Toyota Prius: Electronic Shift Lever System

- Precaution

- Parts Location

- System Diagram

- How To Proceed With Troubleshooting

- Utility

- Problem Symptoms Table

- Terminals Of Ecu

- Freeze Frame Data

- Fail-safe Chart

- Data List / Active Test

- VEHICLE CONTROL HISTORY (RoB)

- Park/Neutral Switch Circuit Short to Ground (P085011,P085015)

- Gear Shift Control Module "A" System Internal Failure (P085D04)

- Gear Shift Control Module "A" Unexpected Operation (P085D94)

- Gear Lever Position Sensor Signal Compare Failure (P08A662)

- Gear Shift Position Circuit "A" Range/Performance Signal Cross Coupled (P09142B)

- Fail Safe Signal (Gear Shift Control Module "B" to "A") No Signal (P175231)

- Lost Communication with Gear Shift Control Module "B" (Local-CAN) Missing Message (P175387)

- Gear Shift Control Module "A" System Voltage Low (P1761A2)

- Sub Battery Module System Voltage Low (P1765A2)

- Gear Shift Control Module "A" A/D Processing Performance (P176900)

- IG2 Signal (Gear Shift Control Module "A") Circuit Short to Auxiliary Battery (P176D12)

- Gear Shift Control Module "B" System Voltage Low (P1771A2)

- Sub Battery Module (Gear Shift Control Module "B") System Voltage Low (P1775A2)

- Gear Shift Control Module Backup Power Supply Internal Electronic Failure (P177949)

- Lost Communication with Gear Shift Control Module Backup Power Supply Missing Message (P177A87)

- Lost Communication with Gear Shift Control Module "A" from "B" Missing Message (P178987)

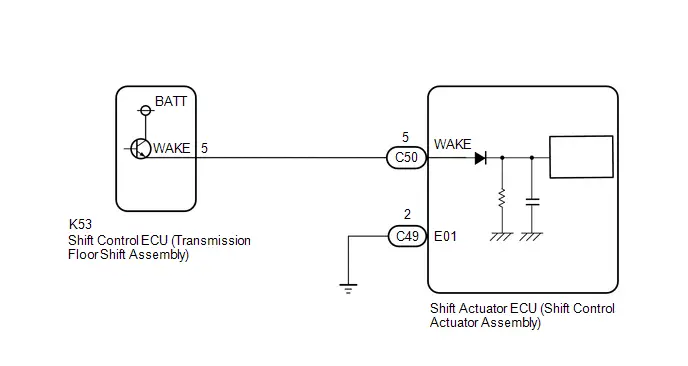

- Gear Shift Control Module "B" Wake-up Circuit Short to Ground or Open (P178A14)

- Gear Shift Actuator "A" Supply Voltage "A" Circuit Short to Ground or Open (P179014)

- Gear Shift Actuator "A" Supply Voltage "B" Circuit Short to Ground or Open (P179314)

- Gear Shift Actuator "A" Control Circuit Internal Electronic Failure (P179C49)

- Gear Shift Actuator "A" Performance (P179E00)

- Gear Shift Control Module "A"/"B" IGCT Signal Compare Failure (P18A762)

- Gear Shift Control Module "A"/"B" IGCT-Scene Signal Compare Failure (P18A862)

- Gear Shift Control Module "B" EPBT Circuit Short to Battery (P18AF12)

- Gear Shift Control Module "B" Motor Angle Sensor "A" Performance (P18B200)

- Gear Shift Control Module "B" Motor Temperature Sensor "A" Circuit Voltage Out of Range (P18B31C)

- Gear Shift Actuator "A" Phase U-V-W Current Sensor Signal Compare Failure (P18B562)

- Gear Lever Position Sensor "A" Signal Plausibility Failure (P2E0064,P2E0464,P2E0864)

- Lost Communication with Body Control Module (Sub) Missing Message (U014000,...,U117000)

- Lost Communication with Gear Shift Control Module "B" (System 2) Missing Message (U029100)

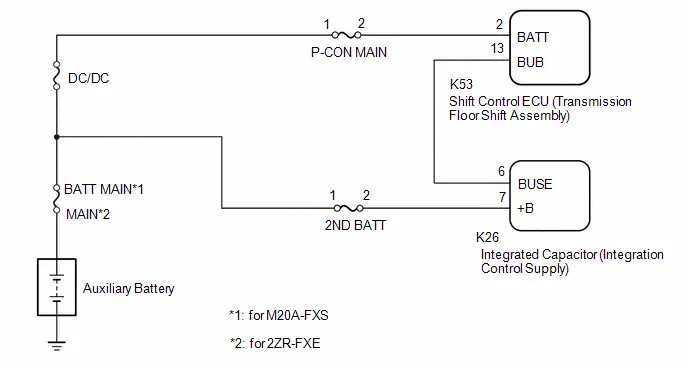

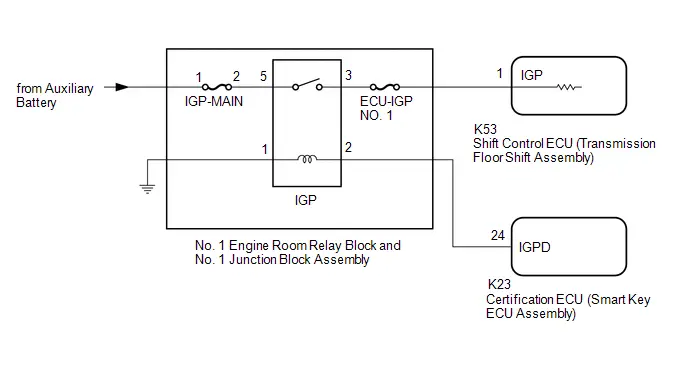

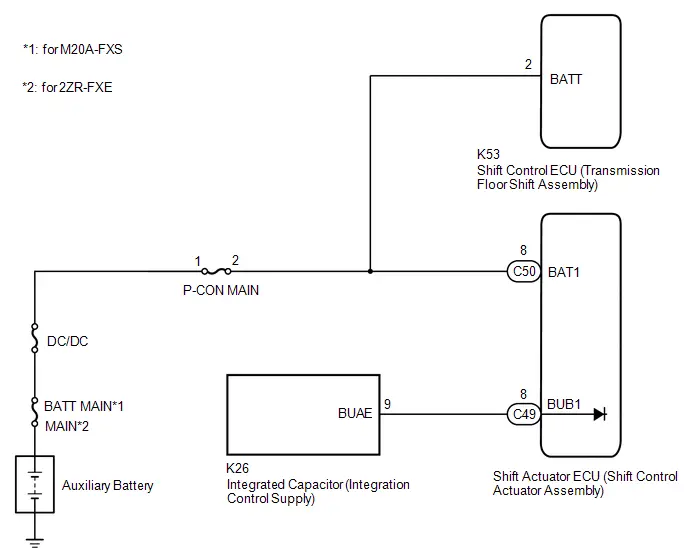

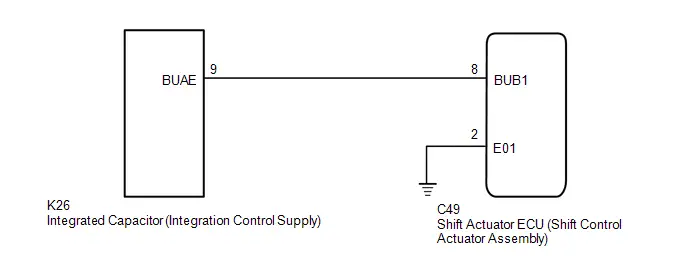

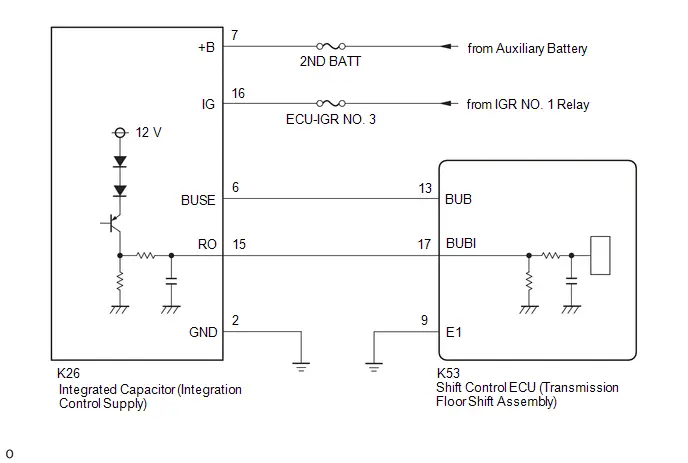

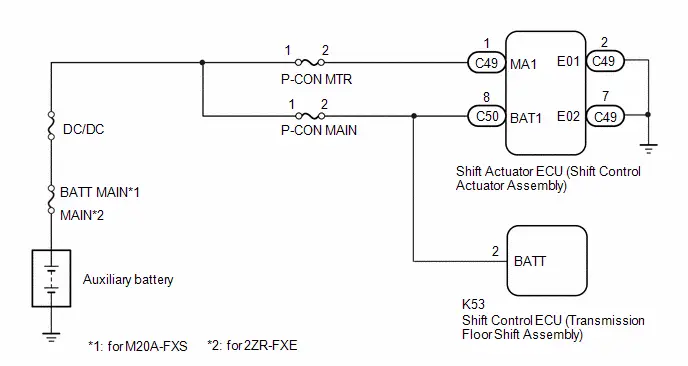

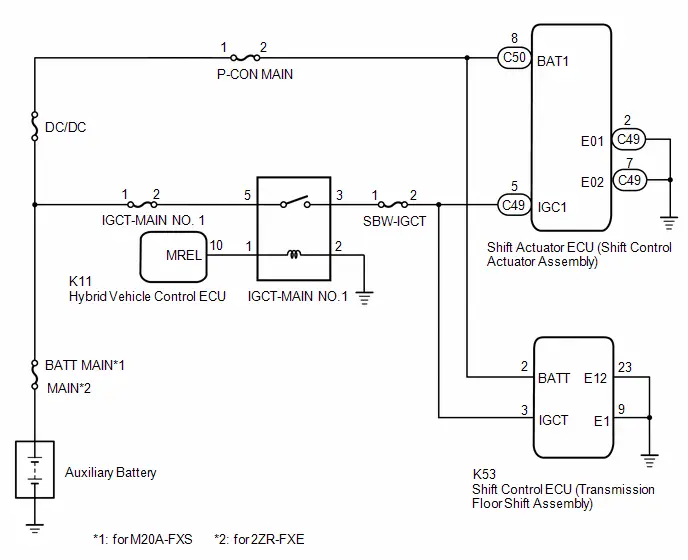

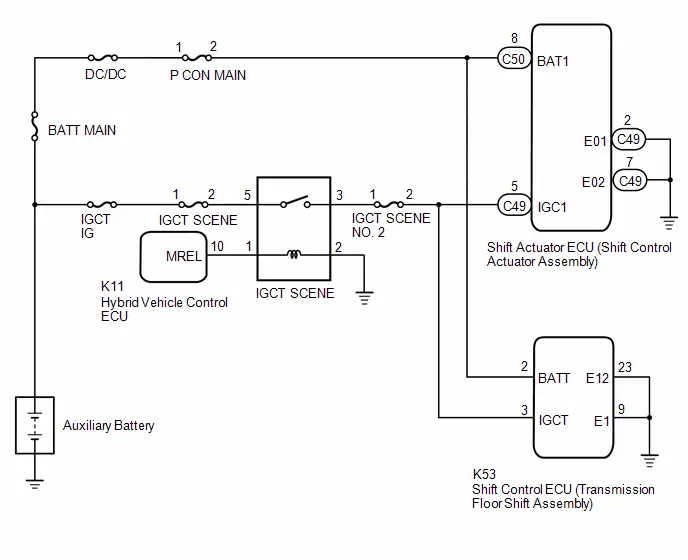

- ECU Power Source Circuit

Precaution

PRECAUTION

PRECAUTIONS FOR DISCONNECTING AND RECONNECTING CABLE TO NEGATIVE (-) AUXILIARY BATTERY TERMINAL

NOTICE:

- After the ignition switch is turned off, there may be a waiting time

before disconnecting the negative (-) auxiliary battery terminal.

