Toyota Prius: Pa10 Hybrid Vehicle Transaxle

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during hybrid vehicle transaxle assembly inspection are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: Even when not replacing the part, it is necessary to perform the specified necessary procedures after installation. | |||

|

Replacement of shift actuator ECU (Shift control actuator assembly)* |

Perform actuator position learning |

|

|

NOTICE:

- When disconnecting a wire harness of any component connected to the supply power of the integrated capacitor (integration control supply) or when removing the integrated capacitor (integration control supply), make sure to wait 5 minutes or more after turning the ignition switch off for self-diagnosis to complete and the voltage of the integrated capacitor (integration control supply) to discharge.

- If the shift control actuator assembly is replaced or removed, make

sure to perform actuator position learning.

If not performed after replacing the shift control actuator assembly, a malfunction such as the shift position not correctly changing, the shift position indicator not illuminating or displaying the incorrect drive state, etc. may occur.

- When the shift control actuator assembly is replaced or removed, although the displayed value of Data List item "ACT Position Learning Complete Status" may be "Complete" based on information from before removal, make sure to perform actuator position learning.

- When any of the above procedures are completed, change the shift position

to all positions and check the following items:

- The shift position indicator illuminates in accordance with the current position.

- The Toyota Prius vehicle does not move when in shift state P (parking brake released)

- The vehicle does not drive when in shift state N

- The vehicle drives when in shift state D or R

PROCEDURE

1. SECURE VEHICLE

(a) Fully apply the parking brake and chock a wheel.

CAUTION:

- Make sure to apply the parking brake and chock a wheel before performing this procedure.

- If the Toyota Prius vehicle is not secure and the shift lever is moved to N, the vehicle may suddenly move, possibly resulting in an accident or serious injury.

2. REMOVE SHIFT CONTROL ACTUATOR ASSEMBLY

HINT:

Click here

3. INSPECT HYBRID Toyota Prius Vehicle TRANSAXLE ASSEMBLY

|

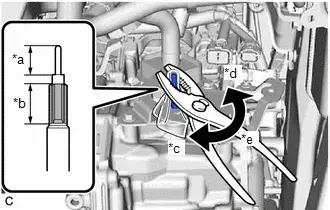

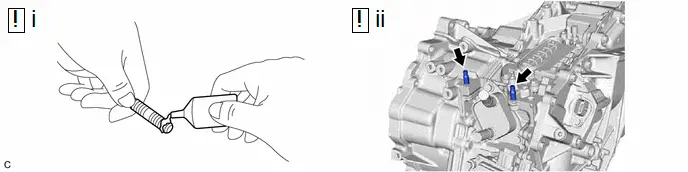

(a) Using a pair of pliers, grip the spline portion (*b) of the parking lock shaft that has been wrapped with a cloth or other material and rotate it in the direction shown by the arrow in the illustration. Standard: The parking lock smoothly engages and disengages. NOTICE:

|

|

4. INSTALL SHIFT CONTROL ACTUATOR ASSEMBLY

HINT:

Click here

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during hybrid vehicle transaxle assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: Also necessary after performing a tire rotation.

*2: It is not necessary to perform this procedure if the tire pressure warning valve and transmitters are installed to the same location. *3: Even when not replacing the part, it is necessary to perform the specified necessary procedures after installation. *4: The Toyota Prius vehicle height changes because of tire replacement. *5: If matchmarks were not placed when removing parts related to steering operation, perform end position initial setting. |

|||

|

Replacement of ECM |

Update ECU security key |

Toyota Prius Vehicle Control History (RoB) are stored |

|

|

ECU configuration |

- |

|

|

|

Perform Toyota Prius Vehicle Identification Number (VIN) registration |

DTC is output |

|

|

|

Replacement of inverter with converter assembly |

ECU configuration |

- |

|

|

Resolver learning |

|

|

|

|

Replacement of hybrid vehicle transaxle assembly |

|

|

|

|

Inspection after repair |

|

|

|

Suspension parts |

Rear television camera assembly optical axis (Back camera position setting) |

Parking Assist Monitor System |

|

|

Parking assist ECU initialization |

Panoramic View Monitor System |

|

|

|

Advanced Park |

|

||

|

Front wheel alignment adjustment |

Perform "Calibration" |

|

|

|

Tires |

|

Tire Pressure Warning System |

Refer to Procedures Necessary When Replacing Parts (for Tire Pressure Warning System) table below

