Toyota Prius: Rear Axle Hub (for Awd)

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear axle hub and bearing assembly on-Toyota Prius vehicle inspection are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: Also necessary after performing a tire rotation.

*2: It is not necessary to perform this procedure if the tire pressure warning valve and transmitters are installed to the same location. *3: The Toyota Prius vehicle height changes because of suspension or tire replacement. |

|||

|

Tires |

|

Tire Pressure Warning System |

Refer to Procedures Necessary When Replacing Parts (for Tire Pressure Warning System)

|

|

Rear television camera assembly optical axis (Back camera position setting)*3 |

Parking Assist Monitor System |

|

|

|

Parking assist ECU initialization*3 |

Panoramic View Monitor System |

|

|

|

Advanced Park |

|

||

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when Toyota Prius vehicle is driven|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Front Camera System |

Drive the Toyota Prius vehicle straight ahead at 35 km/h (22 mph) or more for 5 second or more. |

|

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

| *1: w/o Power Back Door System

*2: w/ Power Back Door System |

||

|

Power Door Lock Control System*1

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch. |

|

|

Power Back Door System*2 |

Reset back door close position |

|

|

Air Conditioning System |

for HEV Model:

for PHEV Model:

|

- |

CAUTION / NOTICE / HINT

NOTICE:

- When removing or installing the rear disc brake caliper assembly, pushing back the disc brake piston may cause a large clearance between the brake pads and brake disc. When the brake pedal is depressed with a large clearance between the brake pads and the brake disc, DTC C140000 and/or C140A00 related to abnormal brake fluid pressure may be stored. Make sure to clear any DTCs after performing this procedure.

- While the auxiliary battery is connected, even if the ignition switch is off, the brake control system activates when the brake pedal is depressed or any door courtesy switch turns on. Therefore, when servicing the brake system components, do not operate the brake pedal or open/close the doors while the auxiliary battery is connected.

- To prevent the key from being locked in the Toyota Prius vehicle, make

sure to enter e-latch inspection mode and enable the manual release handle

before disconnecting the cable from the negative (-) auxiliary battery terminal.

Click here

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH and LH sides.

- The following procedure is for the LH side.

PROCEDURE

1. PRECAUTION

NOTICE:

- After the ignition switch is turned off, there may be a waiting time

before disconnecting the negative (-) auxiliary battery terminal.

Click here

- Make sure to read the precautions of the electric parking brake system

before removing the rear brake assembly.

Click here

2. DISABLE BRAKE CONTROL

HINT:

Click here

3. REMOVE REAR WHEEL

HINT:

Click here

4. DISCONNECT NO. 2 PARKING BRAKE WIRE ASSEMBLY

HINT:

Click here

5. SEPARATE REAR DISC BRAKE CALIPER ASSEMBLY

HINT:

Click here

6. REMOVE REAR DISC

HINT:

Click here

7. INSPECT REAR AXLE HUB BEARING LOOSENESS

|

(a) Using a dial indicator with magnetic base, check for looseness near the center of the rear axle hub and bearing assembly. NOTICE:

|

|

(b) If the looseness exceeds the maximum, replace the rear axle hub and bearing assembly.

8. INSPECT REAR AXLE HUB RUNOUT

|

(a) Using a dial indicator with magnetic base, check for runout on the surface of the rear axle hub and bearing assembly. NOTICE:

|

|

(b) If the runout exceeds the maximum, replace the rear axle hub and bearing assembly.

9. INSTALL REAR DISC

HINT:

Click here

10. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

HINT:

Click here

11. CONNECT NO. 2 PARKING BRAKE WIRE ASSEMBLY

HINT:

Click here

12. INSTALL REAR WHEEL

HINT:

Click here

13. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

HINT:

Click here

14. INITIALIZATION AFTER RECONNECTING AUXILIARY BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear axle hub and bearing assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: Also necessary after performing a tire rotation.