Click here

- When disconnecting and reconnecting the auxiliary battery

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

PRECAUTION FOR INSPECTING ELECTRONIC SHIFT LEVER SYSTEM

(a) As the shift control ECU and shift actuator ECU do not immediately shutdown after the ignition switch is turned off, if the ignition switch is cycled within a short time, the ECUs may not shutdown. After turning the ignition switch off, wait approximately 1 minute or more for the shift control ECU and shift actuator ECU to completely shut down before connecting the GTS, opening/closing a door or operating a pedal.

(b) If the shift state cannot be changed from P, the auxiliary battery voltage may be low.

(c) If the electronic shift lever system has been damaged due to a flood, etc., the shift state will not be able to be changed to or from P. When the shift state cannot be changed from P to any other state, the parking lock is engaged. Therefore, make sure to release the parking lock manually before towing the Toyota Prius vehicle.

for PA10

for PB10, PB12

(d) If the electronic shift lever system is damaged, the ignition switch may not be able to be turned off with the ignition switch off operation. In this case, the ignition switch may be changed to off by operating the parking brake.

(e) Do not turn the ignition switch off when towing the Toyota Prius vehicle. Turning the ignition switch off may result in engagement of the parking lock which locks the drive wheels, resulting in a hazardous situation or accident.

(f) Check that the shift state is P and the parking brake is engaged before disconnecting the cable from the negative (-) auxiliary battery terminal.

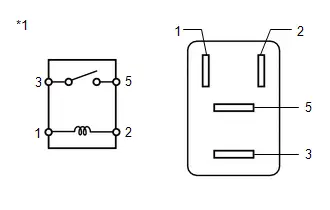

(g) When removing or installing the shift control ECU or shift actuator ECU, make sure there is no power supplied*1 when disconnecting or connecting the connectors.

*1: Auxiliary battery, Bub-battery, Integrated capacitor, etc.

PRECAUTION WHEN REMOVING OR REPLACING SHIFT ACTUATOR ECU (SHIFT CONTROL ACTUATOR ASSSEMBLY)

(a) After any of the following procedures, it is necessary to perform initialization and learning for the shift actuator ECU.

Click here

- When removing and installing the shift actuator ECU (shift control actuator assembly).

- When replacing the shift actuator ECU (shift control actuator assembly).

NOTICE:

When initialization and learning has not been performed after replacing the shift actuator ECU, a malfunction such as the shift position not correctly changing, the shift position indicator not illuminating or displaying the incorrect drive state, etc. may occur.

(b) When any of the above procedures are completed, change the shift position to all positions and check the following items:

- The shift position indicator illuminates in accordance with the current position.

- The Toyota Prius vehicle does not move when in shift state P (parking brake is not engaged)

- The vehicle does not drive when in shift state N

- The vehicle drives when in shift state D or R

HINT:

After replacing the shift control ECU (transmission floor shift assembly), the function that automatically changes the shift state to P may not operate until the shift state has been changed to a drive state with the ignition switch ON (READY).

PRECAUTION WHEN REPLACING SHIFT CONTROL ECU (TRANSMISSION FLOOR SHIFT ASSEMBLY)

(a) After replacing the shift control ECU (transmission floor shift assembly), it is necessary to update the ECU security key.

Click here

(b) When any of the above procedures are completed, change the shift position to all positions and check the following items:

- The shift position indicator illuminates in accordance with the current position.

- The Toyota Prius vehicle does not move when in shift state P (parking brake is not engaged)

- The vehicle does not drive when in shift state N

- The vehicle drives when in shift state D or R

PRECAUTIONS WHEN REMOVING INTEGRATED CAPACITOR (INTEGRATION CONTROL SUPPLY)

(a) When disconnecting a wire harness of any component connected to the supply power of the integrated capacitor (integration control supply) or when removing the integrated capacitor (integration control supply), make sure to wait 5 minutes or more after turning the ignition switch off for self-diagnosis to complete and the voltage of the integrated capacitor (integration control supply) to discharge.

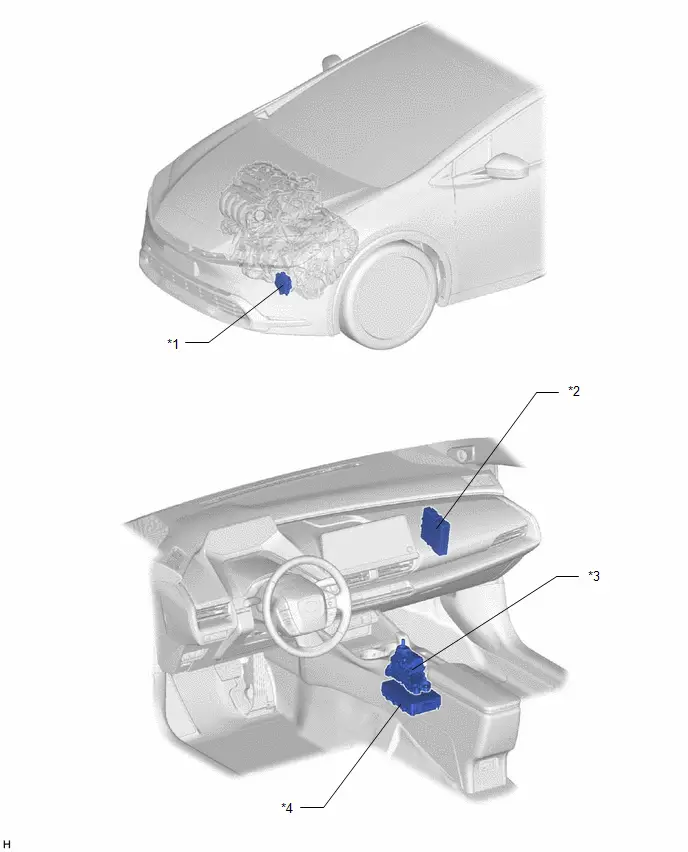

Parts Location

PARTS LOCATION

ILLUSTRATION

|

*1 |

SHIFT CONTROL ACTUATOR ASSEMBLY

|

*2 |

HYBRID Toyota Prius Vehicle CONTROL ECU |

|

*3 |

TRANSMISSION FLOOR SHIFT ASSEMBLY

|

*4 |

INTEGRATED CAPACITOR (INTEGRATION CONTROL SUPPLY) |

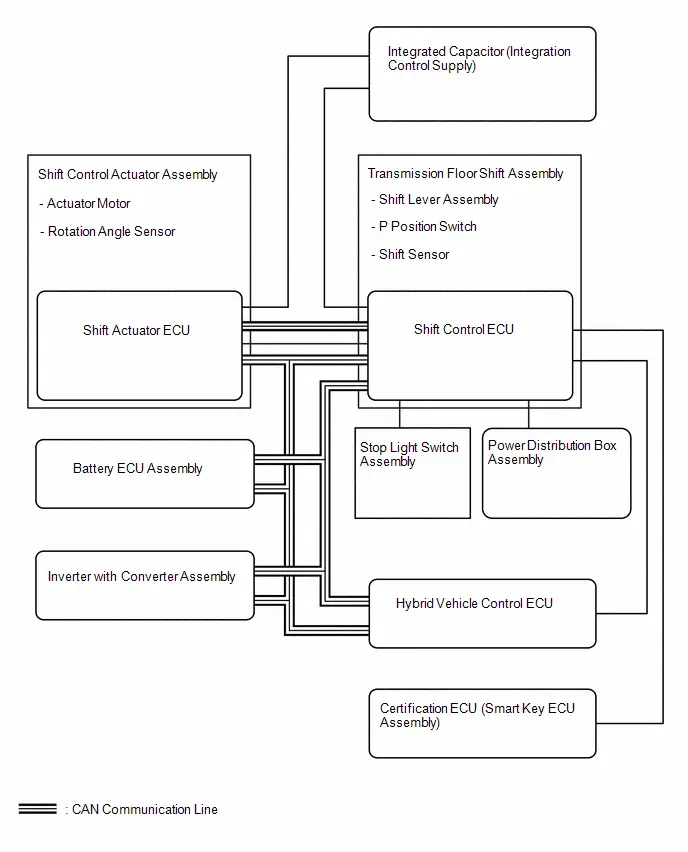

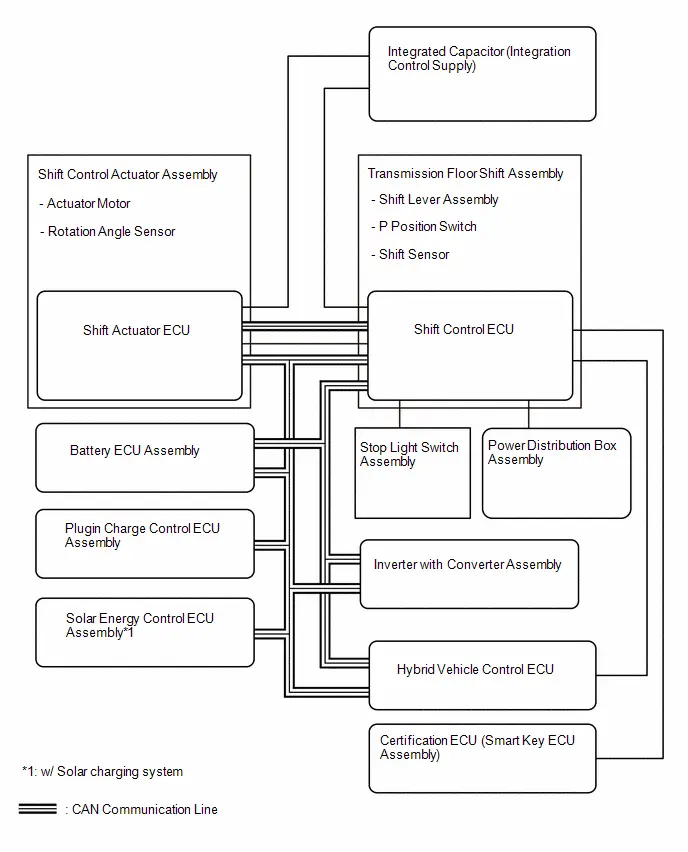

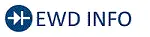

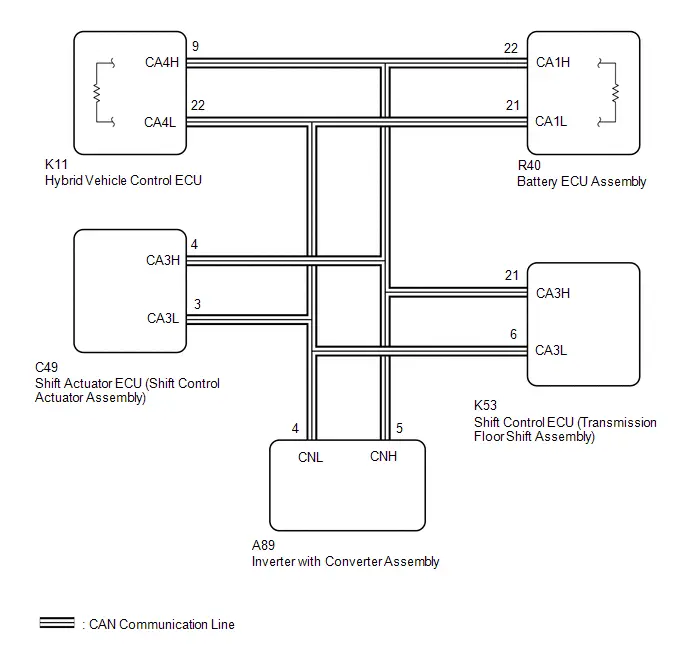

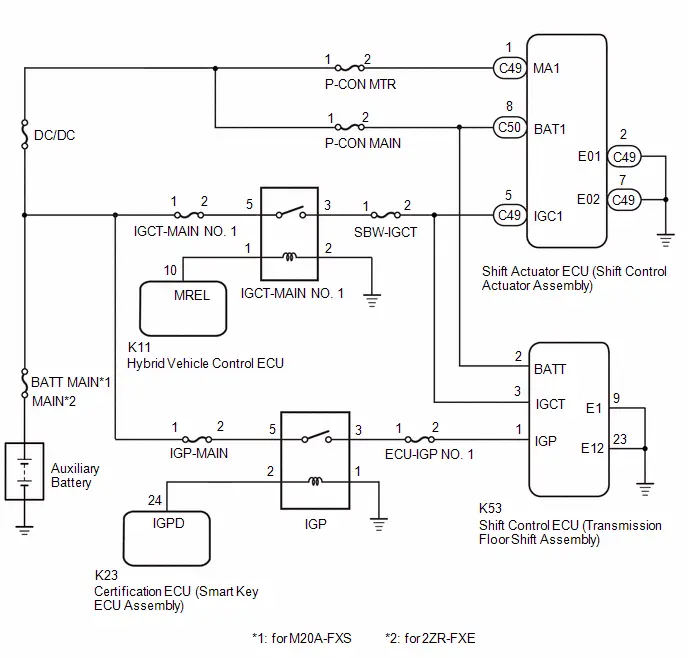

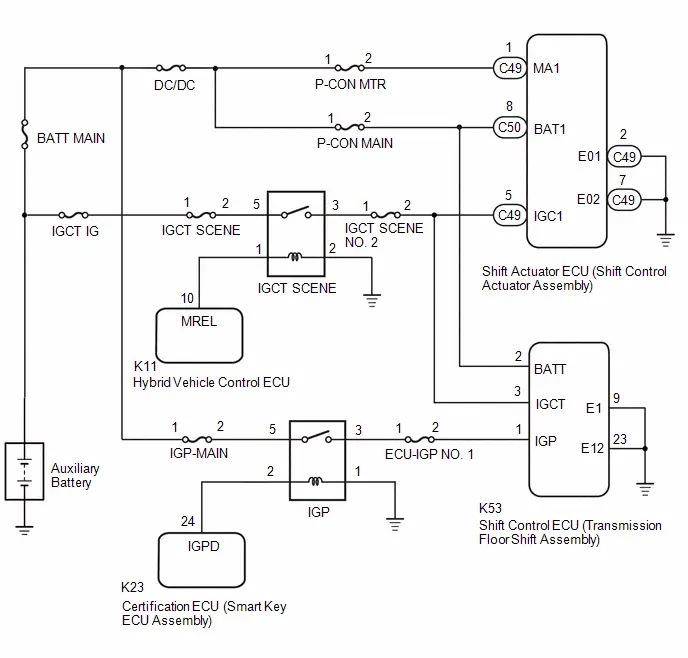

System Diagram

SYSTEM DIAGRAM

for HEV Model for PHEV Model

for PHEV Model

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

*: Use the GTS.

PROCEDURE

|

1. |

VEHICLE BROUGHT TO WORKSHOP |

|

|

2. |

CUSTOMER PROBLEM ANALYSIS |

|

|

3. |

CONNECT GTS TO THE DLC3* |

HINT:

If the display on the GTS indicates a communication error, inspect the DLC3.

|

|

4. |

CHECK DTC AND SAVE FREEZE FRAME DATA* |

(a) Check DTC

Powertrain > Hybrid Control > Trouble Codes(b) Check and save freeze frame data

Click here

HINT:

- Make sure to save freeze frame data because the data is necessary for simulation tests.

- If any CAN communication system DTCs are output, perform troubleshooting

for the CAN communication system first.

for HEV Model:

for PHEV Model:

|

Result |

Proceed to |

|---|---|

|

DTCs are output |

A |

|

DTCs are not output |

B |

| B |

|

PROBLEM SYMPTOMS TABLE |

|

|

5. |

CLEAR DTC AND FREEZE FRAME DATA* |

|

|

6. |

CONDUCT VISUAL INSPECTION |

|

|

7. |

CONFIRM PROBLEM SYMPTOMS |

|

Result |

Proceed to |

|---|---|

|

Malfunction does not occur |

A |

|

Malfunction occurs |

B |

| B |

|

GO TO STEP 10 |

|

|

8. |

DUPLICATE CONDITIONS THAT PRODUCE SYMPTOMS |

|

|

9. |

CHECK FOR DTC* |

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

DTCs are output |

B |

| B |

|

GO TO STEP 17 |

|

|

10. |

CONDUCT BASIC INSPECTION |

|

Result |

Proceed to |

|---|---|

|

Malfunctioning parts not confirmed |

A |

|

Malfunctioning parts confirmed |

B |

| B |

|

GO TO STEP 18 |

|

|

11. |

CHECK ECU POWER SOURCE CIRCUIT |

|

|

12. |

CONFIRM CIRCUITS INDICATED BY OUTPUT DTCS |

|

Result |

Proceed to |

|---|---|

|

Malfunction not confirmed |

A |

|

Malfunction confirmed |

B |

| B |

|

GO TO STEP 14 |

|

|

13. |

CHECK FOR INTERMITTENT PROBLEMS |

Click here

Click here

|

|

14. |

IDENTIFY PROBLEM |

|

|

15. |

ADJUST AND/OR REPAIR |

|

|

16. |

CONDUCT CONFIRMATION TEST |

| NEXT |

|

END |

|

17. |

REFER TO DTC CHART |

Click here

| NEXT |

|

GO TO STEP 12 |

|

18. |

CONDUCT PARTS INSPECTION |

| NEXT |

|

GO TO STEP 14 |

Utility

UTILITY

ALL READINESS

HINT:

- With "All Readiness", you can use the GTS to check whether the DTC judgment has been completed.

- Perform the "All Readiness" check after simulating malfunction symptoms or when performing validation after finishing repairs.

(a) Clear the DTCs even if no DTCs are stored.

Powertrain > Hybrid Control > Clear DTCs(b) Turn the ignition switch off and wait for 1 minute or more without opening/closing a door or operating a pedal.

(c) Turn the ignition switch to ON.

(d) Perform the DTC confirmation driving pattern to run the DTC judgment.

Powertrain > Hybrid Control > Utility|

Tester Display |

|---|

|

All Readiness |

(e) Input the DTCs to be confirmed.

(f) Check the DTC judgment result.

|

GTS Display |

Description |

|---|---|

|

NORMAL |

|

|

ABNORMAL |

|

|

INCOMPLETE |

|

If the judgment result shows INCOMPLETE, perform the DTC confirmation driving pattern again.

(g) Turn the ignition switch off.

CHECK FOR DIAGNOSIS RELATED INFORMATION

(a) Check the diagnosis related information and freeze frame data, and then write them down.

Powertrain > Hybrid Control > Utility|

Tester Display |

|---|

|

Diagnosis Related Information |

HINT:

Clearing the DTCs will also clear the diagnosis related information.

CLEAR DIAGNOSIS RELATED INFORMATION

(a) Clear the diagnosis related information and freeze frame data.

Powertrain > Hybrid Control > Clear DTCsACT POSITION LEARNING

NOTICE:

- If the shift actuator ECU (shift control actuator assembly) is replaced

or removed, make sure to perform actuator position learning.

If not performed after replacing the ECU, a malfunction such as the shift position not correctly changing, the shift position indicator not illuminating or displaying the incorrect drive state, etc. may occur.

- When the shift actuator ECU (shift control actuator assembly) is replaced or removed, although the displayed value of Data List item "ACT Position Learning Complete Status" may be "Complete" based on information from before removal, make sure to perform actuator position learning.

(a) Turn the ignition switch to ON.

(b) Using the GTS, enter the following menus.

Powertrain > Hybrid Control > Utility|

Tester Display |

|---|

|

ACT Position Learning |

(c) According to the display on the GTS, perform ACT Position Learning.

(d) Using the GTS, enter the following menus.

Powertrain > Hybrid Control > Data List|

Tester Display |

|---|

|

ACT Position Learning Complete Status |

(e) Check that "Complete" is displayed.

HINT:

If a value other than "Complete" is displayed, check the part number and installation of the actuator and perform learning again.

(f) When any of the above procedures are completed, change the shift position to all positions and check the following items:

- The shift position indicator illuminates in accordance with the current position.

- The Toyota Prius vehicle does not move when in shift state P (parking brake is not engaged)

- The vehicle does not drive when in shift state N

- The vehicle drives when in shift state D or R

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Electronic Shift Lever System|

Symptom |

Suspected Area |

Link |

|---|---|---|

|

Shift state does not change correctly or shift position indicator displays shift state other than actual |

Initialization and learning has not been performed after replacing the shift actuator ECU (shift control actuator assembly) |

|

|

Shift state cannot be changed from P to any other position |

The brake pedal is not depressed or is lightly depressed |

|

|

The brake pedal was depressed after the shift operation was performed |

||

|

The shift operation was performed at the same time the brake pedal was depressed |

||

|

Shift operation was performed when READY indicator light was blinking |

||

|

Shift state was changed to B |

||

|

Shift operation was performed when READY indicator light was not illuminated |

||

|

Shift operation was performed when accelerator pedal was depressed |

||

|

Auxiliary battery is discharged or voltage is low |

for M20A-FXS:

for 2ZR-FXE:

|

|

|

When stopped on an incline, a shift operation was performed with the READY indicator not illuminated |

|

|

|

When "Braking Power Low Stop in a Safe Place See Owner's Manual" is displayed on the multi-information display, despite depressing the brake pedal and moving the shift lever, "Press Brake to Shift" is displayed |

Release the brake pedal and depress it again, and then operate the shift lever. |

|

|

Shift state cannot change to P |

The P position switch was operated while driving |

|

|

The P position switch was operated when the READY indicator was flashing |

||

|

Auxiliary battery is discharged or voltage is low |

for M20A-FXS:

for 2ZR-FXE:

|

|

|

Inspect the ECU supply power |

|

|

|

Fail-safe is temporarily being performed |

|

|

|

The shift state changed to P unintentionally |

P position switch was operated unintentionally |

Be careful not to touch the P position switch unintentionally |

|

The ignition switch was turned off |

To change the shift state to other than P, turn the ignition switch to ON (IG) |

|

|

Fail-safe is temporarily being performed |

|

|

|

Attempt to exit the Toyota Prius vehicle with the shift state in other than P (driver door open, driver seat belt buckle OFF, brake OFF) |

|

|

|

Does not change to shift state B |

Shift state is being changed to B from a state other than D |

|

|

Auxiliary battery is discharged or voltage is low |

for M20A-FXS:

for 2ZR-FXE:

|

|

|

Does not change to shift state N |

The shift lever operation time was short |

Hold the shift lever in N for a certain amount of time |

|

The shift lever was not held in N long enough while stopped or driving at low speeds |

|

|

|

While performing a shift lever operation, the shift state changed to a state not intended |

After performing a shift operation, the shift lever was unintentionally pulled back to another position |

|

|

The shift state changed to N unintentionally |

The shift lever returned to the home position too slowly |

Check for objects hanging from the shift lever, modifications to the shift knob, foreign matter, etc. |

|

The shift lever was operated while driving or moved due to an object hanging from it |

|

|

|

The shift state was changed to D while reversing |

||

|

The P position switch was repeatedly pressed while driving |

||

|

The P position switch was unintentionally pressed and held while driving |

||

|

The shift state was changed to R while driving forward |

||

|

Auxiliary battery is discharged or voltage is low |

for M20A-FXS:

for 2ZR-FXE:

|

|

|

The shift state cannot be changed to D or R |

The shift lever returned to the home position too slowly |

Check for objects hanging from the shift lever, modifications to the shift knob, foreign matter, etc. |

|

The shift lever was not moved fully or operation time was too short |

Securely move the shift lever to each position. |

|

|

The READY indicator light not illuminated |

|

|

|

The shift state was changed to D while reversing |

||

|

The shift state was changed to R while driving forward |

||

|

Auxiliary battery is discharged or voltage is low |

for M20A-FXS:

for 2ZR-FXE:

|

|

|

The brake pedal is not depressed or is lightly depressed |

|

|

|

When the Toyota Prius vehicle was stopped in shift state N, the brake pedal was depressed after the shift operation was performed |

||

|

When the vehicle was stopped in shift state N, the shift operation was performed at the same time the brake pedal was depressed |

||

|

The shift lever was operated while the accelerator pedal was depressed |

||

|

When "Braking Power Low Stop in a Safe Place See Owner's Manual" is displayed on the multi-information display, despite depressing the brake pedal and moving the shift lever, "Press Brake to Shift" is displayed |

Release the brake pedal and depress it again, and then operate the shift lever. |

|

|

Supply power does not turn off (while the ignition switch is ON (IG)) |

When shift state is in N, the ignition switch was pushed within a certain amount of time of moving the shift lever to N |

|

|

The shift indicator does not illuminate or shift position indicator does not display the selected shift position |

Initialization and learning has not been performed after replacing the shift actuator ECU (shift control actuator assembly) |

|

|

Auxiliary battery is discharged or voltage is low |

for M20A-FXS:

for 2ZR-FXE:

|

|

|

Inspect the ECU supply power |

|

|

|

Shift indicator malfunction |

|

|

|

Electronic shift lever system warning message is displayed on the combination meter assembly |

Check for Toyota Prius vehicle control history (RoB) |

|

|

Auxiliary battery is discharged or voltage is low |

for M20A-FXS:

for 2ZR-FXE:

|

|

|

Inspect the ECU supply power |

|

|

|

Fail-safe is temporarily being performed |

|

|

|

Advanced park was interrupted or canceled |

Shift lever was moved while advanced park was operating |

|

|

P position switch was operated while advanced park was operating |

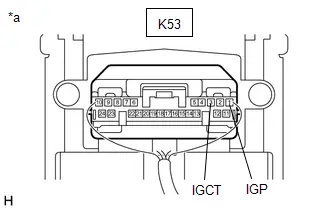

Terminals Of Ecu

TERMINALS OF ECU

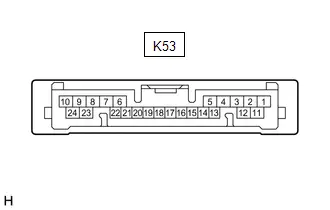

SHIFT CONTROL ECU (TRANSMISSION FLOOR SHIFT ASSEMBLY)

|

Terminal No. (Symbol) |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|

|

K53-1 (IGP) - K53-9 (E1) |

Shift control ECU start signal |

Ignition switch ON |

11 to 14 V |

|

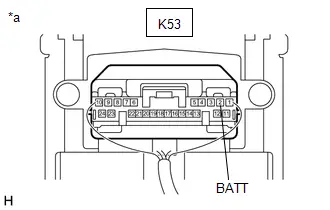

K53-2 (BATT) - K53-9 (E1) |

Auxiliary battery supply power (normal supply power) |

Always |

11 to 14 V |

|

K53-3 (IGCT) - K53-9 (E1) |

Shift control ECU start signal |

Ignition switch ON |

11 to 14 V |

|

K53-4 (BL) - K53-9 (E1) |

Back-up light relay operation signal |

Shift state R |

11 to 14 V |

|

shift state other than R |

Below 1 V |

||

|

K53-5 (WAKE) - K53-9 (E1) |

Shift actuator ECU start signal |

Ignition switch ON |

11 to 14 V |

|

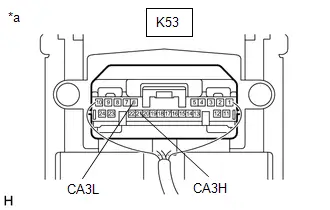

K53-6 (CA3L) - K53-9 (E1) |

CAN communication signal (Battery ECU local bus) |

Ignition switch ON |

Pulse generation (Waveform 1) |

|

K53-7 (PPOS) - K53-9 (E1) |

Shift state signal |

Ignition switch ON, shift state P |

Pulse generation (Waveform 2) |

|

K53-9 (E1) - Body ground |

Ground |

Always |

Below 1 Ω |

|

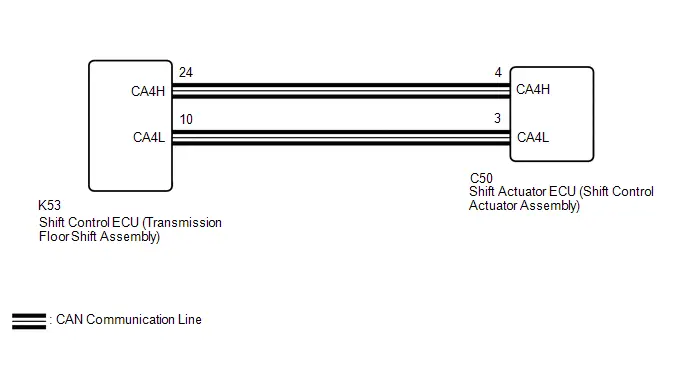

K53-10 (CA4L) - K53-9 (E1) |

CAN communication signal (SBW local bus) |

Ignition switch ON |

Pulse generation (Waveform 3) |

|

K53-11 (STP) - K53-9 (E1) |

Stop light switch signal |

Stop light switch ON (Brake pedal depressed) |

7 V or higher |

|

Stop light switch OFF (Brake pedal released) |

Below 2 V |

||

|

K53-13 (BUB) - K53-9 (E1) |

Integrated capacitor (integration control supply) power supply |

Ignition switch ON |

8 to 14 V |

|

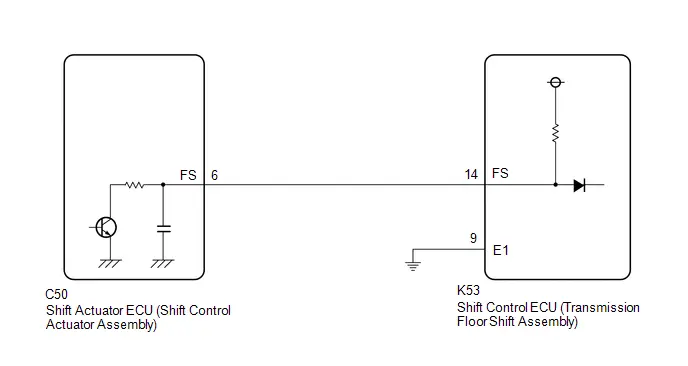

K53-14 (FS) - K53-9 (E1) |

Shift control actuator fail-safe signal |

Ignition switch ON |

Pulse generation (Waveform 4) |

|

K53-15 (CA1H) - K53-9 (E1) |

CAN communication signal (Powertrain Bus) |

Ignition switch ON |

Pulse generation (Waveform 5) |

|

K53-16 (CA1L) - K53-9 (E1) |

CAN communication signal (Powertrain Bus) |

Ignition switch ON |

Pulse generation (Waveform 5) |

|

K53-17 (BUBI) - K53-9 (E1) |

Integrated capacitor (integration control supply) communication signal |

Ignition switch ON |

Pulse generation (Waveform 6) |

|

K53-19 (SBFS) - K53-9 (E1) |

Fail-safe signal |

Ignition switch ON |

Pulse generation (Waveform 7) |

|

K53-20 (BUBO) - K53-9 (E1) |

Integrated capacitor (integration control supply) communication signal |

Ignition switch ON |

Pulse generation (Waveform 8) |

|

K53-21 (CA3H) - K53-9 (E1) |

CAN communication signal (Battery ECU local bus) |

Ignition switch ON |

Pulse generation (Waveform 1) |

|

K53-23 (E12) - Body ground |

Ground |

Always |

Below 1 Ω |

|

K53-24 (CA4H) - K53-9 (E1) |

CAN communication signal (SBW local bus) |

Ignition switch ON |

Pulse generation (Waveform 3) |

HINT:

As the above standard values are based on the specified condition when the auxiliary battery voltage is between 11 and 14 V, the values may vary depending on the actual auxiliary battery condition.

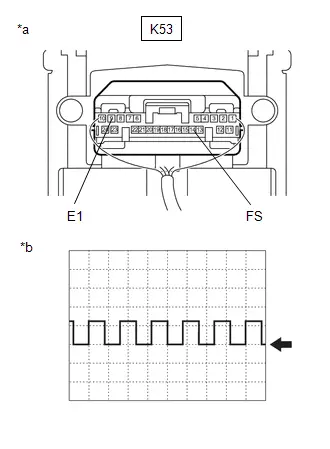

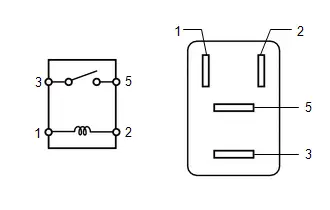

(a) Oscilloscope waveforms

HINT:

Oscilloscope waveform samples are provided here for informational purposes. Noise and fluttering waveforms have been omitted.

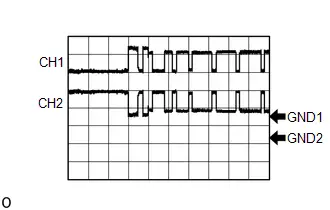

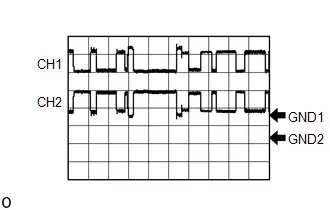

(1) Waveform 1 (CAN communication signal)

|

Item |

Content |

|---|---|

|

Terminal |

CH1: K53-21 (CA3H) - K53-9 (E1) CH2: K53-6 (CA3L) - K53-9 (E1) |

|

Equipment Setting |

1 V/DIV., 10 μs/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will vary depending on the content of the digital communication (digital signal).

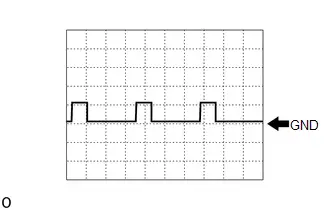

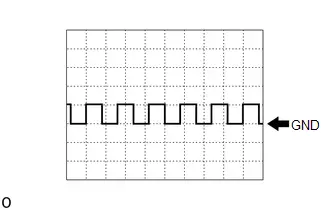

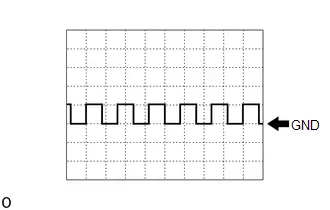

(2) Waveform 2 (Shift state signal)

|

Item |

Content |

|---|---|

|

Terminal |

K53-7 (PPOS) - K53-9 (E1) |

|

Equipment Setting |

10 V/DIV., 10 ms/DIV. |

|

Condition |

Ignition switch ON, shift state P |

HINT:

The waveform differs depending on the shift state.

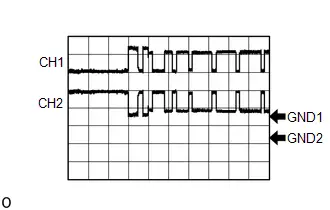

(3) Waveform 3 (CAN communication signal)

|

Item |

Content |

|---|---|

|

Terminal |

CH1: K53-24 (CA4H) - K53-9 (E1) CH2: K53-10 (CA4L) - K53-9 (E1) |

|

Equipment Setting |

1 V/DIV., 10 μs/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will vary depending on the content of the digital communication (digital signal).

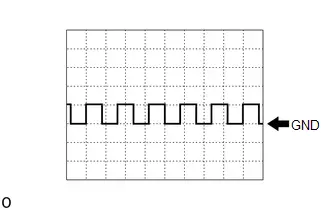

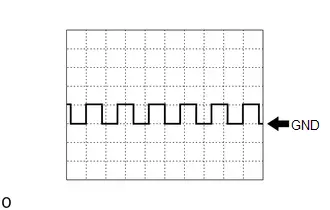

(4) Waveform 4 (Shift control actuator fail-safe signal)

|

Item |

Content |

|---|---|

|

Terminal |

K53-14 (FS) - K53-9 (E1) |

|

Equipment Setting |

10 V/DIV., 20ms/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will differ when the shift control ECU is malfunctioning.

(5) Waveform 5 (CAN communication signal)

|

Item |

Content |

|---|---|

|

Terminal |

CH1: K53-15 (CA1H) - K53-9 (E1) CH2: K53-16 (CA1L) - K53-9 (E1) |

|

Equipment Setting |

1 V/DIV., 10 μs/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will vary depending on the content of the digital communication (digital signal).

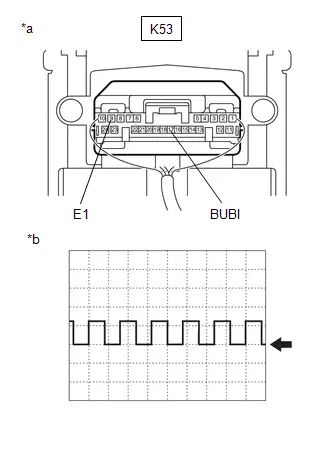

(6) Waveform 6 (Integrated capacitor (integration control supply) communication signal)

|

Item |

Content |

|---|---|

|

Terminal |

K53-17 (BUBI) - K53-9 (E1) |

|

Equipment Setting |

10 V/DIV., 10 ms/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The duty ratio may differ depending on the communication contents of the integrated capacitor.

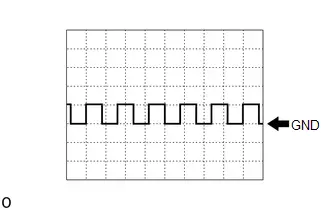

(7) Waveform 7 (Fail-safe signal)

|

Item |

Content |

|---|---|

|

Terminal |

K53-19 (SBFS) - K53-9 (E1) |

|

Equipment Setting |

10 V/DIV., 20ms/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will differ when the shift control ECU is malfunctioning.

(8) Waveform 8 (Integrated capacitor (integration control supply) communication signal)

|

Item |

Content |

|---|---|

|

Terminal |

K53-20 (BUBO) - K53-9 (E1) |

|

Equipment Setting |

10 V/DIV., 10 ms/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The duty ratio may differ depending on the communication contents of the integrated capacitor.

HINT:

As the shift actuator ECU (shift control actuator assembly) uses a waterproof connector, inspection of the resistance, voltage and waveform cannot be performed.

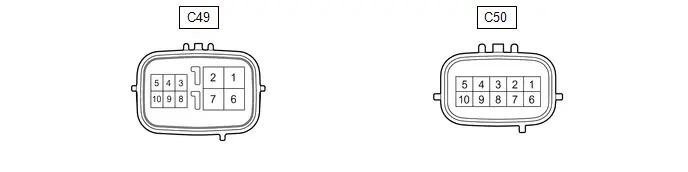

SHIFT ACTUATOR ECU (SHIFT CONTROL ACTUATOR ASSSEMBLY)

|

Terminal No. (Symbol) |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|

|

C49-1 (MA1) - C49-2 (E01) |

Motor supply power (normal supply power) |

Always |

11 to 14 V |

|

C49-2 (E01) - Body ground |

Ground |

Always |

Below 1 Ω |

|

C49-3 (CA3L) - C49-2 (E01) |

CAN communication signal (Battery ECU local bus) |

Ignition switch ON |

Pulse generation (Waveform 1) |

|

C49-4 (CA3H) - C49-2 (E01) |

CAN communication signal (Battery ECU local bus) |

Ignition switch ON |

Pulse generation (Waveform 1) |

|

C49-5 (IGC1) - C49-2 (E01) |

Shift actuator ECU start signal |

Ignition switch ON |

11 to 14 V |

|

C49-6 (MA2) - C49-2 (E01) |

Motor supply power (integrated capacitor supply power) |

Ignition switch ON |

8 to 14 V |

|

C49-7 (E02) - Body ground |

Ground |

Always |

Below 1 Ω |

|

C49-8 (BUB1) - C49-2 (E01) |

Integrated capacitor (integration control supply) power supply |

Ignition switch ON |

8 to 14 V |

|

C50-3 (CA4L) - C49-2 (E01) |

CAN communication signal (SBW local bus) |

Ignition switch ON |

Pulse generation (Waveform 2) |

|

C50-4 (CA4H) - C49-2 (E01) |

CAN communication signal (SBW local bus) |

Ignition switch ON |

Pulse generation (Waveform 2) |

|

C50-5 (WAKE) - C49-2 (E01) |

Shift actuator ECU start signal |

Ignition switch ON |

11 to 14 V |

|

C50-6 (FS) - C49-2 (E01) |

Shift control actuator fail-safe signal |

Ignition switch ON |

Pulse generation (Waveform 3) |

|

C50-8 (BAT1) - C49-2 (E01) |

Auxiliary battery supply power (normal supply power) |

Always |

11 to 14 V |

HINT:

As the above standard values are based on the specified condition when the auxiliary battery voltage is between 11 and 14 V, the values may vary depending on the actual auxiliary battery condition.

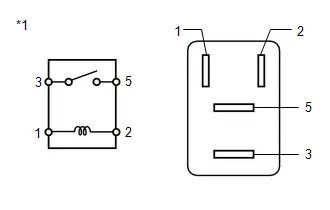

(a) Oscilloscope waveforms

HINT:

Oscilloscope waveform samples are provided here for informational purposes. Noise and fluttering waveforms have been omitted.

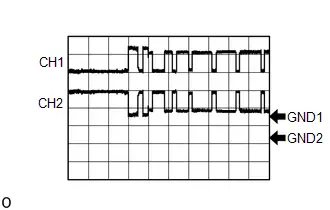

(1) Waveform 1 (CAN communication signal)

|

Item |

Content |

|---|---|

|

Terminal |

CH1: C49-4 (CA3H) - C49-2 (E01) CH2: C49-3 (CA3L) - C49-2 (E01) |

|

Equipment Setting |

1 V/DIV., 10 μs/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will vary depending on the content of the digital communication (digital signal).

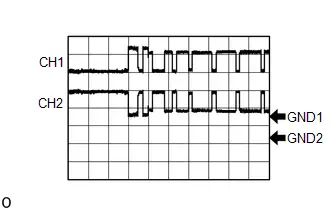

(2) Waveform 2 (CAN communication signal)

|

Item |

Content |

|---|---|

|

Terminal |

CH1: C50-4 (CA4H) - C49-2 (E01) CH2: C50-3 (CA4L) - C49-2 (E01) |

|

Equipment Setting |

1 V/DIV., 10 μs/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will vary depending on the content of the digital communication (digital signal).

(3) Waveform 3 (Shift control actuator fail-safe signal)

|

Item |

Content |

|---|---|

|

Terminal |

C50-6 (FS) - C49-2 (E01) |

|

Equipment Setting |

5 V/DIV., 20 ms/DIV. |

|

Condition |

Ignition switch ON |

HINT:

The waveform will differ when the shift actuator ECU is malfunctioning.

Freeze Frame Data

FREEZE FRAME DATA

CHECK FREEZE FRAME DATA

HINT:

The hybrid vehicle control ECU records vehicle and driving condition information as freeze frame data the moment a DTC is stored. Freeze frame data can help determine the vehicle conditions when the malfunction occurred and help duplicate conditions when troubleshooting.

(a) Select a DTC in order to display its freeze frame data.

Powertrain > Hybrid Control > Trouble CodesLIST OF FREEZE FRAME DATA

Powertrain > Hybrid Control|

Tester Display |

Measurement Item |

Range |

|---|---|---|

|

Toyota Prius Vehicle Speed |

Vehicle speed |

Min.: 0 km/h (0 mph), Max.: 255 km/h (158 mph) |

|

Accelerator Position |

Accelerator pedal depressed angle |

Min.: 0%, Max.: 127.5% |

|

Master Cylinder Control Torque |

Braking torque equivalent to master cylinder brake fluid pressure (Total braking torque) |

Min.: -4096.00 Nm, Max.: 4095.87 Nm |

|

Shift Position |

Current shift state |

P / R / N / D / B (S) |

|

Shift Position (Meter) |

Shift position on the meter |

Not Displayed / P / R / N / D / B (S) |

|

Ready Signal |

READY state is displayed |

ON / OFF |

|

HV/EV Activate Condition |

Startup state of the hybrid system |

Normal / Remote Air Control System / Remote |

|

Request Motor Regenerative Brake Torque |

Requested motor (MG2) regenerative braking torque |

Min.: -4096.00 Nm, Max.: 4095.87 Nm |

|

P Control Request Status |

Shift actuator ECU (shift control actuator assembly) operation request |

No Request / Lock(Normal) / Unlock(Normal) / Lock(Abnormal) / Unlock(Abnormal) / Unlock during Running(Normal) / Unlock during Running(Abnormal) |

|

P Control Status |

Shift state P status |

Control Duty Abnormal / Lock Position(Normal) / Lock Position(Abnormal) / Indefinite Position(Normal) / Indefinite Position(Abnormal) / Unlock Position(Normal) / Unlock Position(Abnormal) / Lock Position(Normal) / Lock Position(Abnormal) / Indefinite Position(Normal) / Indefinite Position(Abnormal) / Unlock Position(Normal) / Unlock Position(Abnormal) |

|

Abnormality Informing Status |

Malfunction notifications of other systems |

ON / OFF |

|

Meter Display Request (P Position Switch ON when Running) |

Notification from shift control displayed on the meter that the shift stated changed to N as a change to shift state P was attempted while driving |

ON or OFF |

|

Meter Display Request (Shift N Operation when Running) |

Notification from shift control displayed on the meter that the shift stated changed to N |

OFF, ON or Shift P Pressed for Extended Time/Repeatedly |

|

Meter Display Request (Shift Operation Rejection) |

Shift operation rejected message |

0 to 255 |

|

Identifying Signal of Shift R/D Operation during Ready OFF |

Identification indicating the shift state was changed to R or D with READY indicator not illuminated and the ignition switch ON |

ON / OFF |

|

P Position Automatic Change Request |

P position automatic change function request status |

ON / OFF |

|

Limiting Driving Force Request from Transmission Control System |

Drive torque limit request status of the HV system sent from the electronic shift lever system |

ON / OFF |

|

SP1 Toyota Prius Vehicle Speed |

Vehicle speed (SP1) |

Min.: 0 km/h (0 mph), Max.: 655.35 km/h (407.23 mph) |

|

Gear Shift Control Module Power Supply Voltage |

Shift control ECU power supply voltage |

Min.: -20.00 V, Max.: 19.84 V |

|

Gear Shift Control Module "B" CPU Temperature |

Shift actuator ECU internal temperature |

Min.: -50°C (-58°F), Max.: 205°C (401°F) |

|

IGCT Signal Status (Gear Shift Control Module) |

IGCT signal status of the shift control ECU |

ON / OFF |

|

IGCT Signal Status (Gear Shift Control Module "B") |

IGCT signal status of the shift actuator ECU |

ON / OFF |

|

IGP Signal Status (Gear Shift Control Module) |

IGP signal status of the shift control ECU |

ON / OFF |

|

IG Status (Gear Shift Control Module "B") |

IG status of the shift actuator ECU |

ON / OFF |

|

WAKE Signal Status (Gear Shift Control Module) |

WAKE signal status of the shift control ECU |

ON / OFF |

|

WAKE Signal Status (Gear Shift Control Module "B") |

WAKE signal status of the shift actuator ECU |

ON / OFF |

|

Backup Power Supply Type |

Backup supply power type |

Capacitor Type / Lithium Type / None |

|

Gear Shift Control Module Backup Signal Status |

System backup signal from the backup supply power |

Wake Up Request / Capacitor Internal Failure / Backup Mode (Low Capacity) / Backup Possible/Remote Charging Complete / Backup Impossible / Communication Stop / Backup Possible/Remote Charging Incomplete / Capacitor Internal Failure (Backup Possible) / Capacitor External Failure / Capacitor External Failure (Backup Possible) / Capacitor External Failure (Brake Factor) |

|

Gear Shift Control Module Backup Request |

System backup request from the backup supply power |

Wake Up/Sleep Permission / Interruption Permission (Not Remote) / ON (Not Remote) / OFF (Not Remote) / ON (Advanced Park) / OFF (Advanced Park) / ON (Stop&Start) |

|

Fail Safe Status (Gear Shift Control Module) |

Fail-safe status of the shift control ECU |

Unknown / OFF / ON |

|

Fail Safe Status (Gear Shift Control Module "B" to "A") |

Shift control ECU fail-safe status from the shift actuator ECU |

Normal / Abnormal / Unknown |

|

Fail Safe Power Supply Relay Connect Request |

Requested connection status of the shift actuator ECU motor drive relay (fail safe power supply) |

ON / OFF |

|

Shift Position (Current Position) |

Actual shift lever position (judged value) |

Home / R / N / D / B/M/S / Not Available |

|

Shift Sensor Status |

Shift sensor malfunction status |

Normal / Abnormal / Abnormal (Extreme) |

|

Shift Sensor 1 Status |

Shift lever sensor input signal status |

H / R / N / D / B/M/S / O / Abnormal / Unknown |

|

Shift Sensor 2 Status |

Shift lever sensor input signal status |

H / R / N / D / B/M/S / O / Abnormal / Unknown |

|

Shift Sensor 3 Status |

Shift lever sensor input signal status |

H / R / N / D / B/M/S / O / Abnormal / Unknown |

|

M or S Shift Position Indicator Turn On Request |

Shift position indicator (B) illumination status |

ON / OFF |

|

D Shift Position Indicator Turn On Request |

Shift position indicator (D) illumination status |

ON / OFF |

|

N Shift Position Indicator Turn On Request |

Shift position indicator (N) illumination status |

ON / OFF |

|

R Shift Position Indicator Turn On Request |

Shift position indicator (R) illumination status |

ON / OFF |

|

P Shift Position Indicator Turn On Request |

P position indicator illumination status |

ON / OFF |

|

Back Up Light Turn On Request |

Back-up light illumination command |

ON / OFF |

|

Stop Light Switch (Gear Shift Control Module) |

Stop light switch status |

ON / OFF |

|

P Position Switch Signal Status (Gear Shift Control Module) |

P position switch status |

ON / OFF |

|

Not P Position Learning Value (Output Side) |

Learned value (output axis) in accordance with the shift state other than P |

Min.: 0.0 deg, Max.: 124.5 deg |

|

Not P Position Learning Value (Motor Side) |

Learned value (calculated output axis angle based on the detected motor axis angle) in accordance with the shift state other than P |

Min.: 0.00 deg, Max.: 42949672.95 deg |

|

Absolute Angle Sensor Value 1 |

Value of axis sensor 1 (detected angle) |

Min.: 0.0 deg, Max.: 124.5 deg |

|

Absolute Angle Sensor Value 2 |

Value of axis sensor 2 (detected angle) |

Min.: 0.0 deg, Max.: 124.5 deg |

|

Gear Shift Actuator Power Supply Voltage (MA1) |

Voltage of gear shift motor supply power terminal (MA1) |

Min.: 0 V, Max.: 255 V |

|

Gear Shift Actuator Power Supply Voltage (MA2) |

Voltage of gear shift motor supply power terminal (MA2) |

Min.: 0 V, Max.: 255 V |

|

Gear Shift Actuator Motor Angle Sensor Value |

Value of motor axis sensor (detected angle) |

Min.: 0.00 deg, Max.: 358.59 deg |

|

Gear Shift Actuator Motor Speed |

Gear shift motor rotation speed |

Min.: 0.00 rpm deg, Max.: 10160.15 rpm |

|

Gear Shift Actuator Power Supply Relay Downstream Voltage |

Internal voltage of the actuator downstream of the motor supply power relay |

Min.: 0 V, Max.: 255 V |

|

U Phase Parking Lock Motor Current-Carrying Status (Gear Shift Control Module "B") |

Parking lock motor (U phase) drive signal |

ON / OFF |

|

V Phase Parking Lock Motor Current-Carrying Status (Gear Shift Control Module "B") |

Parking lock motor (V phase) drive signal |

ON / OFF |

|

W Phase Parking Lock Motor Current-Carrying Status (Gear Shift Control Module "B") |

Parking lock motor (W phase) drive signal |

ON / OFF |

|

U Phase Parking Lock Motor Terminal Current |

Current of the parking lock motor terminal (U phase) |

Min.: -64.0 A, Max.: 63.5 A |

|

V Phase Parking Lock Motor Terminal Current |

Current of the parking lock motor terminal (V phase) |

Min.: -64.0 A, Max.: 63.5 A |

|

W Phase Parking Lock Motor Terminal Current |

Current of the parking lock motor terminal (W phase) |

Min.: -64.0 A, Max.: 63.5 A |

|

ACT Relay Connect Status |

Connection status of drive relay of the shift actuator ECU motor |

ON / OFF |

|

ACT Relay Connect Request |

Requested connection status of drive relay of the shift actuator ECU motor |

ON / OFF |

|

ACT Position Status |

Status of the shift actuator ECU |

Other than P / None / Shift in P |

|

ACT Position Drive Request |

Operation request position of the shift actuator ECU |

Output NG / Shift in P / Other than P |

|

ACT Operation Status |

Operation status of the shift actuator ECU |

ON / OFF |

|

ACT Function Informing Status |

Function failure status of the shift actuator ECU |

Normal / Maintenance / Outside Judgment Guaranteed / Outside Operation Guaranteed / Outside Judgment/Operation Guaranteed / Operation NG / Operation NG/Outside Judgment Guaranteed |

|

ACT Monitoring Information |

Monitor status of the shift actuator ECU |

Normal / Driver Malfunction 1 / Driver Malfunction 2 / Driver Malfunction 3 / Driver Malfunction 4 / Driver Malfunction 5 / Driver Malfunction 6 / Sensor Malfunction 1 / Sensor Malfunction 2 / Sensor Malfunction 3 / Driver Malfunction 7 / Motor Malfunction 1 / Motor Malfunction 2 / Motor Malfunction 3 |

|

Shift Request during Advanced Drive/Park |

Shift request during advanced park operation |

OFF / ON (Gear Shift Control Module) / ON (Clearance Warning Control Module Semi-Auto) / ON (Clearance Warning Control Module Full-Auto) / ON (Advanced Drive Control Module) |

|

IGCT-Scene Signal Status (Gear Shift Control Module) |

IGCT-SCENE signal status of the shift control ECU |

ON / OFF |

|

IGCT-Scene Signal Status (Gear Shift Control Module "B") |

IGCT-SCENE signal status of the shift actuator ECU |

ON / OFF |

Fail-safe Chart

FAIL-SAFE CHART

If the shift control ECU detects a malfunction, a fail-safe function in the following table will be operated.

|

DTC No. |

Detection item |

Problem Symptoms |

Fail-safe Function |

|---|---|---|---|

|

P085011 |

Park/Neutral Switch Circuit Short to Ground |

The shift state cannot be changed to P by operating the P position switch |

- |

|

P085015 |

Park/Neutral Switch Circuit Short to Battery or Open |

The shift state cannot be changed to P by operating the P position switch |

- |

|

P085D04 |

Gear Shift Control Module "A" System Internal Failure |

Depending on the conditions, the shift state may not be able to be changed from P to a state other than P |

- |

|

P085D94 |

Gear Shift Control Module "A" Unexpected Operation |

|

- |

|

P08A662 |

Gear Lever Position Sensor Signal Compare Failure |

|

Shift state only permitted between P and N (however, shift state may not be able to be changed from P) |

|

P09142B |

Gear Shift Position Circuit "A" Range/Performance Signal Cross Coupled |

The following restrictions may occur:

|

The following fail-safe operations may occur:

|

|

P175231 |

Fail Safe Signal (Gear Shift Control Module "B" to "A") No Signal |

- |

- |

|

P175387 |

Lost Communication with Gear Shift Control Module "B" (Local-CAN) Missing Message |

- |

- |

|

P1761A2 |

Gear Shift Control Module "A" System Voltage Low |

- |

- |

|

P1765A2 |

Sub Battery Module System Voltage Low |

- |

- |

|

P176900 |

Gear Shift Control Module "A" A/D Processing Performance |

|

|

|

P176D12 |

IG2 Signal (Gear Shift Control Module "A") Circuit Short to Battery |

- |

- |

|

P1771A2 |

Gear Shift Control Module "B" System Voltage Low |

- |

- |

|

P1775A2 |

Sub Battery Module (Gear Shift Control Module "B") System Voltage Low |

- |

- |

|

P177949 |

Gear Shift Control Module Backup Power Supply Internal Electronic Failure |

- |

- |

|

P177996 |

Gear Shift Control Module Backup Power Supply Component Internal Failure |

- |

- |

|

P177A87 |

Lost Communication with Gear Shift Control Module Backup Power Supply Missing Message |

- |

- |

|

P178987 |

Lost Communication with Gear Shift Control Module "A" from "B" Missing Message |

- |

- |

|

P178A14 |

Gear Shift Control Module "B" Wake-up Circuit Short to Ground or Open |

- |

- |

|

P179014 |

Gear Shift Actuator "A" Supply Voltage "A" Circuit Short to Ground or Open |

|

|

|

P179314 |

Gear Shift Actuator "A" Supply Voltage "B" Circuit Short to Ground or Open |

- |

- |

|

P179C49 |

Gear Shift Actuator "A" Control Circuit Internal Electronic Failure |

The following restrictions may occur:

|

The following fail-safe operations may occur:

|

|

P179E00 |

Gear Shift Actuator "A" Performance |

|

|

|

P18A762 |

Gear Shift Control Module "A"/"B" IGCT Signal Compare Failure |

- |

- |

|

P18A862 |

Gear Shift Control Module "A"/"B" IGCT-Scene Signal Compare Failure |

- |

- |

|

P18AF12 |

Gear Shift Control Module "B" EPBT Circuit Short to Battery |

- |

- |

|

P18B200 |

Gear Shift Control Module "B" Motor Angle Sensor "A" Performance |

The following restrictions may occur:

|

The following fail-safe operations may occur:

|

|

P18B31C |

Gear Shift Control Module "B" Motor Temperature Sensor "A" Circuit Voltage Out of Range |

- |

- |

|

P18B562 |

Gear Shift Actuator "A" Phase U-V-W Current Sensor Signal Compare Failure |

|

|

|

P2E0064 |

Gear Lever Position Sensor "A" Signal Plausibility Failure |

|

Shift state only permitted between P and N (however, shift state may not be able to be changed from P) |

|

P2E0464 |

Gear Lever Position Sensor "B" Signal Plausibility Failure |

|

Shift state only permitted between P and N (however, shift state may not be able to be changed from P) |

|

P2E0864 |

Gear Lever Position Sensor "C" Signal Plausibility Failure |

|

Shift state only permitted between P and N (however, shift state may not be able to be changed from P) |

|

U014000 |

Lost Communication with Body Control Module (Sub) Missing Message |

- |

- |

|

U015586 |

Lost Communication with Instrument Panel Cluster (IPC) Control Module Signal (some circuit quantity, reported via serial data) Invalid |

|

- |

|

U029100 |

Lost Communication with Gear Shift Control Module "B" (System 2) Missing Message |

- |

- |

|

U029300 |

Lost Communication with Hybrid/EV Powertrain Control Module from Gear Shift Control Module "A" |

- |

- |

|

U110700 |

Lost Communication with Power Management Module (Gear Shift Control Module "A") |

P position automatic change function does not operate |

- |

|

U114F00 |

Lost Communication with Power Integration Module (System 2) Missing Message |

- |

- |

|

U117000 |

Lost Communication with Brake System Control Module (Gear Shift Control Module "A") |

Shift shock may occur when shift state changes from P to other state |

- |

Data List / Active Test

DATA LIST / ACTIVE TEST

DATA LIST

NOTICE:

- Some Data List values may vary significantly if there are slight differences in the environment in which the vehicle is operating when measurement is performed. Variations may also occur due to aging of the Toyota Prius vehicle. Due to these considerations, it is not always possible to provide definite values to be used for judgment of malfunctions. It is possible that a malfunction may be present even if measured values are within the "Normal Condition" range.

- In the event of a problem with intricate symptoms, collect sample data from another Toyota Prius vehicle of the same model operating under identical conditions in order to reach an overall judgment by comparing all the items in the Data List.

- In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

HINT:

Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

(a) According to the display on the GTS, read the Data List.

HINT:

When reading the Data List, first determine which items need to be monitored before proceeding. Attempting to view all of the data may result in a delayed, inaccurate inspection.

Powertrain > Hybrid Control > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Toyota Prius Vehicle Speed |

Vehicle speed |

Min.: 0 km/h (0 mph), Max.: 255 km/h (158 mph) |

0 km/h (0 mph): Vehicle stopped No significant fluctuation: While driving at a constant speed |

- |

|

Accelerator Position |

Accelerator pedal depressed angle |

Min.: 0%, Max.: 127.5% |

0%: Accelerator pedal released 100%: Accelerator pedal fully depressed |

- |

|

Master Cylinder Control Torque |

Braking torque equivalent to master cylinder brake fluid pressure (Total braking torque) |

Min.: -4096.00 Nm, Max.: 4095.87 Nm |

Changes with the brake pedal pressure: Brake pedal depressed |

- |

|

Shift Position |

Current shift state |

P / R / N / D / B (S) |

The selected shift state is displayed |

- |

|

Shift Position (Meter) |

Shift position on the meter |

Not Displayed / P / R / N / D / B (S) |

The selected shift state is displayed |

- |

|

Ready Signal |

READY state is displayed |

ON / OFF |

ON: Ignition switch ON (READY) |

- |

|

HV/EV Activate Condition |

Startup state of the hybrid system |

Normal / Remote Air Control System / Remote |

Normal: Started by ignition switch Remote Air Control System: Started by remote air conditioning system Remote: Started by remote starter |

- |

|

Request Motor Regenerative Brake Torque |

Requested motor (MG2) regenerative braking torque |

Min.: -4096.00 Nm, Max.: 4095.87 Nm |

While braking: Varies depending on Toyota Prius vehicle operation conditions |

- |

|

Auxiliary Battery Voltage Low Times |

Auxiliary battery voltage low times |

Min: 0, Max: 255 |

- |

- |

|

P Control Request Status |

Shift actuator ECU (shift control actuator assembly) operation request |

No Request / Lock(Normal) / Unlock(Normal) / Lock(Abnormal) / Unlock(Abnormal) / Unlock during Running(Normal) / Unlock during Running(Abnormal) |

No Request: Ignition switch ON, no shift operation |

- |

|

P Control Status |

Shift state P status |

Control Duty Abnormal / Lock Position(Normal) / Lock Position(Abnormal) / Indefinite Position(Normal) / Indefinite Position(Abnormal) / Unlock Position(Normal) / Unlock Position(Abnormal) / Lock Position(Normal) / Lock Position(Abnormal) / Indefinite Position(Normal) / Indefinite Position(Abnormal) / Unlock Position(Normal) / Unlock Position(Abnormal) |

Lock Position(Normal): Ignition switch ON, no shift operation |

- |

|

Abnormality Informing Status |

Malfunction notifications of other systems |

ON / OFF |

ON: Malfunction occurring in this system OFF: Malfunction not occurring in this system |

- |

|

P Position Automatic Change Request |

P position automatic change function request status |

ON / OFF |

- |

- |

|

Limiting Driving Force Request from Transmission Control System |

Drive torque limit request status of the HV system sent from the electronic shift lever system |

ON / OFF |

OFF: Fail-safe control not being performed |

- |

|

SP1 Toyota Prius Vehicle Speed |

Vehicle speed (SP1) |

Min.: 0 km/h (0 mph), Max.: 655.35 km/h (407.23 mph) |

The same as actual vehicle speed |

- |

|

Gear Shift Control Module Power Supply Voltage |

Shift control ECU power supply voltage |

Min.: -20.00 V, Max.: 19.84 V |

8.00 to 15.40 V |

Displays terminal BATT voltage of the shift control ECU |

|

Gear Shift Control Module "B" CPU Temperature |

Shift actuator ECU internal temperature |

Min.: -50°C (-58°F), Max.: 205°C (401°F) |

0°C (32°F) to 205°C (401°F) |

- |

|

IGCT Signal Status (Gear Shift Control Module) |

IGCT signal status of the shift control ECU |

ON / OFF |

ON: Ignition switch ON |

Displays the ON/OFF value of terminal IGCT input signal |

|

IGCT Signal Status (Gear Shift Control Module "B") |

IGCT signal status of the shift actuator ECU |

ON / OFF |

ON: Ignition switch ON |

Displays the ON/OFF value of terminal IGC1 input signal |

|

IGP Signal Status (Gear Shift Control Module) |

IGP signal status of the shift control ECU |

ON / OFF |

ON: Ignition switch ON |

Displays the ON/OFF value of terminal IGP input signal |

|

IG Status (Gear Shift Control Module "B") |

IG status of the shift actuator ECU |

ON / OFF |

ON: Ignition switch ON |

- |

|

WAKE Signal Status (Gear Shift Control Module) |

WAKE signal status of the shift control ECU |

ON / OFF |

ON: WAKE signal ON OFF: WAKE signal OFF |

Displays the ON/OFF value of terminal WAKE output signal |

|

WAKE Signal Status (Gear Shift Control Module "B") |

WAKE signal status of the shift actuator ECU |

ON / OFF |

ON: WAKE signal ON OFF: WAKE signal OFF |

Displays the ON/OFF value of terminal WAKE input signal |

|

Backup Power Supply Type |

Backup supply power type |

Capacitor Type / Lithium Type / None |

- |

- |

|

Gear Shift Control Module Backup Signal Status |

System backup signal from the backup supply power |

Wake Up Request / Capacitor Internal Failure / Backup Mode (Low Capacity) / Backup Possible/Remote Charging Complete / Backup Impossible / Communication Stop / Backup Possible/Remote Charging Incomplete / Capacitor Internal Failure (Backup Possible) / Capacitor External Failure / Capacitor External Failure (Backup Possible) / Capacitor External Failure (Brake Factor) |

Normal: Backup Possible/Remote Charging Complete |

Displays the integrated capacitor status based on the waveform input to the BUBI terminal of the shift control ECU |

|

Gear Shift Control Module Backup Request |

System backup request from the backup supply power |

Wake Up/Sleep Permission / Interruption Permission (Not Remote) / ON (Not Remote) / OFF (Not Remote) / ON (Advanced Park) / OFF (Advanced Park) / ON (Stop&Start) |

- |

- |

|

Fail Safe Status (Gear Shift Control Module) |

Fail-safe status of the shift control ECU |

Unknown / OFF / ON |

- |

Hybrid Toyota Prius vehicle control ECU SBFS terminal |

|

Fail Safe Status (Gear Shift Control Module "B" to "A") |

Shift control ECU fail-safe status from the shift actuator ECU |

Normal / Abnormal / Unknown |

- |

Shift control ECU FS terminal |

|

Fail Safe Power Supply Relay Connect Request |

Requested connection status of the shift actuator ECU motor drive relay (fail safe power supply) |

ON / OFF |

OFF: Connection not requested ON: Connection requested |

- |

|

Shift Position (Current Position) |

Actual shift lever position (judged value) |

Home / R / N / D / B/M/S / Not Available |

Home: Shift lever in home position R: Shift lever in R N: Shift lever in N D: Shift lever in D B/M/S: Shift lever in B |

- |

|

Shift Sensor Status |

Shift sensor malfunction status |

Normal / Abnormal / Abnormal (Extreme) |

- |

- |

|

Shift Sensor 1 Status |

Shift lever sensor input signal status |

H / R / N / D / B/M/S / O / Abnormal / Unknown |

Home: Shift lever in home position R: Shift lever in R N: Shift lever in N D: Shift lever in D B/M/S: Shift lever in B O: Outside of range |

Shift sensor (type 1) |

|

Shift Sensor 2 Status |

Shift lever sensor input signal status |

H / R / N / D / B/M/S / O / Abnormal / Unknown |

Home: Shift lever in home position R: Shift lever in R N: Shift lever in N D: Shift lever in D B/M/S: Shift lever in B O: Outside of range |

Shift sensor (type 2) |

|

Shift Sensor 3 Status |

Shift lever sensor input signal status |

H / R / N / D / B/M/S / O / Abnormal / Unknown |

Home: Shift lever in home position R: Shift lever in R N: Shift lever in N D: Shift lever in D B/M/S: Shift lever in B O: Outside of range |

Shift sensor (type 3) |

|

M or S Shift Position Indicator Turn On Request |

Shift position indicator (B) illumination status |

ON / OFF |

ON: Shift state B OFF: Shift state not B |

- |

|

D Shift Position Indicator Turn On Request |

Shift position indicator (D) illumination status |

ON / OFF |

ON: Shift state drive (D) OFF: Shift state not drive (D) |

- |

|

N Shift Position Indicator Turn On Request |

Shift position indicator (N) illumination status |

ON / OFF |

ON: Shift state neutral (N) OFF: Shift state not neutral (N) |

- |

|

R Shift Position Indicator Turn On Request |

Shift position indicator (R) illumination status |

ON / OFF |

ON: Shift state reverse (R) OFF: Shift state not reverse (R) |

- |

|

P Shift Position Indicator Turn On Request |

P position indicator illumination status |

ON / OFF |

ON: Shift state park (P) OFF: Shift state not park (P) |

- |

|

Back Up Light Turn On Request |

Back-up light illumination command |

ON / OFF |

ON: Back-up light illuminated OFF: Back-up light not illuminated |

BL (terminal) output status |

|

Stop Light Switch (Gear Shift Control Module) |

Stop light switch status |

ON / OFF |

ON: Brake pedal depressed OFF: Brake pedal released |

- |

|

P Position Switch Signal Status (Gear Shift Control Module) |

P position switch status |

ON / OFF |

ON: P position switch pushed and held OFF: P position switch not pushed |

- |

|

Not P Position Learning Value (Output Side) |

Learned value (output axis) in accordance with the shift state other than P |

Min.: 0.0 deg, Max.: 124.5 deg |

21.8 to 35.8 deg |

- |

|

Not P Position Learning Value (Motor Side) |

Learned value (calculated output axis angle based on the detected motor axis angle) in accordance with the shift state other than P |

Min.: 0.00 deg, Max.: 42949672.95 deg |

50.20 to 64.60 deg |

- |

|

Absolute Angle Sensor Value 1 |

Value of axis sensor 1 (detected angle) |

Min.: 0.0 deg, Max.: 124.5 deg |

0.0 to 46.6 deg |

- |

|

Absolute Angle Sensor Value 2 |

Value of axis sensor 2 (detected angle) |

Min.: 0.0 deg, Max.: 124.5 deg |

0.0 to 46.6 deg |

- |

|

Gear Shift Actuator Power Supply Voltage (MA1) |

Voltage of gear shift motor supply power terminal (MA1) |

Min.: 0 V, Max.: 255 V |

8 to 15 V |

Displays the voltage input signal of shift control ECU terminal (MA1) |

|

Gear Shift Actuator Power Supply Voltage (MA2) |

Voltage of gear shift motor supply power terminal (MA2) |

Min.: 0 V, Max.: 255 V |

8 to 15 V: Ignition switch ON |

Displays the voltage input signal of shift control ECU terminal (MA2) |

|

Gear Shift Actuator Motor Angle Sensor Value |

Value of motor axis sensor (detected angle) |

Min.: 0.00 deg, Max.: 358.59 deg |

0.00 to 358.59 deg |

- |

|

Gear Shift Actuator Motor Speed |

Gear shift motor rotation speed |

Min.: 0.00 rpm deg, Max.: 10160.15 rpm |

0.00 to 10000.00 rpm |

- |

|

Gear Shift Actuator Power Supply Relay Downstream Voltage |

Internal voltage of the actuator downstream of the motor supply power relay |

Min.: 0 V, Max.: 255 V |

8 to 15 V: Ignition switch ON |

Internal voltage of shift control actuator |

|

U Phase Parking Lock Motor Current-Carrying Status (Gear Shift Control Module "B") |

Parking lock motor (U phase) drive signal |

ON / OFF |

ON: U phase energized OFF: U phase not energized |

- |

|

V Phase Parking Lock Motor Current-Carrying Status (Gear Shift Control Module "B") |

Parking lock motor (V phase) drive signal |

ON / OFF |

ON: V phase energized OFF: V phase not energized |

- |

|

W Phase Parking Lock Motor Current-Carrying Status (Gear Shift Control Module "B") |

Parking lock motor (W phase) drive signal |

ON / OFF |

ON: W phase energized OFF: W phase not energized |

- |

|

U Phase Parking Lock Motor Terminal Current |

Current of the parking lock motor terminal (U phase) |

Min.: -64.0 A, Max.: 63.5 A |

-62.5 to 62.5 A |

- |

|

V Phase Parking Lock Motor Terminal Current |

Current of the parking lock motor terminal (V phase) |

Min.: -64.0 A, Max.: 63.5 A |

-62.5 to 62.5 A |

- |

|

W Phase Parking Lock Motor Terminal Current |

Current of the parking lock motor terminal (W phase) |

Min.: -64.0 A, Max.: 63.5 A |

-62.5 to 62.5 A |

- |

|

ACT Relay Connect Status |

Connection status of drive relay of the shift actuator ECU motor |

ON / OFF |

OFF: Not connected ON: Connected |

- |

|

ACT Relay Connect Request |

Requested connection status of drive relay of the shift actuator ECU motor |

ON / OFF |

OFF: Connection not requested ON: Connection requested |

- |

|

ACT Position Status |

Status of the shift actuator ECU |

Other than P / None / Shift in P |

Shift in P: Shift state P Other than P: Shift state not P None: Other than above |

- |

|

ACT Position Drive Request |

Operation request position of the shift actuator ECU |

Output NG / Shift in P / Other than P |

Shift in P: P position request Other than P: Not P position Output NG: Not requested |

- |

|

ACT Operation Status |

Operation status of the shift actuator ECU |

ON / OFF |

OFF: Shift actuator ECU stopped ON: Shift actuator ECU changing |

- |

|

ACT Function Informing Status |

Function failure status of the shift actuator ECU |

Normal / Maintenance / Outside Judgment Guaranteed / Outside Operation Guaranteed / Outside Judgment/Operation Guaranteed / Operation NG / Operation NG/Outside Judgment Guaranteed |

Normal: Normal condition Other than above: Malfunctioning |

- |

|

ACT Monitoring Information |

Monitor status of the shift actuator ECU |

Normal / Driver Malfunction 1 / Driver Malfunction 2 / Driver Malfunction 3 / Driver Malfunction 4 / Driver Malfunction 5 / Driver Malfunction 6 / Sensor Malfunction 1 / Sensor Malfunction 2 / Sensor Malfunction 3 / Driver Malfunction 7 / Motor Malfunction 1 / Motor Malfunction 2 / Motor Malfunction 3 |

Normal: Normal condition Other than above: Malfunctioning |

- |

|

ACT Position Learning Complete Status |

Learning complete status of the shift actuator ECU |

Incomplete / Running / Abort / Complete |

Incomplete: Before learning Running: Learning in progress Abort: Learning failed Complete: Learning complete / normal |

When the shift actuator ECU (shift control actuator assembly) has been removed, perform initialization and learning and confirm that they complete successfully. |

|

Shift Request during Advanced Drive/Park |

Shift request during advanced park operation |

OFF / ON (Gear Shift Control Module) / ON (Clearance Warning Control Module Semi-Auto) / ON (Clearance Warning Control Module Full-Auto) / ON (Advanced Drive Control Module) |

OFF: No shift request ON (Gear Shift Control Module): Is shift request |

- |

|

IGCT-Scene Signal Status (Gear Shift Control Module) |

IGCT-SCENE signal status of the shift control ECU |

ON / OFF |

ON: Ignition switch ON |

Displays the ON/OFF value of terminal IGCT or IGS input signal |

|

IGCT-Scene Signal Status (Gear Shift Control Module "B") |

IGCT-SCENE signal status of the shift actuator ECU |

ON / OFF |

ON: Ignition switch ON |

Displays the ON/OFF value of terminal IGC1 or IGS1 input signal |

|

Shift P Operation during Running Trigger Counter |

Number of times P switch was pressed while Toyota Prius vehicle being driven |

Min: 0, Max: 255 |

- |

- |

|

Shift P Operation before Vehicle Stop Trigger Counter |

Number of times shift state was not changed to P when P position switch was operated before Toyota Prius vehicle stopped |

Min: 0, Max: 255 |

- |

- |

|

Shift P Operation during Other than Shift P Operation Trigger Counter |

Number of times the P position switch was operated when the shift lever was not in the home position |

Min: 0, Max: 255 |

- |

- |

|

Auto Change to Shift Position P Cancel Trigger Counter |

Number of times P position automatic change function did not operate |

Min: 0, Max: 255 |

- |

- |

|

Voltage Low for Shift Control System Trigger Counter |

Number of times shift control system did not operate due to low voltage |

Min: 0, Max: 255 |

- |

- |

|

Shift Operation when Auxiliary Battery Voltage Low Trigger Counter |

Number of times a shift operation was performed while auxiliary battery voltage was low |

Min: 0, Max: 255 |

- |

- |

|

Consecutive Shift Change between Shift P and Other than Shift P in Short Times Trigger Counter |

Number of times shift state was attempted to be changed between P and other than P within a short period of time |

Min: 0, Max: 255 |

- |

- |

|

Shift Operation during Ready Indicator Blinking Trigger Counter |

Number of times shift state was attempted to be changed from P with READY indicator light blinking |

Min: 0, Max: 255 |

- |

- |

|

Shift R/D/B(S) Operation during Ready OFF Trigger Counter |

Number of times shift state was attempted to be changed to R, D or B with READY indicator not illuminated |

Min: 0, Max: 255 |

- |

- |

|

Shift Operation without Depressing Brake from Shift Position P Trigger Counter |

Number of times shift state was attempted to be changed from P with brake pedal not depressed |

Min: 0, Max: 255 |

- |

- |

|

Shift Operation during Accelerator & Brake Depress Trigger Counter |

Number of times shift state was attempted to be changed from P with READY indicator light illuminated and accelerator and brake pedals depressed |

Min: 0, Max: 255 |

- |

- |

|

Shift B(S) Operation from Shift Position P/N Trigger Counter |

Number of times shift state was attempted to be changed from P or N to B |

Min: 0, Max: 255 |

- |

- |

|

Shift B(S) Operation from Shift Position R Trigger Counter |

Number of times shift state was attempted to be changed from R to B |

Min: 0, Max: 255 |

- |

- |

|

Shift D Operation during Backward Movement Trigger Counter |

Number of times shift state was attempted to be changed to D while reversing |

Min: 0, Max: 255 |

- |

- |

|

Shift R Operation during Forward Movement Trigger Counter |

Number of times shift state was attempted to be changed to R while driving forward |

Min: 0, Max: 255 |

- |

- |

|

Shift R/D Operation during Ready OFF Trigger Counter |

Number of times shift state was attempted to be changed to R, D or B with READY indicator not illuminated and the ignition switch ON |

Min: 0, Max: 255 |

- |

- |

|

Shift N Operation during Running Trigger Counter |

Number of times shift state was changed to N by holding shift lever in N for a certain amount of time while driving |

Min: 0, Max: 255 |

- |

- |

|

Quick Shift Operation to Shift Position N during Running Trigger Counter |

Number of times shift state was changed to N when shift lever not held in N while driving |

Min: 0, Max: 255 |

- |

- |

|

Shift N Change by Busy Shift Trigger Counter |

Number of times shift state was changed to neutral (N) by moving the shift lever to R, D and/or N repeatedly within short period of time |

Min: 0, Max: 255 |

- |

- |

|

Shift N Operation on The Way Back to Home Position after Shift D/R Operation Trigger Counter |

Number of times shift state was changed to N when shift lever was returning from R or D |

Min: 0, Max: 255 |

- |

- |

|

Shift R Operation on The Way Back to Home Position after Shift D Operation Trigger Counter |

Number of times shift state was changed to D when shift lever was returning from R |

Min: 0, Max: 255 |

- |

- |

|

Shift D Operation on The Way Back to Home Position after Shift R Operation Trigger Counter |

Number of times shift state was changed to R when shift lever was returning from D |

Min: 0, Max: 255 |

- |

- |

|

Shift N Operation at Short Times during Low Speed/Stopping Trigger Counter |

Number of times shift state was attempted to be changed to N without holding shift lever in N for a long enough time when driving at low speed or stopped |

Min: 0, Max: 255 |

- |

- |

|

Shift P Repeated Operation Trigger Counter during Running |

Number of times shift state changed to N as P position switch was consecutively operated while driving |

Min: 0, Max: 255 |

- |

- |

|

Shift P Hold Down Trigger Counter during Running |

Number of times shift state changed to N as P position switch was pressed and held while driving |

Min: 0, Max: 255 |

- |

- |

|

Shift P Operation when Auxiliary Battery Low Voltage Trigger Counter |

Number of times that the P position switch was operated during battery power failure |

Min: 0, Max: 255 |

- |

- |

|

Auto Change to Shift Position P when Driver Get Out Trigger Counter |

Number of times shift state changed to P automatically due to driver exiting Toyota Prius vehicle |

Min: 0, Max: 255 |

- |

- |

|

Shift Position N Hold Mode ON during IG OFF/ACC ON Trigger Counter |

Number of times the ignition switch was turned off with the shift state N |

Min: 0, Max: 255 |

- |

- |

|

Shift Operation on Gradient during Ready OFF Trigger Counter |

Number of times a shift operation was performed while on an incline with the ignition switch ON, not in READY mode |

Min: 0, Max: 255 |

- |

- |

|

Shift Operation during Advanced Drive/Park Trigger Counter |

Number of times a shift operation was performed while advanced drive or advanced park was operating |

Min: 0, Max: 255 |

- |

- |

|

Shift P Operation during Advanced Drive/Park Trigger Counter |

Number of times the P position switch was operated while advanced drive or advanced park was operating |

Min: 0, Max: 255 |

- |

- |

|

Shift Operation during Release Shift P Restriction Request Trigger Counter |

Number of times shift state was attempted to be changed from P during P release prohibit request |

Min: 0, Max: 255 |

- |

- |

|

Shift D/R Operation Rejection from Shift Position N without Depressing Brake Pedal Trigger Counter |

Number of times shift state was attempted to be changed from N to drive state with brake pedal not depressed |

Min: 0, Max: 255 |

- |

- |

|

Shift D/R Operation Rejection from Shift Position N during Accelerator Pedal Depress Trigger Counter |

Number of times shift state was attempted to be changed from N to drive state with accelerator pedal depressed |

Min: 0, Max: 255 |

- |

- |

VEHICLE CONTROL HISTORY (RoB)

VEHICLE CONTROL HISTORY (RoB)

CHECK THE VEHICLE CONTROL HISTORY (HYBRID CONTROL)

HINT:

- The vehicle control history data (Hybrid control) stores the history of the reject function and system protection operations.

- The number of occurrences, date and distance are stored in batches for each item.

(a) Toyota Prius Vehicle Control History:

Powertrain > Hybrid Control > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

NOTICE:

When several Toyota Prius vehicle control histories are stored, prioritize performing the required actions for "Voltage Low for Shift Control System".

|

Code |

Tester Display |

Measurement Item |

Diagnostic Note |

|---|---|---|---|

|

X0500 |

Shift P Operation during Running |

History of P position switch operation while driving |

Operate the P position switch after the Toyota Prius vehicle has stopped |

|

X0501 |

Shift Operation when Auxiliary Battery Voltage Low |

History of shift position change attempted when auxiliary battery voltage was low |

Replace or recharge the auxiliary battery |

|

X0502 |

Consecutive Shift Change between Shift P and Other than Shift P in Short Times |

History of shift state being attempted to be changed to and from P within a short period of time |

Wait for a while and then attempt to change the shift state again, or try again after turning the ignition switch to ON (READY) |