable CAN communication, a specific type of wiring is used for the CAN communication lines. The wiring used for each communication line is a twisted pair of wires that have an equal length. A bypass wire should not be used, because the data being transmitted will be corrupted.

Definition Of Terms

DEFINITION OF TERMS

| Term | Definition |

|---|---|

| Monitor Description | Description of what the skid control ECU monitors and how it detects malfunctions (monitoring purpose and details). |

| Related DTCs | Group of diagnostic trouble codes that are output by the skid control ECU based on the same malfunction detection logic. |

| Typical Enabling Conditions | Preconditions that allow the skid control ECU to detect malfunctions. With all preconditions satisfied, the skid control ECU stores a DTC when the monitored value(s) exceeds the malfunction threshold(s). |

| Sequence of Operation | The priority order that is applied to monitoring if multiple sensors and components are used to detect the malfunction. While one sensor is being monitored, the next sensor or component will not be monitored. |

| Required Sensors/Components | The sensors and components that are used by the skid control ECU to detect malfunctions. |

| Frequency of Operation | The number of times that the skid control ECU checks for malfunctions per driving cycle. "Continuous" means that the skid control ECU checks for malfunctions every time the enabling conditions are met. "During initial checking" means that the skid control ECU checks for malfunctions for approximately 3 seconds after the ignition switch is turned to ON (while the initial check being performed). "After ignition switch off" means that after the ignition switch is turned off, the system check which is performed using residual power checks for malfunctions that are difficult to detect during normal operation, within a certain amount of time. |

| Duration | The minimum time for which the skid control ECU must detect a continuous deviation in the monitored value(s) in order to store a DTC. Timing begins after the "typical enabling conditions" are met. |

| Typical Malfunction Thresholds | Value beyond which the skid control ECU will determine that there is a malfunction and stores a DTC. |

| MIL Operation | MIL illumination timing after a malfunction is detected. "Immediate" means that the skid control ECU illuminates the MIL the instant the skid control ECU determines that there is a malfunction. |

| Component Operating Range | Normal operation range of sensors and solenoids under normal driving conditions. Use these ranges as a reference. They cannot be used to judge if a sensor or solenoid is defective or not. |

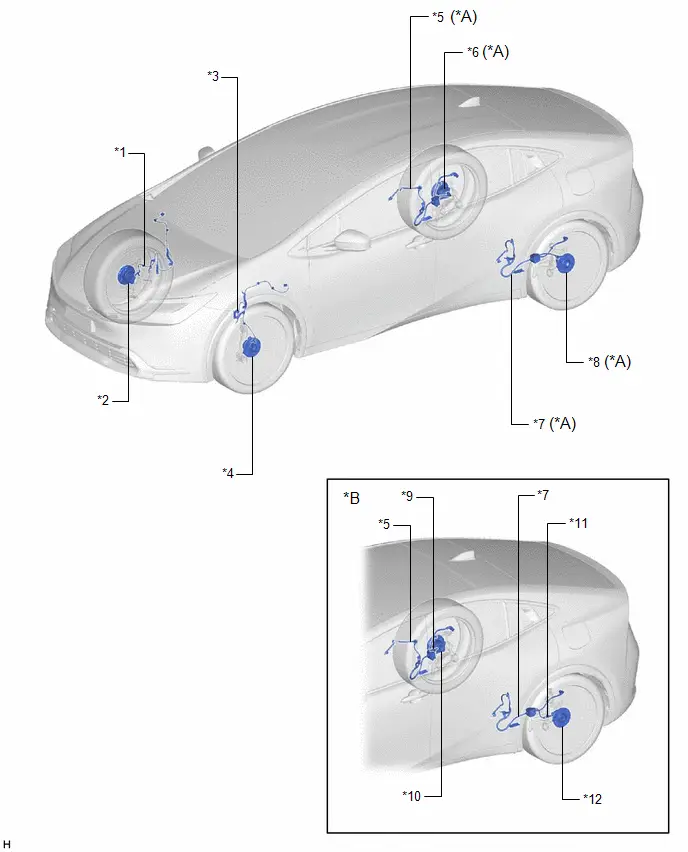

Parts Location

PARTS LOCATION

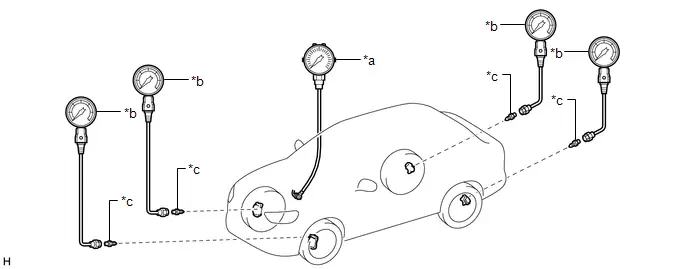

ILLUSTRATION

| *A | for 2WD | *B | for AWD |

| *1 | FRONT SPEED SENSOR RH | *2 | FRONT AXLE HUB SUB-ASSEMBLY RH - FRONT SPEED SENSOR ROTOR RH |

| *3 | FRONT SPEED SENSOR LH | *4 | FRONT AXLE HUB SUB-ASSEMBLY LH - FRONT SPEED SENSOR ROTOR LH |

| *5 | NO. 1 PARKING BRAKE WIRE ASSEMBLY - SKID CONTROL SENSOR WIRE RH | *6 | REAR AXLE HUB AND BEARING ASSEMBLY RH - REAR SPEED SENSOR ROTOR RH - REAR SPEED SENSOR RH |

| *7 | NO. 2 PARKING BRAKE WIRE ASSEMBLY - SKID CONTROL SENSOR WIRE LH | *8 | REAR AXLE HUB AND BEARING ASSEMBLY LH - REAR SPEED SENSOR ROTOR LH - REAR SPEED SENSOR LH |

| *9 | REAR SPEED SENSOR RH (REAR SKID CONTROL SENSOR RH) | *10 | REAR AXLE HUB AND BEARING ASSEMBLY RH - REAR SPEED SENSOR ROTOR RH |

| *11 | REAR SPEED SENSOR LH (REAR SKID CONTROL SENSOR LH) | *12 | REAR AXLE HUB AND BEARING ASSEMBLY LH - REAR SPEED SENSOR ROTOR LH |

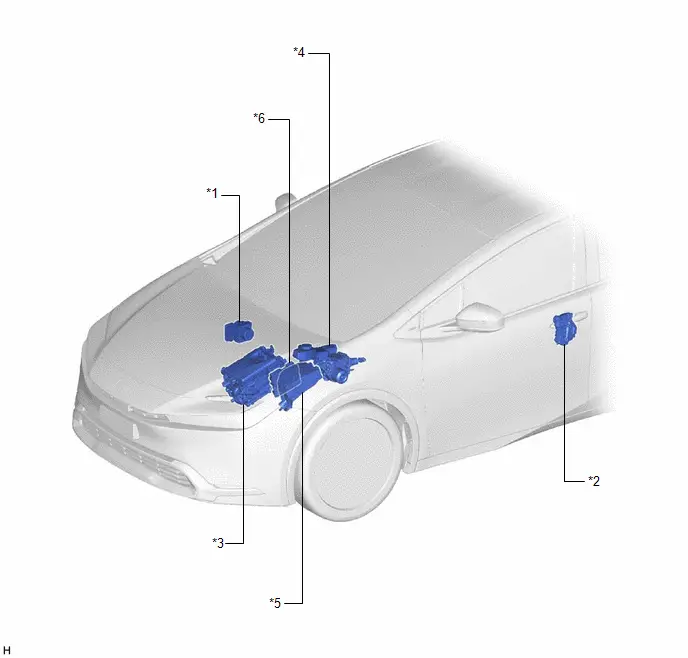

ILLUSTRATION

| *1 | BRAKE ACTUATOR ASSEMBLY - NO. 2 SKID CONTROL ECU | *2 | FRONT DOOR LOCK WITH MOTOR ASSEMBLY (for Driver Side) |

| *3 | INVERTER WITH CONVERTER ASSEMBLY | *4 | BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY - NO. 1 SKID CONTROL ECU - BRAKE ACTUATOR - BRAKE FLUID LEVEL WARNING SWITCH |

| *5 | NO. 1 ENGINE ROOM RELAY BLOCK AND NO. 1 JUNCTION BLOCK ASSEMBLY - ABS MAIN FUSE - ABS MTR NO. 1 FUSE - ABS NO. 1 FUSE - ABS NO. 2 FUSE - ECU-IGP NO. 3 FUSE - 2ND BATT FUSE | *6 | ECM |

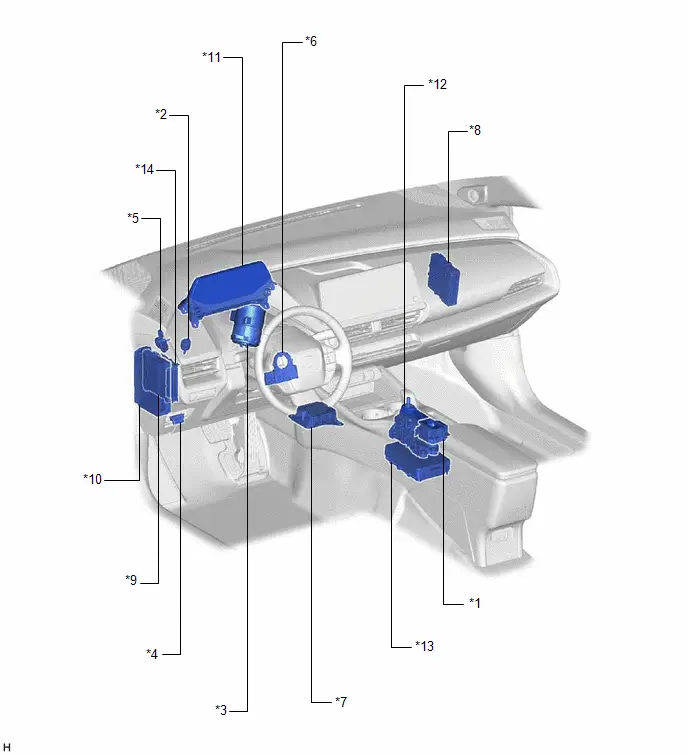

ILLUSTRATION

| *1 | ELECTRIC PARKING BRAKE SWITCH ASSEMBLY - VSC OFF SWITCH - BRAKE HOLD SWITCH | *2 | STOP LIGHT SWITCH ASSEMBLY - STOP LIGHT CONTROL RELAY |