|

|

Rear television camera assembly optical axis (Back camera position setting)*4 |

Parking Assist Monitor System |

|

|

|

Parking assist ECU initialization*4 |

Panoramic View Monitor System |

|

|

|

Advanced Park |

|

||

|

Replacement of front bumper assembly*3 |

Front television camera view adjustment |

Panoramic View Monitor System |

|

|

Advanced Park |

|

||

|

No. 2 steering intermediate shaft assembly*5 |

End position initial setting |

- |

|

CAUTION:

- Orange wire harnesses and connectors indicate high-voltage circuits.

To prevent electric shock, always follow the procedure described in the

repair manual.

Click here

- To prevent electric shock, wear insulated gloves when working on wire

harnesses and components of the high voltage system.

- To prevent burns, do not touch the engine, exhaust manifold or other

high temperature components while the engine is hot.

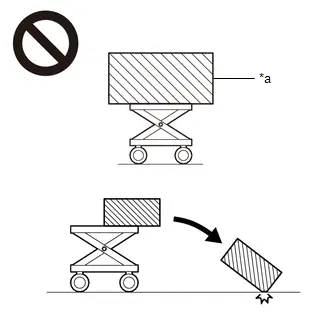

- The engine assembly with transaxle is very heavy. Be sure to follow

the procedure described in the repair manual, or the engine lifter may suddenly

drop or the engine assembly with transaxle may fall off the engine lifter.

*a

An Object Exceeding Weight Limit of Engine Lifter

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when Toyota Prius vehicle is driven|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Front Camera System |

Drive the Toyota Prius vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more. |

|

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

| *1: w/o Power Back Door System

*2: w/ Power Back Door System |

||

|

Power Door Lock Control System*1

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch. |

|

|

Power Back Door System*2 |

Reset back door close position |

|

|

Air Conditioning System |

After the ignition switch is turned to ON, the servo motor standard position is recognized. |