*2: It is not necessary to perform this procedure if the tire pressure warning valve and transmitters are installed to the same location. *3: The Toyota Prius vehicle height changes because of suspension or tire replacement. |

|||

|

Tires |

|

Tire Pressure Warning System |

Refer to Procedures Necessary When Replacing Parts (for Tire Pressure Warning System)

|

|

Rear television camera assembly optical axis (Back camera position setting)*3 |

Parking Assist Monitor System |

|

|

|

Parking assist ECU initialization*3 |

Panoramic View Monitor System |

|

|

|

Advanced Park |

|

||

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when Toyota Prius vehicle is driven|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Front Camera System |

Drive the Toyota Prius vehicle straight ahead at 35 km/h (22 mph) or more for 5 second or more. |

|

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

| *1: w/o Power Back Door System

*2: w/ Power Back Door System |

||

|

Power Door Lock Control System*1

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch. |

|

|

Power Back Door System*2 |

Reset back door close position |

|

|

Air Conditioning System |

for HEV Model:

for PHEV Model:

|

- |

CAUTION / NOTICE / HINT

NOTICE:

- When removing or installing the rear disc brake caliper assembly, pushing back the disc brake piston may cause a large clearance between the brake pads and brake disc. When the brake pedal is depressed with a large clearance between the brake pads and the brake disc, DTC C140000 and/or C140A00 related to abnormal brake fluid pressure may be stored. Make sure to clear any DTCs after performing this procedure.

- While the auxiliary battery is connected, even if the ignition switch is off, the brake control system activates when the brake pedal is depressed or any door courtesy switch turns on. Therefore, when servicing the brake system components, do not operate the brake pedal or open/close the doors while the auxiliary battery is connected.

- To prevent the key from being locked in the Toyota Prius vehicle, make

sure to enter e-latch inspection mode and enable the manual release handle

before disconnecting the cable from the negative (-) auxiliary battery terminal.

Click here

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH and LH sides.

- The following procedure is for the LH side.

CAUTION / NOTICE / HINT

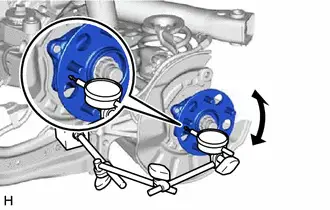

COMPONENTS (REMOVAL)

|

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

1 |

PRECAUTION |

- |

|

- |

- |

|

2 |

DISABLE BRAKE CONTROL |

- |

|

- |

- |

|

3 |

REAR WHEEL |

- |

- |

- |

- |

|

4 |

REAR AXLE SHAFT NUT |

42312B |

|

- |

- |

|

5 |

NO. 2 PARKING BRAKE WIRE ASSEMBLY |

890C0A |

|

- |

- |

|

6 |

REAR SKID CONTROL SENSOR |

89544E |

|

- |

- |

|

7 |

REAR DISC BRAKE CALIPER ASSEMBLY |

- |

|

- |

- |

|

8 |

REAR DISC |

42431 |

- |

- |

- |

|

9 |

REAR AXLE HUB AND BEARING ASSEMBLY |

42450B |

|

- |

- |

|

*1 |

REAR DISC BRAKE DUST COVER |

- |

- |

|

● |

Non-reusable part |

- |

- |

PROCEDURE

1. PRECAUTION

|

NOTICE:

|

2. DISABLE BRAKE CONTROL

|

Click here

|

3. REMOVE REAR WHEEL

Click here

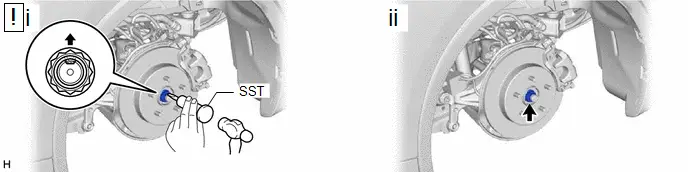

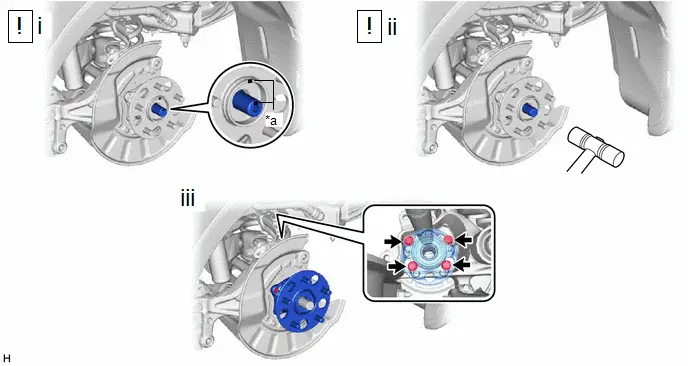

4. REMOVE REAR AXLE SHAFT NUT

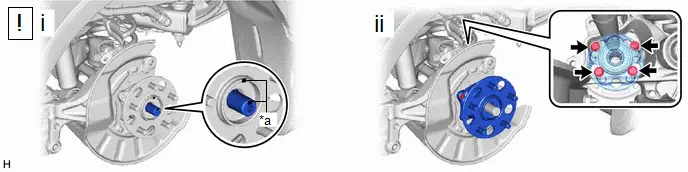

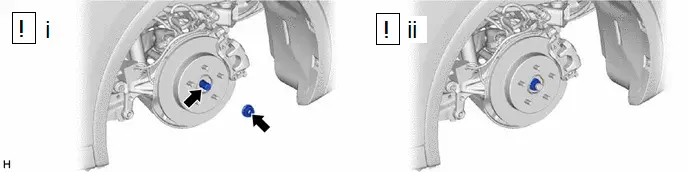

(1) Using SST and a hammer, release the staked part of the rear axle shaft nut.

SST: 09930-00010

NOTICE:

Loosen the staked part of the rear axle shaft nut completely, otherwise the threads of the rear drive shaft assembly may be damaged.

(2) While applying the brakes, remove the rear axle shaft nut.

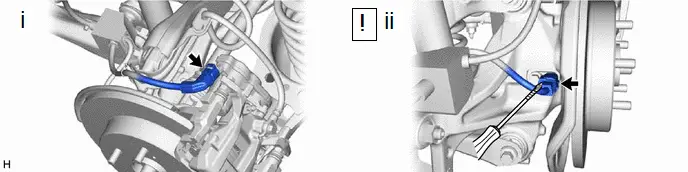

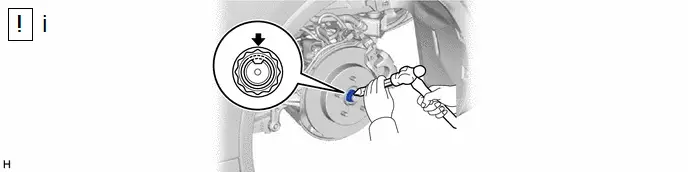

5. DISCONNECT NO. 2 PARKING BRAKE WIRE ASSEMBLY

|

NOTICE:

|

(1) Disconnect the No. 2 parking brake wire assembly connector from the parking brake actuator assembly.

(2) Using a screwdriver with its tip wrapped with protective tape, disconnect the No. 2 parking brake wire assembly connector from the rear skid control sensor.

NOTICE:

Be careful not to damage the rear skid control sensor or connector cover.

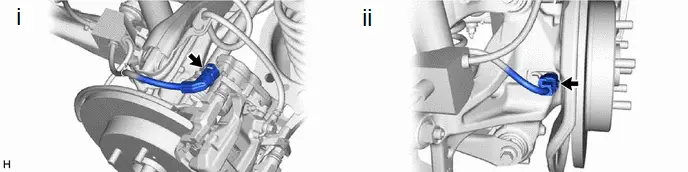

6. REMOVE REAR SKID CONTROL SENSOR

(1) Remove the bolt and the rear skid control sensor from the rear axle carrier sub-assembly.

NOTICE:

- Keep the tip of the rear skid control sensor and installation hole free of foreign matter.

- Do not rotate or apply excessive force to the rear skid control sensor when removing it from the rear axle carrier sub-assembly. Rotating or applying excessive force may result in damage to the rear skid control sensor.

7. SEPARATE REAR DISC BRAKE CALIPER ASSEMBLY

Click here

8. REMOVE REAR DISC

|

Click here

|

9. REMOVE REAR AXLE HUB AND BEARING ASSEMBLY

|

*a |

Matchmark |

- |

- |

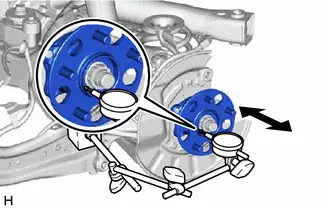

(1) Put matchmarks on the rear drive shaft assembly and the rear axle hub and bearing assembly.

(2) Using a plastic hammer, separate the rear drive shaft assembly from the rear axle hub and bearing assembly.

HINT:

If it is difficult to separate the rear drive shaft assembly rear axle hub and bearing assembly, tap the end of the rear drive shaft assembly using a brass bar and a hammer.