| *3 | POWER STEERING ECU ASSEMBLY | *4 | DLC3 |

| *5 | BRAKE PEDAL STROKE SENSOR ASSEMBLY | *6 | STEERING ANGLE SENSOR |

| *7 | AIRBAG ECU ASSEMBLY - YAW RATE SENSOR - ACCELERATION SENSOR | *8 | HYBRID Toyota Prius Vehicle CONTROL ECU |

| *9 | MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) | *10 | POWER DISTRIBUTION BOX ASSEMBLY - ECU-IGR NO. 2 FUSE - ECU-IGR NO. 3 FUSE - A/BAG-IGR FUSE - ECU-DCC NO. 1 FUSE - STOP FUSE |

| *11 | COMBINATION METER ASSEMBLY - ABS WARNING LIGHT - BRAKE SYSTEM WARNING LIGHT (RED INDICATOR) - BRAKE SYSTEM WARNING LIGHT (YELLOW INDICATOR) - SLIP INDICATOR LIGHT - VSC OFF INDICATOR LIGHT - BRAKE HOLD STANDBY INDICATOR LIGHT - BRAKE HOLD OPERATED INDICATOR LIGHT - MULTI-INFORMATION DISPLAY (TRACTION CONTROL TURNED OFF) - METER BUZZER | *12 | TRANSMISSION FLOOR SHIFT ASSEMBLY - SHIFT CONTROL ECU |

| *13 | INTEGRATION CONTROL SUPPLY | *14 | CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

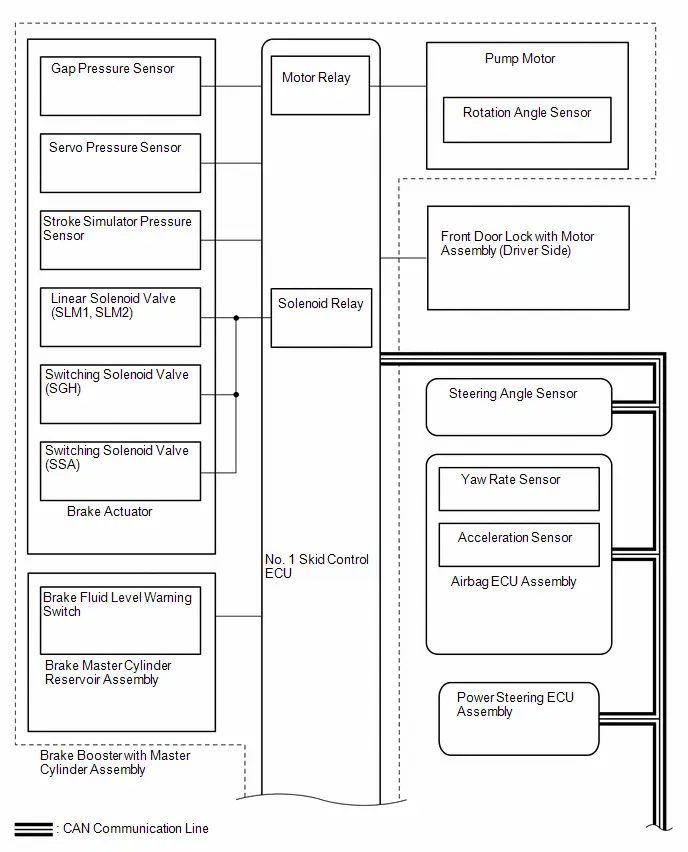

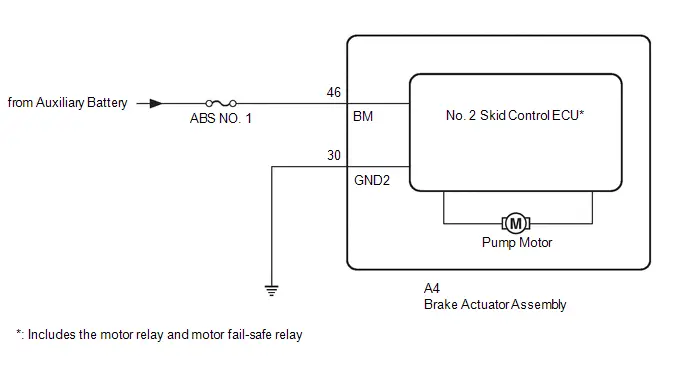

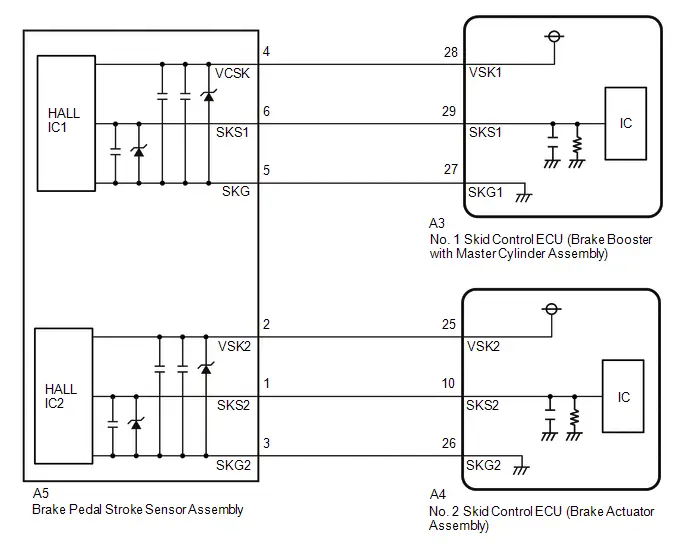

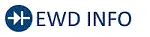

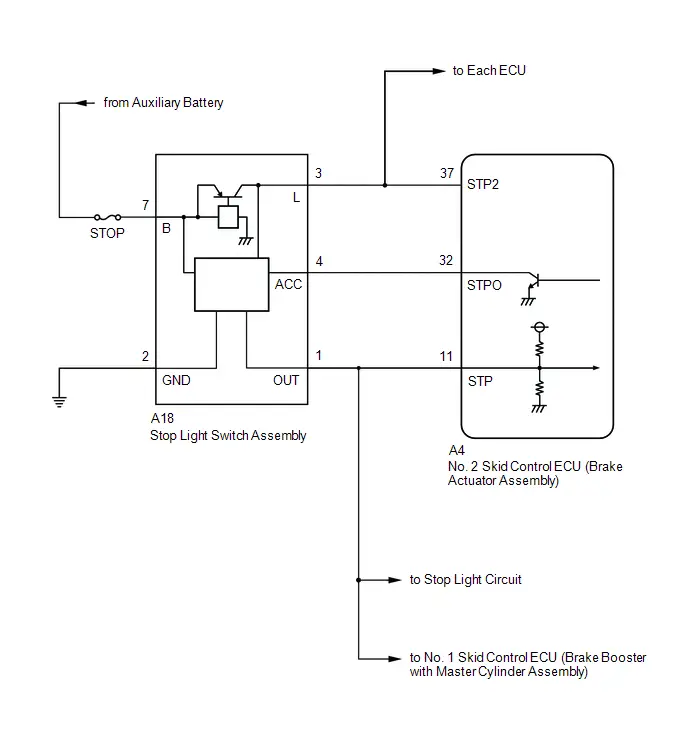

System Diagram

SYSTEM DIAGRAM

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

*: Use the GTS.

PROCEDURE

| 1. | VEHICLE BROUGHT TO WORKSHOP |

|

| 2. | CUSTOMER PROBLEM ANALYSIS |

(a) Interview the customer and confirm the problem.

Click here

|

| 3. | CHECK DTC, FREEZE FRAME DATA AND Toyota Prius Vehicle CONTROL HISTORY (RoB)* |

(a) Check and record DTCs and Freeze Frame Data.

for DTC Check / Clear: Click here

for Freeze Frame Data: Click here

(b) Clear the DTCs and Freeze Frame Data.

for DTC Check / Clear: Click here

for Freeze Frame Data: Click here

(c) Reconfirm the DTCs.

(1) Reconfirm the DTCs based on the recorded DTCs and Freeze Frame Data.

for DTC Check / Clear: Click here

for Freeze Frame Data: Click here

HINT:

-

When CAN communication system DTCs are output, repair the CAN communication system first.

for HEV Model: Click here

for PHEV Model: Click here

-

If DTCs related to momentary interruptions are output, perform troubleshooting for those DTCs first.

Click here

-

If the GTS cannot communicate with the skid control ECU, inspect the CAN communication system.

for HEV Model: Click here

for PHEV Model: Click here

-

If there is no response from the No. 1 skid control ECU (brake booster with master cylinder assembly) or No. 2 skid control ECU (brake actuator assembly), inspect the supply power circuit.

Click here

(d) Check the Toyota Prius Vehicle Control History (RoB).

Click here

| Tester Display |

|---|

| Vehicle Control History (RoB) |

| Tester Display |

|---|

| Toyota Prius Vehicle Control History (RoB) |

| Tester Display |

|---|

| Vehicle Control History (RoB) |

| Result | Proceed to |

|---|---|

| DTCs are not output. (Problem symptom occurs.) | A |

| DTCs are output. | B |

| DTCs are not output. (Problem symptom does not occur.) | C |

| DTCs are not output. (Toyota Prius Vehicle control history (RoB) is stored.) | D |

| A |

| CONFIRM PROBLEM SYMPTOMS |

| B |

| REPAIR CIRCUITS INDICATED BY OUTPUT DTCS* |

| C |

| USE SIMULATION METHOD TO CHECK |

| D |

| PERFORM TROUBLESHOOTING AND REPAIR REGARDING Toyota Prius Vehicle CONTROL HISTORY (RoB)* NOTICE: After performing troubleshooting and repair regarding vehicle control history (RoB), clear the vehicle control history (RoB). |

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

If there are no DTCs but the problem still occurs, check the suspected areas for each problem symptom in the order given in the table below and proceed to the relevant troubleshooting page.

HINT:

- Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the suspected areas in the order they are listed. Replace parts as necessary.

