Toyota Prius: Sfi System

- Precaution

- Definition Of Terms

- Parts Location

- System Diagram

- How To Proceed With Troubleshooting

- Check For Intermittent Problems

- Basic Inspection

- Registration

- Initialization

- Terminals Of Ecm

- Diagnosis System

- Dtc Check / Clear

- Freeze Frame Data

- Check Mode Procedure

- Fail-safe Chart

- Data List / Active Test

- Vehicle Control History

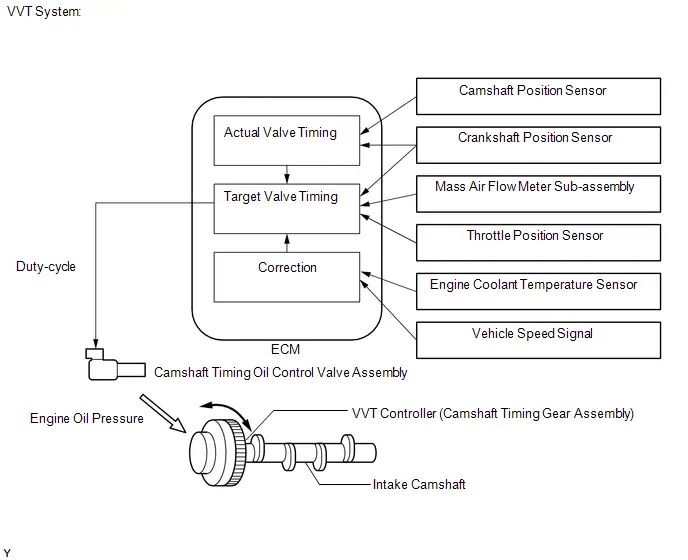

- A Camshaft Position Actuator Bank 1 Circuit Open (P001013)

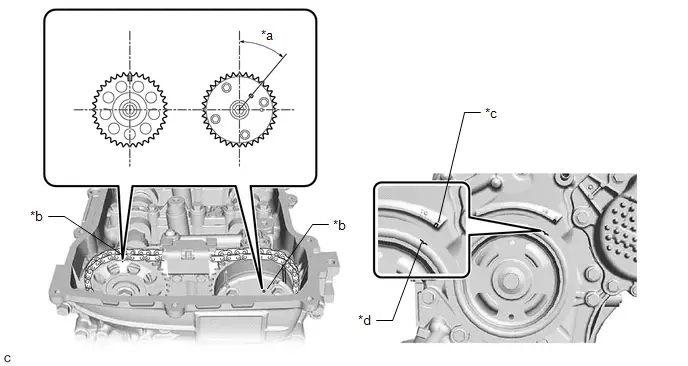

- Camshaft Position "A" - Timing Over-Advanced or System Performance Bank 1 (P001100,P001200)

- Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor A (P001600)

- HO2S Heater Control Bank 1 Sensor 1 Circuit Short to Battery (P003012,P003013,P101A9E)

- HO2S Heater Control Circuit Bank 1 Sensor 2 Circuit Short to Battery (P003612,P003614,P102A9E)

- Manifold Absolute Pressure - Barometric Pressure Correlation (P006900)

- Mass or Volume Air Flow Sensor "A" Circuit Short to Battery (P010012,P010014)

- Manifold Absolute Pressure / Barometric Pressure Sensor Circuit Short to Ground (P010511)

- Manifold Absolute Pressure / Barometric Pressure Sensor Circuit Short to Battery or Open (P010515)

- Intake Air Temperature Sensor 1 Bank 1 Circuit Short to Ground (P011011)

- Intake Air Temperature Sensor 1 Bank 1 Circuit Short to Battery or Open (P011015)

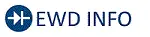

- Engine Coolant Temperature Sensor 1 Circuit Short to Ground (P011511)

- Engine Coolant Temperature Sensor 1 Circuit Short to Battery or Open (P011515)

- Engine Coolant Temperature Sensor 1 Signal Stuck in Range (P01152A)

- Throttle / Pedal Position Sensor / Switch "A" Circuit Short to Ground (P012011)

- Throttle / Pedal Position Sensor / Switch "A" Circuit Short to Battery or Open (P012015)

- Throttle / Pedal Position Sensor / Switch "A" Circuit Voltage Out of Range (P01201C)

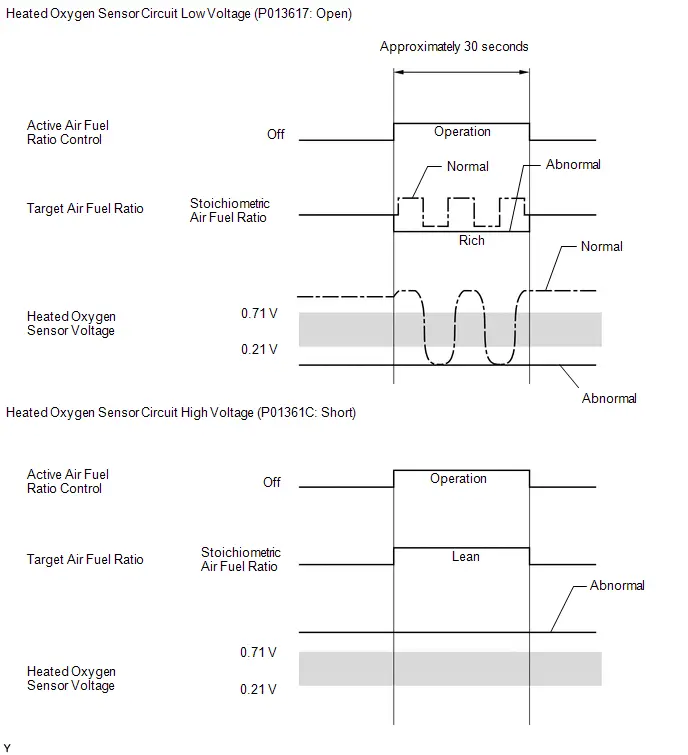

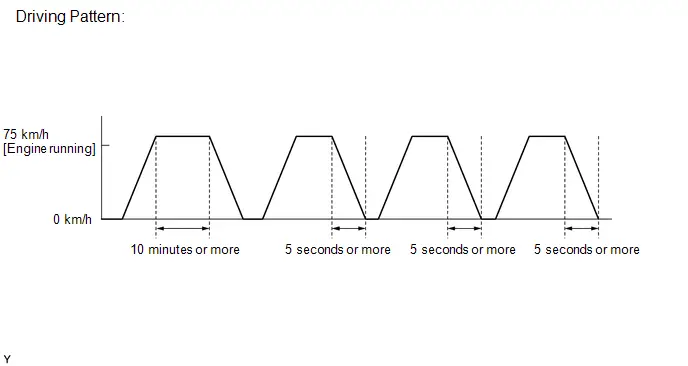

- O2 Sensor Circuit Bank 1 Sensor 2 Circuit Open (P013613,P013617,P01361C)

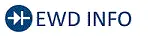

- System Too Lean Bank 1 (P017100,P017200)

- Throttle/Pedal Position Sensor/Switch "B" Circuit Short to Ground (P022011)

- Throttle/Pedal Position Sensor/Switch "B" Circuit Short to Battery or Open (P022015)

- Random/Multiple Cylinder Misfire Detected (P030000,P030027,P030085-P030400)

- Knock Sensor 1 Bank 1 or Single Sensor Circuit Short to Ground (P032511)

- Knock Sensor 1 Bank 1 or Single Sensor Circuit Short to Battery or Open (P032515)

- Crankshaft Position Sensor "A" Circuit Short to Ground (P033511)

- Crankshaft Position Sensor "A" Circuit Short to Battery or Open (P033515)

- Crankshaft Position Sensor "A" Signal Stuck in Range (P03352A)

- Crankshaft Position Sensor "A" No Signal (P033531)

- Camshaft Position Sensor "A" Bank 1 or Single Sensor Circuit Short to Ground (P034011)

- Camshaft Position Sensor "A" Bank 1 or Single Sensor Circuit Short to Battery or Open (P034015)

- Camshaft Position Sensor "A" Bank 1 or Single Sensor Signal Stuck in Range (P03402A)

- Camshaft Position Sensor "A" Bank 1 or Single Sensor No Signal (P034031)

- Exhaust Gas Recirculation "A" Low / Insufficient Flow (P04019C)

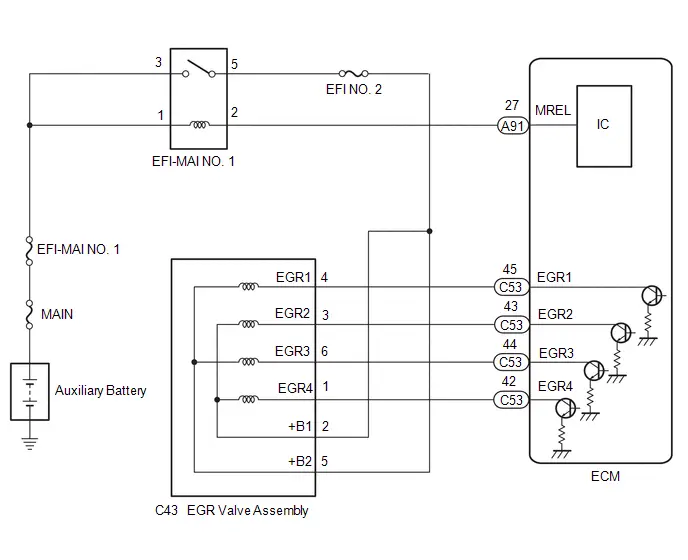

- Exhaust Gas Recirculation "A" Control Circuit 1 Open (P040314,P140000,P140596,P141004)

- Catalyst System Efficiency Below Threshold Bank 1 (P042000)

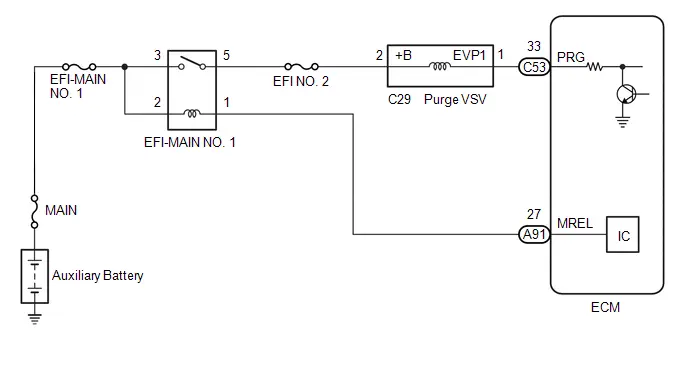

- Evaporative Emission System Purge Control Valve "A" Circuit Open (P044313)

- System Voltage Circuit Short to Ground or Open (P056014)

- Internal Control Module Random Access Memory (RAM) Error Data Memory Failure (P060444)

- Control Module Processor Watchdog/Safety MCU Failure (P060647)

- Control Module Performance Bank 1 Watchdog/Safety MCU Failure (P060747,P060787)

- Internal Control Module Throttle Position Performance Internal Electronic Failure (P060E49)

- VIN Not Programmed (P063051)

- Actuator Supply Voltage "A" Circuit Short to Ground or Open (P065714)

- Throttle Actuator "A" Control Motor Circuit Current Below Threshold (P210018,P210019)

- Throttle/Pedal Position Sensor "A" Minimum Stop Performance (P210900)

- Throttle Actuator "A" Control System Actuator Stuck Open (P211172,P211173)

- Throttle Actuator "A" Control Throttle Body Range/Performance (P211900,P211904,P211977,P21199B)

- Throttle/Pedal Position Sensor/Switch "A"/"B" Voltage Correlation Signal Cross Coupled (P21352B)

- A/F (O2) Sensor Signal Biased/Stuck Lean Bank 1 Sensor 1 Circuit Current Above Threshold (P219519,P219524,P219618,P219623)

- Barometric Pressure Sensor "A" Circuit Short to Ground (P222611,P222615)

- Barometric Pressure Sensor "A" Missing Message (P222687,P222696)

- A/F (O2) Sensor Positive Current Control Circuit / Open Bank 1 Sensor 1 (P223700,P223711,P223712,P223713,P22371B,P225111,P225112)

- Ignition Switch On/Start Position Circuit Low Circuit Short to Ground or Open (P253314)

- ECM/PCM Engine Off Timer Performance Signal Invalid (P261029)

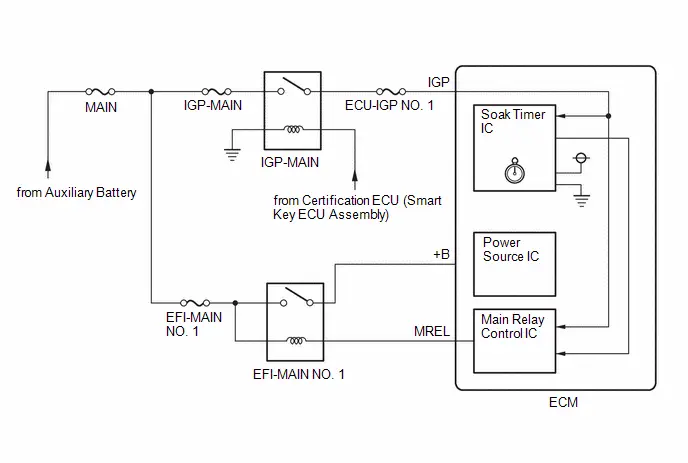

- Engine Coolant Pump Circuit Short to Battery (P26CA12)

- Engine Coolant Pump No Signal (P26CA31)

- Engine Coolant Pump Actuator Stuck (P26CB71)

- Engine Coolant Pump Overspeed (P26CE37)

- O2 Sensor Circuit Range/Performance Bank 1 Sensor 1 Signal Rate of Change Below Threshold (P2A0026)

- Poor Engine Power (P319000,P319100)

- Fuel Run Out (P319300)

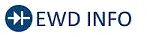

- Lost Communication with Drive Motor Control Module "A" Missing Message (U011087)

- Lost Communication with Hybrid/EV Battery Energy Control Module "A" Missing Message (U011187)

- Lost Communication With Hybrid Powertrain Control Module Missing Message (U029387)

- Lost Communication with Hybrid Powertrain Control Module (ch2) Missing Message (U115087)