- |

CAUTION / NOTICE / HINT

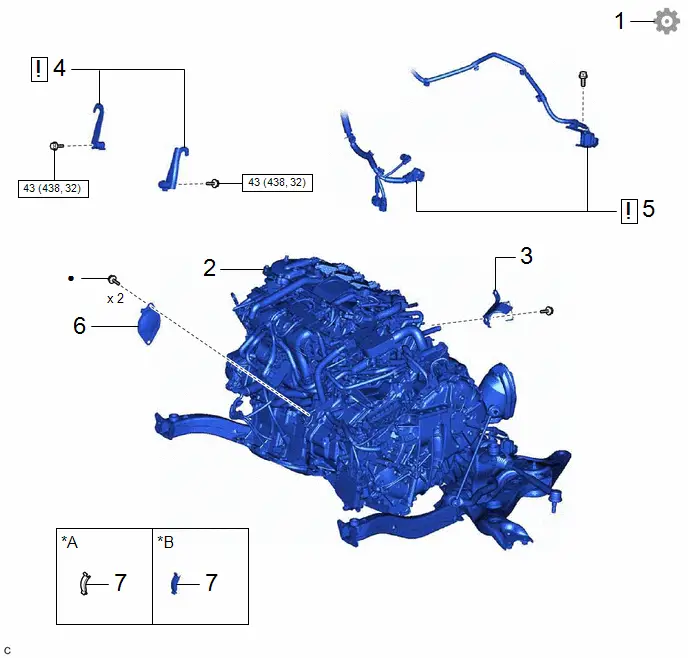

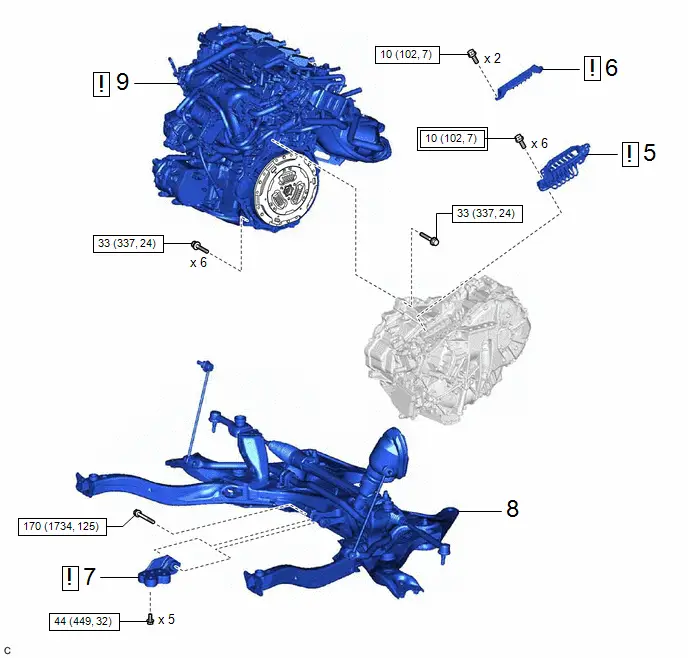

COMPONENTS (REMOVAL)