- Inspect the fuses and relays related to this system before inspecting the suspected areas below.

| Symptom | Suspected Area | Link |

|---|---|---|

| ABS warning light abnormal (Remains on) | Refer to Toyota Prius Vehicle Control History (RoB) |

|

| Refer to Meter / Gauge system |

| |

| Brake system warning light (red indicator) abnormal (Remains on) | Refer to Toyota Prius Vehicle Control History (RoB) |

|

| Refer to Meter / Gauge system |

| |

| Brake system warning light (yellow indicator) abnormal (Remains on) | Refer to Toyota Prius Vehicle Control History (RoB) |

|

| Refer to Meter / Gauge system |

| |

| Brake hold standby indicator light abnormal | Refer to the procedure for "Brake Hold Standby Indicator Light Circuit" |

|

| Brake hold operated indicator light abnormal | Refer to Toyota Prius Vehicle Control History (RoB) |

|

| Refer to the procedure for "Brake Hold Operated Indicator Light Circuit" |

| |

| Slip indicator light abnormal | Refer to Toyota Prius Vehicle Control History (RoB) |

|

| Refer to Meter / Gauge system |

| |

| TRAC does not operate | Refer to the procedure for "TRAC does not Operate" |

|

| Excessive brake pedal travel (No fluid leaks and no air in system) | Refer to the procedure for "Excessive Brake Pedal Travel (No Fluid Leaks and No Air in System)" |

|

| ABS does not operate | Refer to the procedure for "ABS does not Operate" |

|

| ABS operates before necessary when braking | Refer to the procedure for "ABS Operates Before Necessary When Braking" |

|

| VSC does not operate or VSC does not operate correctly | Refer to the procedure for "VSC does not Operate or VSC does not Operate Correctly" |

|

| Abnormal brake pedal response on first depression | Refer to the procedure for "Abnormal Brake Pedal Response on First Depression" |

|

| VSC OFF switch abnormal | Refer to the procedure for "VSC OFF Switch Circuit" |

|

| Meter buzzer abnormal | Refer to Meter / Gauge system |

|

Terminals Of Ecu

TERMINALS OF ECU

CHECK BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY

(a) Disconnect the A3 No. 1 skid control ECU (brake booster with master cylinder assembly) connector and measure the voltage or resistance on the wire harness side.

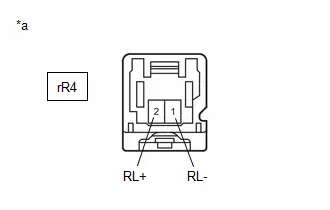

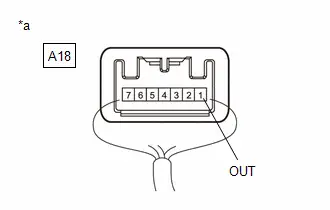

| *a | Front view of wire harness connector (to No. 1 Skid Control ECU (Brake Booster with Master Cylinder Assembly)) | - | - |

NOTICE:

Make sure to wait 5 minutes or more with the ignition switch turned off before removing the integration control supply or disconnecting any supply power circuit from the integration control supply, in order for the voltage to be discharged and self-diagnosis to run.

HINT:

The voltage cannot be measured with the connector connected to the No. 1 skid control ECU (brake booster with master cylinder assembly) as the connector is watertight.

Standard| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

|

*1: Differs depending on the Toyota Prius vehicle model

*2: Refer to Sub Battery System Click here

| |||

| A3-1 (BM) - Body ground | No. 1 skid control ECU (brake booster with master cylinder assembly) power supply input | Always | 11 to 14 V |

| A3-2 (CBKP) | No. 1 skid control ECU (brake booster with master cylinder assembly) backup power supply input | *2 | *2 |

| A3-3 (CSW2) | No. 2 skid control ECU (brake actuator assembly) operation signal output | - | - |

| A3-4 (CA2H) | CAN communication line 2 (H) | - | - |

| A3-5 | - | - | - |

| A3-6 | - | - | - |

| A3-7 | - | - | - |

| A3-8 | - | - | - |

| A3-9 | - | - | - |

| A3-10 | - | - | - |

| A3-11 (BS) - Body ground | Solenoid power supply input | Always | 11 to 14 V |

| A3-12 | - | - | - |

| A3-13 (CA2L) | CAN communication line 2 (L) | - | - |

| A3-14 | - | - | - |

| A3-15 | - | - | - |

| A3-16 | - | - | - |

| A3-17 | - | - | - |

| A3-18 | - | - | - |

| A3-19 | - | - | - |

| A3-20 | - | - | - |

| A3-21 (GND2) - Body ground | No. 1 skid control ECU (brake booster with master cylinder assembly) ground | 1 minute or more after disconnecting the cable from the negative (-) auxiliary battery terminal | Below 1 Ω |

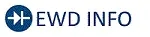

| A3-22 (CTY) - Body ground | Front door lock with motor assembly input (for driver side) | Driver door closed → open | 11 to 14 V or pulse output (maximum 14 V)*1 → Below 1 V |

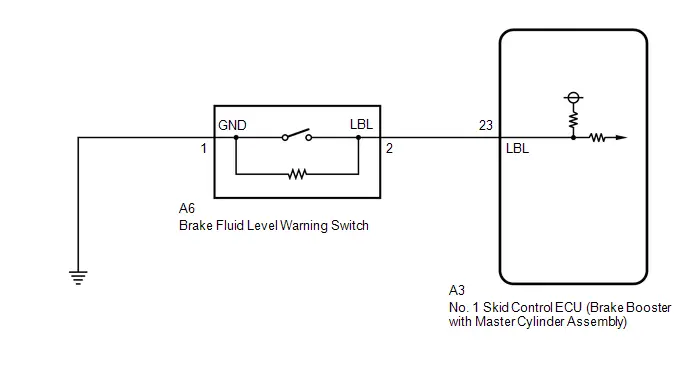

| A3-23 (LBL) | Brake fluid level warning switch input | - | - |

| A3-24 (CWKP) - Body ground | Integration control supply operation signal output | *2 | *2 |

| A3-25 | - | - | - |

| A3-26 | - | - | - |

| A3-27 (SKG1) | Brake pedal stroke sensor 1 ground | - | - |

| A3-28 (VSK1) | Brake pedal stroke sensor 1 power supply output | - | - |

| A3-29 (SKS1) | Brake pedal stroke sensor 1 signal input | - | - |

| A3-30 (IGR) - Body ground | IGR power source input | Ignition switch ON | 11 to 14 V |

| A3-31 (STP) - Body ground | Stop light switch assembly input | Stop light switch assembly on → off (Brake pedal depressed → released) | 11 to 14 V → Below 1.5 V |

| A3-32 | - | - | - |

| A3-33 | - | - | - |

| A3-34 (DC1H) | Daisy chain communication line (H) | - | - |

| A3-35 (DC1L) | Daisy chain communication line (L) | - | - |

| A3-36 (CA1H) | CAN communication line 1 (H) | - | - |

| A3-37 (CA1L) | CAN communication line 1 (L) | - | - |

| A3-38 | - | - | - |

| A3-39 | - | - | - |

| A3-40 | - | - | - |

| A3-41 | - | - | - |

| A3-42 | - | - | - |

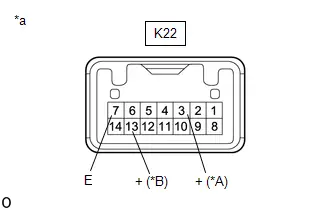

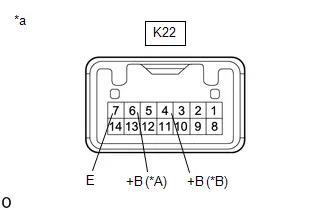

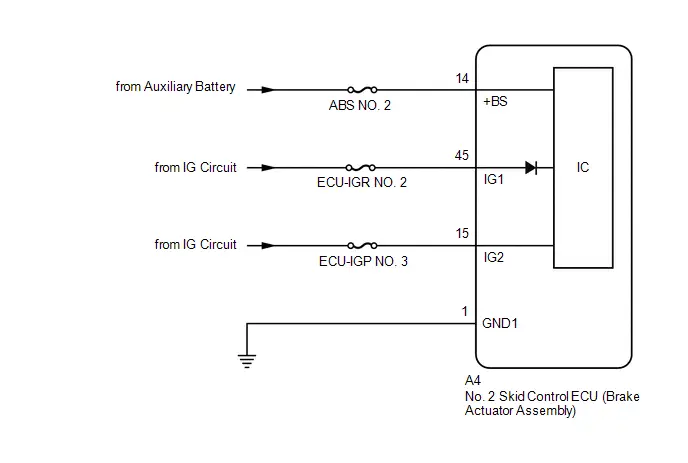

CHECK BRAKE ACTUATOR ASSEMBLY

(a) Disconnect the A4 No. 2 skid control ECU (brake actuator assembly) connector and measure the voltage or resistance on the wire harness side.

| *a | Front view of wire harness connector (to No. 2 Skid Control ECU (brake actuator assembly)) | - | - |

HINT:

The voltage cannot be measured with the connector connected to the No. 2 skid control ECU (brake actuator assembly) as the connector is watertight.