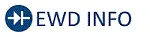

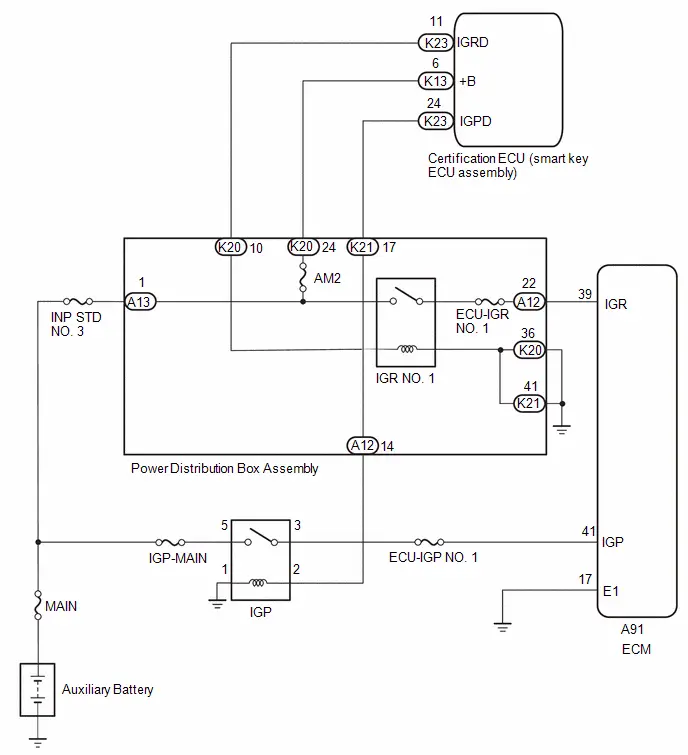

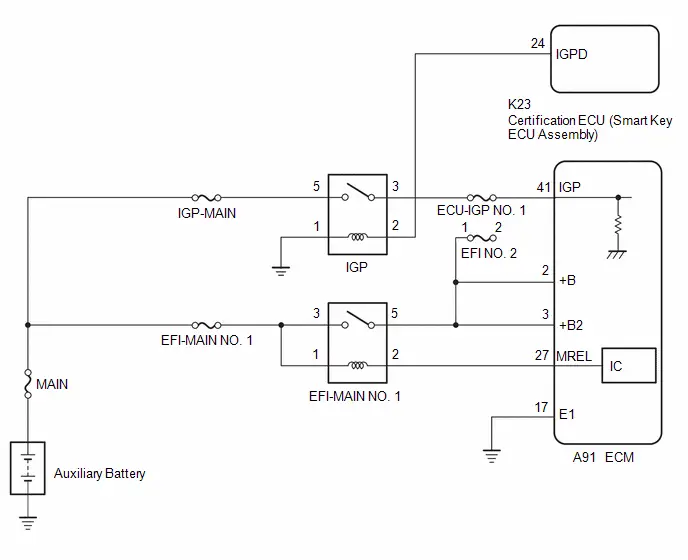

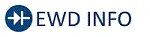

- ECM Power Source Circuit

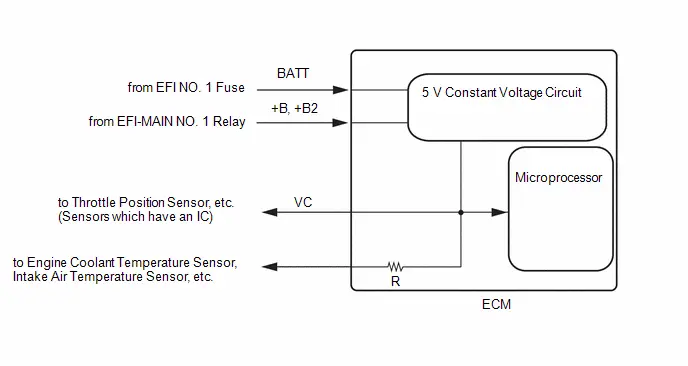

- VC Output Circuit

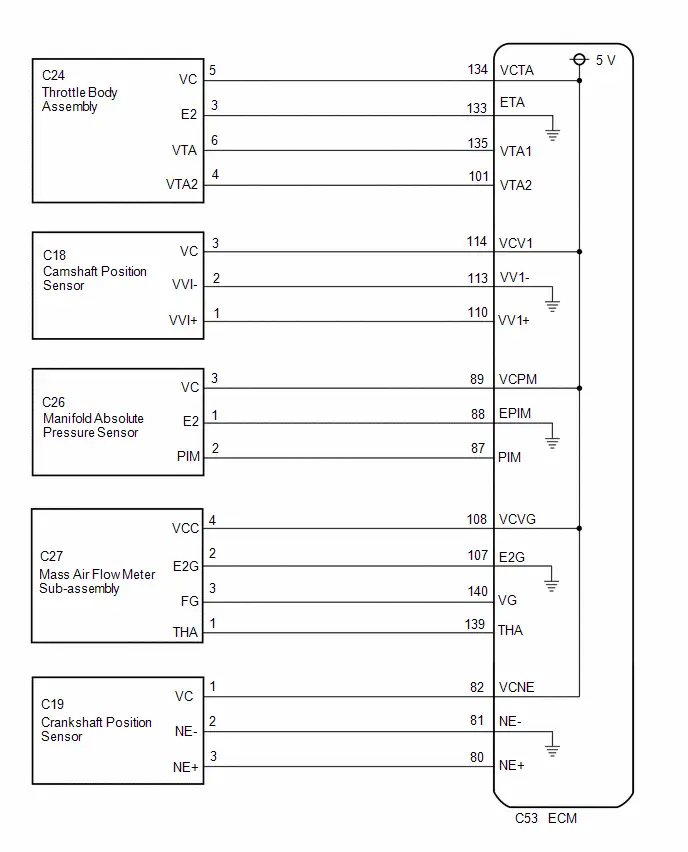

- Fuel Pump Control Circuit

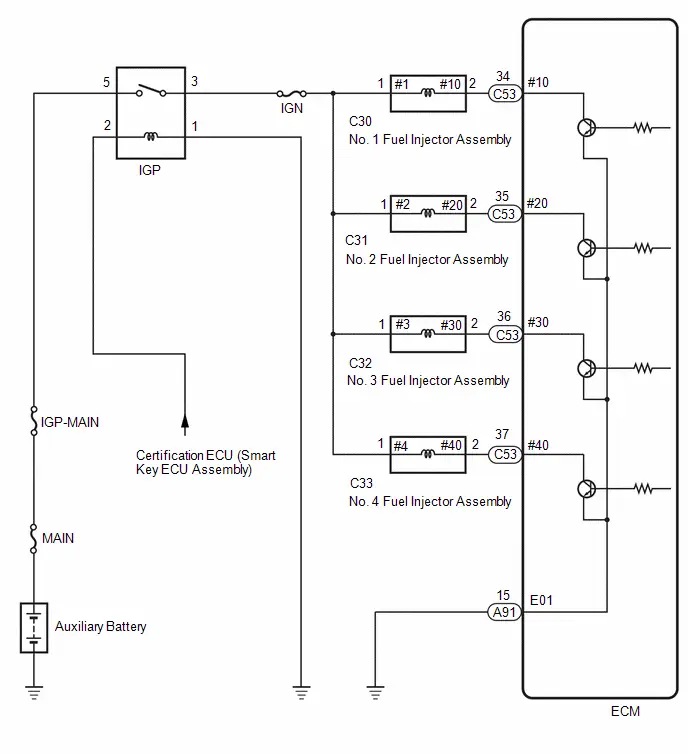

- Fuel Injector Circuit

- MIL Circuit

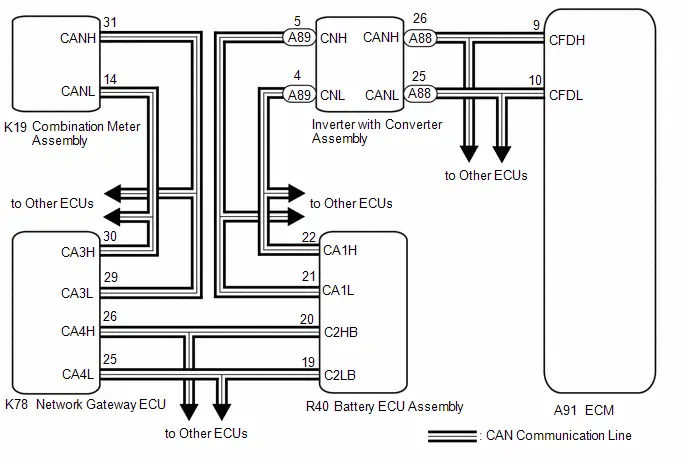

- Ignition Circuit

- Rough Idling

Precaution

PRECAUTION

WHEN USING GTS

CAUTION:

Observe the following items for safety reasons:

- Before using the GTS, read the instruction manual.

- Prevent the GTS cable from being caught on the pedals, shift lever or steering wheel when driving with the GTS connected to the Toyota Prius vehicle.

- When driving the vehicle for testing purposes using the GTS, 2 persons are required. One to drive the vehicle, and another to operate the GTS.

INITIALIZATION

NOTICE:

-

Perform Registration (VIN registration or frame number registration) when replacing the ECM.

Click here

-

When the ECM is replaced, update the ECU security key.

Click here

-

Perform Learning Value Reset and Idle Learning after replacing or servicing parts related to engine operation.

Click here

PRECAUTIONS FOR DISCONNECTING CABLE FROM NEGATIVE (-) AUXILIARY BATTERY TERMINAL

NOTICE:

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

PRECAUTIONS FOR INSPECTING HYBRID CONTROL SYSTEM

(a) Refer to Hybrid Control System.

Click here

NOTICE FOR HYBRID CONTROL SYSTEM ACTIVATION

(a) Refer to Hybrid Control System.

Click here

Definition Of Terms

DEFINITION OF TERMS

| Term | Definition |

|---|---|

| Monitor Description | Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and details). |

| Typical Enabling Conditions | Preconditions that allow the ECM to detect malfunctions. With all preconditions satisfied, the ECM stores a DTC when the monitored value(s) exceeds the malfunction threshold(s). |

| Required Sensors/Components | The sensors and components that are used by the ECM to detect malfunctions. |

| Frequency of Operation | The number of times that the ECM checks for malfunctions per driving cycle. "Once per driving cycle" means that the ECM detects a malfunction only once during a single driving cycle. "Continuous" means that the ECM detects a malfunction every time the enabling conditions are met. |

| Duration | The minimum time for which the ECM must detect a continuous deviation in the monitored value(s) in order to store a DTC. Timing begins after the "typical enabling conditions" are met. |

| Typical Malfunction Thresholds | Value beyond which the ECM will determine that there is a malfunction and stores a DTC. |

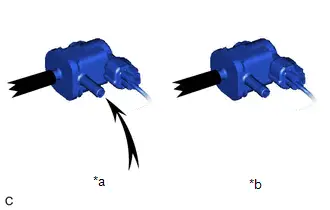

Parts Location

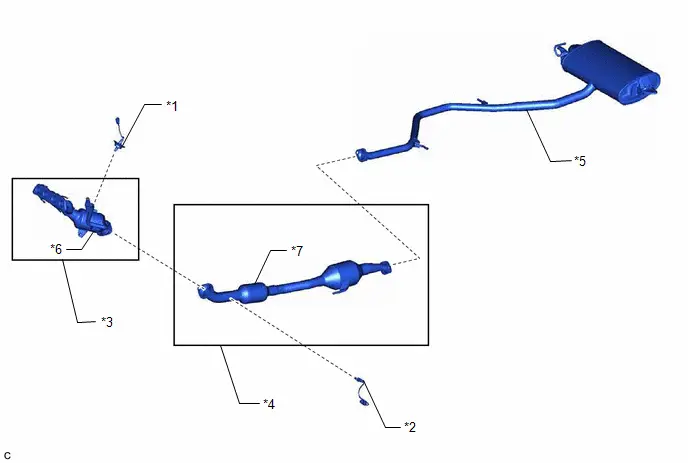

PARTS LOCATION

ILLUSTRATION

| *1 | AIR FUEL RATIO SENSOR | *2 | FUEL PUMP |

| *3 | HEATED OXYGEN SENSOR | *4 | MASS AIR FLOW METER SUB-ASSEMBLY |

| *5 | NO. 1 ENGINE ROOM RELAY BLOCK AND NO. 1 JUNCTION BLOCK ASSEMBLY | *6 | ECM |

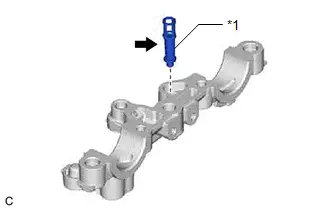

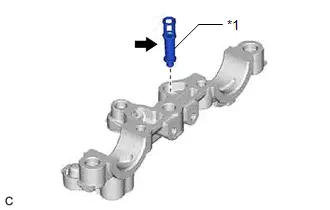

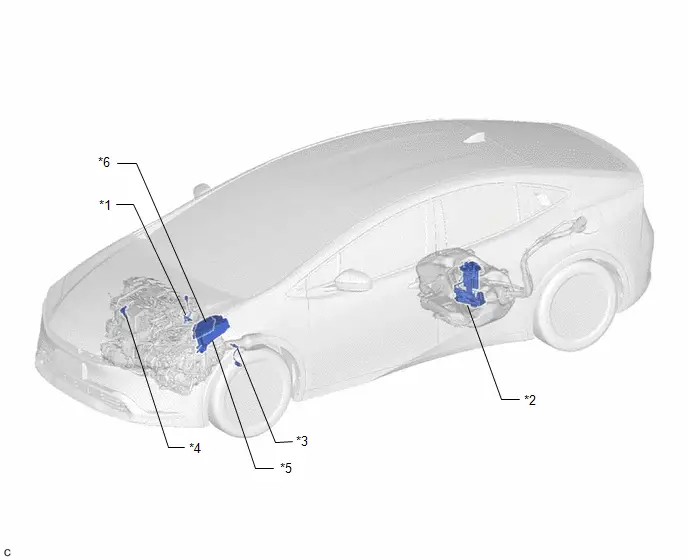

ILLUSTRATION

| *1 | CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY | *2 | CRANKSHAFT POSITION SENSOR |

| *3 | EGR VALVE ASSEMBLY | *4 | ENGINE COOLANT TEMPERATURE SENSOR |

| *5 | FUEL INJECTOR ASSEMBLY | *6 | KNOCK CONTROL SENSOR |

| *7 | PURGE VSV | *8 | THROTTLE BODY ASSEMBLY |

| *9 | ENGINE WATER PUMP ASSEMBLY | *10 | MANIFOLD ABSOLUTE PRESSURE SENSOR |

| *11 | IGNITION COIL ASSEMBLY | *12 | CAMSHAFT POSITION SENSOR |

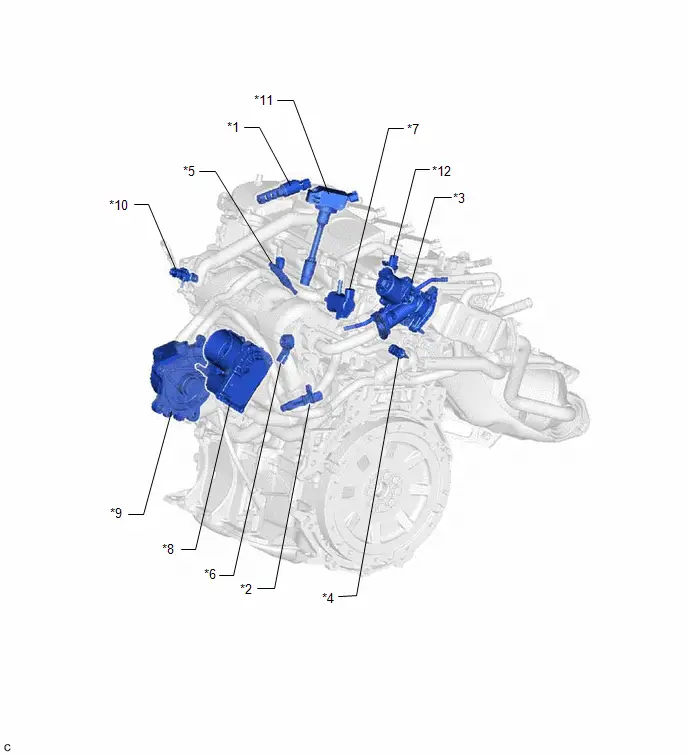

ILLUSTRATION

| *1 | COMBINATION METER ASSEMBLY | *2 | HYBRID Toyota Prius Vehicle CONTROL ECU |

| *3 | DLC3 | - | - |

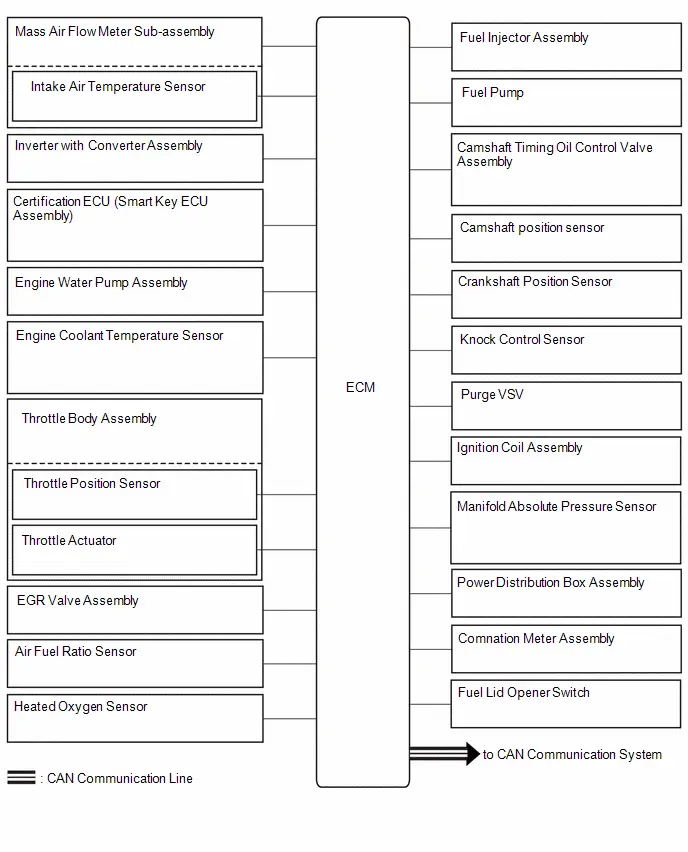

System Diagram

SYSTEM DIAGRAM

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

*: Use the GTS.

PROCEDURE

| 1. | VEHICLE BROUGHT TO WORKSHOP |

|

| 2. | CUSTOMER PROBLEM ANALYSIS |

|

| 3. | CONNECT GTS TO DLC3* |

HINT:

If the display indicates a communication malfunction, inspect the DLC3.

When any CAN communication system DTCs are output, perform troubleshooting for the CAN communication system first.

|

| 4. | CHECK DTC AND FREEZE FRAME DATA* |

(a) Check for DTCs.

Powertrain > Engine > Trouble Codes(b) Check for freeze frame data.

Click here

HINT:

Record or print DTCs and freeze frame data if necessary.

|

| 5. | CLEAR DTC AND FREEZE FRAME DATA* |

(a) Clear the DTCs and freeze frame data.

Powertrain > Engine > Clear DTCs

|

| 6. | CONDUCT VISUAL INSPECTION |

|

| 7. | SELECT CHECK MODE DIAGNOSIS* |

(a) Change the ECM from normal mode to check mode.

Click here

| Tester Display |

|---|

| Check Mode |

|

| 8. | CONFIRM PROBLEM SYMPTOMS |

(a) Confirm the problem symptoms.

HINT:

If the engine does not start, first perform the "Check DTC" procedure and "Conduct Basic Inspection" procedure below.

| Result | Proceed to |

|---|---|

| Malfunction does not occur | A |

| Malfunction occurs | B |

| B |

| GO TO STEP 10 |

|

| 9. | SIMULATE SYMPTOMS |

HINT:

Refer to Symptom Simulation.

Click here

|

| 10. | CHECK DTC* |

(a) Check for DTCs.

Powertrain > Engine > Trouble Codes| Result | Proceed to |

|---|---|

| DTCs are output | A |

| DTCs are not output | B |

| B |

| GO TO STEP 12 |

|

| 11. | REFER TO DTC CHART |

HINT:

Refer to Diagnostic Trouble Code Chart.

Click here

|

| 12. | CONDUCT BASIC INSPECTION |

(a) Conduct basic inspection.

Click here

| Result | Proceed to |

|---|---|

| Malfunctioning parts not confirmed | A |

| Malfunctioning parts confirmed | B |

| B |

| GO TO STEP 17 |

|

| 13. | REFER TO PROBLEM SYMPTOMS TABLE |

HINT:

Refer to Problem Symptoms Table.

Click here

| Result | Proceed to |

|---|---|

| Malfunctioning circuit confirmed | A |

| Malfunctioning parts confirmed | B |

| B |

| GO TO STEP 17 |

|

| 14. | CHECK ECM POWER SOURCE CIRCUIT |

(a) Check the ECM power source circuit.

Click here

|

| 15. | CONDUCT CIRCUIT INSPECTION |

| Result | Proceed to |

|---|---|

| Malfunction not confirmed | A |

| Malfunction confirmed | B |

| B |

| GO TO STEP 18 |

|

| 16. | CHECK FOR INTERMITTENT PROBLEMS |

(a) Check for intermittent problems.

Click here

|

| 17. | CONDUCT PARTS INSPECTION |

|

| 18. | IDENTIFY PROBLEM |

|

| 19. | ADJUST AND/OR REPAIR |

|

| 20. | CONDUCT CONFIRMATION TEST |

| NEXT |

| END |

Check For Intermittent Problems

CHECK FOR INTERMITTENT PROBLEMS

HINT:

Inspect the vehicle ECM using check mode. Intermittent problems are easier to detect with the GTS when the ECM is in check mode. In check mode, the ECM uses 1 trip detection logic, which is more sensitive to malfunctions than normal mode (default), which uses 2 trip detection logic.

-

Clear the DTCs.

Click here

-

Change the ECM from normal mode to check mode using the GTS.

Click here

-

Perform a simulation test.

Click here

-

Check and wiggle the harness(es), connector(s) and terminal(s).

Click here

Basic Inspection

CAUTION / NOTICE / HINT

When a malfunction is not confirmed by the DTC check, troubleshooting should be carried out for all circuits considered to be possible causes of the problem. In many cases, by carrying out the basic engine check shown in the following procedure, the location of the problem can be found quickly and efficiently. Therefore, using this check is essential when troubleshooting the engine.

PROCEDURE

| 1. | CHECK AUXILIARY BATTERY VOLTAGE |

NOTICE:

Carry out this check with the engine stopped and the ignition switch off.

| Result | Proceed to |

|---|---|

| 11 V or higher | OK |

| Below 11 V | NG |

| NG |

| CHARGE OR REPLACE AUXILIARY BATTERY |

|

| 2. | CHECK WHETHER ENGINE CRANKS |

| NG |

| PROCEED TO PROBLEM SYMPTOMS TABLE |

|

| 3. | CHECK WHETHER ENGINE STARTS |

| NG |

| GO TO STEP 6 |

|

| 4. | CHECK AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

(a) Visually check that the air cleaner filter element sub-assembly is not excessively contaminated with dirt or oil.

| NG |

| REPLACE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

|

| 5. | CHECK IDLE SPEED |

(a) Check the engine idle speed.

Click here

| NG |

| PROCEED TO PAGE AND CONTINUE TO TROUBLESHOOT |

|

| 6. | CHECK FUEL PRESSURE |

(a) Check the fuel pressure.

Click here

| NG |

| PROCEED TO PAGE AND CONTINUE TO TROUBLESHOOT |

|

| 7. | CHECK FOR SPARK |

(a) Perform a spark test.

Click here

| OK |

| PROCEED TO PROBLEM SYMPTOMS TABLE |

| NG |

| PROCEED TO PAGE AND CONTINUE TO TROUBLESHOOT |

Registration

REGISTRATION

CAUTION / NOTICE / HINT

PROCEDURE

1. VIN or FRAME NUMBER

NOTICE:

The Vehicle Identification Number (VIN) or frame number must be written to a replacement ECM.