|

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

1 |

PERFORM RESOLVER INITIALIZATION |

- |

- |

- |

|

|

2 |

ENGINE ASSEMBLY WITH TRANSAXLE |

- |

- |

- |

- |

|

3 |

WIRE HARNESS CLAMP BRACKET |

- |

- |

- |

- |

|

4 |

ENGINE HANGERS |

- |

|

- |

- |

|

5 |

ENGINE WIRE |

82121 |

|

- |

- |

|

6 |

STARTER HOLE INSULATOR |

28193 |

- |

- |

- |

|

7 |

FLYWHEEL HOUSING SIDE COVER |

11363A |

- |

- |

- |

|

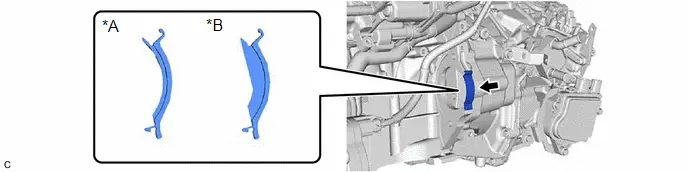

*A |

Type A |

*B |

Type B |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

● |

Non-reusable part |

|

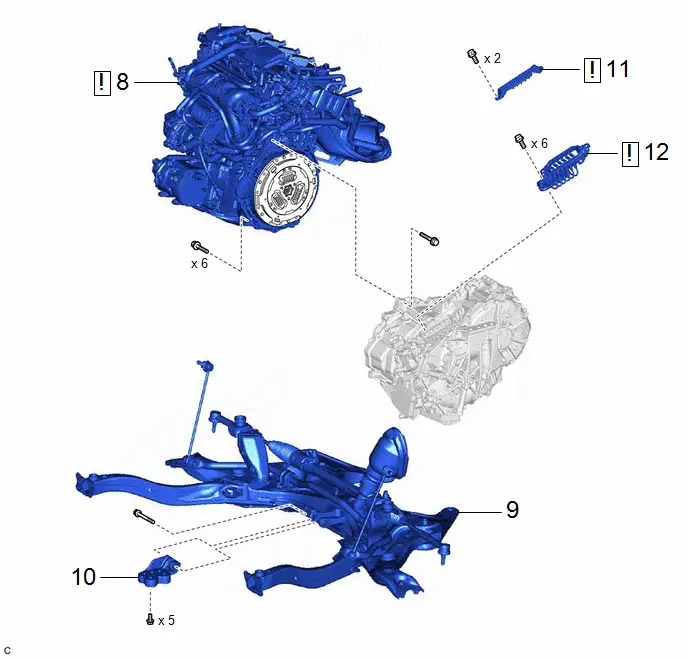

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

8 |

ENGINE ASSEMBLY |

- |

|

- |

- |

|

9 |

FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY |

51201 |

- |

- |

- |

|

10 |

NO. 2 ENGINE MOVING CONTROL ROD |

12364B |

- |

- |

- |

|

11 |

TERMINAL CAP |

82823M |

|

- |

- |

|

12 |

MOTOR CABLE |

G1148 |

|

- |

- |

|

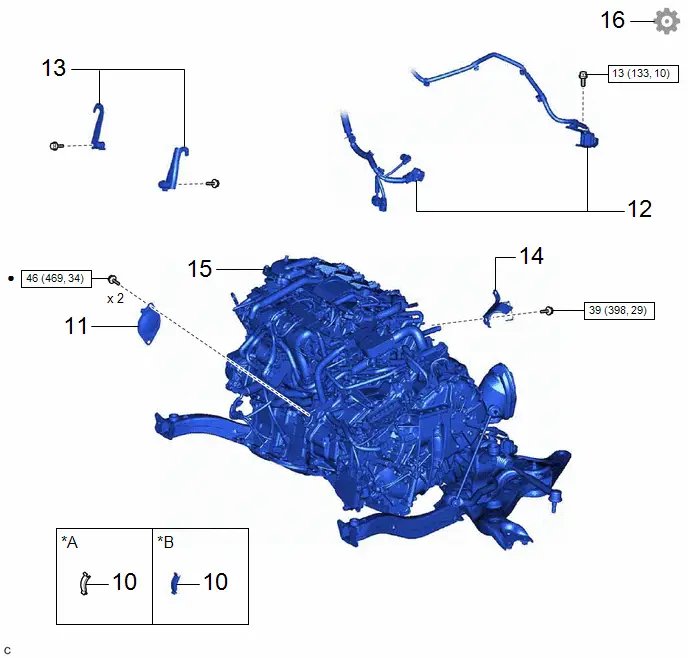

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

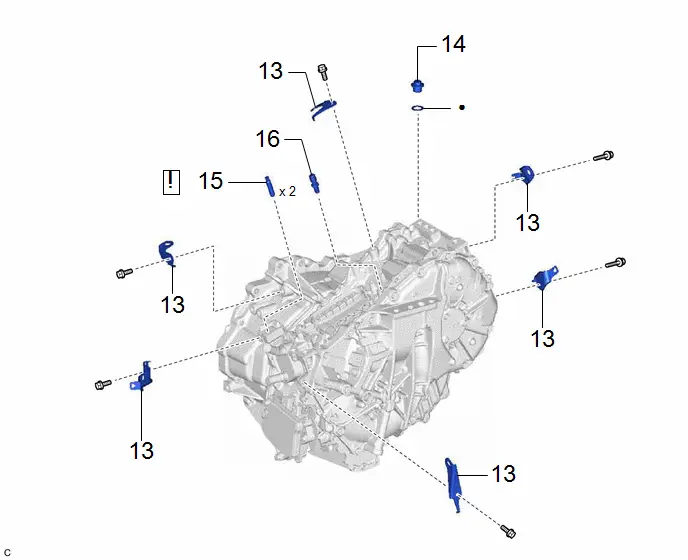

13 |

WIRE HARNESS CLAMP BRACKET |

- |

- |

- |

- |

|

14 |

TRANSAXLE HOUSING PLUG |

- |

- |

- |

- |

|

15 |

STUD BOLT |

- |

|

- |

- |

|

16 |

TRANSAXLE BREATHER PLUG |

30900N |

- |

- |

- |

|

● |

Non-reusable part |

★ |

Precoated part |

PROCEDURE

1. PERFORM RESOLVER INITIALIZATION

|

NOTICE: If it is necessary to replace the hybrid Toyota Prius vehicle transaxle assembly, make sure to perform resolver initialization before starting work. Click here

|

2. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

Click here

3. REMOVE WIRE HARNESS CLAMP BRACKET

Click here

4. INSTALL ENGINE HANGERS

|

Click here

|

5. DISCONNECT ENGINE WIRE

|

NOTICE: Cover the hole where the shift control actuator assembly was installed with tape or equivalent (non-residue type) to prevent entry of foreign matter, water, etc.  |

6. REMOVE STARTER HOLE INSULATOR

7. REMOVE FLYWHEEL HOUSING SIDE COVER

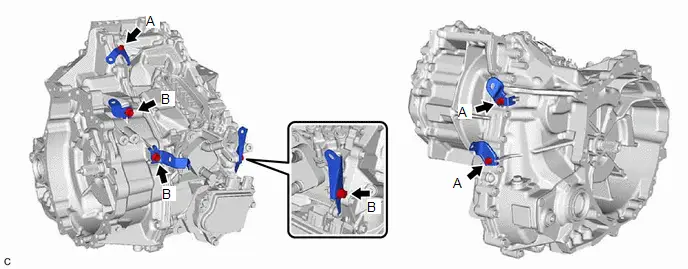

|

*A |

Type A |

*B |

Type B |

8. REMOVE ENGINE ASSEMBLY

|

NOTICE:

