Toyota Prius: Mass Air Flow Meter

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT MASS AIR FLOW METER SUB-ASSEMBLY

Pre-procedure1

(a) Read the value of Data List item "Mass Air Flow Sensor" using the GTS.

NOTICE:

Perform the inspection of the mass air flow meter sub-assembly while it is installed to the air cleaner cap sub-assembly (installed to the Toyota Prius vehicle).

(1) Check and ensure the following conditions:

- Turn off all electrical loads, such as the air conditioning, etc.

- Check that the coolant temperature is 75°C (167°F) or more.

- Put the shift lever in the N position.

(2) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility| Tester Display |

|---|

| Inspection Mode |

(3) Start the engine.

Procedure1

(b) According to the display on the GTS, read the Data List when the engine is running.

Powertrain > Engine > Data List| Tester Display |

|---|

| Mass Air Flow Sensor |

Standard Condition:

| GTS Display | Condition | Specified Condition | Result |

|---|---|---|---|

| Mass Air Flow Sensor | Idling with warmed up engine (inspection mode [maintenance mode], not charge control) | 1.0 to 3.0 gm/sec | gm/sec |

| Mass Air Flow Sensor | Warmed up engine, 2500 rpm (inspection mode [maintenance mode]) | 4.5 to 8.5 gm/sec | gm/sec |

If the result is not as specified, clean the mass air flow meter sub-assembly.

If the result is within the specified range, inspect the mass air flow meter sub-assembly.

Click here

Post-procedure1

(c) None

2. CLEAN MASS AIR FLOW METER SUB-ASSEMBLY

NOTICE:

If the mass air flow meter sub-assembly is removed and installed 10 times or more, the thread of the hole of the mass air flow meter sub-assembly may be damaged. Therefore, do not loosen the screws of the mass air flow meter sub-assembly.

Pre-procedure1

(a) Remove the air cleaner cap sub-assembly.

Procedure1

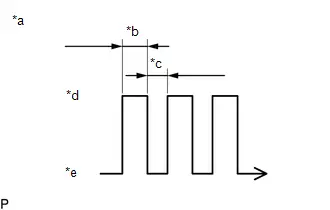

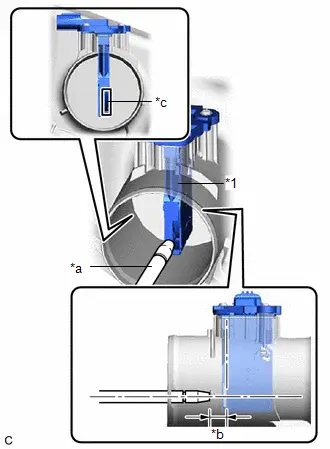

| *1 | Mass Air Flow Meter Sub-assembly |

| *a | Air Blow Gun |

| *b | 10 mm (0.394 in.) |

| *c | Airflow Hole |

(b) Clean the mass air flow meter sub-assembly.

NOTICE:

- Do not contact the mass air flow meter sub-assembly with the nozzle of the air blow gun.

- Do not insert the nozzle of the air blow gun into the airflow hole.

| (1) Using an air blow gun, clean the hole of the mass air flow meter sub-assembly by applying approximately 10 intermittent bursts of air to the airflow hole at a pressure of approximately 392 to 981 kPa (4.0 to 10.0 kgf/cm2, 57 to 142 psi). |

|

Post-procedure1

(c) Install the air cleaner cap sub-assembly.

3. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the mass air flow meter sub-assembly.

HINT:

Click here

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during mass air flow meter sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Replacement of mass air flow meter sub-assembly | Inspection after repair |

|

|

CAUTION / NOTICE / HINT

COMPONENTS (REMOVAL)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | MASS AIR FLOW METER SUB-ASSEMBLY | 22204 |

| - | - |

PROCEDURE

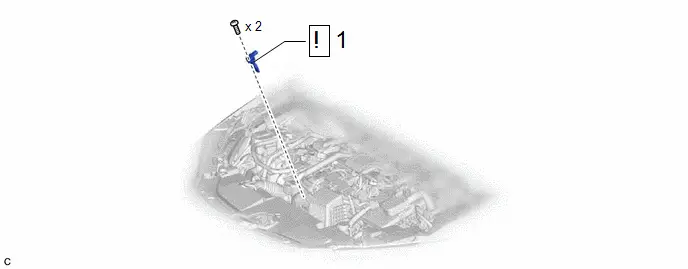

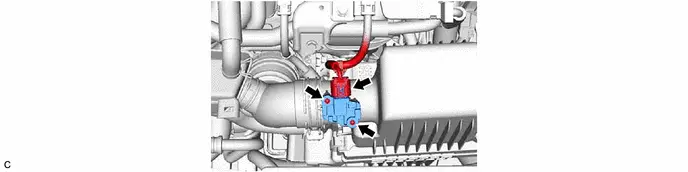

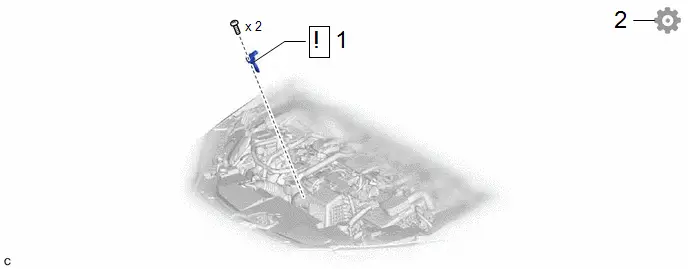

1. REMOVE MASS AIR FLOW METER SUB-ASSEMBLY

| NOTICE: If the mass air flow meter sub-assembly has been struck or dropped, replace it. |

Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | MASS AIR FLOW METER SUB-ASSEMBLY | 22204 |

| - | - |

| 2 | PERFORM INITIALIZATION | - | - | - |

|

PROCEDURE

1. INSTALL MASS AIR FLOW METER SUB-ASSEMBLY

| NOTICE:

|

2. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the mass air flow meter sub-assembly.

Click here

Toyota Prius (XW60) 2023-2026 Service Manual

Mass Air Flow Meter

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image