Standard| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A4-1 (GND1) - Body ground | No. 2 skid control ECU (brake actuator assembly) ground | 1 minute or more after disconnecting the cable from the negative (-) auxiliary battery terminal | Below 1 Ω |

| A4-2 | - | - | - |

| A4-3 | - | - | - |

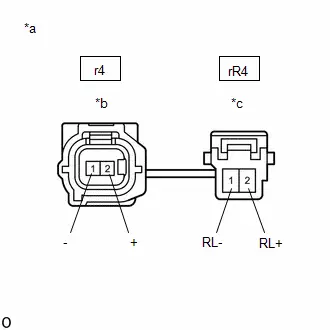

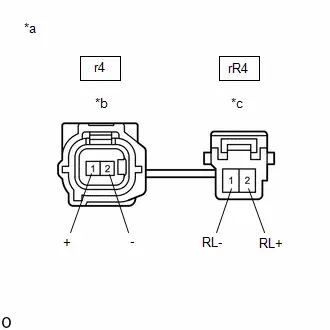

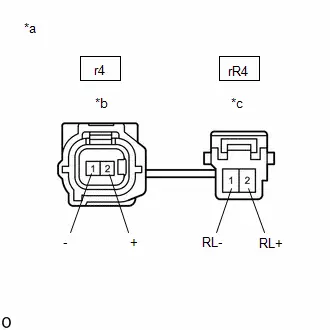

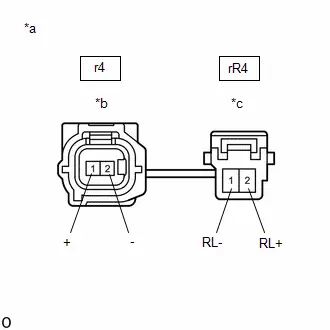

| A4-4 (RL-) | Rear speed sensor LH (-) signal input | - | - |

| A4-5 (RL ) | Rear speed sensor LH ( ) power supply output | - | - |

| A4-6 (FR-) | Front speed sensor RH (-) signal input | - | - |

| A4-7 (FR ) | Front speed sensor RH ( ) power supply output | - | - |

| A4-8 | - | - | - |

| A4-9 (CSW) - Body ground | VSC OFF switch (electric parking brake switch assembly) input | VSC OFF switch (electric parking brake switch assembly) is pushed → released | Below 1 Ω → 10 kΩ or higher |

| A4-10 (SKS2) | Brake pedal stroke sensor 2 signal input | - | - |

| A4-11 (STP) - Body ground | Stop light switch assembly input | Stop light switch assembly on → off (Brake pedal depressed → released) | 11 to 14 V → Below 1.5 V |

| A4-12 | - | - | - |

| A4-13 | - | - | - |

| A4-14 ( BS) - Body ground | ABS solenoid relay power supply input | Always | 11 to 14 V |

| A4-15 (IG2) - Body ground | IG2 power source input | Ignition switch ON | 11 to 14 V |

| A4-16 (CA2H) | CAN communication line 2 (H) | - | - |

| A4-17 (CA2L) | CAN communication line 2 (L) | - | - |

| A4-18 (SP1) | Speed sensor signal output | - | - |

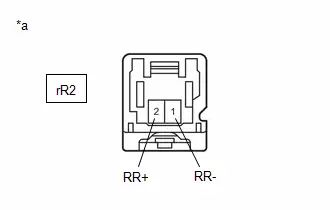

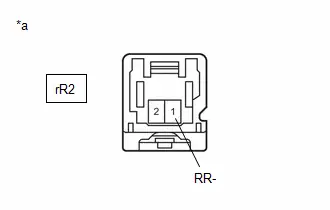

| A4-19 (RR-) | Rear speed sensor RH (-) signal input | - | - |

| A4-20 (RR ) | Rear speed sensor RH ( ) power supply output | - | - |

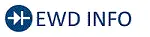

| A4-21 (FL-) | Front speed sensor LH (-) signal input | - | - |

| A4-22 (FL ) | Front speed sensor LH ( ) power supply output | - | - |

| A4-23 | - | - | - |

| A4-24 | - | - | - |

| A4-25 (VSK2) | Brake pedal stroke sensor 2 power supply output | - | - |

| A4-26 (SKG2) | Brake pedal stroke sensor 2 ground | - | - |

| A4-27 (CANH) | CAN communication line (H) | - | - |

| A4-28 | - | - | - |

| A4-29 (CTY) - Body ground | No. 2 Skid control ECU (brake actuator assembly) operation signal input | Ignition switch ON | 11 to 14 V |

| A4-30 (GND2) - Body ground | ABS motor ground | 1 minute or more after disconnecting the cable from the negative (-) auxiliary battery terminal | Below 1 Ω |

| A4-31 | - | - | - |

| A4-32 (STPO) - Body ground | Stop light control relay (stop light switch assembly) output | Always | 11 to 14 V |

| A4-33 | - | - | - |

| A4-34 | - | - | - |

| A4-35 (BH) - Body ground | Brake hold switch (electric parking brake switch assembly) input | Brake hold switch (electric parking brake switch assembly) is pushed → released | Below 1 Ω → 10 kΩ or higher |

| A4-36 | - | - | - |

| A4-37 (STP2) - Body ground | Stop light control relay (stop light switch assembly) input | Stop light switch assembly on → off (Brake pedal depressed → released) | 11 to 14 V → Below 1.5 V |

| A4-38 | - | - | - |

| A4-39 | - | - | - |

| A4-40 | - | - | - |

| A4-41 | - | - | - |

| A4-42 | - | - | - |

| A4-43 (CANL) | CAN communication line (L) | - | - |

| A4-44 | - | - | - |

| A4-45 (IG1) - Body ground | IG1 power source input | Ignition switch ON | 11 to 14 V |

| A4-46 (BM) - Body ground | ABS motor relay power supply input | Always | 11 to 14 V |

Diagnosis System

DIAGNOSIS SYSTEM

OBD II

When troubleshooting OBD II (On-Board Diagnostics) vehicles, the vehicle must be connected to the scan tool (complying with SAE J1978). Various data in the vehicle's computer can then be read.

OBD II regulations require that the Toyota Prius vehicle's on-board computer store an SAE code and illuminate the Malfunction Indicator Lamp (MIL) on the instrument panel when the computer detects a malfunction.

Dtc Check / Clear

DTC CHECK / CLEAR

HINT:

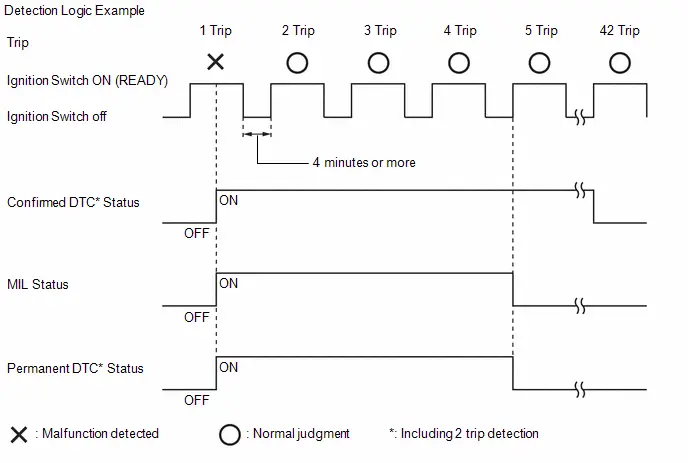

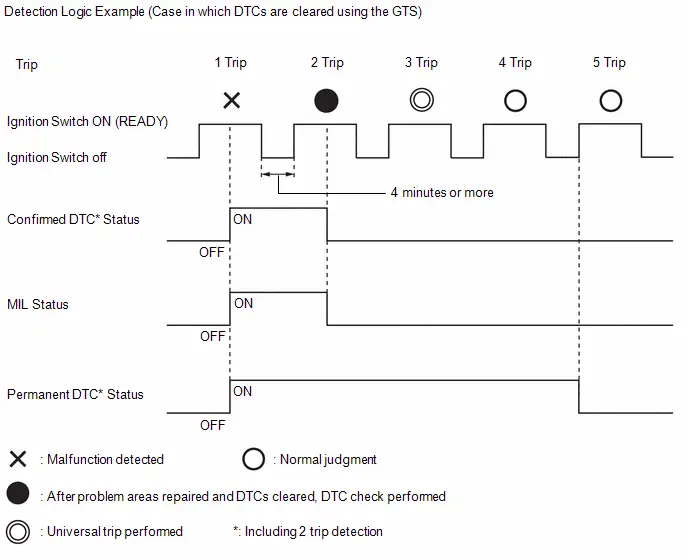

- DTCs which are stored in the skid control ECU can be displayed on the GTS. The GTS can display the confirmed and permanent DTCs.

- If a malfunction is detected during the current driving cycle, confirmed and permanent DTCs are stored.

- Confirmed DTCs can be cleared by using the GTS. However, permanent DTCs cannot be cleared using the GTS.

-

After clearing confirmed DTCs using the GTS, permanent DTCs can be cleared when the system is determined to be normal for the relevant DTCs and then the universal trip is performed. The driving pattern to obtain a normal judgment is described under the "Confirmation Driving Pattern" for the respective DTC.

To clear permanent DTCs, all of the following conditions must be are met:

- There is a history that universal trip driving was performed.

- The Toyota Prius vehicle has been judged as normal for 1 trip.

- No malfunctions are detected.

| *: Including 2 trip detection | ||

| Confirmed DTC* | Store condition | Malfunction detected |

| Clear condition | No malfunctions in 40 driving cycles or DTCs cleared using GTS | |

| Permanent DTC* | Store condition | Malfunction detected |

| Clear condition | Ignition switch is turned to ON (READY) after normal judgment obtained in 3 consecutive driving cycles or After DTCs cleared using GTS, universal trip performed and normal judgment obtained for 1 trip | |

| MIL | ON | Malfunction detected |

| OFF | Ignition switch is turned to ON (READY) after normal judgment obtained in 3 consecutive driving cycles or DTCs cleared using GTS | |

HINT:

- Obtaining a normal judgment and performing a universal trip driving pattern can be done in the same driving cycle or in different driving cycles.

- Ensure to wait at least 4 minutes between each trip.

CHECK DTC

(a) Turn the ignition switch off.

(b) Connect the GTS to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the GTS on.

(e) Enter the following menus: Chassis / Brake Booster / Trouble Codes.

Chassis > Brake Booster > Trouble Codes(f) Enter the following menus: Chassis / Brake/EPB* / Trouble Codes.

*: Electric Parking Brake System

Chassis > Brake/EPB > Trouble Codes(g) Check the DTC(s) and Freeze Frame Data, and then write them down.

NOTICE:

The electronically controlled brake system outputs DTCs for the following system. When DTCs other than those in Diagnostic Trouble Code Chart for the electronically controlled brake system are output, refer to Diagnostic Trouble Code Chart for the relevant system.

| System | Proceed to |

|---|---|

| Electric Parking Brake System |

|

| GTS Display | Description |

|---|---|

| *: Including 2 trip detection | |

| Test Failed | Shows the malfunction judgment results during the current trip. |

| Confirmed* | Shows the DTCs confirmed up to now. (The number of current trips differs for each DTC.) |

(h) Check the details of the DTC(s).

CLEAR DTC (CONFIRMED DTC)

(a) Turn the ignition switch off.