|

9. REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

10. REMOVE NO. 2 ENGINE MOVING CONTROL ROD

11. REMOVE TERMINAL CAP

|

Click here

|

12. REMOVE MOTOR CABLE

|

Click here

|

13. REMOVE WIRE HARNESS CLAMP BRACKET

14. REMOVE TRANSAXLE HOUSING PLUG

15. REMOVE STUD BOLT

(1) Using an E10 "TORX" socket wrench, remove the 2 stud bolts from the hybrid Toyota Prius vehicle transaxle assembly.

16. REMOVE TRANSAXLE BREATHER PLUG

HINT:

Perform this procedure only when replacement of the transaxle breather plug is necessary.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

CAUTION:

The engine assembly with hybrid vehicle transaxle assembly is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop.

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

1 |

TRANSAXLE BREATHER PLUG |

30900N |

- |

- |

- |

|

2 |

STUD BOLT |

- |

|

- |

- |

|

3 |

TRANSAXLE HOUSING PLUG |

- |

- |

- |

- |

|

4 |

WIRE HARNESS CLAMP BRACKET |

- |

- |

- |

- |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

● |

Non-reusable part |

|

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent |

★ |

Precoated part |

|

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

5 |

MOTOR CABLE |

G1148 |

|

- |

- |

|

6 |

TERMINAL CAP |

82823M |

|

- |

- |

|

7 |

NO. 2 ENGINE MOVING CONTROL ROD |

12364B |

|

- |

- |

|

8 |

FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY |

51201 |

- |

- |

- |

|

9 |

ENGINE ASSEMBLY |

- |

|

- |

- |

|

Tightening torque for "Major areas involving basic Toyota Prius vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

|

Procedure |

Part Name Code |

|

|

|

|

|---|---|---|---|---|---|

|

10 |

FLYWHEEL HOUSING SIDE COVER |

11363A |

- |

- |

- |

|

11 |

STARTER HOLE INSULATOR |

28193 |

- |

- |

- |

|

12 |

ENGINE WIRE |

82121 |

- |

- |

- |

|

13 |

ENGINE HANGERS |

- |

- |

- |

- |

|

14 |

WIRE HARNESS CLAMP BRACKET |

- |

- |

- |

- |

|

15 |

ENGINE ASSEMBLY WITH TRANSAXLE |

- |

- |

- |

- |

|

16 |

PERFORM RESOLVER LEARNING |

- |

- |

- |

|

|

*A |

Type A |

*B |

Type B |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

● |

Non-reusable part |

PROCEDURE

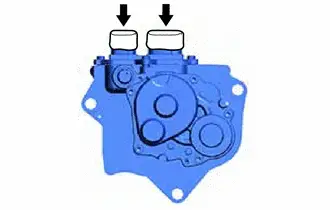

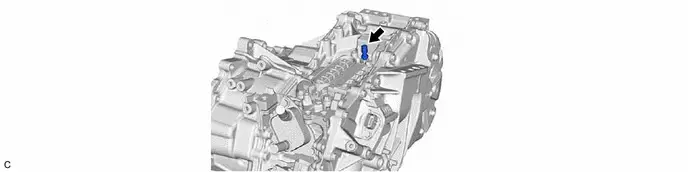

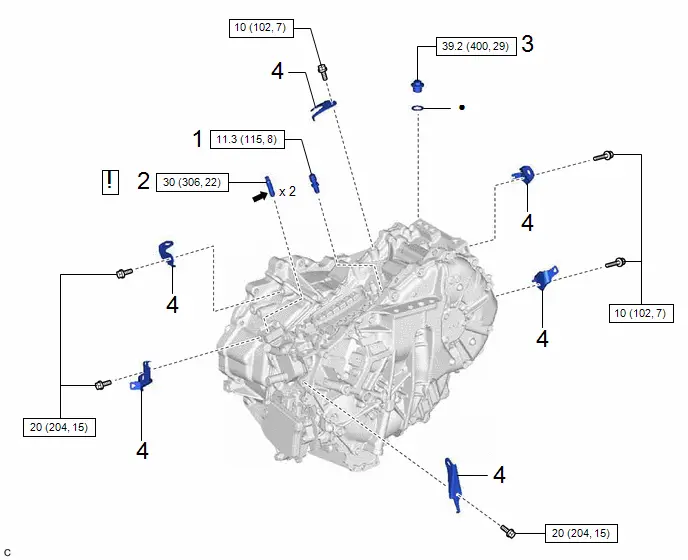

1. INSTALL TRANSAXLE BREATHER PLUG

HINT:

Perform this procedure only when replacement of the transaxle breather plug is necessary.

Torque:

11.3 N·m {115 kgf·cm, 8 ft·lbf}

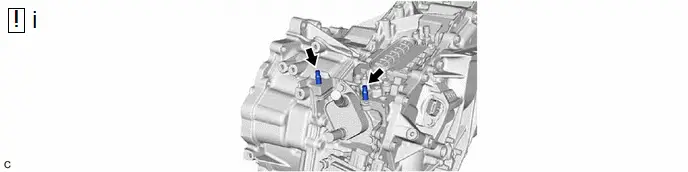

2. INSTALL STUD BOLT

(1) Apply adhesive to the 2 stud bolts.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

NOTICE:

Make sure to install the 2 stud bolts immediately after applying adhesive to prevent foreign matter from attaching to them.

(2) Using an E10 "TORX" socket wrench, install the 2 stud bolts to the hybrid Toyota Prius vehicle transaxle assembly.

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

3. INSTALL TRANSAXLE HOUSING PLUG

Torque:

39.2 N·m {400 kgf·cm, 29 ft·lbf}

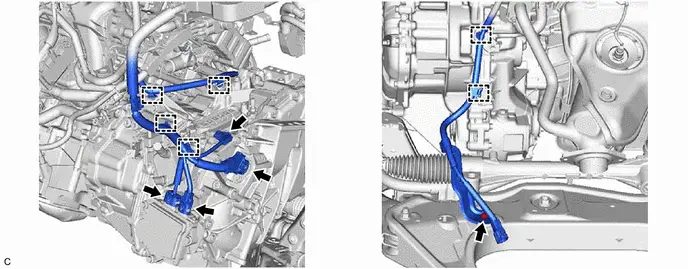

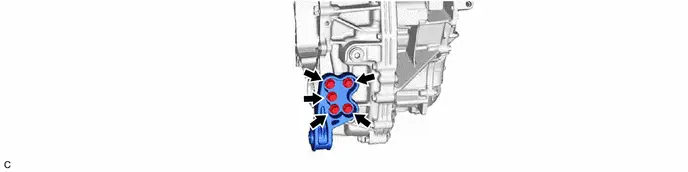

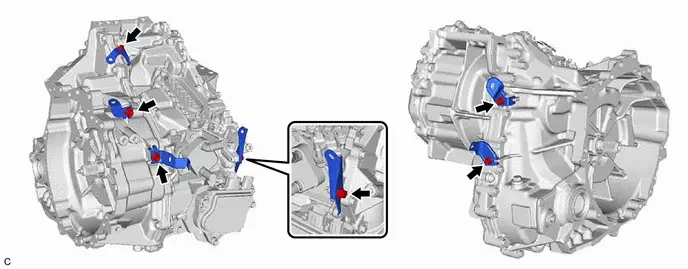

4. INSTALL WIRE HARNESS CLAMP BRACKET

Torque:

Bolt (A) :

10 N·m {102 kgf·cm, 7 ft·lbf}

Bolt (B) :