(a) DESCRIPTION

HINT:

This registration section consists of 2 parts: Read VIN or Frame Number and Write VIN or Frame Number.

(1) Read VIN or Frame Number: This procedure allows the VIN or frame number stored in the ECM to be read in order to confirm that the VINs or frame numbers, provided on the Toyota Prius vehicle body and stored in the vehicle ECM, are the same.

(2) Write VIN or Frame Number: This procedure allows the VIN or frame number to be written to the ECM. If the ECM is replaced, or the ECM VIN or frame number and vehicle VIN or frame number do not match, the VIN or frame number can be registered, or overwritten in the ECM by following this procedure.

(b) READ VIN OR FRAME NUMBER

(1) Confirm the Toyota Prius vehicle VIN or frame number.

(2) Enter the following menus: Powertrain / Engine / Utility / VIN / VIN Read.

Powertrain > Engine > Utility| Tester Display |

|---|

| VIN |

(3) According to the display on the GTS, read the frame number or VIN stored in the ECM.

(c) WRITE VIN OR FRAME NUMBER

(1) Confirm the Toyota Prius vehicle VIN or frame number.

(2) Enter the following menus: Powertrain / Engine / Utility / VIN / VIN Write.

Powertrain > Engine > Utility| Tester Display |

|---|

| VIN |

(3) According to the display on the GTS, write the Toyota Prius vehicle frame number or VIN to the ECM.

Initialization

INITIALIZATION

Inspection After Repair

Perform Learning Value Reset and Idle Learning after replacing or servicing parts related to engine operation. Details on procedures required are indicated by an asterisk and a number, and are explained in detail following the table.

| Part Replaced | Engine Operation | Learning Value Reset*1 | Idle Learning*2 |

|---|---|---|---|

| - | ○ | ○ |

| Engine assembly | - | ○ | ○ |

| Confirm the following and perform Learning Value Reset and Idle Learning when one or more of the following conditions is met:

| ○ | ○ |

| None of the conditions in the list above are met. | - | - | |

| Knock control sensor*4 | - | - | - |

- ○: Necessary.

- -: Unnecessary.

NOTICE:

Engine learned values cannot be reset by disconnecting the cable from the negative (-) auxiliary battery terminal or removing the EFI-MAIN and ETCS fuses.

-

*1: Learning Value Reset

- Enter the following menus: Powertrain / Engine / Utility / Learning Value Reset.

-

Confirm the following conditions as instructed on the screen.

- - Ignition switch ON

- - Engine stopped

- - Auxiliary battery voltage is higher than 9 V

-

Select "Next" and initialize the learned value.

HINT:

If a message indicating learned value initialization failure is displayed on the screen, confirm the execution conditions, and perform Learning Value Reset again.

-

After the completion of learned value initialization, confirm the air fuel ratio learned values (A/F Learn Value Idle Bank 1, A/F Learn Value Low Bank 1, A/F Learn Value Mid No.1 Bank 1, A/F Learn Value Mid No.2 Bank 1, and A/F Learn Value High Bank 1) in the Data List.

If 0 is displayed for all of the air fuel ratio learned values, initialization has completed correctly.

If a value other than 0 is displayed for one of the air fuel ratio learned values, perform initialization again. After initialization, confirm the air fuel ratio learned values. If a value other than 0 is displayed, replace the ECM.

-

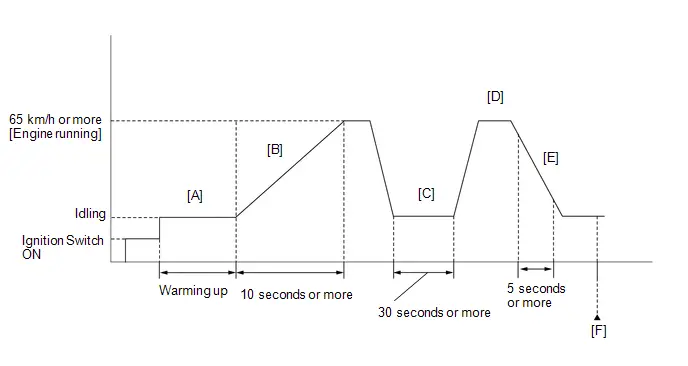

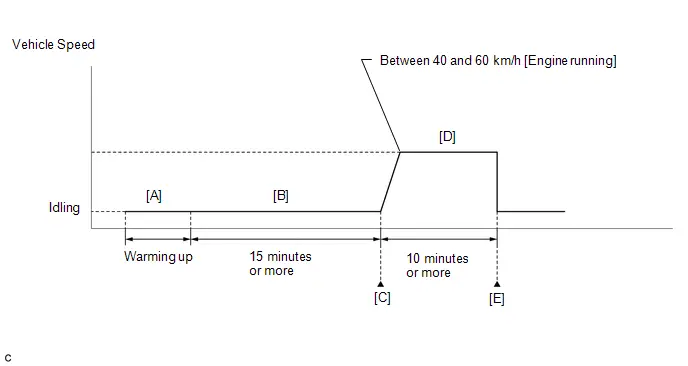

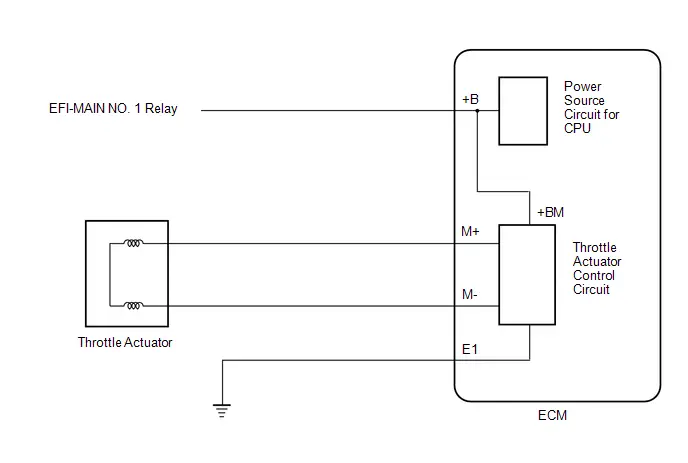

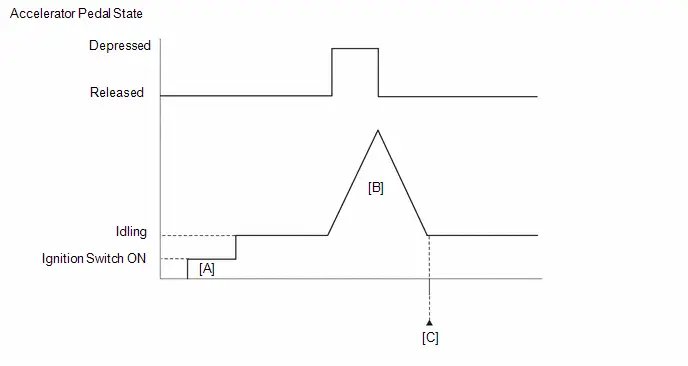

*2: Idle Learning

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch ON.

-

Put the engine in Inspection Mode (Maintenance Mode).

Click here

- Enter the following menus: Powertrain / Engine / Data List / Coolant Temperature.

- Start the engine and warm it up until the engine coolant temperature is 70°C (158°F) or higher.

- Turn the ignition switch off, and then ON (READY).

- With park (P) selected, lightly depress the accelerator pedal to start the engine.

-

Wait until the engine stops.

HINT:

The engine normally stops within 1 minute. However, when the HV battery SOC is low, the engine may remain running for approximately 3 minutes.

- Enter the following menus: Powertrain / Engine / Data List / ISC Learning.

- Confirm that "Compl" is displayed on the GTS screen.

-

Put the engine in Inspection Mode (Maintenance Mode).

Click here

- Start the engine.

- Enter the following menus: Powertrain / Engine / Data List / Engine Speed and Engine Independent.

-

Check the Engine Speed when the value of Data List item Engine Independent is "Operate".

Standard:

Engine Idle Speed

950 to 1050 rpm

HINT:

- Be sure to perform this step with the A/C switch and all accessories off.

- Make sure that park (P) is selected.

- If the value of Data List item Engine Independent is "Not Opr" when the engine is idling, charge control is being performed. Check the Engine Speed after charge control is complete ("Operate" is displayed).

-

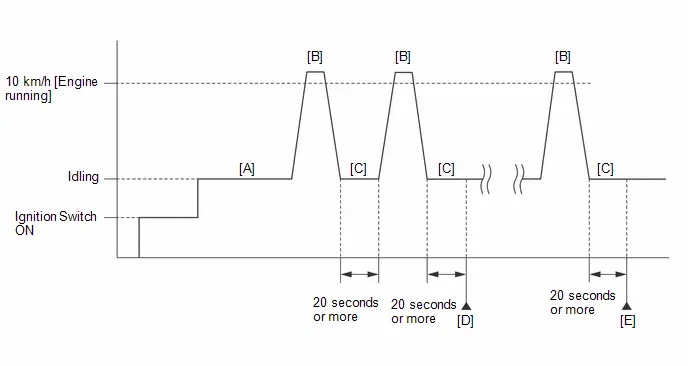

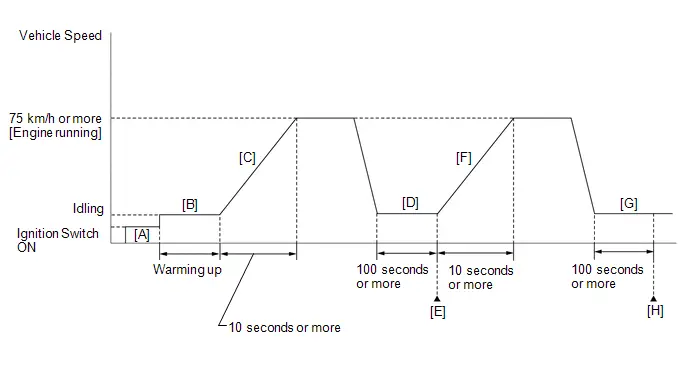

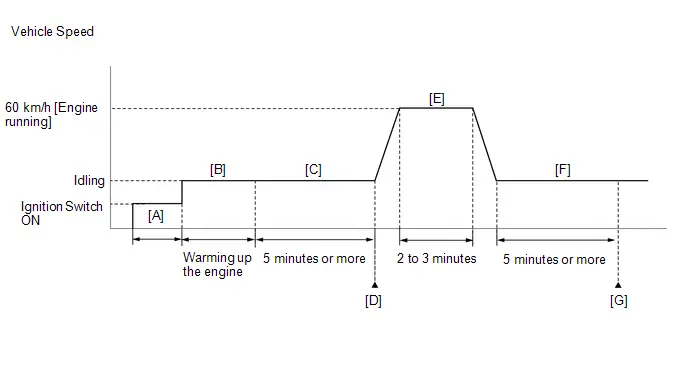

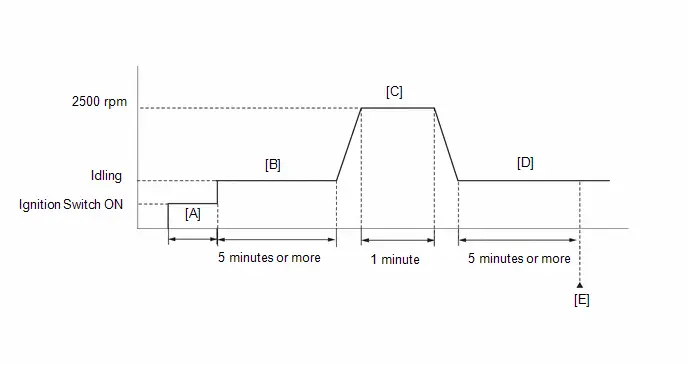

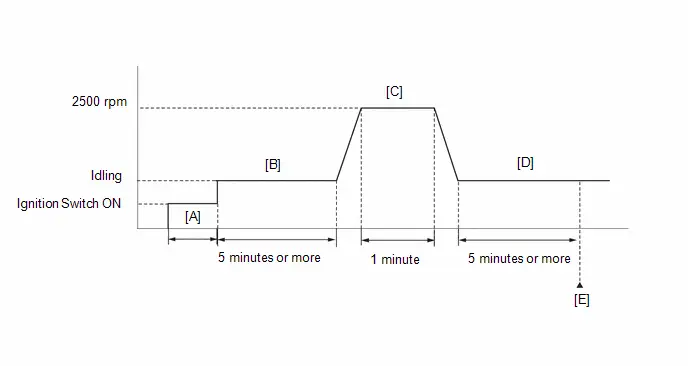

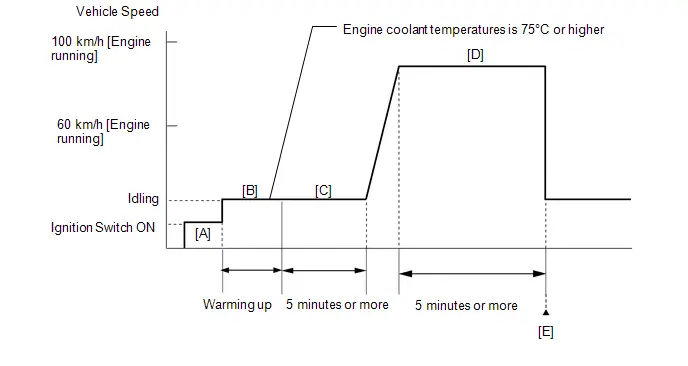

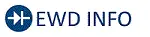

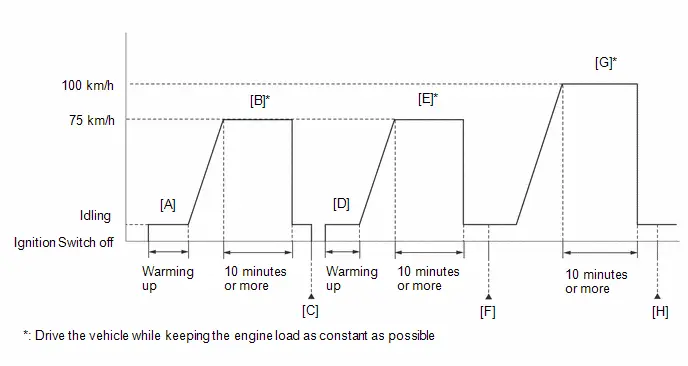

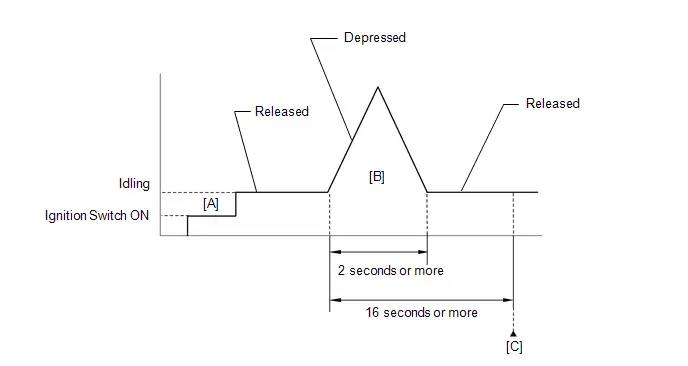

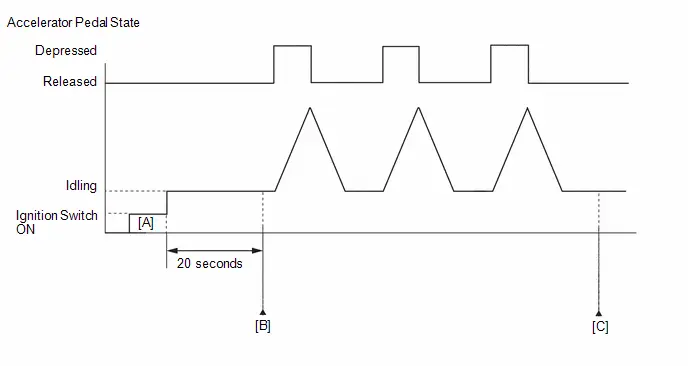

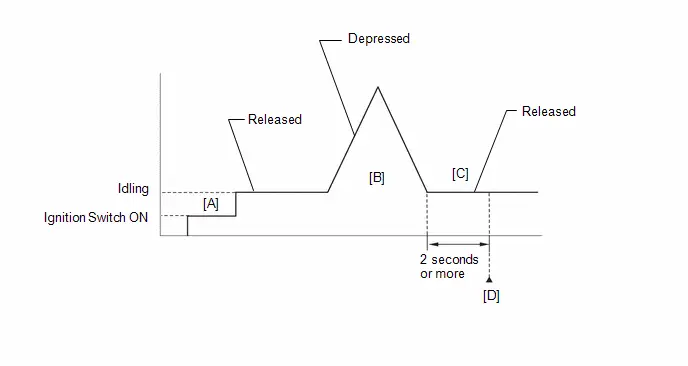

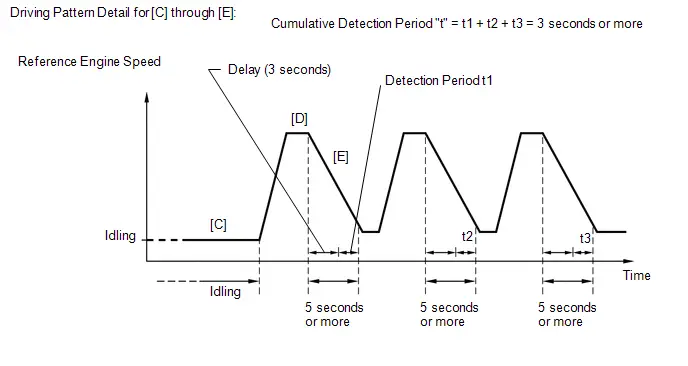

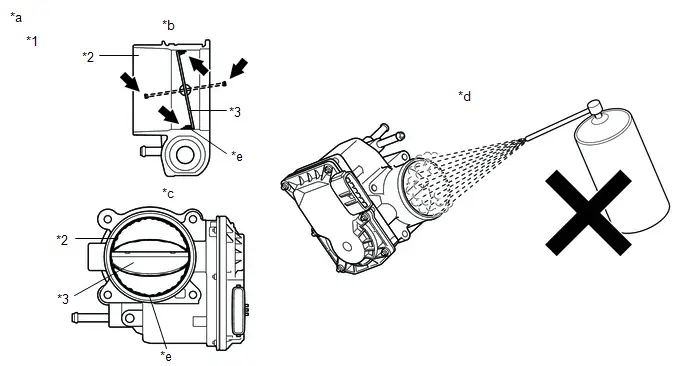

*3: Perform Learning Value Reset and Idle Learning after replacing the throttle body assembly or cleaning deposits from the throttle body assembly.

After that, check the idle speed. If the idle speed is out of the specified range, perform the following procedure.