(b) Connect the GTS to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the GTS on.

(e) Enter the following menus: Chassis / Brake Booster / Trouble Codes.

Chassis > Brake Booster > Clear DTCs(f) Enter the following menus: Chassis / Brake/EPB* / Trouble Codes.

*: Electric Parking Brake System

Chassis > Brake/EPB > Clear DTCs(g) Press the clear button.

- After clearing confirmed DTCs using the GTS, permanent DTCs can be cleared when the universal trip is performed and then the system is determined to be normal for the relevant DTCs. The driving pattern to obtain a normal judgment is described under the "Confirmation Driving Pattern" for the respective DTC.

-

To clear permanent DTCs, all of the following conditions must be are met:

- There is a history that universal trip driving was performed.

- The Toyota Prius vehicle has been judged as normal for 1trip.

- No malfunctions are detected.

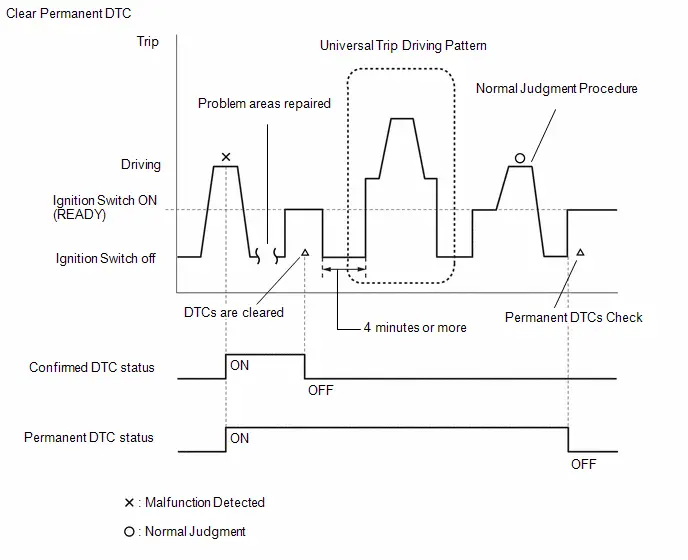

CLEAR PERMANENT DTC

NOTICE:

When performing the following procedure, make sure that the driver door is closed and is not opened at any time during the procedure.

(a) Turn the ignition switch off.

(b) Connect the GTS to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the GTS on.

(e) Enter the following menus: Chassis / Brake Booster / Trouble Codes.

Chassis > Brake Booster > Trouble CodesHINT:

If "PERMANENT" in the top right of the screen displays "YES", permanent DTCs are stored.

(f) Enter the following menus: Chassis / Brake/EPB* / Trouble Codes.

*: Electric Parking Brake System

Chassis > Brake/EPB > Trouble CodesHINT:

If "PERMANENT" in the top right of the screen displays "YES", permanent DTCs are stored.

(g) Select the "Generic" tab.

(h) Check if permanent DTCs are stored.

HINT:

If permanent DTCs are not output, it is not necessary to continue this procedure.

(i) Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

Chassis > Brake Booster > Clear DTCs Chassis > Brake/EPB > Clear DTCsNOTICE:

Do not clear the DTCs or disconnect the cable from the auxiliary battery terminal after performing this step.

(j) Turn the ignition switch off and wait for 4 minutes or more.

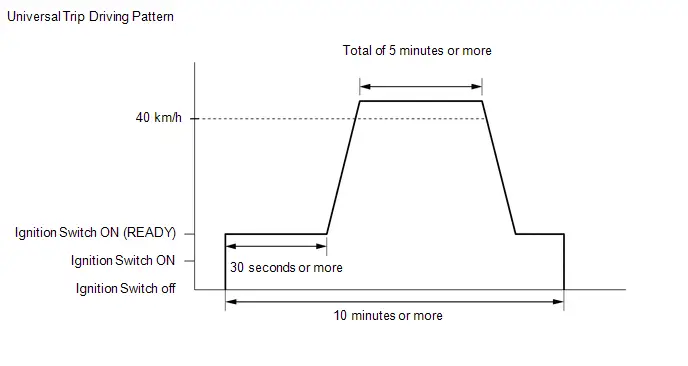

(k) Perform the universal trip.

HINT:

The driving pattern to obtain a normal judgment and the universal trip driving can be performed consecutively in the same driving cycle.

- Turn the ignition switch to ON (READY) and wait for 30 seconds or more.

-

With the engine running, drive the Toyota Prius vehicle at 40 km/h (25 mph) or more for a total of 5 minutes or more.

CAUTION:

When performing a driving pattern, obey all speed limits and traffic laws.

HINT:

It is possible to complete the drive pattern even if the vehicle decelerates to less than 40 km/h (25 mph) during the driving cycle provided that the Toyota Prius vehicle is driven at 40 km/h (25 mph) or more for a total of 5 minutes.

- Allow 10 minutes or more to elapse from the time the ignition switch turned to ON (READY).

(l) Turn the ignition switch off and wait for 4 minutes or more.

(m) Turn the ignition switch to ON (READY).

(n) Perform the normal judgment procedure in the respective confirmation driving pattern of each output DTC.

HINT:

Do not turn the ignition switch off by mistake during this step.

(o) With the ignition switch ON (READY) wait for 5 seconds or more. (Except when the ignition switch is already turned to ON (READY) or the engine is running)

(p) Turn the ignition switch off and wait for 4 minutes or more.

(q) Turn the ignition switch to ON (READY).

(r) Enter the following menus: Chassis / Brake Booster / Trouble Codes.

Chassis > Brake Booster > Trouble Codes(s) Enter the following menus: Chassis / Brake/EPB* / Trouble Codes.

*: Electric Parking Brake System

Chassis > Brake/EPB > Trouble Codes(t) Check that the permanent DTCs have been cleared.

Freeze Frame Data

FREEZE FRAME DATA

FREEZE FRAME DATA

(a) Using the GTS, check the vehicle condition (ECU, sensor) when a DTC is output.

CHECK FREEZE FRAME DATA WHEN DTC WAS STORED

(a) Freeze Frame Data is stored when a DTC is output.

(b) Once Freeze Frame Data is stored when a DTC is output, it is not updated or cleared until the DTC is cleared.

(c) Check the Freeze Frame Data when a DTC is output.

(1) Turn the ignition switch off.

(2) Connect the GTS to the DLC3.

(3) Turn the ignition switch to ON.

(4) Turn the GTS on.

(5) Enter the following menus: Chassis / Brake Booster / Trouble Codes.

Chassis > Brake Booster > Trouble Codes(6) Enter the following menus: Chassis / Brake/EPB* / Trouble Codes.

*: Electric Parking Brake System

Chassis > Brake/EPB > Trouble Codes(7) Select a DTC to display the Freeze Frame Data.

(8) Check the Freeze Frame Data for the output DTC.

Chassis > Brake Booster| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Total Distance Traveled - Unit | Total distance traveled unit | km / mile | - | - |

| Total Distance Traveled | Total distance traveled | Min.: 0 Max.: 16777215 | - | - |

| Solenoid Power Supply Voltage | Solenoid power supply voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| Stop Light SW | Stop light switch assembly (STP terminal input) | OFF / ON | OFF: Brake pedal released ON: Brake pedal depressed | HINT: The brake pedal state is determined using the voltage at terminal STP |

| Parking Brake SW | Parking brake status | OFF / ON | OFF: Parking brake released ON: Parking brake applied | - |

| Buzzer | Meter buzzer | OFF / ON | OFF: Buzzer off ON: Buzzer on | - |

| Dealer Mode | Dealer Mode (Signal Check mode or Calibration mode) status | OFF / ON | OFF: Normal mode ON: Dealer Mode (Signal Check mode or Calibration mode) | HINT:

|

| Reservoir Warning SW | Brake fluid level warning switch | OFF / ON | OFF: Reservoir level normal ON: Reservoir level low | - |

| ECB Solenoid (SGH) | Switching solenoid valve (SGH) | OFF / ON | OFF: Solenoid off ON: Solenoid on | ECB: Electronically Controlled Brake System |

| ECB Solenoid (SSA) | Switching solenoid valve (SSA) | OFF / ON | OFF: Solenoid off ON: Solenoid on | ECB: Electronically Controlled Brake System |

| IGP_PT2 | IGP_PT2 status | OFF / ON | OFF: IGP_PT2 OFF ON: IGP_PT2 ON | - |

| Stop Switch Open | Momentary interruption (open circuit) status in wire harness between No. 1 skid control ECU (brake booster with master cylinder assembly) and stop light switch assembly status | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Stroke Open | Brake pedal stroke sensor 1 open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Servo Pressure Sensor Open | Servo pressure sensor open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Gap Hold Chamber Pressure Sensor Open | Gap pressure sensor open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Stroke Sensor | Brake pedal stroke sensor 1 | Min.: 0.0 V Max.: 5.0 V | Brake pedal released: 0.6 to 1.4 V | Reading increases when brake pedal is depressed |

| Quantity of Brake Pedal Stroke | Brake pedal stroke amount | Min.: 0 mm Max.: 255 mm | Brake pedal released: 0 mm | Reading increases when brake pedal is depressed |

| Servo Pressure | Pressure value of servo | Min.: 0.00 MPa Max.: 24.48 MPa | 0.00 to 21.60 MPa | Brake pedal is being depressed: Changes in proportion to the depression force of the brake pedal Brake pedal released: 0.00 to 1.53 MPa |

| Voltage of Stroke Sensor | Voltage of brake pedal stroke sensor 1 | Min.: 0.0 V Max.: 5.0 V | - | - |

| Brake Pedal Stroke Change Speed | Brake pedal stroke rate of change | Min.: -2560 mm/s Max.: 2540 mm/s | Brake pedal released or depressed and held: 0 mm/s | Brake pedal is being moved: Changes in proportion to the operation speed of the brake pedal |

| Target Oil Pressure | Wheel target hydraulic pressure | Min.: 0.00 MPa Max.: 20.00 MPa | - | Changes according to the target wheel cylinder hydraulic pressure |

| VCSK Voltage Value | VCSK voltage value | Min.: 0.000 V Max.: 5.500 V | 4.800 to 5.200 V | - |