20 N·m {204 kgf·cm, 15 ft·lbf}

|

Bolt |

Bolt Length |

|---|---|

|

(A) |

16 mm (0.630 in.) |

|

(B) |

20 mm (0.787 in.) |

5. INSTALL MOTOR CABLE

|

Click here

|

6. INSTALL TERMINAL CAP

|

Click here

|

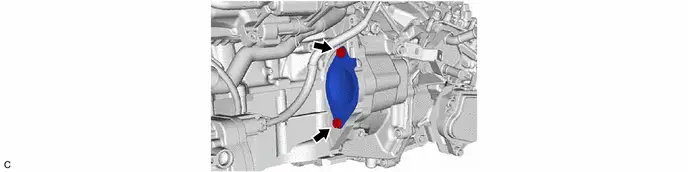

7. INSTALL NO. 2 ENGINE MOVING CONTROL ROD

|

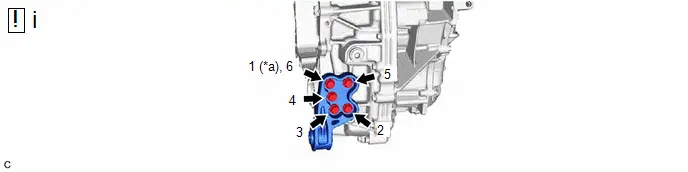

*a |

Temporarily Tighten |

- |

- |

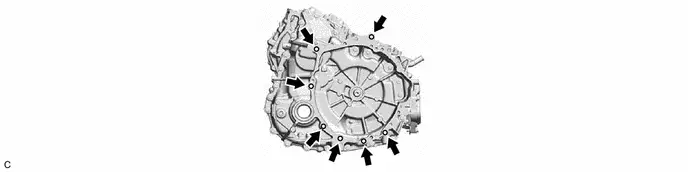

(1) Install the No. 2 engine moving control rod to the hybrid Toyota Prius vehicle transaxle assembly with the 5 bolts in the order shown in the illustration.

Torque:

44 N·m {449 kgf·cm, 32 ft·lbf}

8. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

Torque:

170 N·m {1734 kgf·cm, 125 ft·lbf}

9. INSTALL ENGINE ASSEMBLY

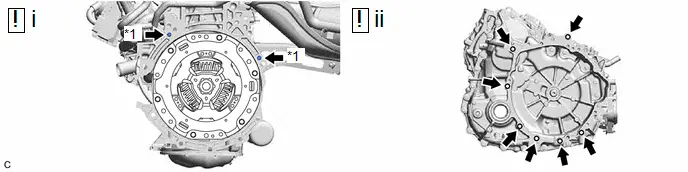

|

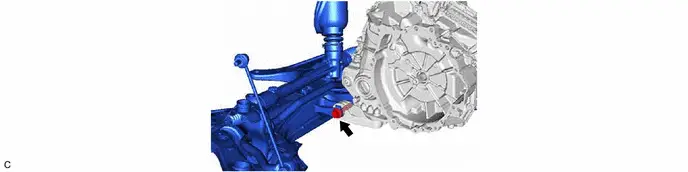

*1 |

Knock Pin |

- |

- |

(1) Make sure that the knock pins are installed to the engine assembly.

(2) Install the engine assembly to the hybrid Toyota Prius vehicle transaxle assembly with the 7 bolts.

Torque:

33 N·m {337 kgf·cm, 24 ft·lbf}

NOTICE:

- When tightening the bolts, be sure that the contact surfaces of the engine assembly and hybrid vehicle transaxle assembly are in close contact with one another.

- Do not apply grease to the inner splines of the transmission input damper assembly or input shaft assembly.

- Make sure that the wire harness or similar items are not pinched between the contact surfaces.

- Do not use excessive force when installing the engine assembly.

- Make sure to align the hybrid Toyota Prius vehicle transaxle assembly so that the input shaft assembly of the hybrid vehicle transaxle assembly will be inserted straight into the inner splines of the transmission input damper assembly.

- When inserting the input shaft assembly of the hybrid vehicle transaxle assembly into the inner splines of the transmission input damper assembly, do not shake the engine assembly excessively.

- When installing the engine assembly to the hybrid Toyota Prius vehicle transaxle assembly, make sure to securely fit the knock pins into the knock pin holes.

10. INSTALL FLYWHEEL HOUSING SIDE COVER

11. INSTALL STARTER HOLE INSULATOR

Torque:

46 N·m {469 kgf·cm, 34 ft·lbf}

12. CONNECT ENGINE WIRE

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

13. REMOVE ENGINE HANGERS

14. INSTALL WIRE HARNESS CLAMP BRACKET

Click here

15. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

Click here

16. PERFORM RESOLVER LEARNING

|

NOTICE: If the hybrid Toyota Prius vehicle transaxle assembly has been replaced, make sure to perform resolver learning. Click here

|

Toyota Prius (XW60) 2023-2026 Service Manual

Pa10 Hybrid Vehicle Transaxle

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image