(3) Remove the 4 bolts, rear axle hub and bearing assembly and rear disc brake dust cover sub-assembly from the rear axle carrier sub-assembly.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

- When removing or installing the rear disc brake caliper assembly, pushing back the disc brake piston may cause a large clearance between the brake pads and brake disc. When the brake pedal is depressed with a large clearance between the brake pads and the brake disc, DTC C140000 and/or C140A00 related to abnormal brake fluid pressure may be stored. Make sure to clear any DTCs after performing this procedure.

- While the auxiliary battery is connected, even if the ignition switch is off, the brake control system activates when the brake pedal is depressed or any door courtesy switch turns on. Therefore, when servicing the brake system components, do not operate the brake pedal or open/close the doors while the auxiliary battery is connected.

- To prevent the key from being locked in the Toyota Prius vehicle, make

sure to enter e-latch inspection mode and enable the manual release handle

before disconnecting the cable from the negative (-) auxiliary battery terminal.

Click here

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH and LH sides.

- The following procedure is for the LH side.

CAUTION / NOTICE / HINT

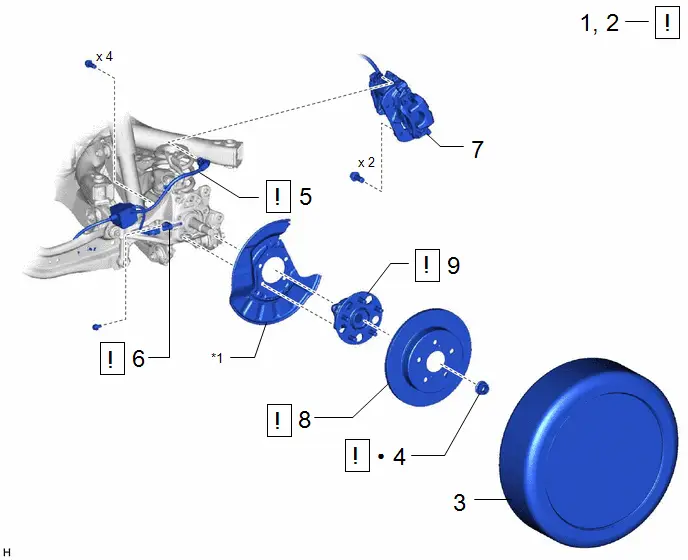

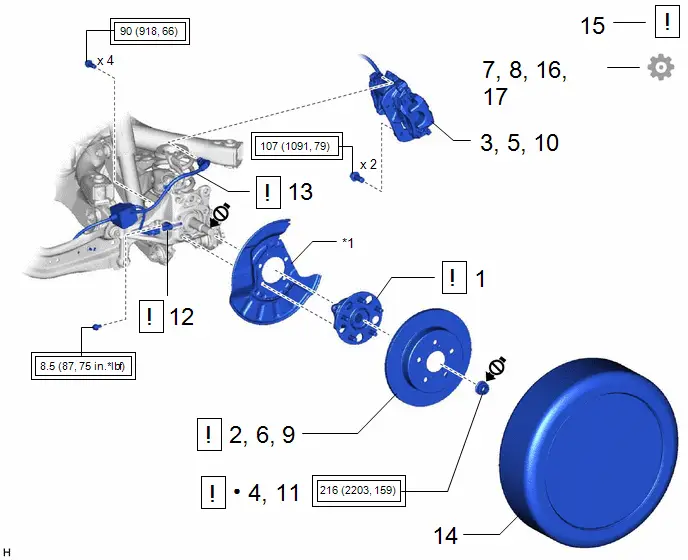

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

1 |

REAR AXLE HUB AND BEARING ASSEMBLY |

42450B |

|

- |

- |

|

2 |

INSTALL REAR DISC |

42431 |

|

- |

- |

|

3 |

REAR DISC BRAKE CALIPER ASSEMBLY |

- |

- |

- |

- |

|

4 |

TEMPORARILY INSTALL REAR AXLE SHAFT NUT |

42312B |

|

- |

- |

|

5 |

REAR DISC BRAKE CALIPER ASSEMBLY |

- |

- |

- |

- |

|

6 |

REMOVE REAR DISC |

42431 |

|

- |

- |

|

7 |

INSPECT REAR AXLE HUB BEARING LOOSENESS |

- |

- |

- |

|

|

8 |

INSPECT REAR AXLE HUB RUNOUT |

- |

- |

- |

|

|

9 |

INSTALL REAR DISC |

42431 |

|

- |

- |

|

10 |

REAR DISC BRAKE CALIPER ASSEMBLY |

- |

- |

- |

- |

|

11 |

STAKE REAR AXLE SHAFT NUT |

42312B |

|

- |

- |

|

12 |

SKID CONTROL SENSOR |

89544E |

|

- |

- |

|

13 |

NO. 2 PARKING BRAKE WIRE ASSEMBLY |

890C0A |

|

- |

- |

|

14 |

REAR WHEEL |

- |

- |

- |

- |

|

15 |

CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL |

- |

|

- |

- |

|

16 |

INITIALIZATION AFTER RECONNECTING AUXILIARY BATTERY TERMINAL |

- |

- |

- |

|

|

17 |

CHECK FOR SPEED SENSOR SIGNAL |

- |

- |

- |

|

|

*1 |

REAR DISC BRAKE DUST COVER |

- |

- |

|