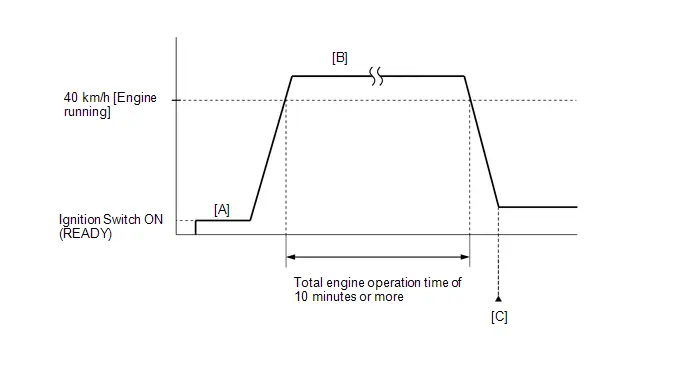

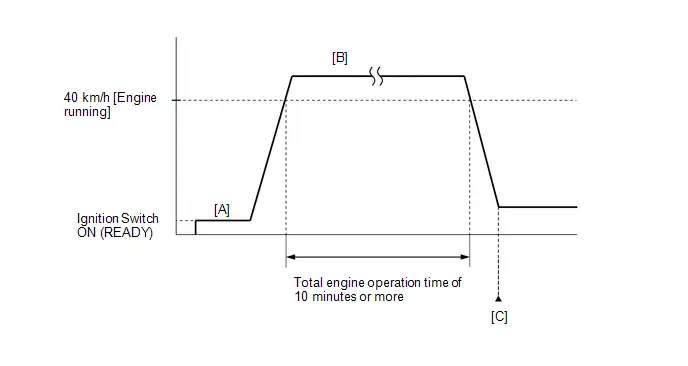

CAUTION:

When performing a driving test, obey all speed limits and traffic laws.

HINT:

History information for driving and stopping is necessary to update Idle Learning.

-

Put the engine in Inspection Mode (Maintenance Mode).

Click here

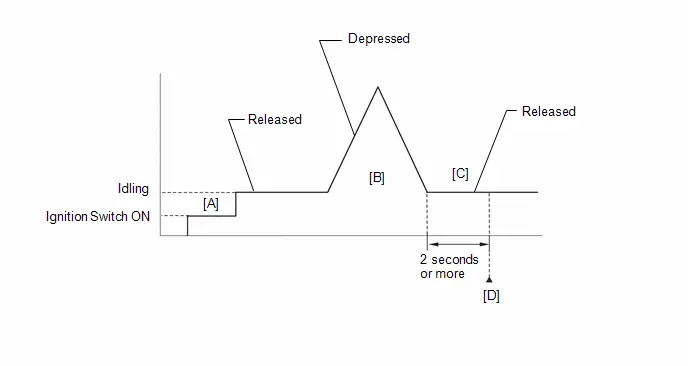

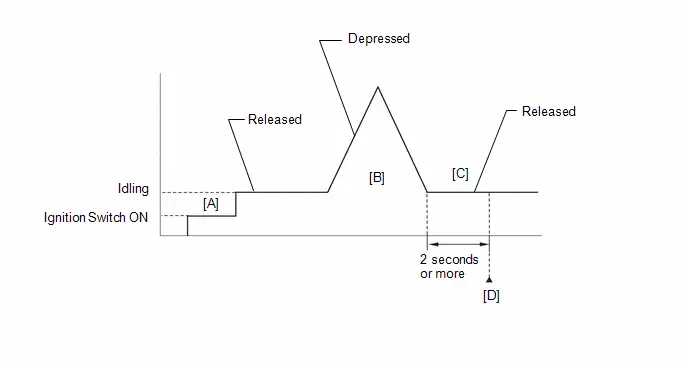

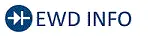

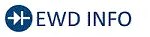

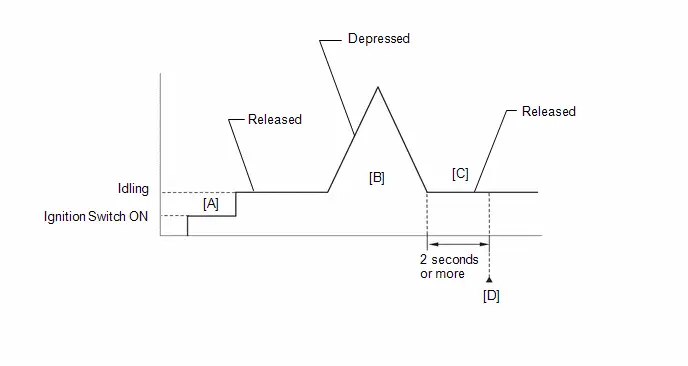

- Warm up the engine (engine coolant temperature of 80°C (176°F) or higher) with the A/C switch and all accessories off [A].

-

While the engine running, drive the Toyota Prius vehicle at a speed of 10 km/h (6 mph) or more [B].

HINT:

If the engine stops, further depress the accelerator pedal to restart the engine.

- Idle the engine for 20 seconds or more [C].

- Repeat procedure [B] and [C].

- Enter the following menus: Powertrain / Engine / Data List / Engine Speed and Engine Independent.

-

Check the Engine Speed when the value of Data List item Engine Independent is "Operate" [D].

Standard:

Engine Idle Speed

950 to 1050 rpm

HINT:

- Be sure to perform this step with the A/C switch and all accessories off.

- Make sure that park (P) is selected.

- If the value of Data List item Engine Independent is "Not Opr" when the engine is idling, charge control is being performed. Check the Engine Speed after charge control is complete ("Operate" is displayed).

- If the idle speed is still out of the specified range, repeat procedure [B] and [C] until the idle speed is within the specified range [E].

-

Put the engine in Inspection Mode (Maintenance Mode).

- *4: Drive the Toyota Prius vehicle for a short while after replacing the knock control sensor and check if knocking occurs. If knocking occurs, drive the vehicle until knocking stops.

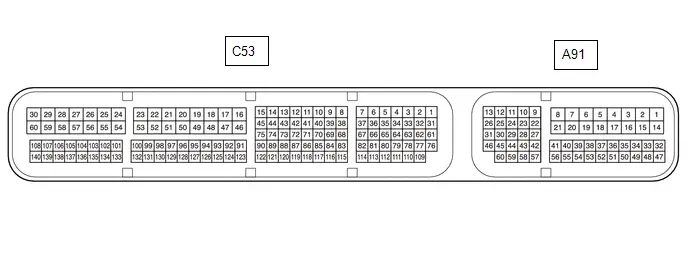

Terminals Of Ecm

TERMINALS OF ECM

HINT:

The standard voltage, resistance and waveform between each pair of the ECM terminals is shown in the table below. The appropriate conditions for checking each pair of the terminals is also indicated. The result of checks should be compared with the standard voltage, resistance and waveform for each pair of the terminals as displayed in the Specified Condition column. The illustration above can be used as a reference to identify the ECM terminal locations.

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

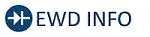

| A91-1 (BATT) - A91-17 (E1) | Auxiliary battery (for measuring auxiliary battery voltage and for ECM memory) | Ignition switch off | 11 to 16 V |

| A91-2 ( B) - A91-17 (E1) | Power source of ECM | Engine stopped, ignition switch ON | 11 to 14 V |

| A91-3 ( B2) - A91-17 (E1) | Power source of ECM | Engine stopped, ignition switch ON | 11 to 14 V |

| A91-9 (CFDH) - A91-17 (E1) | CAN communication line | Engine stopped, ignition switch ON | Pulse generation (See waveform 1) |

| A91-10 (CFDL) - A91-17 (E1) | CAN communication line | Engine stopped, ignition switch ON | Pulse generation (See waveform 2) |

| A91-11 (CFDT) - A91-17 (E1) | CAN communication line | Engine stopped, ignition switch ON | Pulse generation (See waveform 1) |

| A91-12 (CFDB) - A91-17 (E1) | CAN communication line | Engine stopped, ignition switch ON | Pulse generation (See waveform 2) |

| A91-15 (E01) - Body ground | Ground | Always | Below 1 Ω |

| A91-17 (E1) - Body ground | Ground | Always | Below 1 Ω |

| A91-22 (NEO) - A91-17 (E1) | Crankshaft revolution signal | Idling with warm engine | Pulse generation (See waveform 3) |

| A91-23 (G2O) - A91-17 (E1) | Camshaft revolution signal | Idling with warm engine | Pulse generation (See waveform 4) |

| A91-27 (MREL) - A91-17 (E1) | EFI-MAIN relay operation signal | Engine stopped, ignition switch ON | Below 1.5 V |

| A91-28 (FREL) - A91-17 (E1) | Fuel lid lock with motor assembly operation signal | Fuel lid lock with motor assembly operating | Below 1.0 V |

| Fuel lid lock with motor assembly not operating | 11 to 14 V | ||

| A91-29 (FC) - A91-17 (E1) | Fuel pump control | Engine stopped, ignition switch ON | 11 to 14 V |

| Idling | Below 1.5 V | ||

| A91-32 (EC) - Body ground | Ground | Always | Below 1 Ω |

| A91-39 (IGR) - A91-17 (E1) | Ignition signal | Ignitionr switch ON | 11 to 14 V |

| A91-41 (IGP) - A91-17 (E1) | Ignition switch signal | Ignition switch ON | 11 to 14 V |

| A91-42 (FANL) - A91-17 (E1) | Cooling fan motor operation signal (low) | Ignition switch ON | 11 to 14 V |

| Idling, high engine coolant temperature | Below 1.5 V | ||

| A91-43 (FANH) - A91-17 (E1) | Cooling fan motor operation signal (high) | Ignition switch ON | 11 to 14 V |

| Idling, high engine coolant temperature | Below 1.5 V | ||

| A91-60 (FUEL) - A91-17 (E1) | Fuel lid opener switch signal | Fuel lid opener switch pressed | Below 1.0 V |

| Fuel lid opener switch not pressed | 4.5 to 5.5 V | ||

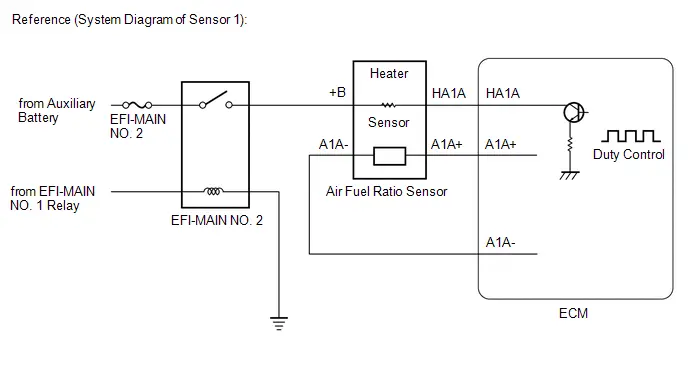

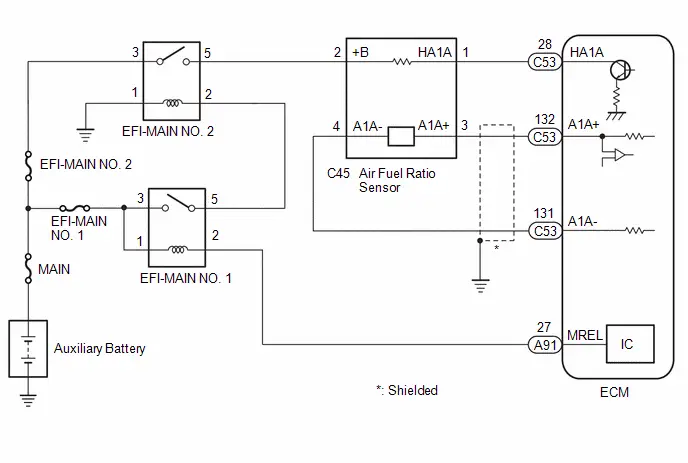

| C53-28 (HA1A) - A91-17 (E1) | Air fuel ratio sensor heater operation signal | Engine stopped, ignition switch ON | 11 to 14 V |

| Idling with cold engine | Pulse generation (See waveform 5) | ||

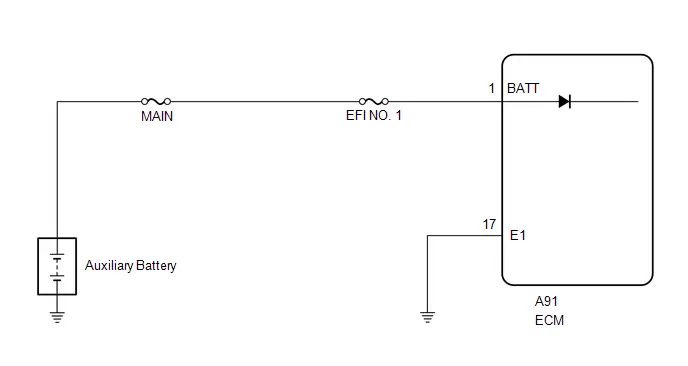

| C53-29 (M ) - A91-17 (E1) | Throttle actuator operation signal (positive terminal) | Idling with warm engine | Pulse generation (See waveform 6) |

| C53-30 (M-) - A91-17 (E1) | Throttle actuator operation signal (negative terminal) | Idling with warm engine | Pulse generation (See waveform 7) |

| C53-33 (PRG) - A91-17 (E1) | Purge VSV operation signal | Engine stopped, ignition switch ON | 11 to 14 V |

| Idling with warm engine, under purge control | Pulse generation (See waveform 8) | ||

| C53-34 (#10) - A91-15 (E01) | No. 1 fuel injector assembly signal | Idling with warm engine | Pulse generation (See waveform 9) |

| C53-35 (#20) - A91-15 (E01) | No. 2 fuel injector assembly signal | Idling with warm engine | Pulse generation (See waveform 9) |

| C53-36 (#30) - A91-15 (E01) | No. 3 fuel injector assembly signal | Idling with warm engine | Pulse generation (See waveform 9) |

| C53-37 (#40) - A91-15 (E01) | No. 4 fuel injector assembly signal | Idling with warm engine | Pulse generation (See waveform 9) |

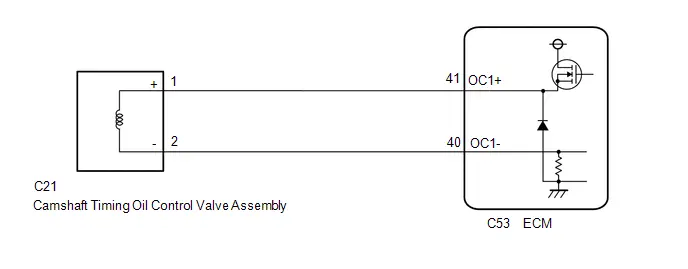

| C53-41 (OC1 ) - C53-40 (OC1-) | Camshaft timing oil control valve assembly operation signal | Idling | Pulse generation (See waveform 10) |

| C53-42 (EGR4) - A91-17 (E1) | EGR valve assembly signal | EGR valve assembly operating | Pulse generation (See waveform 11) |

| C53-43 (EGR2) - A91-17 (E1) | EGR valve assembly signal | EGR valve assembly operating | Pulse generation (See waveform 11) |

| C53-44 (EGR3) - A91-17 (E1) | EGR valve assembly signal | EGR valve assembly operating | Pulse generation (See waveform 11) |

| C53-45 (EGR1) - A91-17 (E1) | EGR valve assembly signal | EGR valve assembly operating | Pulse generation (See waveform 11) |

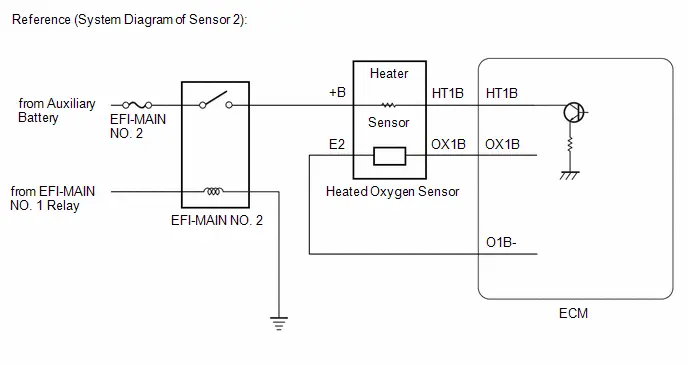

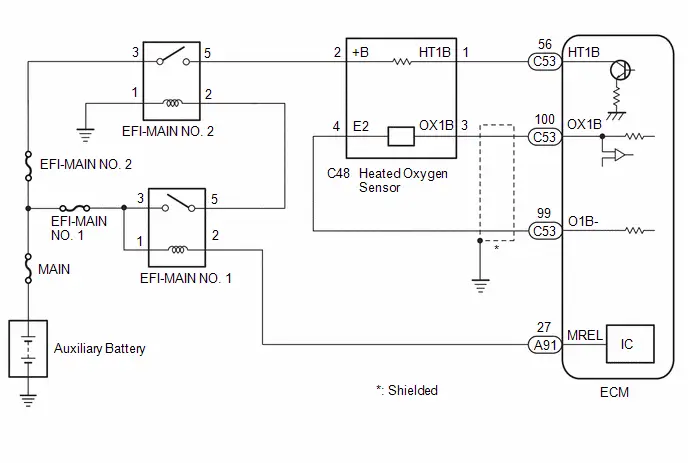

| C53-56 (HT1B) - A91-17 (E1) | Heated oxygen sensor heater operation signal | Engine stopped, ignition switch ON | 11 to 14 V |

| Idling with cold engine | Below 3.0 V | ||

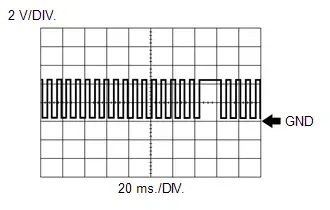

| C53-70 (WPI) - A91-17 (E1) | Electric water pump assembly signal | Idling with warm engine | Pulse generation (See waveform 12) |

| C53-71 (WPO) - A91-17 (E1) | Electric water pump assembly signal | Idling with warm engine | Pulse generation (See waveform 13) |

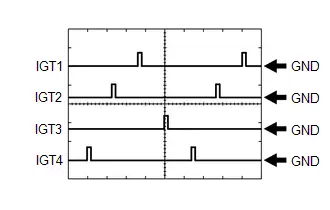

| C53-72 (IGT4) - A91-17 (E1) | No. 4 ignition coil assembly signal (ignition signal) | Idling with warm engine | Pulse generation (See waveform 14) |

| C53-73 (IGT3) - A91-17 (E1) | No. 3 ignition coil assembly signal (ignition signal) | Idling with warm engine | Pulse generation (See waveform 14) |

| C53-74 (IGT2) - A91-17 (E1) | No. 2 ignition coil assembly signal (ignition signal) | Idling with warm engine | Pulse generation (See waveform 14) |

| C53-75 (IGT1) - A91-17 (E1) | No. 1 ignition coil assembly signal (ignition signal) | Idling with warm engine | Pulse generation (See waveform 14) |

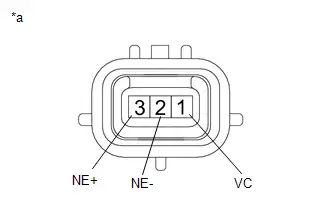

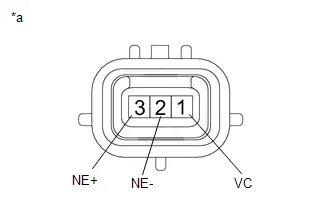

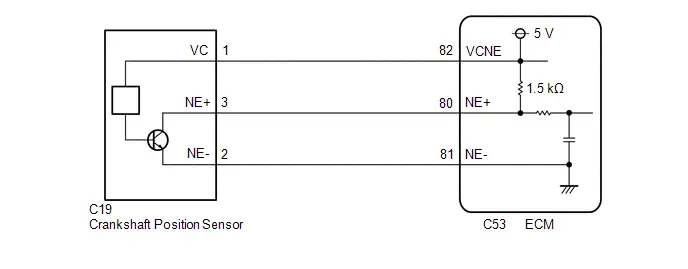

| C53-80 (NE ) - C53-81 (NE-) | Crankshaft position sensor signal | Idling with warm engine | Pulse generation (See waveform 15) |

| C53-82 (VCNE) - A91-17 (E1) | Power source of crankshaft position sensor (specific voltage) | Ignition switch ON | 4.5 to 5.5 V |

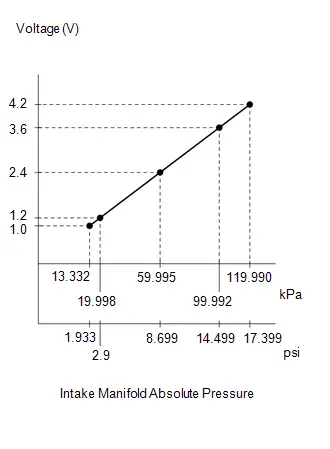

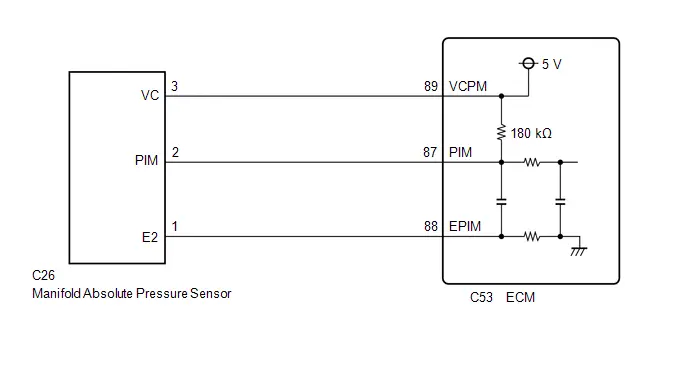

| C53-87 (PIM) - C53-88 (EPIM) | Manifold absolute pressure sensor signal | Engine stopped, ignition switch ON | 3.0 to 4.5 V |

| C53-89 (VCPM) - C53-88 (EPIM) | Power source of manifold absolute pressure sensor | Engine stopped, ignition switch ON | 4.75 to 5.25 V |

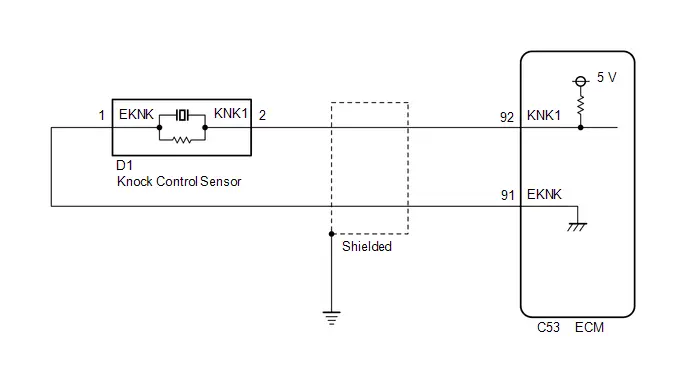

| C53-92 (KNK1) - C53-91 (EKNK) | Knock control sensor signal | Engine speed maintained at 2500 rpm after warming up engine | Pulse generation (See waveform 16) |

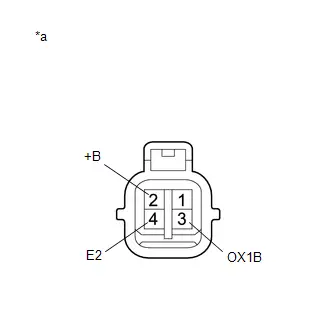

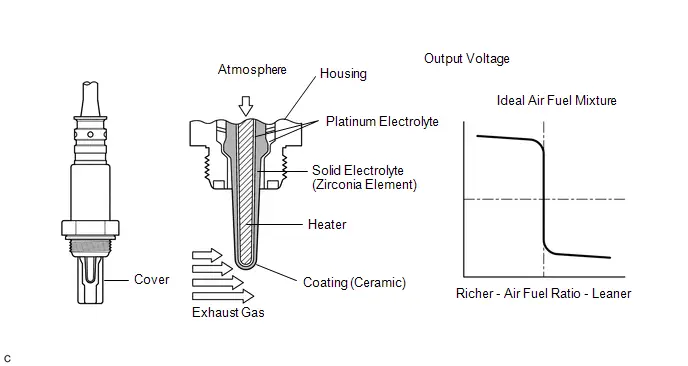

| C53-100 (OX1B) - C53-99 (O1B-) | Heated oxygen sensor signal | Engine speed maintained at 2500 rpm for 2 minutes after warming up engine | Pulse generation (See waveform 17) |

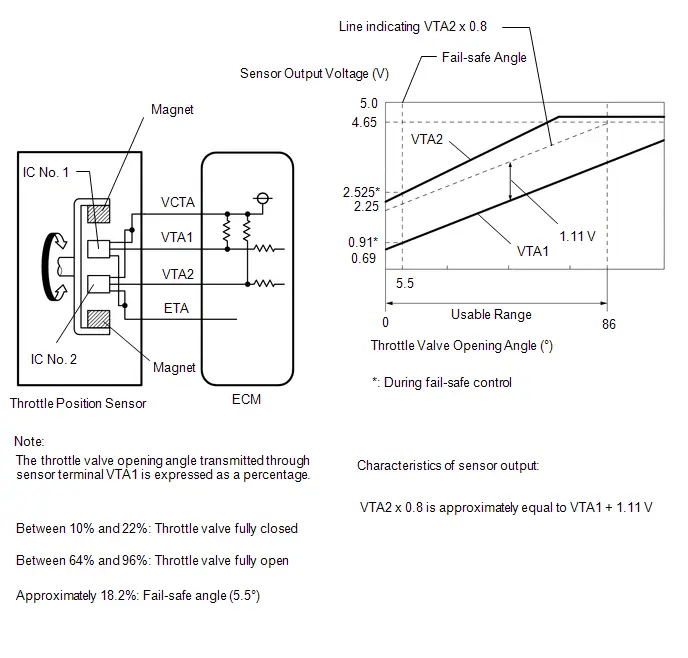

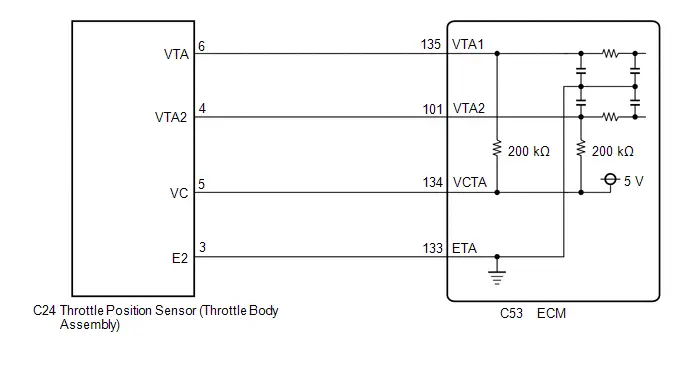

| C53-101 (VTA2) - C53-133 (ETA) | Throttle position sensor signal (for sensor malfunction detection) | Engine stopped, ignition switch ON, accelerator pedal fully released | 2.1 to 3.1 V |

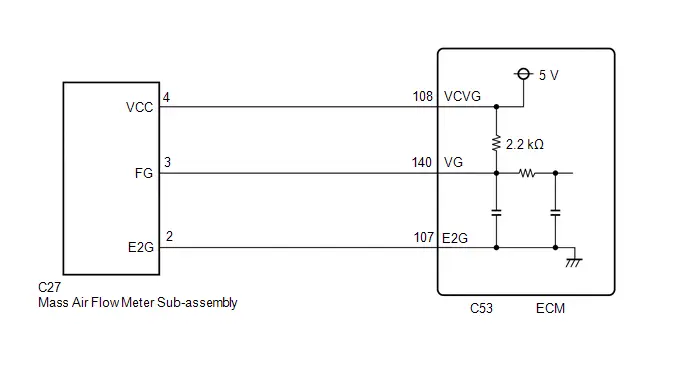

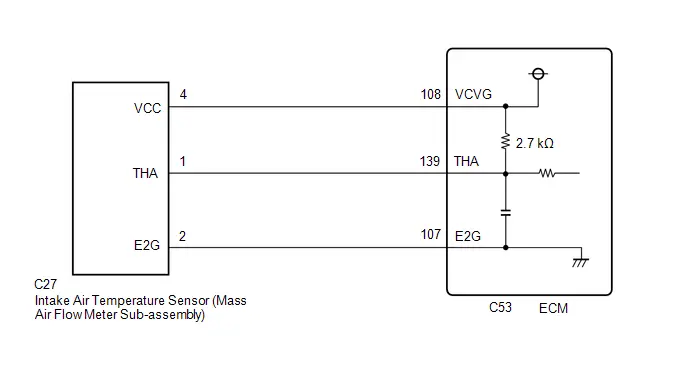

| C53-108 (VCVG) - A91-17 (E1) | Power source of mass air flow meter sub-assembly (specific voltage) | Ignition switch ON | 4.8 to 5.2 V |

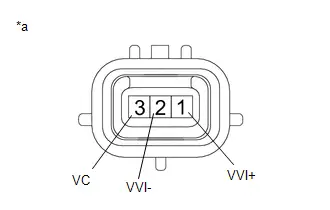

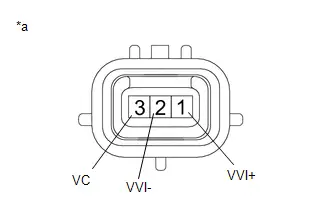

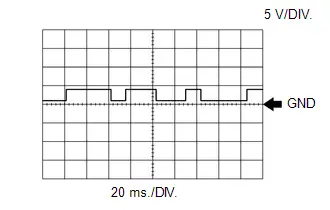

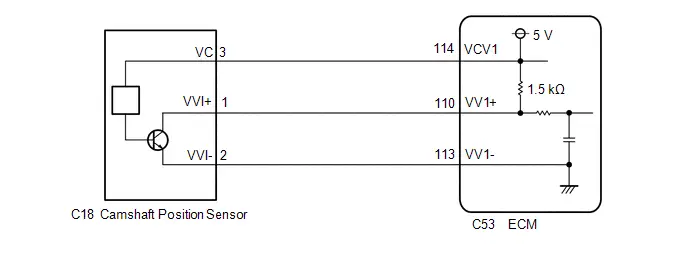

| C53-110 (VV1 ) - C53-113 (VV1-) | Camshaft position sensor signal | Idling with warm engine | Pulse generation (See waveform 18) |

| C53-114 (VCV1) - A91-17 (E1) | Power source of camshaft position sensor | Engine stopped, ignition switch ON | 4.5 to 5.5 V |

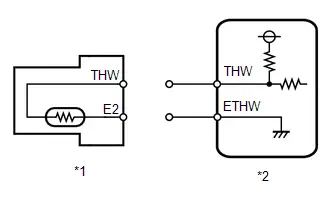

| C53-124 (THW) - C53-123 (ETHW) | Engine coolant temperature sensor signal | Idling, engine coolant temperature 75 to 100°C (167 to 212°F) | 0.2 to 1.0 V |

| C53-131 (A1A-) - A91-17 (E1) | Air fuel ratio sensor signal | Engine stopped, ignition switch ON | 2.2 to 2.8 V*1 |

| C53-132 (A1A ) - A91-17 (E1) | Air fuel ratio sensor signal | Engine stopped, ignition switch ON | 2.2 to 3.5 V*1 |

| C53-134 (VCTA) - C53-133 (ETA) | Power source of throttle position sensor (specific voltage) | Engine stopped, ignition switch ON | 4.5 to 5.5 V |

| C53-135 (VTA1) - C53-133 (ETA) | Throttle position sensor signal (for engine control) | Engine stopped, ignition switch ON, accelerator pedal fully released | 0.6 to 1.1 V |

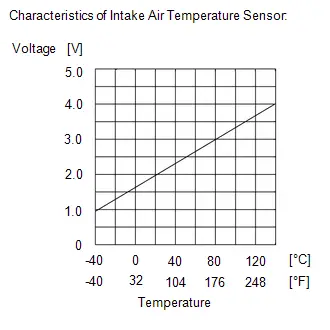

| C53-139 (THA) - C53-107 (E2G) | Intake air temperature sensor (mass air flow meter sub-assembly) signal | Idling, intake air temperature 0 to 80°C (32 to 176°F) | 0.5 to 3.4 V |

| C53-140 (VG) - C53-107 (E2G) | Mass air flow meter sub-assembly signal | Ignition switch ON | Pulse generation (See waveform 19) |

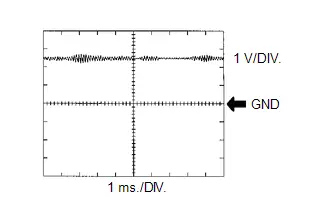

*1: The ECM terminal voltage is constant regardless of the voltage output from the sensor.

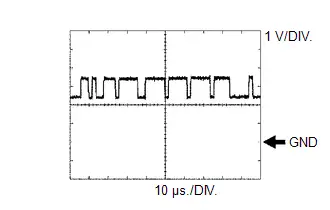

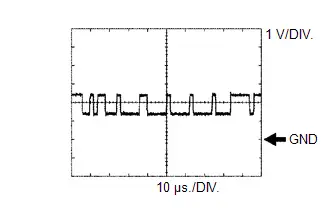

WAVEFORM 1

CAN Communication Signal (Reference)

CAN Communication Signal (Reference) | ECM Terminal Name | Between CFDH and E1 Between CFDT and E1 |

| Tester Range | 1 V/DIV., 10 μs./DIV. |

| Condition | Engine stopped, ignition switch ON |

HINT:

The waveform varies depending on the CAN communication signal.

WAVEFORM 2

CAN Communication Signal (Reference)

CAN Communication Signal (Reference) | ECM Terminal Name | Between CFDL and E1 Between CFDB and E1 |

| Tester Range | 1 V/DIV., 10 μs./DIV. |

| Condition | Engine stopped, ignition switch ON |

HINT:

The waveform varies depending on the CAN communication signal.

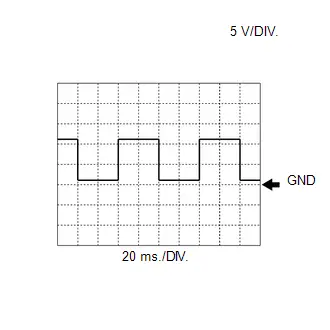

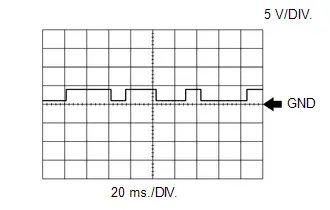

WAVEFORM 3

Crankshaft Revolution Signal from ECM to Inverter with Converter Assembly

Crankshaft Revolution Signal from ECM to Inverter with Converter Assembly | ECM Terminal Name | Between NEO and E1 |

| Tester Range | 5 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

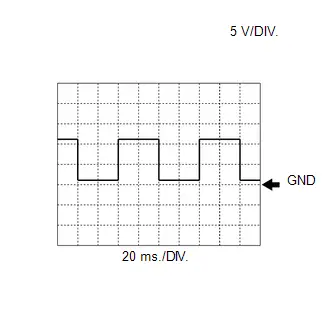

WAVEFORM 4

Camshaft Revolution Signal from ECM to Inverter with Converter Assembly

Camshaft Revolution Signal from ECM to Inverter with Converter Assembly | ECM Terminal Name | Between G2O and E1 |

| Tester Range | 5 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

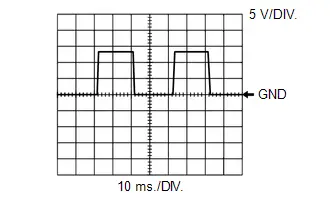

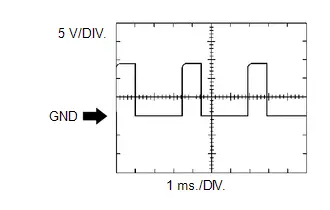

WAVEFORM 5

Air Fuel Ratio Sensor Heater Operation Signal

Air Fuel Ratio Sensor Heater Operation Signal | ECM Terminal Name | Between HA1A and E1 |

| Tester Range | 5 V/DIV., 10 ms./DIV. |

| Condition | Idling with cold engine |

WAVEFORM 6

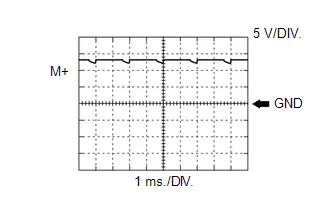

Throttle Actuator Positive Terminal Signal

Throttle Actuator Positive Terminal Signal | ECM Terminal Name | Between M and E1 |

| Tester Range | 5 V/DIV., 1 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The duty ratio varies depending on the throttle actuator operation.

WAVEFORM 7

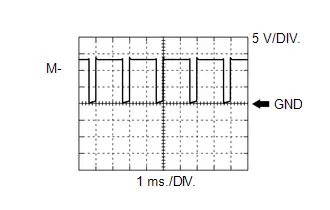

Throttle Actuator Negative Terminal Signal

Throttle Actuator Negative Terminal Signal | ECM Terminal Name | Between M- and E1 |

| Tester Range | 5 V/DIV., 1 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The duty ratio varies depending on the throttle actuator operation.

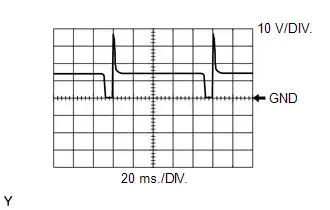

WAVEFORM 8

Purge VSV Operation Signal

Purge VSV Operation Signal | ECM Terminal Name | Between PRG and E1 |

| Tester Range | 10 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine, under purge control |

HINT:

If the waveform is not similar to the illustration, check the waveform again after idling for 10 minutes or more.

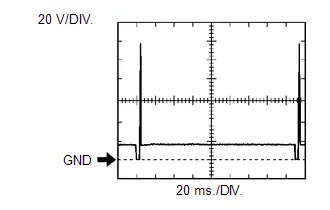

WAVEFORM 9

No. 1 (to No. 4) Fuel Injector Assembly Signal

No. 1 (to No. 4) Fuel Injector Assembly Signal | ECM Terminal Name | Between #10 (to #40) and E01 |

| Tester Range | 20 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

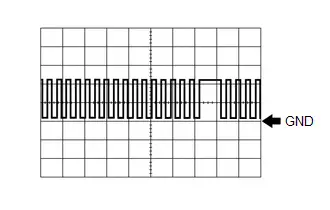

WAVEFORM 10

Camshaft Timing Oil Control Valve Assembly Operation Signal

Camshaft Timing Oil Control Valve Assembly Operation Signal | ECM Terminal Name | Between OC1 and OC1- |

| Tester Range | 5 V/DIV., 1 ms./DIV. |

| Condition | Idling |

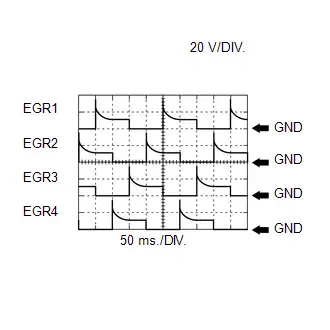

WAVEFORM 11

EGR Valve Assembly Signal

EGR Valve Assembly Signal | ECM Terminal Name | Between EGR (1 to 4) and E1 |

| Tester Range | 20 V/DIV., 50 ms./DIV. |

| Condition | EGR valve assembly operating |

WAVEFORM 12

Engine Water Pump Assembly Signal (from Engine Water Pump Assembly to ECM)

Engine Water Pump Assembly Signal (from Engine Water Pump Assembly to ECM) | ECM Terminal Name | Between WPI and E1 |

| Tester Range | 5 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine water pump speed increases.

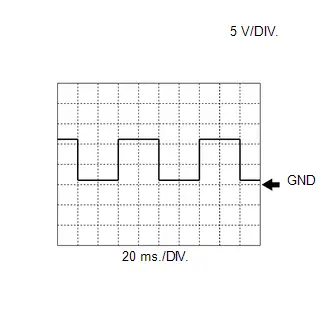

WAVEFORM 13

Engine Water Pump Assembly Signal (from ECM to Engine Water Pump Assembly)

Engine Water Pump Assembly Signal (from ECM to Engine Water Pump Assembly) | ECM Terminal Name | Between WPO and E1 |

| Tester Range | 5 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The duty ratio varies depending on the engine water pump assembly speed.

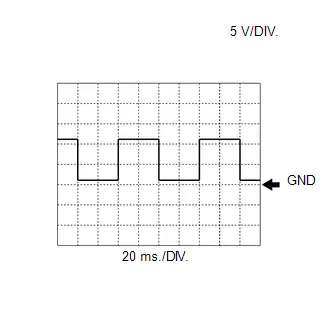

WAVEFORM 14

Ignition Coil Assembly Signal (IGT Signal)

Ignition Coil Assembly Signal (IGT Signal) | ECM Terminal Name | Between IGT (1 to 4) and E1 |

| Tester Range | 5 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

WAVEFORM 15

Crankshaft Position Sensor Signal

Crankshaft Position Sensor Signal | ECM Terminal Name | Between NE and NE- |

| Tester Range | 2 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

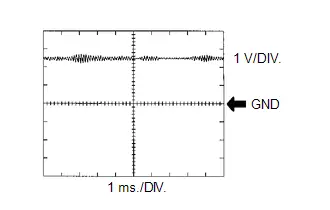

WAVEFORM 16

Knock Control Sensor Signal

Knock Control Sensor Signal | ECM Terminal Name | Between KNK1 and EKNK |

| Tester Range | 1 V/DIV., 1 ms./DIV. |

| Condition | Engine speed maintained at 2500 rpm after warming up engine |

HINT:

- The wavelength becomes shorter as the engine speed increases.

- The waveforms and amplitudes displayed will differ slightly depending on the Toyota Prius vehicle.

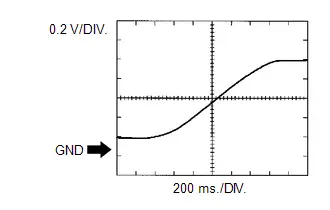

WAVEFORM 17

Heated Oxygen Sensor Signal

Heated Oxygen Sensor Signal | ECM Terminal Name | Between OX1B and O1B- |

| Tester Range | 0.2 V/DIV., 200 ms./DIV. |

| Condition | Engine speed maintained at 2500 rpm for 2 minutes after warming up engine |

HINT:

Data List item "O2 Sensor Voltage B1S2" shows the ECM values from the heated oxygen sensor.

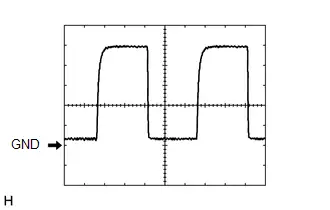

WAVEFORM 18

Camshaft Position Sensor Signal

Camshaft Position Sensor Signal | ECM Terminal Name | Between VV1 and VV1- |

| Tester Range | 5 V/DIV., 20 ms./DIV. |

| Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

WAVEFORM 19

Mass Air Flow Meter Sub-assembly Signal

Mass Air Flow Meter Sub-assembly Signal | ECM Terminal Name | Between VG and E2G |

| Tester Range | 1 V/DIV., 100 μs./DIV. |

| Condition | Ignition switch ON |

Diagnosis System

DIAGNOSIS SYSTEM

EURO-OBD (EUROPEAN SPEC.)

When troubleshooting Europe On-Board Diagnostic (Euro-OBD) vehicles, the vehicle must be connected to an OBD scan tool (complying with ISO 15765-4). Various data output from the Toyota Prius vehicle's ECM can then be read.

Euro-OBD regulations require that the vehicle's on-board computer illuminate the Malfunction Indicator Lamp (MIL) on the instrument panel when the computer detects a malfunction in:

- The emission control system and components.

- The powertrain control components (which affect Toyota Prius vehicle emissions).

- The computer.

In addition, the applicable Diagnostic Trouble Codes (DTCs) prescribed by ISO 15765-4 are stored in the ECM memory. If the malfunction does not reoccur in 3 consecutive trips, the MIL turns off automatically but the DTCs remain stored in the ECM memory.

To check for DTCs, connect the GTS or OBD scan tool to the Data Link Connector 3 (DLC3) of the Toyota Prius vehicle.

The GTS displays DTCs, the freeze frame data and a variety of engine data.

The DTCs and freeze frame data can be cleared using the GTS.

Click here

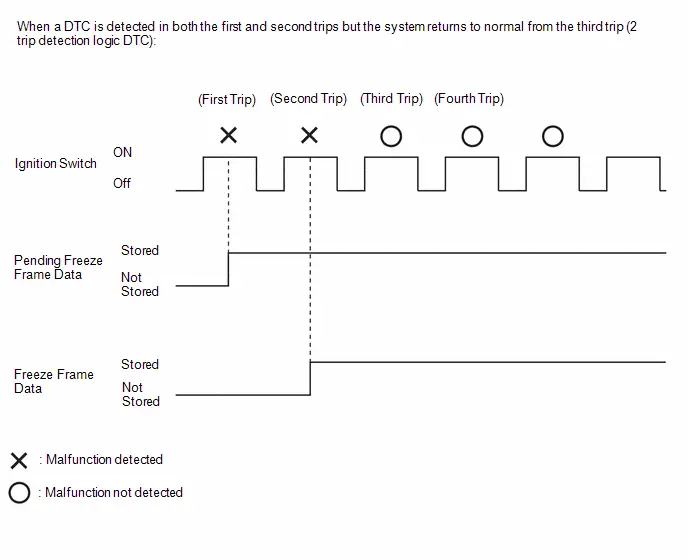

NORMAL MODE AND CHECK MODE

The diagnosis system operates in normal mode during normal Toyota Prius vehicle use. In normal mode, 2 trip detection logic is used to ensure accurate detection of malfunctions. Check mode is also available as an option for technicians. In check mode, 1 trip detection logic is used for duplicating malfunction symptoms and increasing the system's ability to detect malfunctions, including intermittent problems (GTS only).

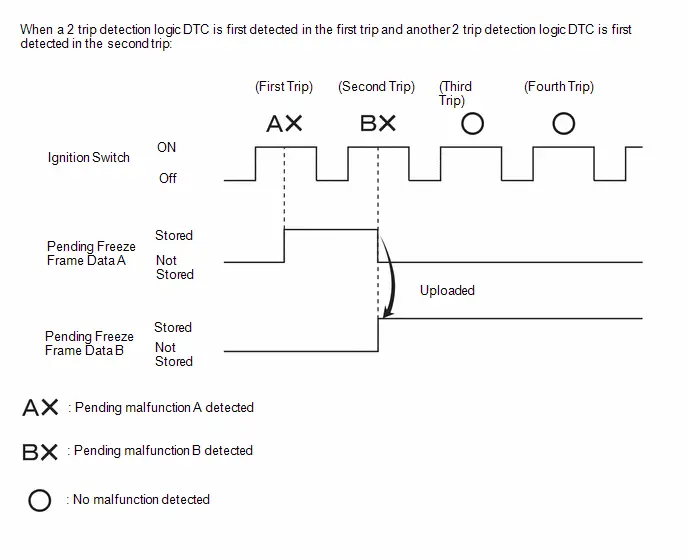

2 TRIP DETECTION LOGIC

When a malfunction is first detected, the malfunction is temporarily stored in the ECM memory (1st trip). If the same malfunction is detected during the subsequent drive cycle, the MIL is illuminated (2nd trip).

DLC3 (Data Link Connector 3)

(a) Check the DLC3.

Click here

FREEZE FRAME DATA

The ECM records Toyota Prius vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was moving or stationary, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

AUXILIARY BATTERY VOLTAGE

Standard Voltage:

11 to 16 V

If the voltage is less than 11 V, recharge or replace the auxiliary battery.

MIL (Malfunction Indicator Lamp)

(a) The MIL is illuminated when the ignition switch is turned ON (with the engine is not running).

(b) The MIL will turn off when the ignition switch is turned ON (READY). If the MIL remains illuminated, the diagnosis system has detected a malfunction or abnormality in the system.

HINT:

If the MIL does not illuminate when the ignition switch is turned ON, check the MIL circuit.

Click here

ALL READINESS

HINT:

- With "All Readiness", you can use the GTS to check whether or not DTC judgment has been completed.

- You should check "All Readiness" after simulating malfunction symptoms or for validation after finishing repairs.

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs(b) Turn the ignition switch off and wait for at least 30 seconds.

(c) Turn the ignition switch ON.

(d) Perform the DTC judgment driving pattern to run the DTC judgment.

(e) Enter the following menus: Powertrain / Engine / Utility / All Readiness.

Powertrain > Engine > Utility| Tester Display |

|---|

| All Readiness |

(f) Input the DTCs to be confirmed.

(g) Check the DTC judgment result.

| GTS Display | Description |

|---|---|

| NORMAL |

|

| ABNORMAL |

|

| INCOMPLETE |

|

Diagnosis Related Information

HINT:

- If the detection conditions of certain DTCs are met before a malfunction can be confirmed, the ECM will store Diagnosis Related Information. Toyota Prius Vehicle condition information from when the detection conditions were met can be checked using the Diagnosis Related Information. Diagnosis Related Information should be used as a reference only, and should not be relied upon solely when determining whether a part is faulty or not.

- Clearing DTCs will also clear Diagnosis Related Information.

- DTCs and Diagnosis Related Information are saved in the GTS at the same time.

(a) Enter the following menus: Powertrain / Engine / Utility / Diagnosis Related Information.

Powertrain > Engine > Utility| Tester Display |

|---|

| Diagnosis Related Information |

(b) Select a Diagnosis Related Information item to display it' s details.

Dtc Check / Clear

DTC CHECK / CLEAR

NOTICE:

When the diagnosis system is changed from normal mode to check mode or vice versa, all DTCs and freeze frame data recorded in normal mode are cleared. Before changing modes, always check and make a note of DTCs and freeze frame data.

HINT:

- DTCs which are stored in the ECM can be displayed on the GTS. The GTS can display the confirmed and pending DTCs.

- Some DTCs are not stored if the ECM does not detect the same malfunction again during a second consecutive driving cycle. However, such malfunctions, detected on only one occasion, are stored as pending DTCs.

CHECK DTC

(a) Enter the following menus: Powertrain / Engine / Trouble Codes.

Powertrain > Engine > Trouble Codes(b) Check the DTC(s) and freeze frame data, and then write them down.

| GTS Display | Description |

|---|---|

| Test Failed | Shows the malfunction judgment results during the current trip. |

| Pending | Shows the malfunction judgment results up to now. (Indicates the possibility of a malfunction when no DTC is confirmed.) |

| Confirmed | Shows the DTCs confirmed up to now. (The number of current trips differs for each DTC.) |

(c) Check the details of the DTC(s).

Click here

CHECK TIME STAMP

HINT:

By checking Time Stamp, the time and order in which DTCs were stored in an ECU can be checked.

(a) Enter the following menus: Health Check.

(b) Perform the following steps when the data setting screen is displayed.

(c) Select the systems for which to perform Health Check and check for time stamp data.

- Powertrain

- Chassis

- Body

- Store All Data

(d) Select "Yes" when "Do you want to store time stamp data?" is displayed.

HINT:

If "Yes" is not selected, time stamp data will not be stored.

(e) After Health Check has completed, select "Time Stamp Data" to display the Time Stamp screen.

(f) Select the desired system from the drop-down list on the bottom of the Time Stamp screen.

(g) Check the order and time which DTCs were stored for the selected system.

CLEAR DTC

(a) Enter the following menus: Powertrain / Engine / Trouble Codes.

(b) Clear the DTCs.

Powertrain > Engine > Clear DTCsCLEAR DTC (Without using GTS)

(a) Perform either of the following operations:

NOTICE:

After turning ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

Click here

(1) Disconnect the cable from the negative (-) auxiliary battery terminal for more than 1 minute.

(2) Remove the EFI-MAIN and ETCS fuses from the No. 1 engine room relay block and No. 1 junction block assembly located inside the engine compartment for more than 1 minute.

Freeze Frame Data

FREEZE FRAME DATA

DESCRIPTION

The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was moving or stationary, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

HINT:

- If it is impossible to replicate the problem even though a DTC is detected, confirm the freeze frame data.

- Freeze frame data is available in long and short forms.

PENDING FREEZE FRAME DATA

HINT:

Pending freeze frame data is stored when a 2 trip detection logic DTC is first detected during the first trip.

(a) Enter the following menus: Powertrain / Engine / Trouble Codes.

(b) Select a DTC in order to display its pending freeze frame data.

Powertrain > Engine > Trouble CodesHINT:

-

Pending freeze frame data is cleared when any of the following occurs.

- Using the GTS, the DTCs cleared.

- The cable is disconnected from the negative (-) auxiliary battery terminal.

- 40 trips with the engine fully warmed up have been performed after returning to normal. (Pending freeze frame data will not be cleared by only returning the system to normal.)

- With previous pending freeze frame data stored, if pending freeze frame data is newly stored when a 2 trip detection logic DTC is detected in the first trip, the old freeze frame data will be replaced with the new data of the newly detected DTC in the next trip.

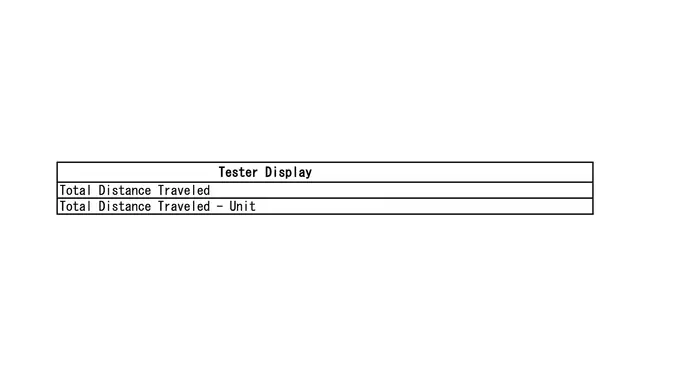

LIST OF FREEZE FRAME DATA

Powertrain > Engine| Tester Display |

|---|

| Total Distance Traveled |

| Total Distance Traveled - Unit |

| Key Cycle |

| Elapsed Time |

| Toyota Prius Vehicle Speed |

| Engine Speed |

| Calculate Load |

| Vehicle Load |

| Mass Air Flow Sensor |

| Atmospheric Pressure |

| Intake Manifold Absolute Pressure |

| Intake Manifold Absolute Pressure Supported |

| Coolant Temperature |

| Intake Air Temperature |

| Ambient Temperature |

| Engine Run Time |

| IG-ON Coolant Temperature |

| Initial Engine Coolant Temperature |

| IG-ON Intake Air Temperature |

| Initial Engine Intake Air Temperature |

| Battery Voltage |

| BATT Voltage |

| IG2 / IGP |

| IGR |

| Intake Camshaft Position Sensor Voltage |

| Intake Camshaft Position Sensor Speed Bank 1 |

| Crankshaft Position Sensor Voltage |

| Throttle Position Sensor No.1 Voltage % |

| Throttle Position Sensor No.2 Voltage % |

| System Guard |

| Open Side Malfunction |

| Throttle Request Position |

| Throttle Sensor Position |

| Throttle Position Sensor No.1 Voltage |

| Throttle Position Sensor No.2 Voltage |

| Throttle Position Command |

| Throttle Position Sensor Open Position No.1 |

| Throttle Position Sensor Open Position No.2 |

| Throttle Motor Current |

| Throttle Motor Duty Ratio |

| Throttle Motor Duty Ratio (Open) |

| Throttle Motor Duty Ratio (Close) |

| Throttle Position Sensor Fully Closed Learn Value |

| BM Voltage |

| Actuator Power Supply |

| Throttle Air Flow Learn Value (Area 1) |

| Throttle Air Flow Learn Value (Area 2) |

| Throttle Air Flow Learn Value (Area 3) |

| Throttle Air Flow Learn Value (Calculated Value) |

| Throttle Air Flow Learn Value (Atmosphere Pressure Offset Value) |

| Low Revolution Control |

| Engine Stall Control F/B Flow |

| Injector Cylinder #1 (Port) |

| Injection Volume Cylinder #1 |

| Injection Volume |

| Fuel Pump/Speed Status |

| Current Fuel Type |

| EVAP (Purge) VSV |

| Fuel Lid SW |

| Target Air-Fuel Ratio |

| A/F (O2) Lambda Sensor B1S1 |

| A/F (O2) Sensor Current B1S1 |

| A/F (O2) Sensor Heater Duty Ratio B1S1 |

| A/F Sensor Impedance B1S1 |

| O2 Sensor Voltage B1S2 |

| A/F (O2) Sensor Heater Current-Carrying Status B1S2 (at Heater OFF) |

| A/F (O2) Sensor Heater Overcurrent B1S2 |

| A/F (O2) Sensor Heater Control Run Time B1S2 |

| A/F (O2) Sensor Terminal Voltage Bank 1 |

| A/F (O2) Sensor -Terminal Voltage Bank 1 |

| A/F (O2) Sensor Heater Control Duty Ratio Bank1 |

| A/F (O2) Sensor Heater Output Duty Ratio Bank1 |

| A/F (O2) Sensor Heater ON Current Value Bank1 |

| A/F (O2) Sensor Heater Current-Carrying Status Bank1 (at Heater OFF) |

| A/F (O2) Sensor Heater Overcurrent Bank1 |

| A/F (O2) Sensor Heater Control Run Time Bank1 |

| A/F (O2) Sensor Impedance B1S2 |

| O2 Sensor Heater B1S2 |

| A/F (O2) Sensor Heater Current Value B1S2 |

| Short FT B1S1 |

| Short FT B1S2 |

| Long FT B1S1 |

| Long FT B1S2 |

| Total FT Bank 1 |

| Fuel System Status Bank 1 |

| Fuel System Status Bank 2 |

| Ignition Timing Cylinder #1 |

| Knock F/B Value |

| Knock Correct Learn Value |

| Idle Spark Advance Control Cylinder #1 |

| Idle Spark Advance Control Cylinder #2 |

| Idle Spark Advance Control Cylinder #3 |

| Idle Spark Advance Control Cylinder #4 |

| Mass Air Flow Circuit |

| Air Flow Meter Output Frequency |

| Target EGR Valve Position No.1 |

| Target EGR Valve Position No.1 Supported |

| Actual EGR Valve Position No.1 Supported |

| Target EGR Valve Position No.2 Supported |

| Actual EGR Valve Position No.2 Supported |

| EGR Step Position |

| VVT Advance Fail |

| Intake VVT Hold Learn Value Bank 1 |

| Intake VVT Change Angle Bank 1 |

| Intake VVT OCV Control Duty Ratio Bank 1 |

| Intake VVT Target Angle Bank 1 |

| Intake VVT Timing Most Over-Retarded Learn Value Bank 1 |

| Catalyst Temperature B1S1 |

| Catalyst Temperature B1S2 |

| TC Terminal |

| MIL ON Run Distance |

| Running Time from MIL ON |

| Time after DTC Cleared |

| Distance from DTC Cleared |

| Warmup Cycle Cleared DTC |

| Distance Traveled from Last Battery Cable Disconnect |

| IG OFF Elapsed Time |

| Soak IC Current Timer Value |

| Ignition Trigger Count |

| Misfire Count Cylinder #1 |

| Misfire Count Cylinder #2 |

| Misfire Count Cylinder #3 |

| Misfire Count Cylinder #4 |

| All Cylinders Misfire Count |

| Misfire RPM |

| Misfire Load |

| Misfire Margin |

| Catalyst OT Misfire Fuel Cut |

| Catalyst OT Misfire Fuel Cut History |

| Catalyst OT Misfire Fuel Cut Cylinder #1 |

| Catalyst OT Misfire Fuel Cut Cylinder #2 |

| Catalyst OT Misfire Fuel Cut Cylinder #3 |

| Catalyst OT Misfire Fuel Cut Cylinder #4 |

| IG ON Duration Time |

| IG OFF Duration Time |

| Engine Start Hesitation |

| Low Revolution for Engine Start |

| A/F Learn Value Idle Bank 1 |

| A/F Learn Value Low Bank 1 |

| A/F Learn Value Mid No.1 Bank 1 |

| A/F Learn Value Mid No.2 Bank 1 |

| A/F Learn Value High Bank 1 |

| Engine ECU Internal Temperature |

| Engine Cooling Fan |

| Engine Speed Cylinder #1 |

| Engine Speed Cylinder #2 |

| Engine Speed Cylinder #3 |

| Engine Speed Cylinder #4 |

| Average Engine Speed of All Cylinder |

| Requested Engine Torque |

| HV Target Engine Speed |

| Actual Engine Torque |

| Engine Driving Time |

| Request Engine Run Time |

| Judge Time Engine Ignition |

| Judge Time Engine Output |

| Fuel Level |

| ISC Learning Value |

| ISC Learning |

| F/C for Engine Stop Req |

| Engine Independent |

| Racing Operation |

| Request Warm-up |

| Engine Independent Control |

| Electric Water Pump Target Speed |

| Electric Water Pump Speed |

Check Mode Procedure

CHECK MODE PROCEDURE

HINT:

Compared to normal mode, check mode is more sensitive to malfunctions. Therefore, check mode can detect malfunctions that cannot be detected in normal mode.

NOTICE:

All of the stored DTCs and freeze frame data are cleared if: 1) the ECM is changed from normal mode to check mode or vice versa; or 2) the ignition switch is turned from ON to ACC or off while in check mode. Before changing modes, always check for and note any DTCs and freeze frame data.

CHECK MODE PROCEDURE

(a) Check and ensure the following conditions:

(1) Auxiliary battery voltage is 11 V or higher.

(2) Accelerator pedal fully released.

(3) Park (P) is selected.

(4) A/C switch is off.

(b) Turn the ignition switch off.

(c) Turn the ignition switch ON.

(d) Enter the following menus: Powertrain / Engine / Utility / Check Mode.

Powertrain > Engine > Utility| Tester Display |

|---|

| Check Mode |

(e) Change the ECM from normal mode to check mode.

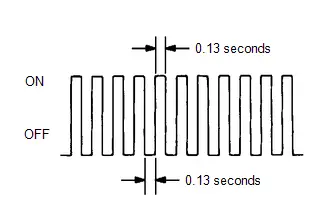

(f) Check that the MIL flashes as shown in the illustration.

(g) Turn the ignition switch ON (READY).

(h) Check that the MIL turns off.

(i) Simulate the conditions of the malfunction described by the customer.

(j) Check for DTCs and freeze frame data using the GTS.

Fail-safe Chart

FAIL-SAFE CHART

If any of the following DTCs are stored, the ECM enters fail-safe mode to allow the vehicle to be driven temporarily or stops fuel injection.

| DTC Code | Component | Fail-Safe Operation | Fail-Safe Deactivation Condition |

|---|---|---|---|

| P001100 | VVT system | Idle up (control of combustion decreased). | Pass condition detected |

| P003012 P003013 P101A9E | Air fuel ratio sensor heater | The ECM turns off the air fuel ratio sensor heater. | Ignition switch off |

| P003612 P003614 P102A9E | Heated oxygen sensor heater | The ECM turns off the heated oxygen sensor heater. | Ignition switch off |

| P006900 P222611 P222615 P222687 P222696 |

| The ECM maintains the last learned atmospheric pressure value. | Pass condition detected |

| P010012 P010014 | Mass air flow meter sub-assembly | The ECM calculates ignition timing according to the engine speed and throttle valve position. | Pass condition detected |

| P010511 P010515 | Manifold absolute pressure sensor | The ECM disables EGR valve operation | Pass condition detected |

| P011011 P011015 | Intake air temperature sensor | The ECM estimates the intake air temperature to be 20°C (68°F). | Pass condition detected |

| P011511 P011515 P01152A | Engine coolant temperature sensor | The ECM estimates the engine coolant temperature to be 80°C (176°F). | Pass condition detected |

| P012011 P012015 P01201C P022011 P022015 P060444 P060647 P060747 P060787 P060E49 P065714 P06579E P16B09F P210018 P210019 P211900 P211904 P211977 P21199B P21352B | Electronic throttle control system | The ECM cuts off throttle actuator current and the throttle valve is returned to a 6.5° throttle position by the return spring. The ECM controls the fuel injection duration and ignition timing in accordance with the engine torque requested by the hybrid Toyota Prius vehicle control ECU. Fuel-cut is performed intermittently.*1 | Pass condition detected and then ignition switch turned off |

| P030000 P030027 P030085 P030100 P030200 P030300 P030400 *2 |

| When a catalyst-damaging misfire occurs (MIL blinking), the following fail-safe operation is performed for catalyst overheat malfunction prevention.

| Pass condition detected and then ignition switch turned off |

| P032511 P032515 | Knock control sensor | The ECM sets the ignition timing to maximum retard. | Ignition switch off |

| P04019C P040314 P140000 P140596 P141004 | EGR valve assembly | The ECM fully closes the EGR valve and stops EGR control. | Pass condition detected |

| P211172 P211173 | Electronic throttle control system | The ECM stops the engine and the Toyota Prius vehicle can be driven using solely the hybrid system.*1 | Pass condition detected and then ignition switch turned off |

| P223700 P223711 P223712 P223713 P22371B P225111 P225112 | Air fuel ratio sensor | Air fuel ratio feedback control is stopped. | Pass condition detected and then ignition switch turned off |

| P26CA12 P26CA31 P26CB71 | Inverter water pump with motor assembly |

| Pass condition detected and then ignition switch is turned off |

| P26CA14 | Inverter water pump with motor assembly |

| Pass condition detected and then ignition switch is turned off |

| P26CE37 | Inverter water pump with motor assembly | The inverter water pump with motor assembly is temporarily operated and stopped in a repeating cycle.

| Pass condition detected and then ignition switch is turned off |

HINT:

- *1: The Toyota Prius vehicle can be driven slowly when the accelerator pedal is depressed firmly and slowly.

- *2: Misfire-related fail-safe operations occur when catalyst overheat malfunctions occur.

Data List / Active Test

DATA LIST / ACTIVE TEST

DATA LIST

HINT:

Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

NOTICE:

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

(a) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility| Tester Display |

|---|

| Inspection Mode |

(b) Start the engine.

(c) Warm up the engine.

(d) Turn the A/C switch off.

(e) Turn the ignition switch off.

(f) Turn the ignition switch ON.

(g) Enter the following menus: Powertrain / Engine / Data List.

HINT:

- To display the list box, press the pull down menu button next to Primary. Then select a measurement group.

- When you select a measurement group, the ECU data belonging to that group is displayed.

-

Measurement Group List / Description

- All Data / All data

- Primary / -

- Engine Control / Engine control system related data

- Ptrl General / -

- Ptrl AF Control / Air fuel ratio control system related data

- Ptrl AF O2 Sensor / Air fuel ratio sensor and heated oxygen sensor related data

- Ptrl Throttle / Gasoline throttle system related data

- Ptrl Intake Control / Intake control system related data

- Ptrl Valve Control / Valve control system related data

- Ptrl Misfire / "Misfire" related data

- Ptrl Starting / "Difficult to start" related data

- Ptrl Rough Idle / "Rough idle" related data

- Ptrl Evaporative / Evaporative system related data

- Ptrl CAT Converter / Catalyst converter related data

- Check Mode / Check mode related data

- Monitor Status / Monitor status related data

- Ignition / Ignition system related data

- Charging Control / Charging control system related data

- Compression / Data used during "Check the Cylinder Compression" Active Test

- AT / Automatic transaxle system related data

- Toyota Prius Vehicle Information / Vehicle information

(h) Read the Data List according to the display on the GTS.

HINT:

The title used for each group of Data List items in this repair manual does not appear on the GTS. However, the name in parentheses after the title, which is a Measurement Group, does appear on the GTS. When the name shown in parentheses is selected on the GTS, all of the Data List items listed for that group will be displayed.

Various Toyota Prius Vehicle Conditions 1 (All Data)

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Total Distance Traveled | Total distance traveled | Min.: 0, Max.: 16777215 | - | - |

| Total Distance Traveled - Unit | Total Distance Traveled unit | km or mile | - | - |

| Toyota Prius Vehicle Speed | Vehicle speed | Min.: 0 km/h (0 mph), Max.: 255 km/h (158 mph) | Actual vehicle speed | This is the current vehicle speed. |

| Engine Speed | Engine speed | Min.: 0 rpm, Max.: 16383 rpm | 950 to 1050 rpm: Idling with warmed up engine (inspection mode [maintenance mode], not charge control, park (P) selected) | When the crankshaft position sensor is malfunctioning, "Engine Speed" is approximately 0 rpm or varies greatly from the actual engine speed. |

| Calculate Load | Load calculated by ECM | Min.: 0%, Max.: 100% |

|

|

| Toyota Prius Vehicle Load | Vehicle load | Min.: 0%, Max.: 25700% | Actual vehicle load |

HINT: Due to individual engine differences, intake air temperature, etc., the value may exceed 100%. Intake airflow (g/rev.) = Intake airflow (gm/sec) x 60 / Engine speed (rpm) (Intake airflow (gm/sec) is value of Mass Air Flow Sensor) |

| Mass Air Flow Sensor | Airflow rate from mass air flow meter sub-assembly | Min.: 0 gm/sec, Max.: 655.35 gm/sec |

| This is the intake air amount measured by the mass air flow meter sub-assembly. |

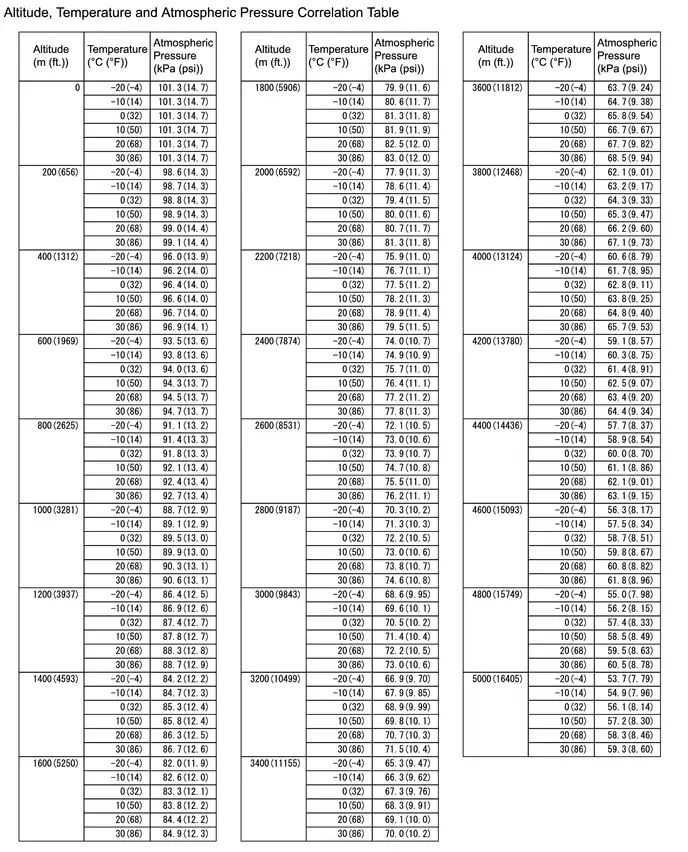

| Atmospheric Pressure | Atmospheric pressure | Min.: 0 kPa (0 psi), Max.: 255 kPa (37 psi) | Equivalent to atmospheric pressure |

|

| Intake Manifold Absolute Pressure | Intake manifold absolute pressure | Min.: 0 kPa (0 psi), Max.: 2047.96 kPa (296.95 psi) |

|

HINT: When the ignition switch ON, the manifold absolute pressure and atmospheric pressure are approximately the same (standard atmospheric pressure = 101 kPa(abs) [15 psi(abs)]). |

| Intake Manifold Absolute Pressure Supported | Status of Intake Manifold Absolute Pressure | Unsupp or Supp | Supp | - |

| Coolant Temperature | Engine coolant temperature | Min.: -40°C (-40°F), Max.: 140°C (284°F) | 75 to 100°C (167 to 212°F): After warming up | This is the engine coolant temperature. HINT:

|

| Intake Air Temperature | Intake air temperature | Min.: -40°C (-40°F), Max.: 140°C (284°F) | Equivalent to temperature at location of mass air flow meter sub-assembly | This is the engine intake air temperature. HINT:

|

| Ambient Temperature | Ambient temperature | Min.: -40°C (-40°F), Max.: 215°C (419°F) | Equivalent to ambient temperature | This is the ambient temperature. HINT: After a long soak, the engine coolant temperature, intake air temperature and ambient air temperature will be approximately equal. |

| Engine Run Time | Engine run time | Min.: 0 sec, Max.: 65535 sec | Time after engine start |

|

| IG-ON Coolant Temperature | Engine coolant temperature when the ignition switch is turned ON | Min.: -40°C (-40°F), Max.: 119.3°C (246.7°F) | - | This is the engine coolant temperature stored when the ignition switch is turned ON. |

| Initial Engine Coolant Temperature | Engine coolant temperature when the ignition switch is turned ON (READY) | Min.: -40°C (-40°F), Max.: 119.3°C (246.7°F) | - | This is the engine coolant temperature stored when the ignition switch is turned ON (READY). |

| IG-ON Intake Air Temperature | Intake air temperature when the ignition switch is turned ON | Min.: -40°C (-40°F), Max.: 119.3°C (246.7°F) | - | This is the intake air temperature stored when the ignition switch is turned ON |

| Initial Engine Intake Air Temperature | Intake air temperature when the ignition switch is turned ON (READY) | Min.: -40°C (-40°F), Max.: 119.3°C (246.7°F) | - | This is the intake air temperature stored when the ignition switch is turned ON (READY). |

| Battery Voltage | Auxiliary battery voltage | Min.: 0 V, Max.: 65.5 V | 11 to 16 V: Ignition switch ON | If 11 V or less, characteristics of some electrical components may change. |

| BATT Voltage | Auxiliary battery voltage | Min.: 0 V, Max.: 79.998 V | 11 to 16 V: Ignition switch ON | If 11 V or less, characteristics of some electrical components may change. |

| IG2 / IGP | Status of IGP terminal | ON or OFF | ON: Ignition switch ON | - |

| IGR | Status of IGR terminal | ON or OFF | ON: Ignition switch ON | - |

| Intake Camshaft Position Sensor Voltage | Camshaft position sensor voltage | Min.: 0 V, Max.: 4.999 V | - | - |

| Intake Camshaft Position Sensor Speed Bank 1 | Intake camshaft speed | Min.: 0 rpm, Max.: 65535 rpm | - | - |

| Crankshaft Position Sensor Voltage | Crankshaft position sensor voltage | Min.: 0 V, Max.: 4.999 V | - | - |

Throttle Control (All Data)

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Throttle Position Sensor No.1 Voltage % | Absolute No. 1 throttle position sensor | Min.: 0%, Max.: 100% | 10 to 22%: Ignition switch ON, accelerator pedal fully released | The No. 1 throttle position sensor output is converted using 5 V = 100%. HINT: If there are no throttle position sensor DTCs stored, it is possible to conclude that the throttle position sensor system is normal. |

| Throttle Position Sensor No.2 Voltage % | Absolute No. 2 throttle position sensor | Min.: 0%, Max.: 100% | 42 to 62%: Ignition switch ON, accelerator pedal fully released | The No. 2 throttle position sensor output is converted using 5 V = 100%. |

| System Guard | System guard | ON or OFF | ON: Idling or throttle actuator operating |

|

| Open Side Malfunction | Open malfunction | ON or OFF | OFF | This item indicates a malfunction in the electronic throttle when the throttle valve is open. |

| Throttle Request Position | Required throttle position | Min.: 0 V, Max.: 4.98 V | 0.6 to 1.1 V: Idling with warmed up engine (inspection mode [maintenance mode]) | The value of this item is calculated by the ECM and shows the voltage for the target throttle valve position. |

| Throttle Sensor Position | Throttle sensor position | Min.: 0%, Max.: 100% | - | - |

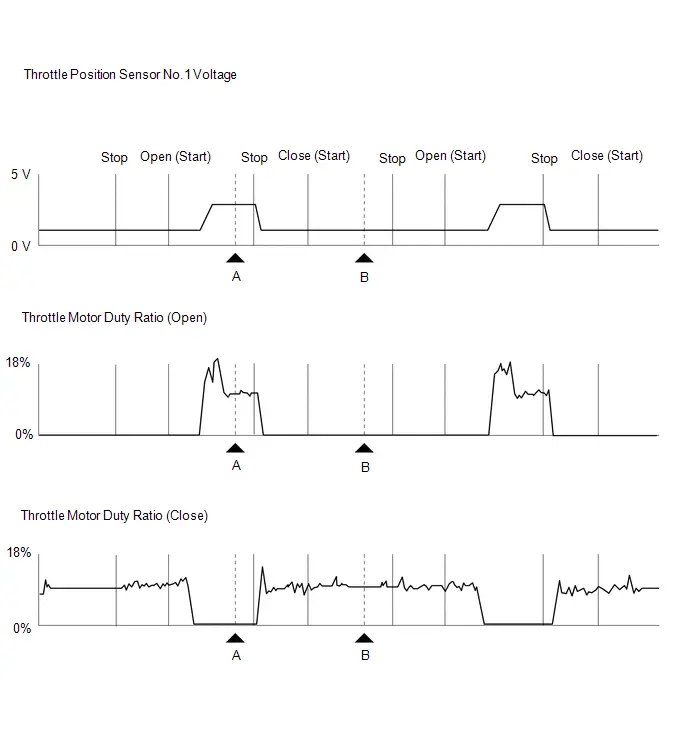

| Throttle Position Sensor No.1 Voltage | No. 1 throttle position sensor output voltage | Min.: 0 V, Max.: 4.98 V |

| This is the No. 1 throttle position sensor output voltage. |

| Throttle Position Sensor No.2 Voltage | No. 2 throttle position sensor output voltage | Min.: 0 V, Max.: 4.98 V |

| This is the No. 2 throttle position sensor output voltage. |

| Throttle Position Command | Throttle position command value | Min.: 0 V, Max.: 4.98 V | 0.6 to 1.1 V: Idling with warmed up engine (inspection mode [maintenance mode]) | The value displayed for this item is the same as Throttle Request Position. |

| Throttle Position Sensor Open Position No.1 | No. 1 throttle position sensor | Min.: 0 V, Max.: 4.98 V | 0.6 to 1.4 V | This is the No. 1 throttle position sensor output voltage when there is no current supplied to the electronic throttle actuator. If the accelerator pedal is released the throttle valve is kept open by the throttle valve opener when the ignition switch ON. |

| Throttle Position Sensor Open Position No.2 | No. 2 throttle position sensor | Min.: 0 V, Max.: 4.98 V | 1.7 to 2.5 V | This is the No. 2 throttle position sensor output voltage when there is no current supplied to the electronic throttle actuator. If the accelerator pedal is released the throttle valve is kept open by the throttle valve opener when the ignition switch ON. |

| Throttle Motor Current | Throttle actuator current | Min.: 0 A, Max.: 19.9 A | 0 to 3.0 A: Idling with warmed up engine (inspection mode [maintenance mode]) | When the value of this item is large but the actual opening angle (Throttle Position Sensor No.1 Voltage) does not reach the target opening angle (Throttle Request Position), there is an "unable to open" malfunction. |

| Throttle Motor Duty Ratio | Throttle actuator | Min.: 0%, Max.: 100% | 10 to 22%: Idling with warmed up engine (inspection mode [maintenance mode]) | This is the output duty ratio of the throttle actuator drive circuit. |

| Throttle Motor Duty Ratio (Open) | Throttle actuator duty ratio (open) | Min.: 0%, Max.: 255% | 0 to 40%: Idling with warmed up engine (inspection mode [maintenance mode]) | This is the duty ratio used to drive the throttle actuator and open the throttle valve. It is an ECM command signal. |

| Throttle Motor Duty Ratio (Close) | Throttle actuator duty ratio (close) | Min.: 0%, Max.: 255% | 0 to 40%: Idling with warmed up engine (inspection mode [maintenance mode]) | This is the duty ratio used to drive the throttle actuator and close the throttle valve. It is an ECM command signal. HINT: During idle, the throttle valve opening angle is usually controlled using a duty ratio drive signal which closes the throttle valve. However, if carbon deposits have built up, it may be necessary to open the throttle valve more than the throttle valve opener does. In that case, the opening angle is controlled using the Throttle Motor Duty Ratio (Open) signal. |

| Throttle Position Sensor Fully Closed Learn Value | Throttle valve fully closed position (learned value) | Min.: 0 V, Max.: 4.98 V | 0.4 to 1.0 V: Ignition switch ON, accelerator pedal fully released |

|

| BM Voltage | BM voltage | Min.: 0 V, Max.: 79.998 V | 11 to 16 V: Ignition switch ON | This is the power supply for the electronic throttle actuator. When the power supply is interrupted for approximately 1 second, DTCs P065714 (open circuit) and P06579E (short circuit, ECU malfunction) are stored and the electronic throttle control system enters fail-safe mode (normal operation is not restored until the ignition switch is turned off). |

| Actuator Power Supply | Actuator power supply | ON or OFF | ON: Engine running or throttle actuator operating | - |

| Throttle Air Flow Learn Value (Area 1) | Throttle air flow learning value of area 1 | Min.: 0, Max.: 1.99 | - | - |

| Throttle Air Flow Learn Value (Area 2) | Throttle air flow learning value of area 2 | Min.: 0, Max.: 1.99 | - | - |

| Throttle Air Flow Learn Value (Area 3) | Throttle air flow learning value of area 3 | Min.: 0, Max.: 1.99 | - | - |

| Throttle Air Flow Learn Value (Calculated Value) | Throttle air flow learning value (calculated value) | Min.: 0, Max.: 1.99 | - | - |

| Throttle Air Flow Learn Value (Atmosphere Pressure Offset Value) | Throttle air flow learning value (atmosphere pressure offset value) | Min.: 0, Max.: 2.55 | - | - |

Idle Speed Control (Ptrl Rough Idle)

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Low Revolution Control | Low engine speed control operation state | ON or OFF | OFF | This item indicates whether the engine speed dropped immediately after starting due to poor combustion, etc. |

| Engine Stall Control F/B Flow | ISC torque lower limit value to prevent engine stall | Min.: -1024 Nm, Max.: 1023.96 Nm | - |

|

Fuel System (All Data)

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Injector Cylinder #1 (Port) | Injection period of the No. 1 cylinder | Min.: 0 μs, Max.: 65535 μs | 1000 to 3000 μs: Idling with warmed up engine (inspection mode [maintenance mode], not charge control) | This is the injection period of the No. 1 cylinder (the command value from the ECM). |

| Injection Volume Cylinder #1 | Injection volume (cylinder 1) | Min.: 0 ml, Max.: 2 ml | 0.03 to 0.13 ml: Idling with warmed up engine (inspection mode [maintenance mode], not charge control) | This is the fuel injection volume for 10 injections. |

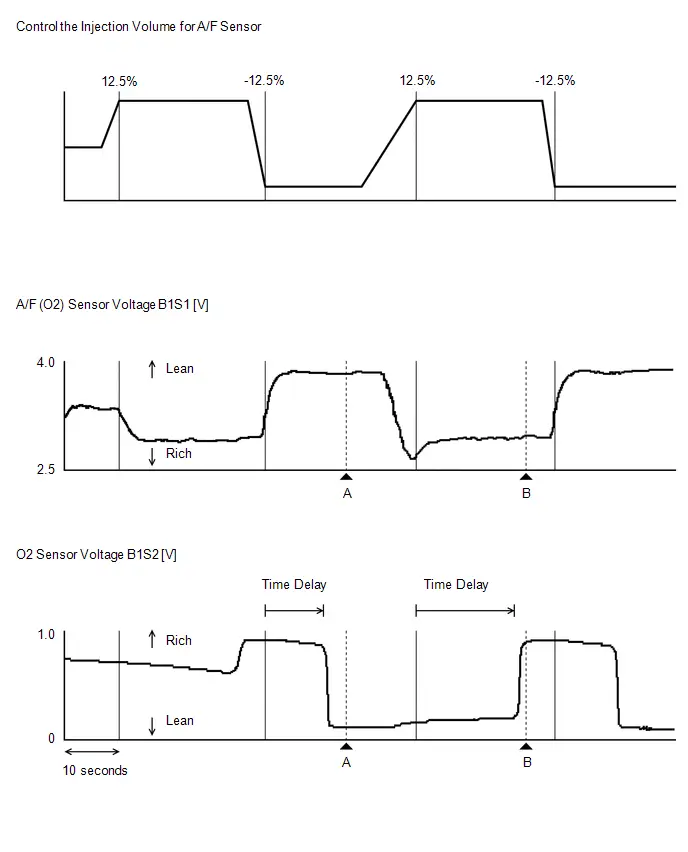

| Injection Volume | Fuel injection volume | Min.: -25%, Max.: 24.8% | - | Active Test [Control the Injection Volume for A/F Sensor] support data. |

| Engine Fuel Rate | Fuel consumption (engine) | Min.: 0 gm/sec, Max.: 1310.7 gm/sec | - | - |

| Toyota Prius Vehicle Fuel Rate | Fuel consumption (vehicle) | Min.: 0 gm/sec, Max.: 1310.7 gm/sec | - | - |

| Fuel Pump/Speed Status | Fuel pump status | ON or OFF | ON: Engine running | - |

| Current Fuel Type | Current fuel type | - | Gasoline/petrol | - |

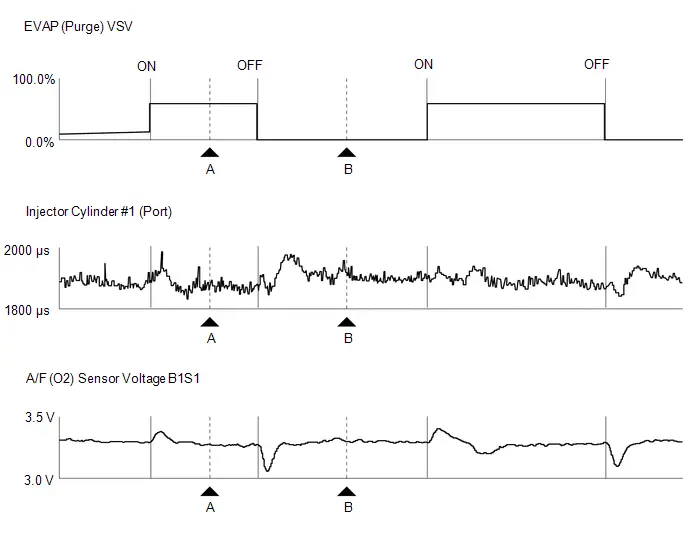

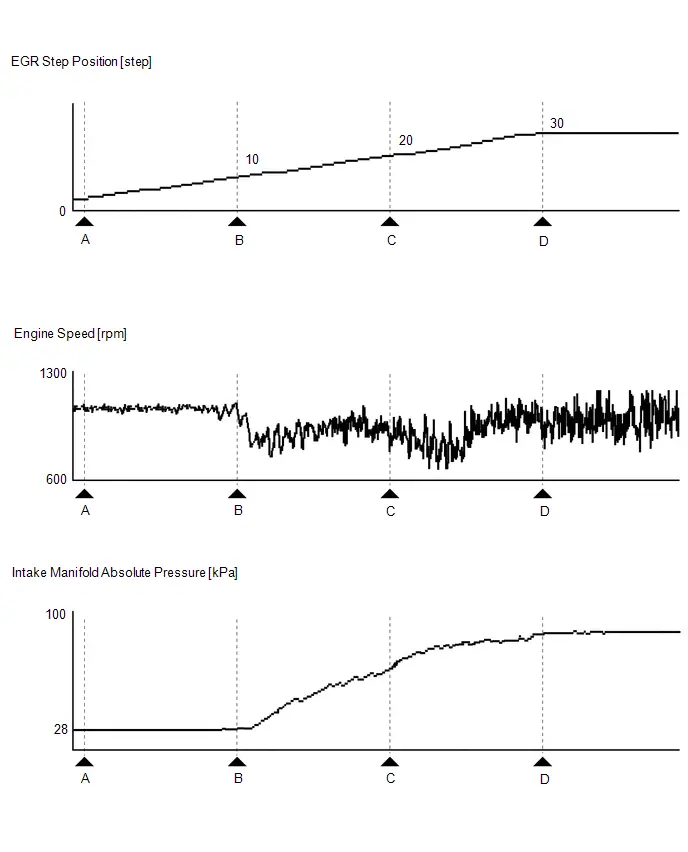

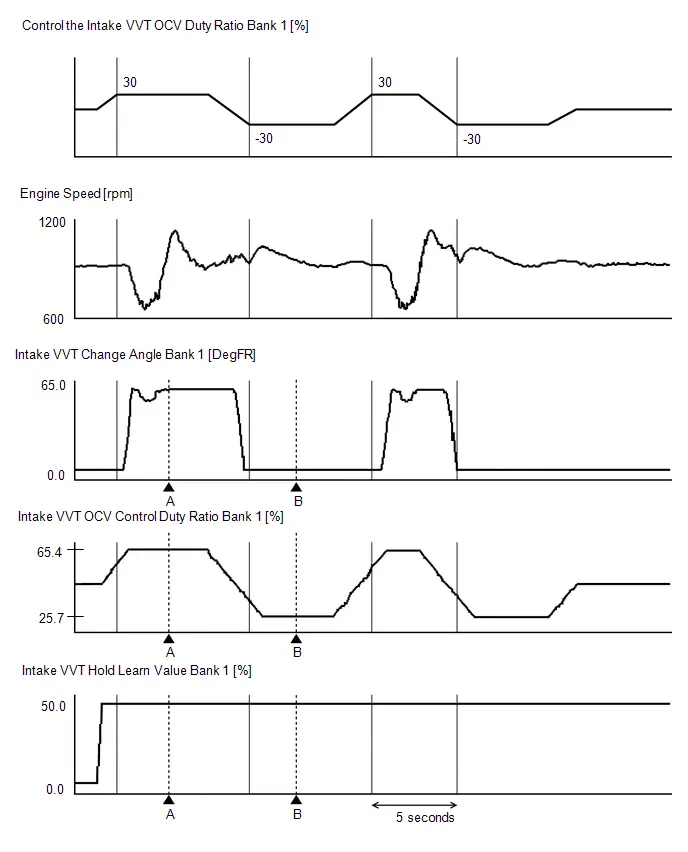

EVAP System (Ptrl Evaporative)

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| EVAP (Purge) VSV | Purge VSV control duty | Min.: 0%, Max.: 100% | 10 to 70%: Idling with warmed up engine (inspection mode [maintenance mode]) |

|

| EVAP Purge Flow | Purge flow | Min.: 0%, Max.: 399.9% | - | This is the percentage of total engine airflow contributed by EVAP purge operation. (Evap Purge Flow = Purge flow / Engine airflow x 100 (%)) |

| EVAP Purge Density Learn Value | Purge density learned value | Min.: -200, Max.: 199.993 | - |

HINT:

|

| Fuel Lid SW | Fuel lid courtesy switch status | Open or Close |

| This item is displayed only with Canister Pump Module models. |

| EVAP Purge VSV | VSV status for EVAP control | ON or OFF | - | This item is ON when EVAP (Purge) VSV is approximately 30% or higher, and is OFF when the VSV duty ratio is less than 30%. |

| Purge Cut VSV Duty | Purge VSV duty | Min.: 0%, Max.: 399.9% | - | - |

Air Fuel Ratio Control 1 (All Data)

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Target Air-Fuel Ratio | Target air fuel ratio | Min.: 0, Max.: 2 | 0.8 to 1.2: During idling (engine warmed up) |

|

Air Fuel Ratio Control 2 (Ptrl AF O2 Sensor)

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

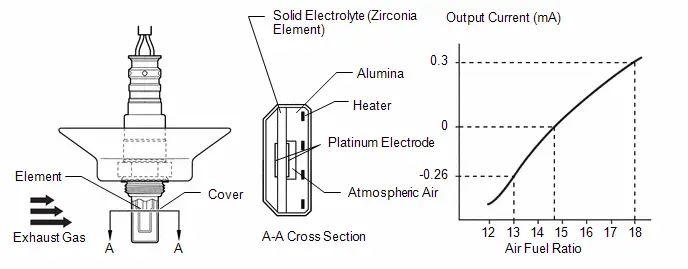

| A/F (O2) Lambda Sensor B1S1 | Output air fuel ratio associated | Min.: 0, Max.: 1.99 |

| This is the actual air fuel ratio calculated based on the air fuel ratio sensor output. |

| A/F (O2) Sensor Current B1S1 | Air fuel ratio sensor output current | Min.: -128 mA, Max.: 127.99 mA | -0.5 to 0.5 mA: Idling with warmed up engine (inspection mode [maintenance mode]) |

|

| A/F (O2) Sensor Heater Duty Ratio B1S1 | Air fuel ratio sensor heater duty ratio | Min.: 0%, Max.: 399.9% | 0 to 100% | When the value of this item is more than 0%, current is being supplied to the heater. |

| A/F Sensor Impedance B1S1 | Air fuel ratio sensor impedance | Min.: 0 ohm, Max.: 21247.67 ohm | 5 to 15000 ohm: Idling with warmed up engine (inspection mode [maintenance mode]) | - |

| O2 Sensor Voltage B1S2 | Heated oxygen sensor output voltage | Min.: 0 V, Max.: 1.275 V | 0 to 1.0 V |

|

| A/F (O2) Sensor Heater Current-Carrying Status B1S2 (at Heater OFF) | Air fuel ratio sensor heater off energizing status | ON or OFF | OFF: Ignition switch ON | - |

| A/F (O2) Sensor Heater Overcurrent B1S2 | Air fuel ratio sensor heater overcurrent | ON or OFF | OFF | - |

| A/F (O2) Sensor Heater Control Run Time B1S2 | Time elapsed since air fuel ratio sensor heater control started | Min.: 0 ms, Max.: 536862 ms | - | - |

| A/F (O2) Sensor Terminal Voltage Bank 1 | Air fuel ratio sensor positive terminal voltage | Min.: 0 V, Max.: 79.998 V | - | - |

| A/F (O2) Sensor -Terminal Voltage Bank 1 | Air fuel ratio sensor negative terminal voltage | Min.: 0 V, Max.: 79.998 V | - | - |

| A/F (O2) Sensor Heater Control Duty Ratio Bank1 | Air fuel ratio sensor heater control duty ratio | Min.: -327.68%, Max.: 327.67% | - |

|

| A/F (O2) Sensor Heater Output Duty Ratio Bank1 | Air fuel ratio sensor heater output duty ratio | Min.: 0%, Max.: 399.99% | - |

|

| A/F (O2) Sensor Heater ON Current Value Bank1 | Air fuel ratio sensor heater on output current | Min.: 0 A, Max.: 65.535 A | -0.5 to 0.5 mA: Idling with engine warmed up (inspection mode [maintenance mode], not charge control) | - |

| A/F (O2) Sensor Heater Current-Carrying Status Bank1 (at Heater OFF) | Air fuel ratio sensor heater off energizing status | ON or OFF | OFF: Ignition switch ON | - |

| A/F (O2) Sensor Heater Overcurrent Bank1 | Air fuel ratio sensor heater overcurrent | ON or OFF | OFF | - |

| A/F (O2) Sensor Heater Control Run Time Bank1 | Time elapsed since air fuel ratio sensor heater control started | Min.: 0 ms, Max.: 65535 ms | - | - |

| A/F (O2) Sensor Impedance B1S2 | Air fuel ratio sensor impedance | Min.: 0 ms, Max.: 21247.67 ohm | 5 to 15000 ohm: Idling with warmed up engine (inspection mode [maintenance mode]) | - |

| O2 Sensor Heater B1S2 | Heated oxygen sensor heater | Active or Not Act | Active: Heater on | - |