| SGH Solenoid Current | Switching solenoid valve (SGH) current | Min.: 0.000 A Max.: 3.000 A | 0.000 to 1.500 A | - |

| SSA Solenoid Current | Switching solenoid valve (SSA) current | Min.: 0.000 A Max.: 3.000 A | 0.000 to 1.500 A | - |

| The Number of Capacitor Operation | Displays the number of integration control supply operations | Min.: 0 Max.: 255 | - | - |

| Gap Hold Chamber Oil Pressure | Pressure value of stroke simulator | Min.: 0.00 MPa Max.: 24.48 MPa | Brake pedal released: 0.00 to 1.53 MPa | Brake pedal is being depressed: Changes in proportion to the depression force of the brake pedal |

| Gap Hold Chamber Oil Pressure Grade | Amount of change in stroke simulator oil pressure | Min.: -30 MPa/s Max.: 225 MPa/s | - | - |

| Linear Solenoid Current (SLM1) | Linear solenoid valve (SLM1) current | Min.: 0.000 A Max.: 1.500 A | Brake pedal released: 0 A | - |

| Linear Solenoid Current (SLM2) | Linear solenoid valve (SLM2) current | Min.: 0.000 A Max.: 1.500 A | Brake pedal released: 0 A | - |

| IGR Voltage | IGR voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| BS Voltage | BS voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| BM Voltage | BM voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| Zero point Calibrated Value of Phase U Current Monitor | Displays zero point calibrated value of phase U current monitor for brushless motor | Min.: -32.768 A Max.: 32.767 A | - | - |

| Zero point Calibrated Value of Phase V Current Monitor | Displays zero point calibrated value of phase V current monitor for brushless motor | Min.: -32.768 A Max.: 32.767 A | - | - |

| Zero point Calibrated Value of Phase W Current Monitor | Displays zero point calibrated value of phase W current monitor for brushless motor | Min.: -32.768 A Max.: 32.767 A | - | - |

| Thermistor1 Temperature for Inverter Circuit | Temperature of thermistor1 in inverter circuit | Min.: -327.68°C (-558°F) Max.: 327.67°C (622°F) | - | - |

| Thermistor2 Temperature for Inverter Circuit | Temperature of thermistor2 in inverter circuit | Min.: -327.68°C (-558°F) Max.: 327.67°C (622°F) | - | - |

| Brushless Motor Inverter end Voltage | Inverter end voltage for brushless motor | Min.: 0.00 V Max.: 655.35 V | - | Changes in proportion to auxiliary battery voltage |

| Brushless Motor Required Rotation Speed (with Rotation Angle Sensor) | Requested brushless motor rotation speed | Min.: -32768 rpm Max.: 32767 rpm | Brake pedal released: 0 rpm | - |

| Brushless Motor Actual Rotation Speed (with Rotation Angle Sensor) | Actual brushless motor rotation speed | Min.: -32768 rpm Max.: 32767 rpm | Brake pedal released: 0 rpm | - |

| Brushless Motor Operation Status (with Rotation Angle Sensor) | Operation status of brushless motor | Abnormal / Stop / Synchronization drive / Extended Induced voltage | - | - |

| Down Stream Voltage Solenoid Relay | Solenoid relay downstream voltage | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| CBKP Voltage | CBKP voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

-

*1: for performing Dealer Mode (Signal Check): Click here

-

*2: for entering Dealer Mode (Calibration): Click here

| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Total Distance Traveled - Unit | Total distance traveled unit | km / mile | - | - |

| Total Distance Traveled | Total distance traveled | Min.: 0 Max.: 16777215 | - | - |

| FR Wheel Speed | Front wheel speed sensor RH reading | Min.: 0.0 km/h (0 mph) Max.: 6553.5 km/h (4072 mph) | Toyota Prius Vehicle stopped: 0.0 km/h (0 mph) | When driving at constant speed: No large fluctuations |

| FL Wheel Speed | Front wheel speed sensor LH reading | Min.: 0.0 km/h (0 mph) Max.: 6553.5 km/h (4072 mph) | Toyota Prius Vehicle stopped: 0.0 km/h (0 mph) | When driving at constant speed: No large fluctuations |

| RR Wheel Speed | Rear wheel speed sensor RH reading | Min.: 0.0 km/h (0 mph) Max.: 6553.5 km/h (4072 mph) | Toyota Prius Vehicle stopped: 0.0 km/h (0 mph) | When driving at constant speed: No large fluctuations |

| RL Wheel Speed | Rear wheel speed sensor LH reading | Min.: 0.0 km/h (0 mph) Max.: 6553.5 km/h (4072 mph) | Toyota Prius Vehicle stopped: 0.0 km/h (0 mph) | When driving at constant speed: No large fluctuations |

| Master Cylinder Sensor 1 | Master cylinder pressure sensor pressure (value detected by ECU) | Min.: -1.00 MPa Max.: 23.99 MPa | Brake pedal released: -1.00 to 0.00 MPa | Reading increases when brake pedal is depressed |

| Master Cylinder Sensor Temperature | Master cylinder pressure sensor temperature | Min.: -80°C (-112°F) Max.: 175°C (347°F) | Current master cylinder pressure sensor temperature | - |

| M/C Sensor Grade | Master cylinder pressure sensor change (value detected by ECU) | Min.: -30 MPa/s Max.: 225 MPa/s | Brake pedal released or pedal held at constant position: 0 MPa/s | When brake pedal is being operated: Changes in proportion with the pedal movement speed |

| Lateral G | Lateral G | Min.: -25.105 m/s2 Max.: 24.908 m/s2 | Turning right: -25.105 to 0.000 m/s2 Turning left: 0.000 to 24.908 m/s2 | During turning: Changes in proportion with lateral acceleration |

| Forward and Rearward G | Forward and rearward G | Min.: -25.105 m/s2 Max.: 24.908 m/s2 | During deceleration: -25.105 to 0.000 m/s2 During acceleration: 0.000 to 24.908 m/s2 | During acceleration/deceleration: Changes in proportion with acceleration |

| Yaw Rate Sensor Value | Yaw rate sensor value | Min.: -128°/s Max.: 127°/s | Toyota Prius Vehicle stopped: 0°/s Turning right: -128 to 0°/s Turning left: 0 to 127°/s | - |

| Steering Angle Value | Steering angle sensor value | Min.: -3276.8° Max.: 3276.7° | Turning left: 0.0 to 3276.7° Turning right: -3276.8 to 0.0° | - |

| Zero Point of Steering Angle | Zero point of steering angle | Min.: -3276.8° Max.: 3276.7° | - | - |

| MT Voltage Value | ABS motor drive voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage HINT: This is the voltage downstream of the ABS motor as monitored by the No. 2 skid control ECU (brake actuator assembly) |

| Solenoid Power Supply Voltage | Solenoid power supply voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage HINT: This is the voltage output (which supplies power to each solenoid) from the No. 2 skid control ECU (brake actuator assembly) to the ABS solenoid relay |

| Accelerator Opening Angle % | Percentage of accelerator pedal opening angle | Min.: 0.0% Max.: 127.5% | Accelerator pedal released: 0.0% | During accelerator pedal operation: Changes in proportion with the pedal movement |

| Shift Lever Position | Shift position information | fail / 1st / 2nd / 3rd / 4th / 5th / 6th / B / D/M / N / P / R / No input | Actual shift position | - |

| TRC(TRAC)/VSC OFF Mode | TRAC/VSC off mode | Normal mode (TRC(TRAC) ON/VSC ON) / TRC(TRAC) OFF mode (TRC(TRAC) OFF/VSC ON) / VSC expert mode (VSC expert mode MID ON) / VSC OFF mode (TRC(TRAC) OFF/VSC OFF) | Normal mode (TRC(TRAC) ON/VSC ON): Normal mode TRC(TRAC) OFF mode (TRC(TRAC) OFF/VSC ON): TRAC off mode VSC expert mode (VSC expert mode MID ON): VSC expert mode VSC OFF mode (TRC(TRAC) OFF/VSC OFF): VSC off mode | - |

| Brake Hold Control Mode | Brake hold control mode | Out of control mode / Pressure hold mode / Pressure release mode / EPB lock mode | Out of control mode: Brake hold control system is off or brake hold control system is stand-by mode (brake hold standby indicator light is illuminated) Pressure hold mode: Brake hold control is operating (brake hold operated indicator light is illuminated) Pressure release mode: Brake hold control is released (brake hold operated indicator light not illuminated) EPB lock mode: Parking brake is engaged during brake hold control | HINT:

|

| FR Target Oil Pressure | Front wheel RH target oil pressure | Min.: 0.0 MPa Max.: 20.0 MPa | - | Different according to target oil pressure of each wheel |

| FL Target Oil Pressure | Front wheel LH target oil pressure | Min.: 0.0 MPa Max.: 20.0 MPa | - | Different according to target oil pressure of each wheel |

| RR Target Oil Pressure | Rear wheel RH target oil pressure | Min.: 0.0 MPa Max.: 20.0 MPa | - | Different according to target oil pressure of each wheel |

| RL Target Oil Pressure | Rear wheel LH target oil pressure | Min.: 0.0 MPa Max.: 20.0 MPa | - | Different according to target oil pressure of each wheel |

| Toyota Prius Vehicle Speed | Vehicle speed (estimated vehicle speed used for various controls) | Min.: 0.0 km/h (0 mph) Max.: 6553.5 km/h (4072 mph) | Vehicle stopped: 0.0 km/h (0 mph) | When driving at constant speed: No large fluctuations |

| Toyota Prius Vehicle Speed Grade | Vehicle acceleration/deceleration | Min.: -25.105 m/s2 Max.: 24.908 m/s2 | Vehicle stopped: 0.000 m/s2 During deceleration: -25.105 to 0.000 m/s2 During acceleration: 0.000 to 24.908 m/s2 | During driving: Changes in proportion with Toyota Prius vehicle acceleration/deceleration |

| Vehicle Stop Time from IG ON | Time vehicle stopped after ignition switch turned to ON | Min.: 0 s Max.: 1275 s | - | - |

| Travel Distance from IG ON | Driving time after ignition switch turned to ON | Min.: 0 s Max.: 1275 s | - | - |

| Stop Light SW | Stop light switch assembly status (STP or STP2 terminal input) | OFF / ON | OFF: Brake pedal released ON: Brake pedal depressed | HINT:

|

| Parking Brake SW | Parking brake status | OFF / ON | OFF: Parking brake released ON: Parking brake applied | - |

| Brake Hold Switch | Brake hold switch (electric parking brake switch assembly) (BH terminal input) | OFF / ON | OFF: Brake hold switch (electric parking brake switch assembly) OFF ON: Brake hold switch (electric parking brake switch assembly) ON | HINT: The brake hold switch (electric parking brake switch assembly) state is determined using the voltage at terminal BH |

| Stop Light Relay | Stop light control relay (stop light switch assembly) status (STP terminal input) | OFF / ON | OFF: Stop light control relay (stop light switch assembly) off and brake pedal released ON: Stop light control relay (stop light switch assembly) on or brake pedal depressed | HINT: The voltage of power supplied to the stop lights is measured at the STP terminal. |

| Inspection Mode | Inspection mode | OFF / ON | OFF: Normal mode ON: Inspection mode | - |

| TRC(TRAC) Control | TRAC control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| TRC(TRAC) Engine Control | TRAC throttle control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| TRC(TRAC) Brake Control | TRAC brake control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| FR Wheel VSC Ctrl Status | Front wheel RH VSC control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| FL Wheel VSC Ctrl Status | Front wheel LH VSC control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| RR Wheel VSC Ctrl Status | Rear wheel RH VSC control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| RL Wheel VSC Ctrl Status | Rear wheel LH VSC control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| FR Wheel ABS Ctrl Status | Front wheel RH ABS control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| FL Wheel ABS Ctrl Status | Front wheel LH ABS control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| RR Wheel ABS Ctrl Status | Rear wheel RH ABS control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| RL Wheel ABS Ctrl Status | Rear wheel LH ABS control status | Out of controlling / Under Controlling | Out of controlling: Not during control Under Controlling: During control | - |

| BA Ctrl Status | BA control status | OFF / ON | OFF: Not during control ON: During control | - |

| PBA Ctrl Status | PBA control status | OFF / ON | OFF: Not during control ON: During control | - |

| Stop Light Relay State for ECU Control | Stop light control relay (stop light switch assembly) status (STPO terminal output) (for ECU control) | OFF / ON | OFF: Stop light control relay (stop light switch assembly) off (Stop light off) ON: Stop light control relay (stop light switch assembly) on (Stop light on) | - |

| Solenoid State for ECU Control | ABS solenoid relay status (for ECU control) | OFF / ON | OFF: ABS solenoid relay not operating ON: ABS solenoid relay operating | - |

| Motor State for ECU Control | ABS motor relay status (for ECU control) | OFF / ON | OFF: ABS motor relay not operating ON: ABS motor relay operating | - |

| Buzzer | Meter buzzer | OFF / ON | OFF: Buzzer off ON: Buzzer on | - |

| Dealer Mode | Dealer Mode (Signal Check mode or Calibration mode) status | OFF / ON | OFF: Normal mode ON: Dealer Mode (Signal Check mode or Calibration mode) | HINT:

|

| Zero Point Memory State of Steering Angle Sensor | Steering angle sensor zero point memorization status | Zero point is not memorized / Zero point is memorized | - | HINT: The steering angle sensor zero point is acquired when the Toyota Prius vehicle is being driven in a straight line at a speed of 35 km/h (22 mph) or more for approximately 5 seconds. |

| Regenerative Cooperation | Regenerative cooperation | OFF / ON | OFF: Not operating ON: Operating | - |

| TRC(TRAC)/VSC OFF SW | VSC OFF switch (electric parking brake switch assembly) (CSW terminal input) | OFF / ON | OFF: VSC OFF switch (electric parking brake switch assembly) OFF ON: VSC OFF switch (electric parking brake switch assembly) ON | HINT: The VSC OFF switch (electric parking brake switch assembly) state is determined using the voltage at terminal CSW |

| IGP_PT2 | IGP_PT2 status | OFF / ON | OFF: IGP_PT2 OFF ON: IGP_PT2 ON | - |

| FR Wheel | Front right wheel rotation direction | Forward / Back | When driving forward: forward When reversing: Back | - |

| FL Wheel | Front left wheel rotation direction | Forward / Back | When driving forward: forward When reversing: Back | - |

| RR Wheel | Rear right wheel rotation direction | Forward / Back | When driving forward: forward When reversing: Back | - |

| RL Wheel | Rear left wheel rotation direction | Forward / Back | When driving forward: forward When reversing: Back | - |

| FR Speed Open | Front speed sensor RH open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| FL Speed Open | Front speed sensor LH open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| RR Speed Open | Rear speed sensor RH open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| RL Speed Open | Rear speed sensor LH open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Yaw Rate Open | Yaw rate sensor (airbag ECU assembly) open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Deceleration Open | Acceleration sensor (airbag ECU assembly) open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Steering Open | Steering angle sensor open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Master Cylinder Open | Master cylinder pressure sensor open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| FR Speed Sensor Voltage Open | Front speed sensor RH voltage open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| FL Speed Sensor Voltage Open | Front speed sensor LH voltage open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| RR Speed Sensor Voltage Open | Rear speed sensor RH voltage open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| RL Speed Sensor Voltage Open | Rear speed sensor LH voltage open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| M/C Pressure Sensor Noise | Master cylinder pressure sensor noise detection | Normal / Under intermittent | Normal: Noise is not detected Under intermittent: Noise is detected | - |

| Yaw Rate Sensor Voltage Open | Yaw rate sensor (airbag ECU assembly) voltage open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Master Cylinder Pressure Sensor Power Supply Open | Master cylinder pressure sensor power supply voltage status | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Solenoid Power Supply Open | Solenoid power supply voltage status | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Motor Power Supply Open | Motor power supply voltage status | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Stop Switch Open | Momentary interruption (open circuit) status in wire harness between No. 2 skid control ECU (brake actuator assembly) and stop light switch assembly status | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| A/C ECU Communication Open | Air conditioning amplifier assembly communication open detection | Normal / Under intermittent | Normal: Momentary interruption not detected Under intermittent: Momentary interruption detected | - |

| Air Bag ECU Communication Open | Airbag ECU assembly open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Stroke2 Open | Brake pedal stroke sensor 2 open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| HV Communication Open | Hybrid Toyota Prius vehicle control ECU communication open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Body ECU Communication Open | Main body ECU (multiplex network body ECU) communication open detection | Normal / Under intermittent | Normal: Normal Under intermittent: Momentary interruption | - |

| Brake Hold Ready | Brake hold control permission status | Not in stand-by mode / Stand-by mode | Not in stand-by mode: Brake hold function not operating (brake hold standby indicator light not illuminated) Stand-by mode: Brake hold function stand-by state (brake hold standby indicator light illuminated) | - |

| Stroke Sensor2 | Brake pedal stroke sensor 2 | Min.: 0.0 V Max.: 5.0 V | Brake pedal released: 3.6 to 4.4 V | Reading decreases when brake pedal is depressed |

| Quantity of Brake Pedal Stroke | Brake pedal stroke amount | Min.: 0 mm Max.: 255 mm | Brake pedal released: 0 mm | Reading increases when brake pedal is depressed |

| Voltage of Stroke Sensor2 | Voltage of brake pedal stroke sensor 2 | Min.: 0.0 V Max.: 5.0 V | - | - |

| FR Regenerative Request | FR regenerative request torque | Min.: 0 Nm Max.: 1048560 Nm | - | Changes according to brake pedal force (When depressing the brake pedal lightly after reaching 30 km/h (19 mph) or more, avoiding sudden braking.) |

| FR Regenerative Operation | FR regenerative operation torque | Min.: 0 Nm Max.: 1048560 Nm | - | Changes according to brake pedal force (When depressing the brake pedal lightly after reaching 30 km/h (19 mph) or more, avoiding sudden braking.) |

| Brake Pedal Stroke Change Speed | Brake pedal stroke rate of change | Min.: -2560 mm/s Max.: 2540 mm/s | Brake pedal released or depressed and held: 0 mm/s | Brake pedal is being moved: Changes in proportion to the operation speed of the brake pedal |

| VCSK Voltage Value | VSK2 voltage value | Min.: 0.000 V Max.: 5.500 V | 4.800 to 5.200 V | - |

| IGR Voltage | IG1 voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| BS Voltage | BS voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| BM Voltage | BM voltage value | Min.: 0.0 V Max.: 25.5 V | - | Changes in proportion to auxiliary battery voltage |

| Voltage Difference between Motor Input-Output Terminal | Voltage difference between motor input-output terminal | Min.: -640.00 V Max.: 639.98 V | - | - |

| Yaw Rate Sensor 1 Higher Resolution Signal | Yaw rate sensor 1 higher resolution signal | Min.: -327.68 deg/sec Max.: 327.67 deg/sec | Turning right: -327.68 to 0.00 deg/sec Turning left: 327.68 to 0.00 deg/sec | - |

| Yaw Rate Sensor 2 Higher Resolution Signal | Yaw rate sensor 2 higher resolution signal | Min.: -327.68 deg/sec Max.: 327.67 deg/sec | Turning right: -327.68 to 0.00 deg/sec Turning left: 327.68 to 0.00 deg/sec | - |

| GL1 GX Sensor Higher Resolution Signal | GL1 GX sensor higher resolution signal | Min.: -32768 mG Max.: 32767 mG | During deceleration: -32768 to 0 mG During acceleration: 0 to 32767 mG | - |

| GL2 GY Sensor Higher Resolution Signal | GL2 GY sensor higher resolution signal | Min.: -32768 mG Max.: 32767 mG | Turning right: -32768 to 0 mG Turning left: 0 to 32767 mG | - |

| Brakes Specifications Change by C-BEST | Brakes specifications change by C-BEST | None / Exist | - | - |

| SLM2 Refresh Drive Completed Status | Linear solenoid (SLM2) refresh complete/incomplete | Not Complete / Complete | Complete: Linear solenoid (SLM2) refresh complete Not complete: Linear solenoid (SLM2) refresh incomplete | - |

-

*1: for performing Dealer Mode (Signal Check): Click here

-

*2: for entering Dealer Mode (Calibration): Click here

CLEAR FREEZE FRAME DATA

NOTICE:

Clearing the DTCs will also clear the Freeze Frame Data.