Tightening torque for "Major areas involving basic Toyota Prius vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● |

Non-reusable part |

|

Do not apply lubricants to the threaded parts |

- |

- |

PROCEDURE

1. INSTALL REAR AXLE HUB AND BEARING ASSEMBLY

|

*a |

Matchmark |

- |

- |

(1) Install the rear axle hub and bearing assembly and rear disc brake dust cover sub-assembly to the rear drive shaft assembly.

NOTICE:

Align the matchmarks on the rear drive shaft assembly and rear axle hub and bearing assembly.

(2) Install the rear axle hub and bearing assembly and rear disc brake dust cover sub-assembly to the rear axle carrier sub-assembly with the 4 bolts.

Torque:

90 N·m {918 kgf·cm, 66 ft·lbf}

2. INSTALL REAR DISC

|

Click here

|

3. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

Click here

4. TEMPORARILY INSTALL REAR AXLE SHAFT NUT

(1) Clean the threaded parts on the rear drive shaft assembly and a new rear axle shaft nut using non-residue solvent.

NOTICE:

- Be sure to perform this work even when using a new rear drive shaft assembly.

- Keep the threaded parts free of oil and foreign matter.

(2) Using a 30 mm deep socket wrench, temporarily install the rear axle shaft nut.

Torque:

216 N·m {2203 kgf·cm, 159 ft·lbf}

NOTICE:

Stake the rear axle shaft nut after inspecting for looseness and runout in the following steps.

HINT:

Keep depressing the brake pedal to prevent the rear drive shaft assembly from rotating.

5. SEPARATE REAR DISC BRAKE CALIPER ASSEMBLY

Click here

6. REMOVE REAR DISC

|

Click here

|

7. INSPECT REAR AXLE HUB BEARING LOOSENESS

Click here

8. INSPECT REAR AXLE HUB RUNOUT

Click here

9. INSTALL REAR DISC

|

Click here

|

10. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

Click here

11. STAKE REAR AXLE SHAFT NUT

(1) Using a chisel and hammer, stake the rear axle shaft nut.

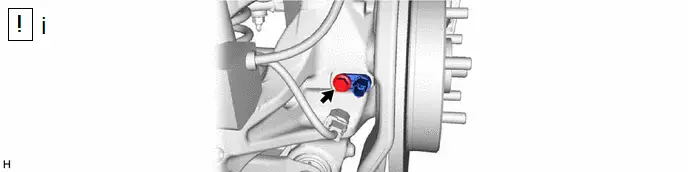

12. INSTALL SKID CONTROL SENSOR

|

NOTICE:

|

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

13. CONNECT NO. 2 PARKING BRAKE WIRE ASSEMBLY

|

NOTICE:

|

(1) Connect the No. 2 parking brake wire assembly connector to the parking brake actuator assembly.

(2) Connect the No. 2 parking brake wire assembly connector to the rear skid control sensor.

14. INSTALL REAR WHEEL

Click here

15. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

|

Click here

|

16. INITIALIZATION AFTER RECONNECTING AUXILIARY BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

17. CHECK FOR SPEED SENSOR SIGNAL

Click here

Toyota Prius (XW60) 2023-2026 Service Manual

Rear Axle Hub (for Awd)

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image