(a) Turn the ignition switch off.

(b) Connect the GTS to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the GTS on.

(e) Enter the following menus: Chassis / Brake Booster / Trouble Codes.

Chassis > Brake Booster > Clear DTCs(f) Enter the following menus: Chassis / Brake/EPB* / Trouble Codes.

*: Electric Parking Brake System.

Chassis > Brake/EPB > Clear DTCs(g) Press the clear button.

Signal Check

SIGNAL CHECK

SENSOR CHECK USING DEALER MODE (SIGNAL CHECK)

NOTICE:

- After performing "Calibration", perform a master cylinder pressure sensor check.

- After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

- After replacing or removing and installing a speed sensor rotor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

HINT:

- Signals related to the electronically controlled brake system can be inspected by performing a Dealer Mode (Signal Check) inspection. During the inspection, the display of items determined normal by the skid control ECU changes from incomplete to complete.

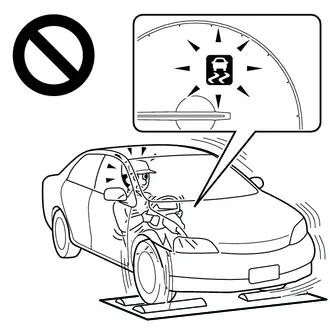

- During Dealer Mode (Signal Check), the VSC and TRAC do not operate regardless of whether the system is normal or a malfunction is detected.

- If a sensor is malfunctioning, ABS does not operate and the ABS warning light, brake system warning light (yellow indicator) and slip indicator light illuminate.

-

Even during Dealer Mode (Signal Check), if there is a system malfunction that causes brake hold control to be prohibited, when the Toyota Prius vehicle is under the following conditions and the brake hold switch (electric parking brake switch assembly) is turned on, the brake hold operated indicator light blinks.

-

Vehicle Conditions:

- The driver door is closed.

- The driver seat belt is fastened.

-

Vehicle Conditions:

(a) Procedure to Enter Dealer Mode (Signal Check)

(1) Turn the ignition switch off.

(2) Check that the steering wheel is centered.

(3) Check that park (P) is selected.

(4) Connect the GTS to the DLC3.

(5) Turn the ignition switch to ON.

(6) Turn the GTS on.

(7) Switch the skid control ECU to Dealer Mode (Signal Check) using the GTS. Enter the following menus: Chassis / Brake/EPB* / Utility / Signal Check.

*: Electric Parking Brake System

Chassis > Brake/EPB > Utility| Tester Display |

|---|

| Signal Check |

(b) Confirm the system has entered Dealer Mode (Signal Check)

(1) Confirm that the ABS warning light, brake system warning light (yellow indicator) and slip indicator light indicate the Dealer Mode pattern (blinking at 0.25 second intervals).

HINT:

- When in Dealer Mode (signal check), "Traction Control Turned OFF" is displayed on the multi-information display.

- When entering Dealer Mode (Signal Check), if the parking brake is engaged, the parking brake indicator light (red) will illuminate, and if the parking brake is not engaged, the parking brake indicator light (red) will blink in the Dealer Mode pattern (blinking at 0.25 second intervals).

(c) Master Cylinder Pressure Sensor Check

(1) With the Toyota Prius vehicle stopped, release the brake pedal for 1 second or more and check that the value of Dealer Mode (Signal Check) Inspection Item "Output in Master Cylinder Pressure Sensor" changes from incomplete to complete.

HINT:

- The status of the ABS warning light, brake system warning light (yellow indicator) and slip indicator light will not change.

- If the master cylinder pressure sensor is normal and the above step is performed when in Dealer Mode (Signal Check), the master cylinder pressure sensor check will complete normally.

(d) Speed Sensor Check

NOTICE:

Before performing the speed sensor check, complete the master cylinder pressure sensor check.

(1) Turn the ignition switch to ON (READY).

(2) With the steering wheel held straight, accelerate the Toyota Prius vehicle to a speed of 45 km/h (28 mph) or more without spinning the wheels.

(3) Accelerating to a vehicle speed of 3 km/h (2 mph) or more, drive the vehicle in reverse for 1 second or more.

(4) Check that the ABS warning light goes off.

NOTICE:

- If the sensor check does not complete successfully or a malfunctioning sensor is detected, the ABS warning light indicates the Dealer Mode pattern (blinking at 0.25 second intervals) and the ABS system will not operate.

- If the Toyota Prius vehicle is driven at 80 km/h (50 mph) or more after the ABS warning light turns off, the speed sensor check will be performed again. In this situation, the ABS warning light will start blinking again.

- The speed sensor check may not complete if the speed sensor check is started while turning the steering wheel or spinning the wheels.

(5) Stop the Toyota Prius vehicle.

(e) End of Sensor Check

(1) If the sensor check completes successfully, the ABS warning light turns off when the vehicle is being driven, and indicates the Dealer Mode pattern (blinking at 0.25 second intervals) when the vehicle is stopped.

NOTICE:

- When all Dealer Mode (Signal Check) Inspection Items are complete, the sensor check is complete.

- If the sensor checks have not completed, the ABS warning light will remain blinking while the Toyota Prius vehicle is being driven, and the ABS will not operate.

- If any malfunctions are detected during Dealer Mode (Signal Check), the ABS warning light, brake system warning light (yellow indicator) or slip indicator light remains illuminated.

- If any DTCs are output or if Dealer Mode (Signal Check) Inspection Items do not complete even after repeated attempts, repair or replace the malfunctioning part.

(f) End of Dealer Mode (Signal Check)

(1) Turn the ignition switch off.

(2) Disconnect the GTS.

(g) Dealer Mode (Signal Check) Inspection Item Chart

| Item Name | Range | Judgment Description | Trouble Area |

|---|---|---|---|

| Output Signal of Front Speed Sensor RH | Incomplete/complete |

|

|

| Output Signal of Front Speed Sensor LH | Incomplete/complete |

|

|

| Output Signal of Rear Speed Sensor RH | Incomplete/complete |

|

|

| Output Signal of Rear Speed Sensor LH | Incomplete/complete |

|

|

| Change in Output Signal of Front Speed Sensor RH | Incomplete/complete | Check the stability of the sensor input waveform |

|

| Change in Output Signal of Front Speed Sensor LH | Incomplete/complete | Check the stability of the sensor input waveform |

|

| Change in Output Signal of Rear Speed Sensor RH | Incomplete/complete | Check the stability of the sensor input waveform |

|

| Change in Output Signal of Rear Speed Sensor LH | Incomplete/complete | Check the stability of the sensor input waveform |

|

| Output in Master Cylinder Pressure Sensor | Incomplete/complete | Evaluate the master cylinder pressure sensor zero point voltage |

|

| Learning of Stroke Sensor Zero Point | Incomplete/complete | Check the stroke sensor zero point output value |

|

Fail-safe Chart

FAIL-SAFE CHART

FAIL-SAFE FUNCTION OF CONTROL SYSTEM

(a) When a malfunction is detected in the electronically controlled brake system, the skid control ECU turns the ABS warning light, brake system warning light (red indicator), brake system warning light (yellow indicator) and slip indicator light on, flashes the brake hold operated indicator light*, as well as prohibits ABS, BA, TRAC, VSC, secondary collision brake and brake hold operation.

-

*: The brake hold switch (electric parking brake switch assembly) is turned on under the following Toyota Prius vehicle conditions.

-

Vehicle Conditions:

- The driver door is closed.

- The driver seat belt is fastened.

-

Vehicle Conditions:

HINT:

When a component of the electronically controlled brake system is in fail-safe mode, operation is prohibited. However, if the system enters fail-safe mode while braking is being controlled, control is gradually suspended to prevent sudden changes in Toyota Prius vehicle behavior.

(b) If the skid control ECU detects that a system related to the hybrid control system is malfunctioning, it will prohibit operation of the TRAC and VSC systems in order to prevent further malfunctions and to protect the systems.

(c) If a malfunction in the electronically controlled brake system, electric parking brake system or hybrid control system is detected, control by the brake hold function is prohibited to prevent undesired operation and to protect the system.

HINT:

When control by the brake hold system is prohibited, the brake hold switch (electric parking brake switch assembly) is on and the following conditions are met, the brake hold operated indicator light will blink.

-

Toyota Prius Vehicle conditions:

- The driver door is closed.

- The driver seat belt is fastened.

(d) If the skid control ECU detects that a system related to the airbag system is malfunctioning, it will prohibit operation of the secondary collision brake in order to prevent further malfunctions and to protect the systems.

| Item | Operation |

|---|---|

|

*1: Only during brake hold control

*2: The systems for which control is prohibited differ depending on the status of the malfunction. | |

| Malfunction in the ABS. | ABS, BA, TRAC and VSC control prohibited. Brake hold control prohibited.*1 |

| Malfunction in the BA system. | ABS, BA, TRAC and VSC control prohibited. Brake hold control prohibited.*1 |

| Malfunction in the EBD system. | ABS, EBD, BA, TRAC and VSC control prohibited. Brake hold control prohibited.*1 |

| Malfunction in the TRAC system. | ABS, BA, TRAC and VSC control prohibited.*2 Brake hold control prohibited.*1 |

| Malfunction in the VSC system. | ABS, BA, TRAC and VSC control prohibited.*2 Brake hold control prohibited.*1 |

FAIL-SAFE FUNCTION OF HYDRAULIC SYSTEM

(a) If a skid control ECU or brake fluid control component malfunctions or the brake fluid pressure supply stops, the system performs the following fail-safe operations:

| Item | Operation |

|---|---|

| A function controlled by No. 1 skid control ECU (brake booster with master cylinder assembly) stops working. | No. 2 skid control ECU (brake actuator assembly) generates braking force. |

| A function controlled by No. 2 skid control ECU (brake actuator assembly) stops working. | No. 1 skid control ECU (brake booster with master cylinder assembly) generates braking force. |

| A brake fluid pressure control component inside the brake booster with master cylinder assembly or brake actuator assembly stops working. | Braking force solely generated by the driver. |

| The brake fluid pressure supply to the brake booster with master cylinder assembly and brake actuator assembly stops. | Braking force solely generated by the driver. |

Data List / Active Test

DATA LIST / ACTIVE TEST

DATA LIST

NOTICE: