Toyota Prius: Hybrid Battery System (for Phev Model)

- Precaution

- Definition Of Terms

- Parts Location

- How To Proceed With Troubleshooting

- Utility

- Terminals Of Ecu

- Diagnosis System

- Dtc Check / Clear

- Freeze Frame Data

- Vehicle Behavior Chart

- Data List / Active Test

- Diagnostic Trouble Code Chart

- Registration / Initialization / Learning

- VEHICLE CONTROL HISTORY (RoB)

- System Voltage (BATT) Circuit Short to Ground or Open (P056014)

- Hybrid/EV Battery Energy Control Module Processor to Monitoring Processor Signal Invalid (P060629)

- Hybrid/EV Battery Temperature Sensor "A" Circuit Short to Ground (P0A9B11,...,P0CB215)

- Hybrid/EV Battery Temperature Sensor "A" Voltage Out of Range (P0A9B1C,...,P0CB21C)

- Hybrid/EV Battery Temperature Sensor "A" Signal Stuck In Range (P0A9B2A,...,P306B62)

- Hybrid/EV Battery Voltage Isolation Sensor Circuit Internal Electronic Failure (P0AA749)

- Hybrid/EV Battery Current Sensor "A" Circuit Short to Ground (P0ABF11,P0ABF15,P0B0E11,P0B0E15,P1CBB12,P1CBB14,P2BE411,P2BE415)

- Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure (P0ABF28)

- Hybrid/EV Battery Current Sensor "A" Signal Stuck In Range (P0ABF2A)

- Hybrid/EV Battery Current Sensor "A"/"B" Signal Compare Failure (P0B1362)

- Hybrid/EV Battery State of Charge High (P0C3000)

- Hybrid/EV Battery Cooling System "A" Performance (P0C3200)

- Hybrid/EV Battery Pack Coolant Temperature Sensor "A" Circuit Low Circuit Short to Ground (P0C4211,P0C4215,P0CD511,P0CD515)

- Hybrid/EV Battery Charging System Positive Contactor Control Circuit Short to Ground (P0D0A11)

- Hybrid/EV Battery Charging System Positive Contactor Control Circuit Short to Auxiliary Battery or Open (P0D0A15)

- Hybrid/EV Battery Charging System Negative Contactor Control Circuit Short to Ground (P0D1111)

- Hybrid/EV Battery Charging System Negative Contactor Control Circuit Short to Auxiliary Battery or Open (P0D1115)

- Hybrid/EV Battery Pack Coolant Control Valve "B" Control Circuit Low Circuit Current Below Threshold (P0D1A18,P0D1A19,P1F6900)

- Hybrid/EV Battery Pack Coolant Control Valve "B" Performance/Stuck Off Actuator Stuck (P0D1A71)

- Hybrid/EV Battery Energy Control Module Hybrid/EV Battery Monitor Performance (P0E2D00)

- Hybrid/EV Battery Charging System Precharge Contactor Control Circuit Short to Ground (P0E6D11)

- Hybrid/EV Battery Charging System Precharge Contactor Control Circuit Short to Auxiliary Battery or Open (P0E6D15)

- Hybrid/EV Battery Pack Coolant Temperature Sensor System Signal Compare Failure (P19CF62)

- Hybrid Battery Stack 2 Cell Voltage Detection Voltage Out of Range (P1A001C,P1A051C,P301A1C)

- Hybrid/EV Battery Stack 2 Cell Circuit Voltage Above Threshold (P1A6017,P1A6317,P31AA17)

- Hybrid/EV Battery Stack 2 Cell Circuit Voltage Below Threshold (P1A6116,P1A6416,P31AB16)

- Hybrid/EV Battery Stack 1 Delta SOC High (Extreme) (P1A8100,P1A8600,P1A8B00)

- Hybrid/EV Battery Stack 1 Current Interrupt Device Circuit Open (P1AC413-P1AC613)

- Hybrid/EV Battery Stack 1 Current Interrupt Device Stuck On (P1AC49E-P1AC69E)

- System Voltage (AM) Circuit Voltage Below Threshold (P1AFC00)

- Flying Capacitor Circuit Voltage Out of Range (P1AFD00)

- Flying Capacitor/Internal Control Module Hybrid/EV Battery Monitor Voltage Out of Range (P1AFD1C)

- Hybrid/EV Battery Heater 1 Temperature Sensor Circuit Short to Ground (P1B4011,P1B4015,P1B4511,P1B4515)

- Hybrid/EV Battery Heater Temperature Sensor Signal Compare Failure (P1B4A62)

- Hybrid/EV Battery Heater Relay Actuator Stuck Open (P1B4B72)

- Hybrid/EV Battery Heater Relay Actuator Stuck Closed (P1B4B73)

- Hybrid/EV Battery Pack Refrigerant Pressure Sensor "A" Circuit High Circuit Short to Auxiliary Battery (P1B8312,P1B8314)

- Hybrid/EV Battery Pack Refrigerant Pressure Sensor "A" Circuit Range/Performance Circuit Voltage Out of Range (P1B831C)

- High Voltage Power Resource Internal Electronic Failure (P1C8549)

- Hybrid/EV Battery Stack 1 Voltage Difference Out of Range (P1CC81E,P1CC91E,P1CCA1E)

- Hybrid/EV Battery Pack Current Sensor "C" Circuit Range/Performance Circuit Voltage Out of Range (P2BE41C)

- Hybrid/EV Battery Pack Current Sensor "C" Circuit Range/Performance Signal Bias Level Out of Range / Zero Adjustment Failure (P2BE428)

- Hybrid/EV Battery Discharge Control Malfunction (P300000)

- Hybrid/EV Battery Control System Circuit Voltage Below Threshold (P300016)

- Hybrid/EV Battery Control System Over Temperature (P30004B)

- Hybrid/EV Battery Voltage High (P31B300)

- Hybrid/EV Battery Stack 1 Circuit Resistance Out of Range (P33DA1E-P33DC1E)

- Hybrid/EV Battery Stack 1 Capacity Decline (P33E600-P33E800)

- Lost Communication with ECM/PCM "A" Missing Message (U010087)

- Lost Communication with Hybrid Powertrain Control Module (Hybrid/EV Battery Local Bus) Missing Message (U115087)

- "HAVE TRACTION BATTERY INSPECTED" is displayed

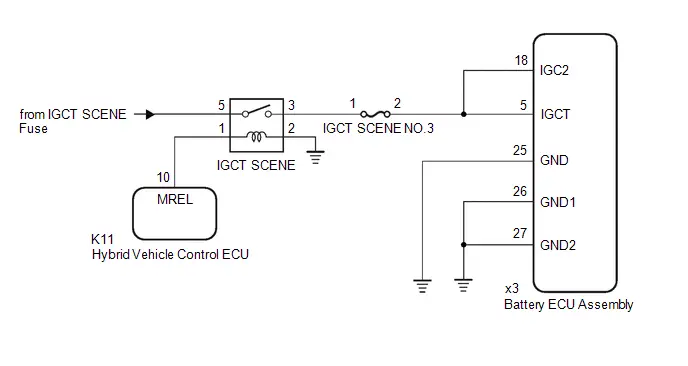

- ECU Power Source Circuit

- Instructions for Connecting SST

Precaution

PRECAUTION

CAUTION:

-

Before the following operations are conducted, take precautions to prevent electric shock by turning the ignition switch off, wearing insulated gloves, and removing the service plug grip from HV battery.

-

To prevent electric shock, make sure to remove the service plug grip to cut off the high voltage circuit before servicing the Toyota Prius vehicle.

-

After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

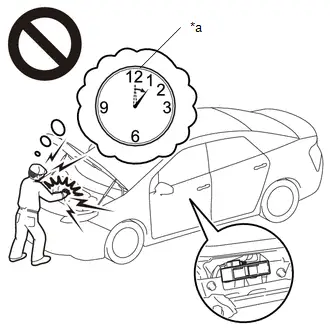

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals.

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

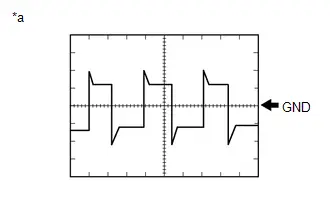

*a

Without waiting for 10 minutes

-

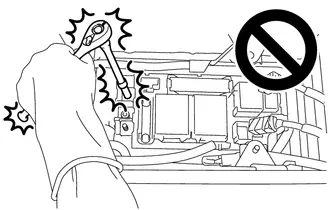

When troubleshooting high voltage circuit, use either a tool wrapped with vinyl insulation tape or an insulated tool. (It is extremely dangerous when a high-voltage charge passes through a non-insulated tool causing a short.)

-

When turning the ignition switch ON during an inspection, do not press the ignition switch while depressing the brake pedal.

Pressing the ignition switch with the brake pedal depressed causes the system to enter the READY-on state. This is very dangerous because high voltage may be applied to the inspection area.

NOTICE:

- After removing the service plug grip, turning the ignition switch to ON (READY) may cause a malfunction. Do not turn the ignition switch to ON (READY) unless instructed by the repair manual.

- Turn the ignition switch off before performing any resistance checks.

- Turn the ignition switch off before disconnecting or reconnecting any connectors.

- When high-voltage connectors are removed, wrap the connectors with insulation tape to prevent them from contacting foreign matter.

PRECAUTIONS FOR INSPECTING HYBRID BATTERY SYSTEM

HINT:

-

Removing the service plug grip

Click here

-

Checking the terminal voltage

Click here

-

Disconnecting the motor cable

Click here

-

Disconnecting the floor under wire

Click here

-

Removing the inverter with converter

Click here

HYBRID CONTROL SYSTEM ACTIVATION

HINT:

- When the warning is illuminated, or the auxiliary battery has been disconnected and reconnected, attempting to turn the ignition switch to ON (READY) may not start the system (the system may not enter the READY-on state) on the first attempt. If so, turn the ignition switch off and reattempt to start the hybrid system.

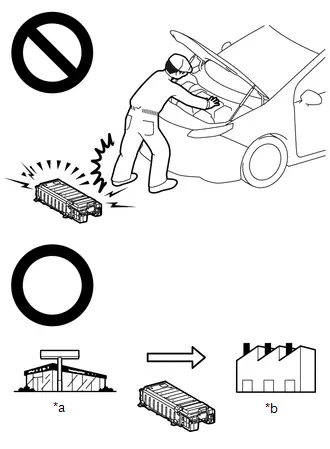

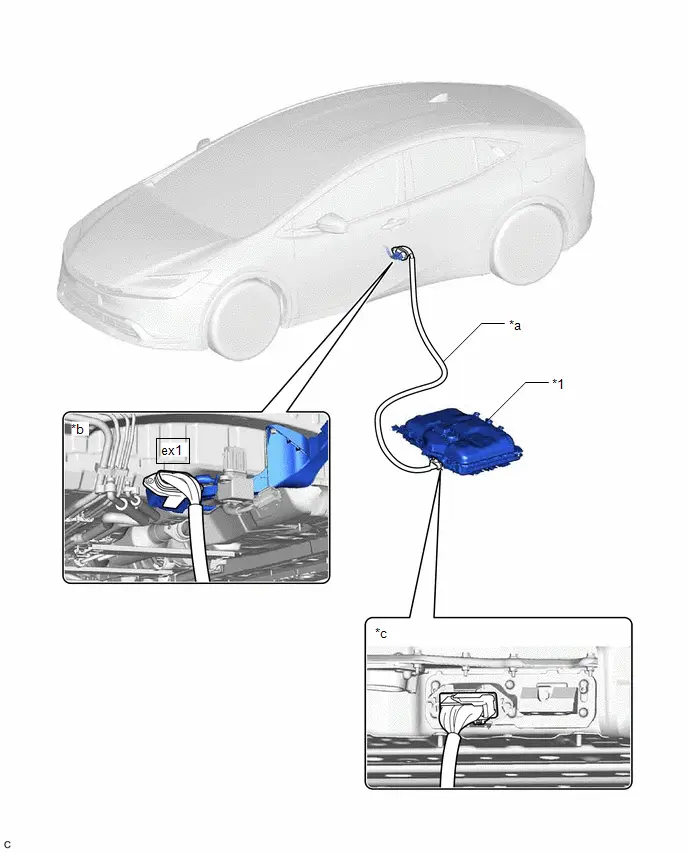

DISPOSING OF HV BATTERY

When disposing of HV batteries, make sure to return them through an authorized collection agent who is capable of handling them safely. If they are returned via the manufacturer specified route, they will be returned properly and in a safe manner by an authorized collection agent.

CAUTION:

-

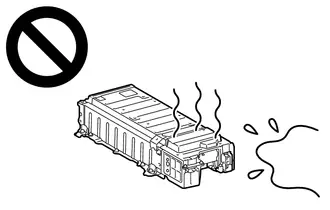

After removing the HV battery, keep it away from water. Exposure to water may cause the HV battery to produce heat, resulting in a fire.

-

Accidents such as electric shock may result if the HV battery is disposed of improperly or abandoned.

Therefore, make sure to return HV battery through an authorized collection agent.

*a

Dealer

*b

Battery Collection Agent

- To reduce the risk of fire, HV battery must not be stored in an area where they will be exposed to fire or high temperatures.

- If the temperature of the HV battery is high, leave the Toyota Prius vehicle until the temperature drops.

-

Make sure to insulate the high-voltage connectors and terminals of the HV battery with insulating tape after removing them.

If the HV battery stored without insulating the connectors and terminals, electric shock or fire may result.

NOTICE:

Before returning the HV battery, make sure to perform a recovery inspection.

Click here

PRECAUTIONS WHEN REPLACING HYBRID Toyota Prius Vehicle CONTROL ECU

NOTICE:

-

Before replacing the hybrid vehicle control ECU, refer to Registration.

Click here

-

When the hybrid vehicle control ECU is replaced, perform the ECU configuration.

Click here

-

When the hybrid Toyota Prius vehicle control ECU is replaced, update the ECU security key.

Click here

-

After replacing the hybrid vehicle control ECU, it is necessary to perform the vehicle specification information procedure for the ECU.

Click here

- If the Toyota Prius vehicle specification information procedure has not been performed, vehicle control history (RoB) will be stored.

- After performing the vehicle specification information procedure, perform a health check using the GTS and confirm that there are no DTCs stored.

PRECAUTIONS WHEN REPLACING INVERTER WITH CONVERTER ASSEMBLY

NOTICE:

When the inverter with converter assembly is replaced, perform the ECU configuration.

Click here

DISCONNECTING AND RECONNECTING NEGATIVE AUXILIARY BATTERY CABLE

NOTICE:

- To prevent damage to electronic components, disconnect the cable from the negative (-) auxiliary battery terminal before performing work.

- Be sure to turn the ignition switch off before disconnecting the cable from the negative (-) auxiliary battery terminal.

- Be careful not to damage the cable or terminal.

- When the negative (-) auxiliary battery terminal is disconnected, the clock and radio settings, etc., as well as any stored DTCs, will be cleared.

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

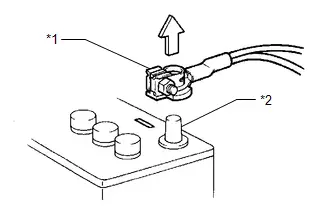

| *1 | Cable |

| *2 | Negative (-) Auxiliary Battery Terminal |

PRECAUTIONS FOR DISCONNECTING AMD TERMINAL

The AMD terminal is connected to the positive terminal of the auxiliary battery.

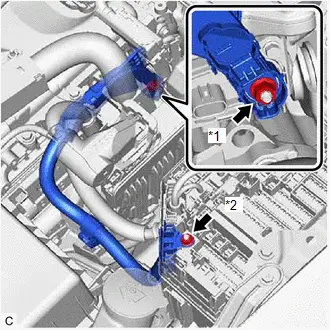

| *1 | AMD Terminal (Inverter with Converter Assembly Side) |

| *2 | AMD Terminal (No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly Side) |

(a) Be sure to disconnect the cable from the negative (-) auxiliary battery terminal before disconnecting the AMD terminal from the No. 1 luggage room relay block and No. 1 junction block assembly.

NOTICE:

- Be sure to disconnect the cable from the negative (-) auxiliary battery terminal before disconnecting the AMD terminal from the No. 1 engine room relay block and No. 1 junction block assembly.

- A short circuit to ground may occur if the AMD terminal is disconnected before the cable is disconnected from the negative (-) auxiliary battery terminal. If a short circuit to ground occurs, a fusible link or fuse may break.

-

Do not disconnect the AMD terminal except when replacing the inverter with converter assembly.

When disconnection is necessary, be careful not to apply excessive force to the terminal.

- After disconnecting the AMD terminal, wrap it with vinyl insulating tape.

- Be sure to reconnect the AMD terminal to the No. 1 engine room relay block and No. 1 junction block assembly before reconnecting the cable to the negative (-) terminal of the auxiliary battery.

Definition Of Terms

DEFINITION OF TERMS

| Term | Definition |

|---|---|

| Monitor Description | Description of what the battery ECU assembly monitors and how to detects malfunctions (monitoring purpose and its details). |

| Related DTCs | A group of diagnostic trouble codes that are output by the battery ECU assembly based on the same malfunction detection logic. |

| Typical Enabling Conditions | Preconditions that allow the battery ECU assembly to detect malfunctions. With all preconditions satisfied, the battery ECU assembly stores DTCs when the monitored value(s) exceeds malfunction threshold(s). |

| Sequence of Operation | Order of monitor priority, applied if multiple sensors and components are involved in a single malfunction detection process. Each sensor and component are monitored in turn and subsequent items are not monitored until the previous detection operation completes. |

| Required Sensors/Components | Sensors and components used by the battery ECU assembly to detect each malfunction. |

| Frequency of Operation | Number of times the battery ECU assembly checks for each malfunction during each driving cycle. "Once per driving cycle" means that the battery ECU assembly only checks for malfunctions once during a single driving cycle. "Continuous" means that the battery ECU assembly checks for malfunctions whenever enabling conditions are met. |

| Duration | Minimum time for which the battery ECU assembly must detect continuous deviation in monitored value(s) in order to store a DTC. Timing begins when typical enabling conditions are met. |

| Malfunction Thresholds | Value beyond which the battery ECU assembly determines malfunctions exist and stores DTCs. |

| MIL Operation | Timing of MIL illumination after a malfunction is detected. "Immediate" means that the battery ECU assembly illuminates the MIL as soon as a malfunction is detected. "2 driving cycles" means that the battery ECU assembly illuminates the MIL if the same malfunction is detected again during the next driving cycle. |

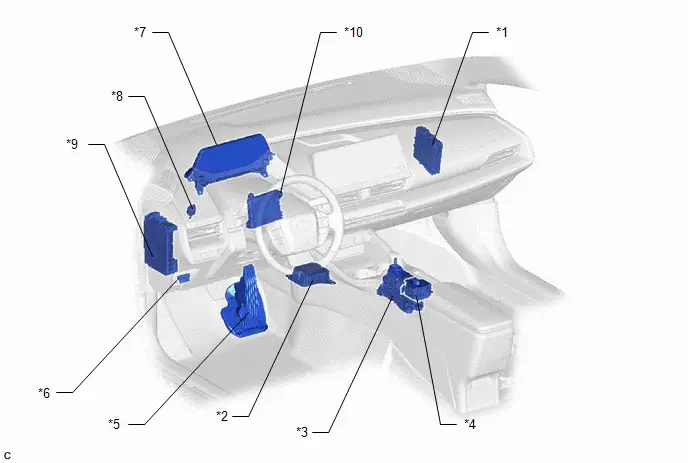

Parts Location

PARTS LOCATION

ILLUSTRATION

| *1 | HYBRID Toyota Prius Vehicle CONTROL ECU | *2 | AIRBAG SENSOR ASSEMBLY |

| *3 | TRANSMISSION FLOOR SHIFTASSEMBLY | *4 | ELECTRIC PARKING BRAKE SWITCH ASSEMBLY (COMBINATION SWITCH) - AUTO EV/HV MODE SWITCH - HV EV CHG HOLD MODE SWITCH - DRIVE MODE SELECT SWITCH |

| *5 | ACCELERATOR PEDAL (WITH SENSOR) ROD ASSEMBLY | *6 | DLC3 |

| *7 | COMBINATION METER ASSEMBLY | *8 | STOP LIGHT SWITCH ASSEMBLY |

| *9 | POWER DISTRIBUTION BOX ASSEMBLY | *10 | AIR CONDITIONING AMPLIFIER ASSEMBLY |

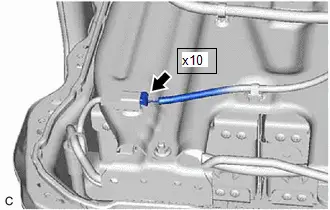

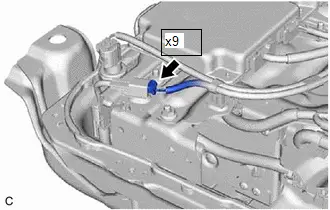

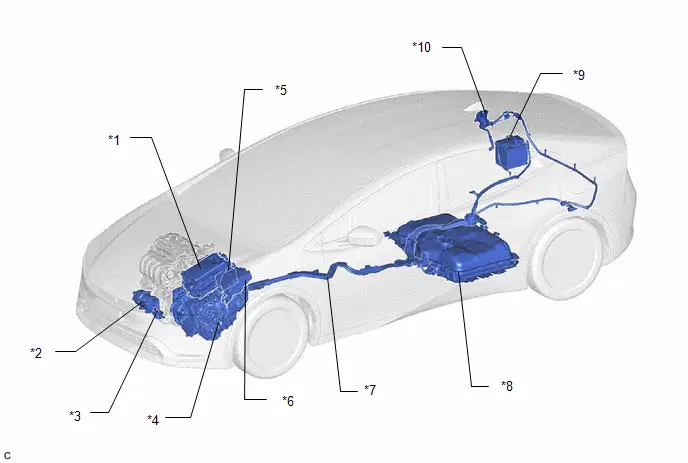

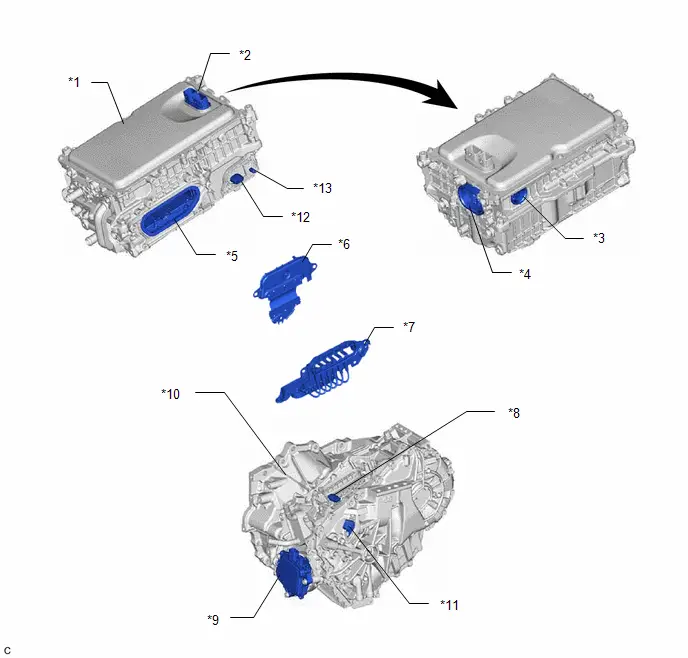

ILLUSTRATION

| *1 | INVERTER WITH CONVERTER ASSEMBLY | *2 | COMPRESSOR WITH MOTOR ASSEMBLY |

| *3 | INVERTER WATER PUMP ASSEMBLY | *4 | HYBRID Toyota Prius Vehicle TRANSAXLE ASSEMBLY |

| *5 | ECM | *6 | NO. 1 ENGINE ROOM RELAY BLOCK AND NO. 1 JUNCTION BLOCK ASSEMBLY |

| *7 | HV FLOOR UNDER WIRE | *8 | HV SUPPLY BATTERY ASSEMBLY |

| *9 | AUXILIARY BATTERY | *10 | AC CHARGER INLET CABLE |

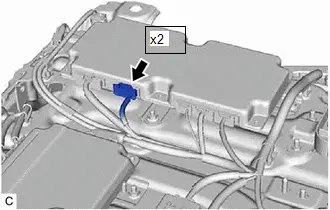

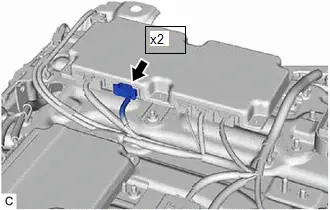

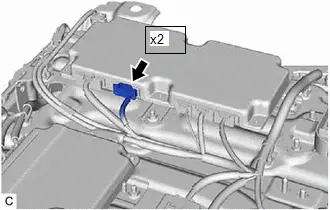

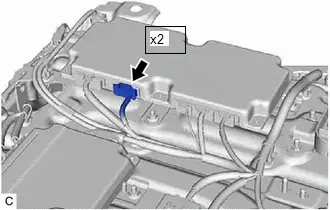

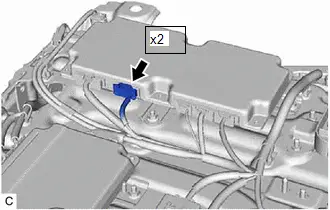

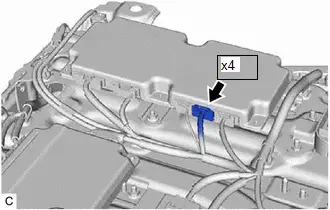

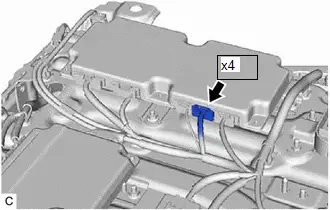

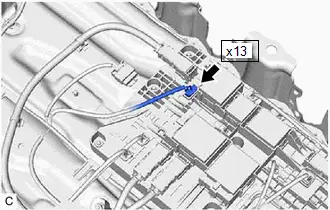

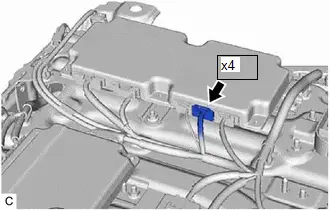

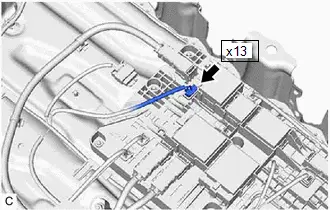

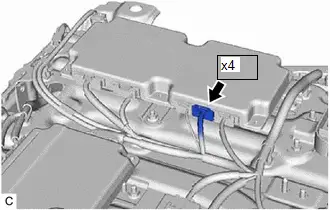

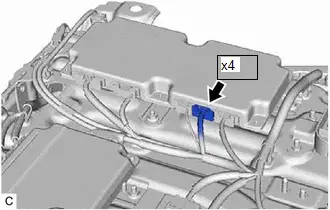

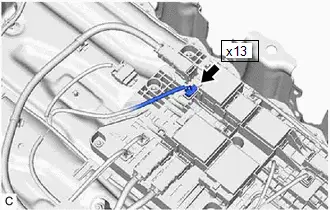

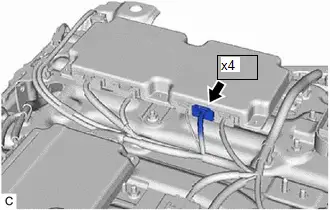

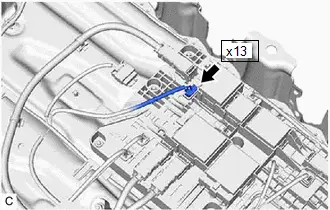

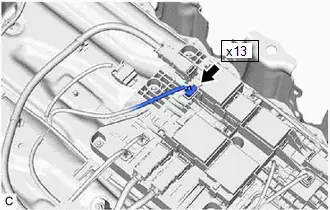

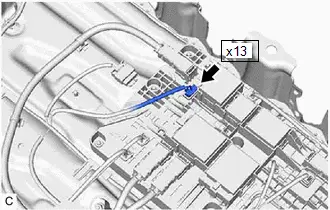

ILLUSTRATION

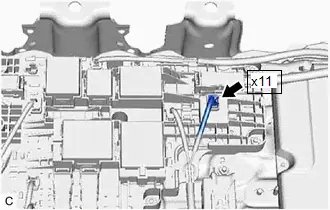

| *1 | INVERTER WITH CONVERTER ASSEMBLY | *2 | LOW VOLTAGE CONNECTOR |

| *3 | HV AIR CONDITIONING WIRE CONNECTION | *4 | HV FLOOR UNDER WIRE (HV BATTERY) CONNECTION |

| *5 | MOTOR CABLE CONNECTION | *6 | INVERTER COVER - INTERLOCK |

| *7 | MOTOR CABLE | *8 | MOTOR TEMPERATURE SENSOR AND GENERATOR TEMPERATURE SENSOR CONNECTOR |

| *9 | SHIFT CONTROL ACTUATOR ASSEMBLY | *10 | HYBRID Toyota Prius Vehicle TRANSAXLE ASSEMBLY |

| *11 | MOTOR RESOLVER, GENERATOR RESOLVER AND TRANSAXLE FLUID TEMPERATURE SENSOR CONNECTOR | *12 | LOW VOLTAGE CONNECTOR (DC/DC CONVERTER) |

| *13 | AMD TERMINAL | - | - |

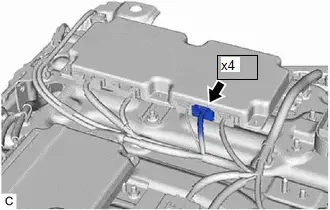

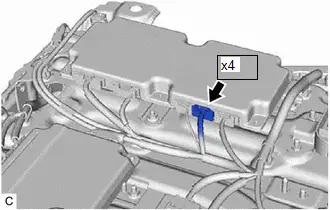

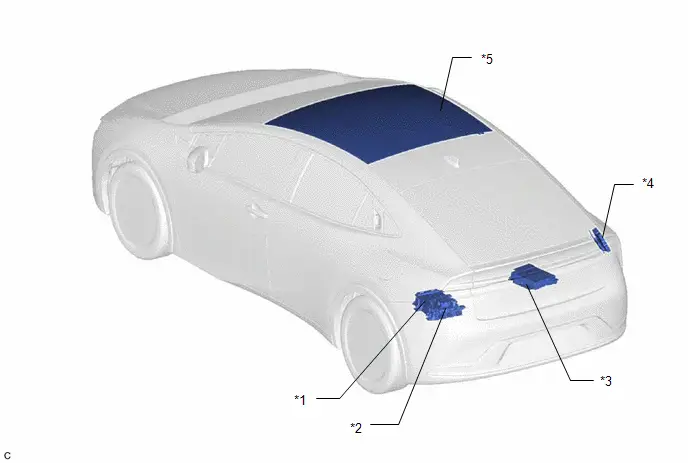

ILLUSTRATION

| *1 | ELECTRIC Toyota Prius Vehicle CHARGER ASSEMBLY | *2 | CHARGER COOLING BLOWER |

| *3 | SOLAR ENERGY CONTROL ECU ASSEMBLY | *4 | PLUGIN CHARGE CONTROL ECU ASSMBLY |

| *5 | ROOF WINDOW GLASS | - | - |

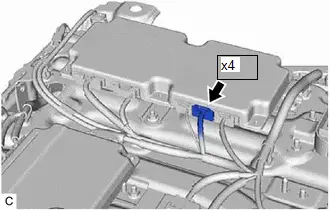

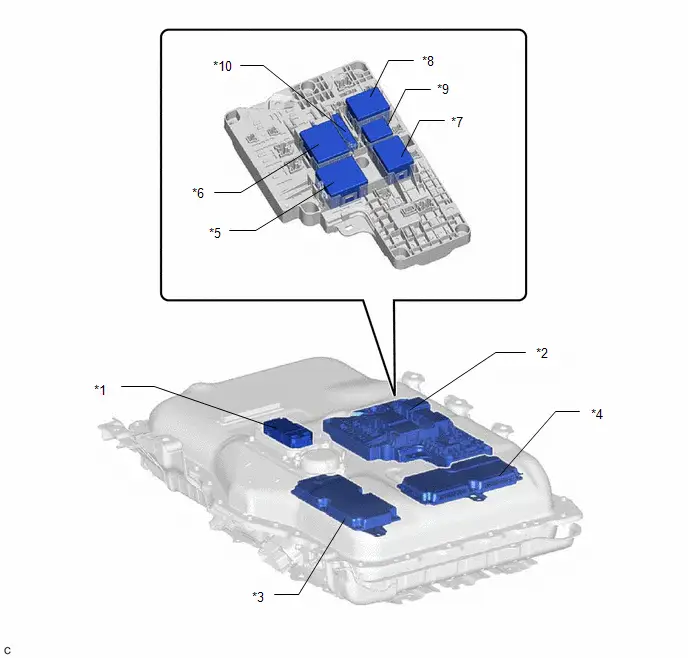

ILLUSTRATION

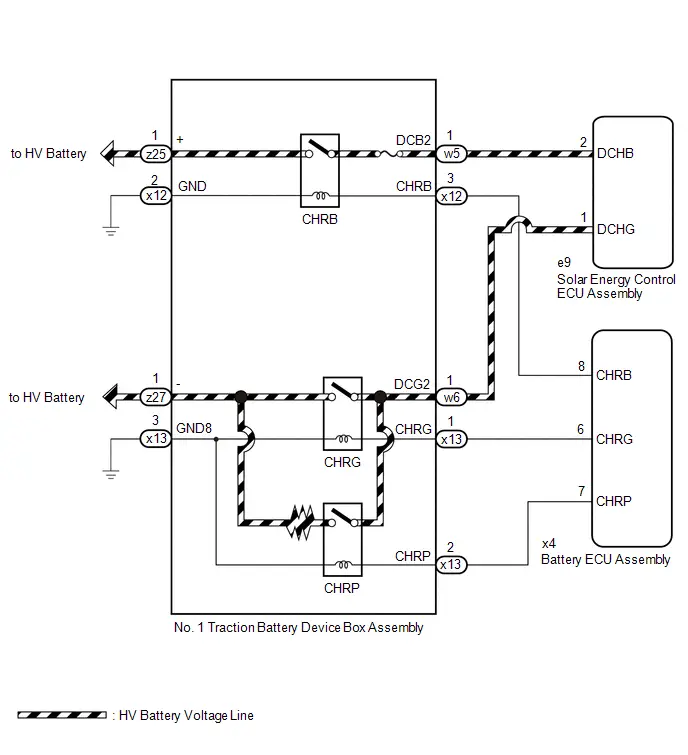

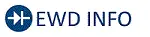

| *1 | SERVICE PLUG GRIP | *2 | NO. 1 TRACTION BATTERY DEVICE BOX ASSEMBLY |

| *3 | BATTERY ECU ASSEMBLY | *4 | BATTERY VOLTAGE SENSOR |

| *5 | SMRB | *6 | SMRG |

| *7 | CHRB | *8 | CHRG |

| *9 | CHRP | *10 | PRECHARGE RESISTOR |

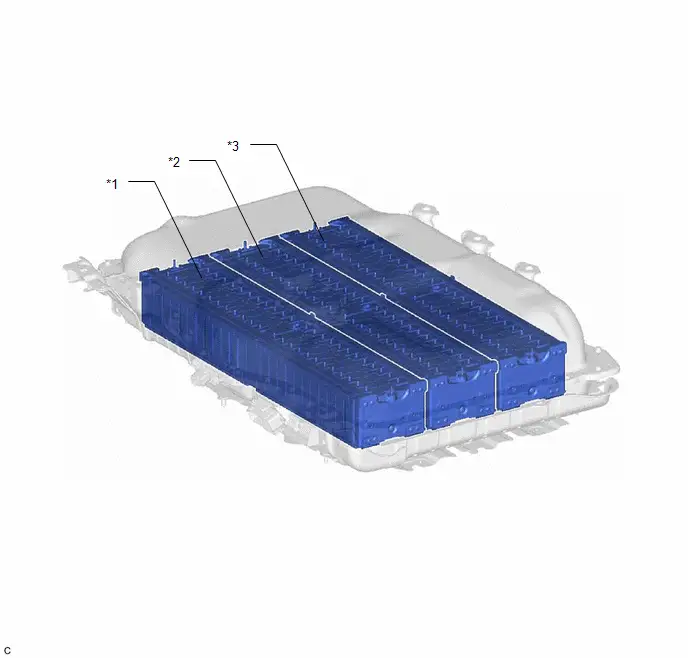

ILLUSTRATION

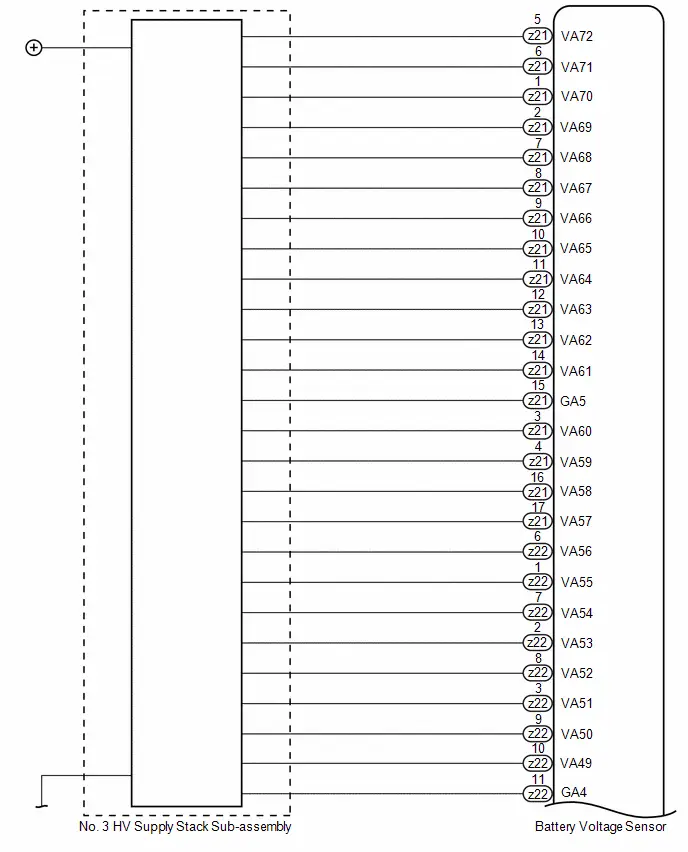

| *1 | NO. 1 HV SUPPLY STACK SUB-ASSEMBLY | *2 | NO. 2 HV SUPPLY STACK SUB-ASSEMBLY |

| *3 | NO. 3 HV SUPPLY STACK SUB-ASSEMBLY | - | - |

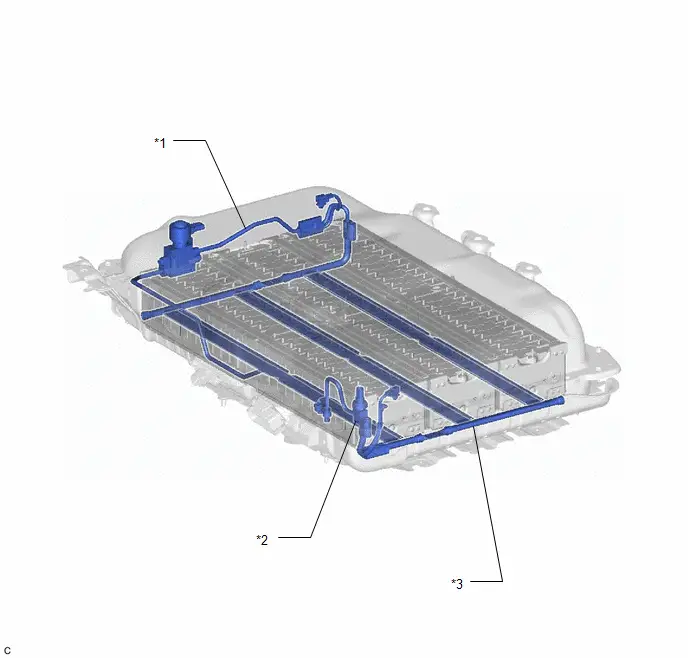

ILLUSTRATION

| *1 | NO. 1 TRACTION BATTERY COOLER TUBE - AIR CONDITIONING THERMISTOR - MAGNET VALVE | *2 | NO. 2 TRACTION BATTERY COOLER TUBE - AIR CONDITIONING PRESSURE SENSOR |

| *3 | NO. 1 TRACTION BATTERY COOLER CONDUCTOR - AIR CONDITIONING THERMISTOR | - | - |

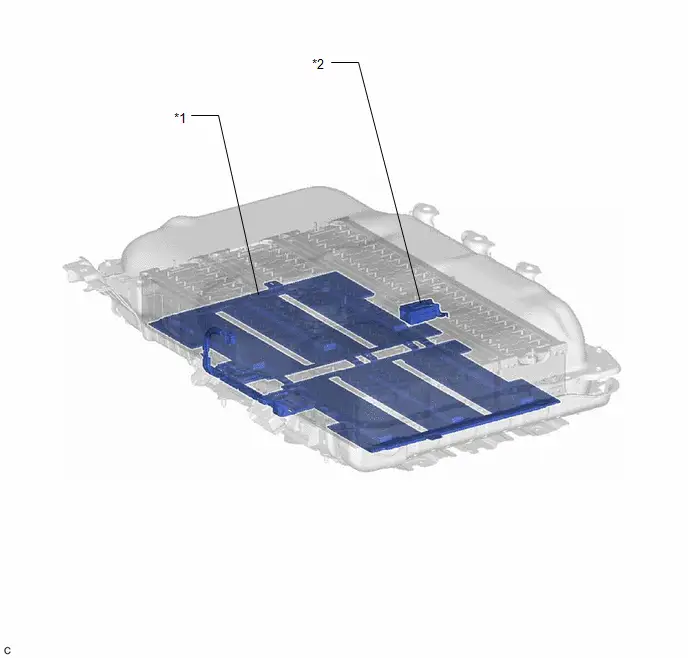

ILLUSTRATION

| *1 | NO. 1 TRACTION BATTERY HEATER | *2 | NO. 1 TRACTION BATTERY HEATER RELAY |

How To Proceed With Troubleshooting

PROCEDURE

| 1. | VEHICLE BROUGHT TO WORKSHOP |

|

| 2. | CUSTOMER PROBLEM ANALYSIS |

HINT:

If the malfunction is not reproduced, perform a simulation test.

Click here

- For the simulation test, reproduce the driving conditions that were present when the problem occurred. These conditions should be based on the customer's comments and Freeze Frame Data that is recorded with DTCs, such as the opening angle of the accelerator pedal, SOC (stateof charge), engine coolant temperature, engine speed, and generator (MG1) / front motor (MG2) / rear motor (MGR) rpm and torque.

-

When inspecting electrical circuits, check the connection condition of the connector and the contact pressure of each terminal.

Check the terminals for deformation, and check the connector for water ingress and foreign matter.

Click here

|

| 3. | CONDUCT BASIC INSPECTION |

(a) Measure the auxiliary battery voltage with the ignition switch off.

Standard Voltage:

11 to 14 V

(b) Check the connection of the negative (-) and positive ( ) auxiliary battery terminals.

OK:

The terminals are connected securely and there is no contact problem.

(c) Check the connector connections and terminals to make sure that there are no abnormalities such as loose connections, deformation, etc.

|

| 4. | READ VALUE USING GTS |

(a) Perform the Health Check using the GTS.

(b) Perform the following steps when the data setting screen is displayed.

(1) Select the systems for which to perform Health Check and check for time stamp data.

- Powertrain

- Chassis

- Body

- Store All Data

HINT:

The hybrid system performs control and intercommunication with other systems, so check and record the DTCs for all systems.

(c) Select "Yes" when "Do you want to store time stamp data?" is displayed.

HINT:

If "Yes" is not selected, time stamp data will not be stored.

(d) Check for DTC and Toyota Prius Vehicle Control History (RoB) code output.

- If an abnormality judgment flag has not been output during the current trip, perform the inspection for simulation method.

-

If the malfunction symptoms are not reproduced, it can be judged that the condition has returned to normal. GTS Display

Current / Confirmed

Pending

History

Test Failed

5 digits DTC

7 digits DTC

x

Shows the malfunction judgment results during the current trip.

Shows the malfunction judgment results during the current trip.

x

Shows the malfunction judgment results up to now.

-

x

Shows the malfunction judgment results up to now.

Shows the malfunction judgment results up to now.

x

x

-

Shows the malfunction judgment results during the current trip.

| Result | Proceed to |

|---|---|

| DTCs are output. | A |

| Toyota Prius Vehicle Control History (RoB) code is output, but DTC is not output. | B |

| DTC is not output and Vehicle Control History (RoB) code is not output, but malfunction symptoms are reproduced. | C |

| B |

| GO TO Toyota Prius Vehicle CONTROL HISTORY (RoB) |

| C |

| GO TO PROBLEM SYMPTOMS TABLES |

|

| 5. | GO TO DTC CHART |

Referring to the DTC chart, perform troubleshooting according to the applicable code.

-

Hybrid control system

Click here

-

Motor Generator control system

Click here

-

Hybrid battery system

Click here

|

| 6. | ADJUST AND/OR REPAIR |

| NEXT |

| CONDUCT CONFIRMATION TEST (a) Clear the DTCs. (b) Then check that the Toyota Prius vehicle has returned to normal by performing the following All Readiness check procedure. For details, refer to the confirmation driving pattern for the relevant DTC diagnostic procedure. |

Utility

UTILITY

NOTICE:

- "Maintenance Required for Traction Battery at Your Dealer" is displayed, perform "Battery Diagnosis" to diagnose the extent of deterioration of each HV battery cell.

- "Maintenance Required for Traction Battery at Your Dealer" is cleared after "Battery Diagnosis" are performed and "There is no need to replace HV supply battery assembly." is displayed.

-

After the "Maintenance Required for Traction Battery at Your Dealer" is displayed, if the traction battery is used continually without performing "Battery Diagnosis" for a few weeks*, use of the HV battery (input/output voltage) will be limited. If it is used more, the ignition switch ON (READY) operation will be disabled.

*: Timing may vary depending on Toyota Prius vehicle usage.

- If the ignition switch cannot be turned to ON (READY), perform "Temporary Vehicle Start Up", "Battery Diagnosis".

HINT:

If "Maintenance Required for Traction Battery at Your Dealer" is displayed,

.

.

Purpose

| Utility Items (GTS Display) | Main Purpose | Control Description |

|---|---|---|

| All Readiness | Check whether or not DTC judgment has been completed. | - |

| Diagnosis Related Information | Confirm the diagnosis related information. | - |

| Battery Diagnosis | Discharge the HV battery and diagnose the extent of deterioration of each HV supply stack sub-assembly based on the SOC. | - |

| Battery Status Info Update | Initialize the HV battery age information. | - |

| Temporary Toyota Prius Vehicle Start Up | Temporarily enable the ignition switch on (Ready) operation which has been disabled due to continual usage of the vehicle without performing battery diagnosis. | - |

| HV/EV Battery Thermal Keep Control Mode Setting | Prevent HV battery from freezing. | - |

| High Voltage Fuse Accumulated Load History Reset | Initialize the load history of the high voltage fuse. |

|

ALL READINESS

HINT:

- With "All Readiness", you can check whether or not the DTC judgment has been completed by using the GTS.

- You should check "All Readiness" after simulating malfunction symptoms or for validation after finishing repairs.

(a) Clear the DTCs even if no DTCs are stored.

(b) Turn the ignition switch off and wait for at least 2 minutes.

(c) Perform the DTC judgment driving pattern to run the DTC judgment.

(d) Enter the following menus: Powertrain / HV Battery / Utility / All Readiness.

Powertrain > HV Battery > Utility| Tester Display |

|---|

| All Readiness |

(e) Input the DTCs to be confirmed.

(f) Check the DTC judgment result.

| GTS Display | Description |

|---|---|

| NORMAL |

|

| ABNORMAL |

|

| INCOMPLETE |

|

| N/A |

|

(g) Turn the ignition switch off.

DIAGNOSIS RELATED INFORMATION

(a) Check for diagnosis related information.

(1) Check the Diagnosis Related Information, and then write them down.

Powertrain > HV Battery > Utility| Tester Display |

|---|

| Diagnosis Related Information |

(b) Clear diagnosis related information.

NOTICE:

Clearing the DTCs will also clear the diagnosis related information.

(1) Clear the DTCs.

(2) Turn the ignition switch off.

BATTERY DIAGNOSIS

NOTICE:

- Do not perform battery diagnosis while the hybrid system light is illuminated.

- Perform battery diagnosis with the HV battery installed correctly.

- Do not perform battery diagnosis while changing from inspection mode to another mode.

- Make sure to turn the ignition switch off after battery diagnosis to prevent the auxiliary battery from being discharged.

-

If the SOC (state of charge) learning has not been performed*1, perform battery diagnosis after plug-in charging the Toyota Prius vehicle as specified.

- *1: Refer to "Procedure when Battery Diagnosis is Suspended".

(a) Turn the ignition switch off and wait for 2 minutes or more.

(b) Turn the ignition switch to ON.

(c) Enter the following menus: Powertrain / HV Battery / Utility / Battery Diagnosis.

Powertrain > HV Battery > Utility| Tester Display |

|---|

| Battery Diagnosis |

(d) Check items on the display and press "Next".

(e) The screen transitions to the next screen and "Now diagnosing" is displayed.

HINT:

- "Progress" is displayed as a reference to the estimated time to complete the diagnosis.

- To suspend battery diagnosis, press "Exit" and turn the ignition switch off.

(f) When battery diagnosis is complete, the result will be displayed.

(g) Check the diagnosis result.

| GTS Display | Diagnosis Result | After performing diagnosis |

|---|---|---|

| There is no need to replace the battery. Be sure to refer to the repair manual for procedures to take after this. | Normal | Perform "Battery Status Info Update". |

| Replace the HV supply stack sub-assemblies listed below. | Replace | Replace the listed HV supply stack sub-assemblies. |

HINT:

- If "Maintenance Required for Traction Battery at Your Dealer" is displayed on the multi-information display, the message will not be cleared even after it is determined that "There is no need to replace battery". It can be cleared only after performing "Battery Status Info Update".

- If the listed HV supply stack sub-assemblies are replaced, perform "Battery Status Info Update" after replacing them.

(h) Turn the ignition switch off.

NOTICE:

Make sure to turn the ignition switch off after battery diagnosis to prevent the auxiliary battery from being discharged.

(i) When the battery diagnosis is suspended because the diagnosis conditions are not met anymore, the reasons of suspension are displayed on the GTS. Perform "Battery Diagnosis" after checking the causes and troubleshoot the suspected area in accordance with instructions in the "Procedure when battery diagnosis is suspended" table.

Procedure when battery diagnostic is suspended| GTS Display | Reason for Diagnosis Suspension (Related Condition) | Procedure |

|---|---|---|

| 007 | Shift state park (P) is not selected. | Push the P position switch (parking switch) to select park (P). |

| 008 | HV battery connection malfunction | Confirm the connection condition of the HV battery. |

| 012 | Time-out | If the ignition switch is turned off by the time-out function, perform "Battery Diagnosis" again. |

| 013 | Low auxiliary battery voltage | Inspect the auxiliary battery and DC/DC converter function.

|

| 014 | HV battery malfunction |

|

| 016 | HV battery stack high voltage circuit connection malfunction | |

| 001 / 006 / 009 / Communication error | The ignition switch was turned off or a GTS communication error occurred. | After checking that the connector of the GTS is not disconnected from the DLC3, perform "battery diagnosis" again. |

| Other than abave | Full charge capacity information is not updated |

|

BATTERY STATUS INFO UPDATE

HINT:

If the HV supply battery assembly or an HV supply stack sub-assembly has been replaced, make sure to perform "Battery Status Info Update" to initialize the HV battery age information stored in the battery ECU assembly and turn off the light on the combination meter assembly.

(a) Turn the ignition switch off and wait for 2 minutes or more.

(b) Turn the ignition switch to ON.

(c) Enter the following menus: Powertrain / HV Battery / Utility / Battery Status Info Update.

Powertrain > HV Battery > Utility| Tester Display |

|---|

| Battery Status Info Update |

(d) Turn the ignition switch off.

TEMPORARY Toyota Prius Vehicle START UP

NOTICE:

- Do not perform temporary vehicle start up while the master warning is illuminated.

- Perform only when "Vehicle Start Disabled Until Traction Battery Inspected" is displayed on the multi-information display and the vehicle cannot be started.

- "Toyota Prius Vehicle Start Disabled Until Traction Battery Inspected" is not cleared even after "Temporary Vehicle Start Up" is performed.

(a) Enter the following menus: Powertrain / HV Battery / Utility / Temporary Vehicle Start Up

Powertrain > HV Battery > Utility| Tester Display |

|---|

| Temporary Toyota Prius Vehicle Start Up |

NOTICE:

If once the ignition switch is turned to ON (READY) while depressing the brake pedal, "Temporary Vehicle Start Up" is not possible. Retry after turning the ignition switch off.

(b) Check items on the display and press "Next".

(c) The screen transitions to the next screen and "Please wait" is displayed.

(d) The screen transitions to the next screen and "Now the Toyota Prius vehicle is ready to start." is displayed.

HINT:

- If the ignition switch is turned off after "Temporary Vehicle Start Up", the vehicle will not be able to start again.

- The GTS can be disconnected after turning the ignition switch to ON (READY).

(e) Turn the ignition switch to ON (READY).

(f) When the condition to perform "Temporary Toyota Prius Vehicle Start Up" is not met, the reasons for suspension are displayed on the GTS. Perform "Temporary Vehicle Start Up" again after checking the causes and troubleshooting the suspected area in accordance with instructions in the "Procedure when "Temporary Vehicle Start Up" is suspended" table.

Procedure when "Temporary Toyota Prius Vehicle Start Up" is suspended| GTS Display | Reason for Temporary Vehicle Start Up Suspension (Related Condition) | Procedure |

|---|---|---|

| Temporary Toyota Prius Vehicle Start Up has failed. Confirm the following condition. | GTS communication error | After checking that the connector of the GTS is not disconnected and the ignition switch is ON, perform "Temporary Vehicle Start Up" again. |

HV/EV Battery Thermal Keep Control Mode Setting

HINT:

HV battery may be frozen in Canada, Alaska and Greenland. As a result, the HV battery may become excessively weak and the engine may not be able to be started. By setting "HV/EV Battery Thermal Keep Control Mode", it is possible to warm the HV battery and maintain its current temperature in order to prevent it from becoming excessively weak.

When this mode is set to ON, the timer charging timer settings are canceled at temperatures of -10°C (14°F) or lower, and charging will begin immediately when the charging cable is connected to the Toyota Prius vehicle. Therefore, never set this mode to ON in any region other than the above.

HV/EV Battery Thermal Keep Control Mode Setting| Purpose | Condition | Operation |

|---|---|---|

| Prevent HV battery from freezing |

| Begins to warm the HV battery to maintain its current temperature when the ambient temperature drops to -10°C (14°F) or lower when the charging cable is connected to the vehicle. To prevent the HV battery from freezing when a charging start time is set, when HV/EV Battery Thermal Keep Mode is enabled, the charging timer will be disabled and charging will begin immediately when the charging cable is connected to the Toyota Prius vehicle. |

In extremely cold areas, before delivering a new vehicle or after replacing the battery ECU assembly, it is necessary to enable Hybrid Battery Thermal Keep Control Mode using the GTS.

NOTICE:

When not in an extremely cold area, as the temperature is not likely to drop low enough to cause the HV battery to become excessively weak and the engine to not be able to be started, do not enable Hybrid Battery Thermal Keep Control Mode.

(a) Enter the following menus: Powertrain / HV Battery / Utility / HV/EV Battery Thermal Keep Control Mode Setting.

Powertrain > HV Battery > Utility| Tester Display |

|---|

| HV/EV Battery Thermal Keep Control Mode Setting |

(b) Check items on the display and press "Next".

(c) Check that "Select HV/EV Battery Thermal Keep Control Mode." is displayed.

(d) Select "ON", and then press "Next".

(e) Check that "HV/EV Battery Thermal Keep Control Mode is complete." is displayed.

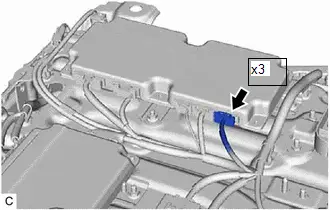

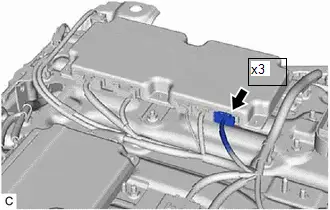

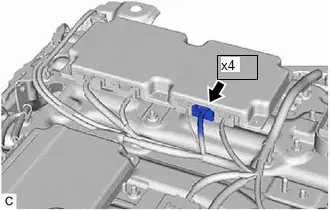

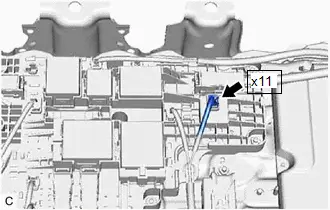

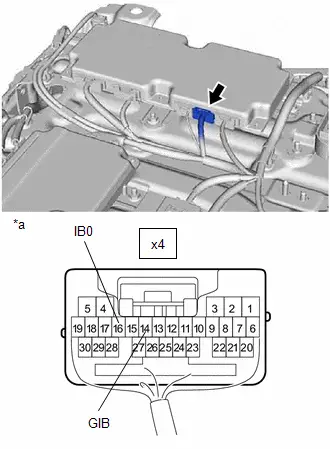

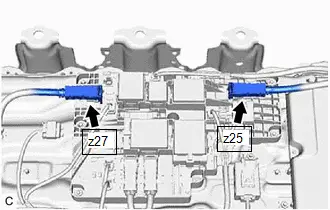

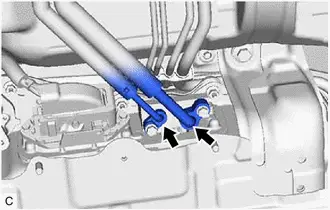

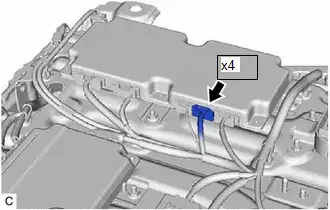

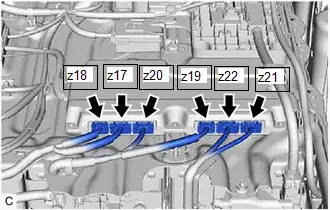

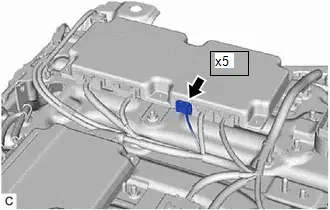

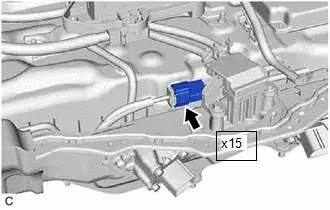

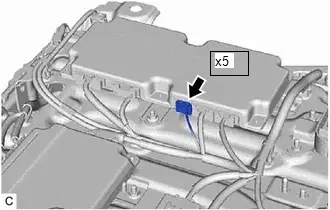

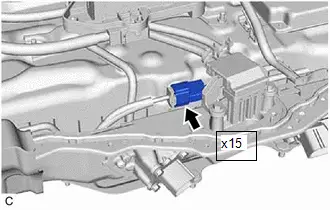

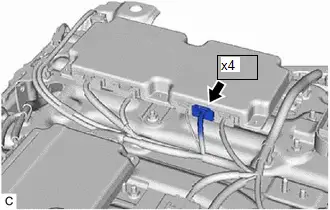

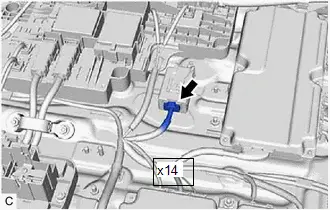

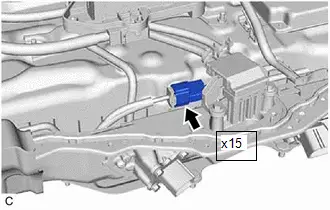

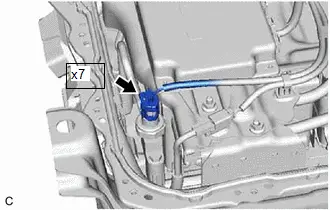

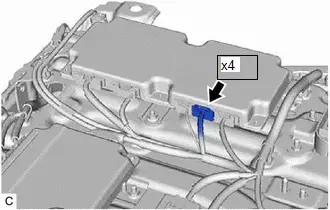

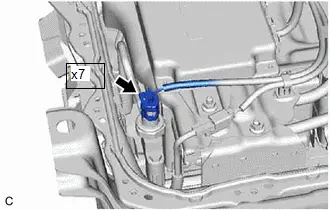

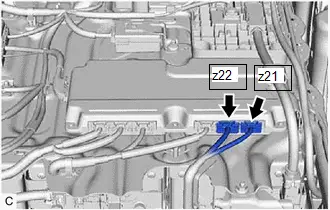

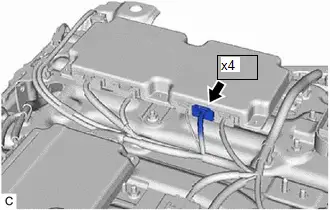

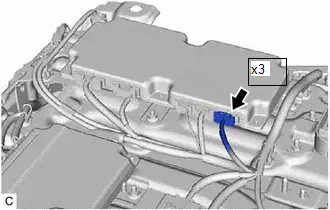

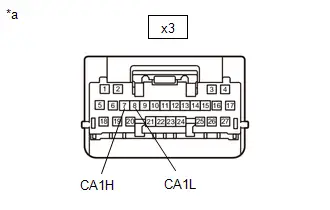

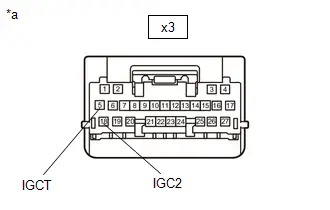

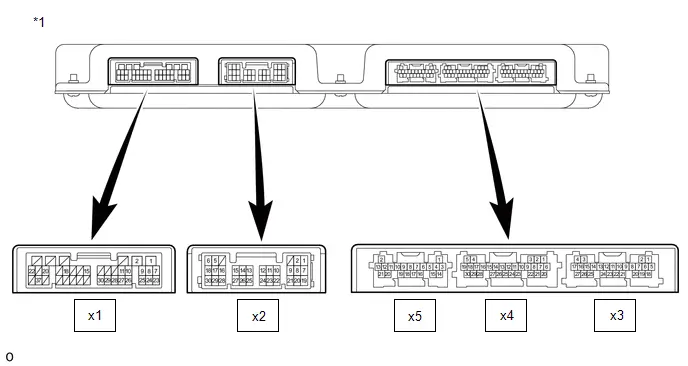

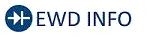

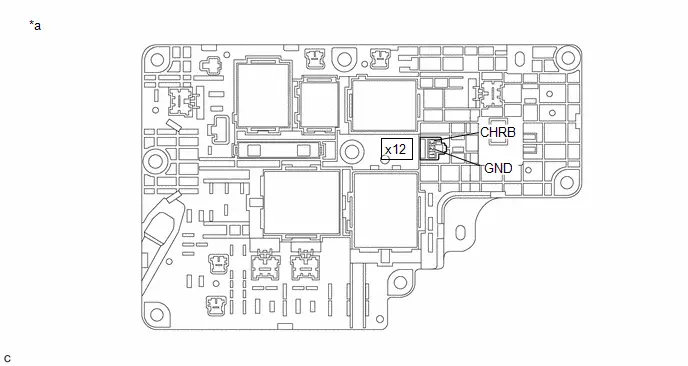

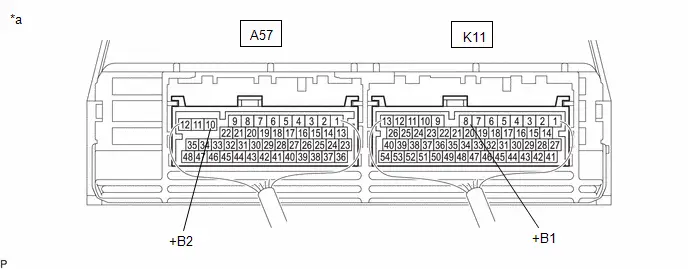

Terminals Of Ecu

TERMINALS OF ECU

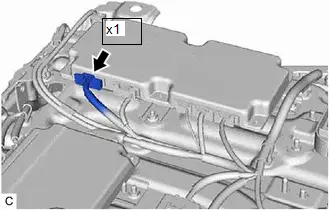

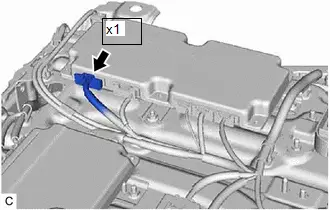

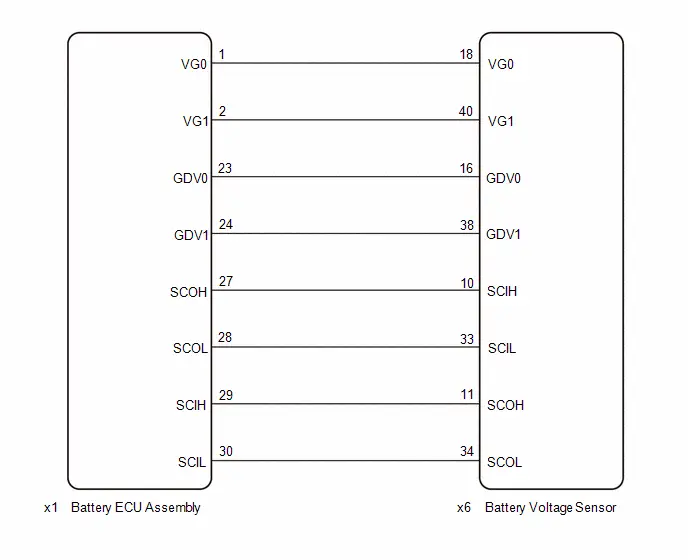

| *1 | Battery ECU Assembly | - | - |

| Connector code | Terminal No. | Symbol | Terminal Description |

|---|---|---|---|

| x1 | 1 | VG0 | Power source for battery voltage sensor 0 |

| 2 | VG1 | Power source for battery voltage sensor 1 | |

| 3 | - | - | |

| 4 | - | - | |

| 5 | - | - | |

| 6 | - | - | |

| 7 | VBS0 | Stack selection signal 0 | |

| 8 | VBS1 | Stack selection signal 1 | |

| 9 | VBS2 | Stack selection signal 2 | |

| 10 | VBSG | Ground for shield | |

| 11 | VDEN | Voltage sensor circuit control signal | |

| 12 | - | - | |

| 13 | - | - | |

| 14 | - | - | |

| 15 | GGB0 | Surge protection circuit | |

| 16 | - | - | |

| 17 | - | - | |

| 18 | VLKB | Isolation sensor signal | |

| 19 | - | - | |

| 20 | VBB0 | Stack voltage sensor | |

| 21 | - | - | |

| 22 | GBB0 | Stack voltage sensor ground | |

| 23 | GDV0 | Battery voltage sensor 0 ground | |

| 24 | GDV1 | Battery voltage sensor 1 ground | |

| 25 | VHS0 | Isolation sensor signal | |

| 26 | VHS1 | Relay drive A Signal | |

| 27 | SCOH | ECU - battery voltage sensor communication line | |

| 28 | SCOL | ECU - battery voltage sensor communication line | |

| 29 | SCIH | ECU - battery voltage sensor communication line | |

| 30 | SCIL | ECU - battery voltage sensor communication line | |

| 31 | - | - | |

| 32 | - | - | |

| 33 | - | - | |

| 34 | - | - | |

| 35 | - | - | |

| 36 | - | - | |

| 37 | VLKG | Isolation sensor ground | |

| 38 | - | - | |

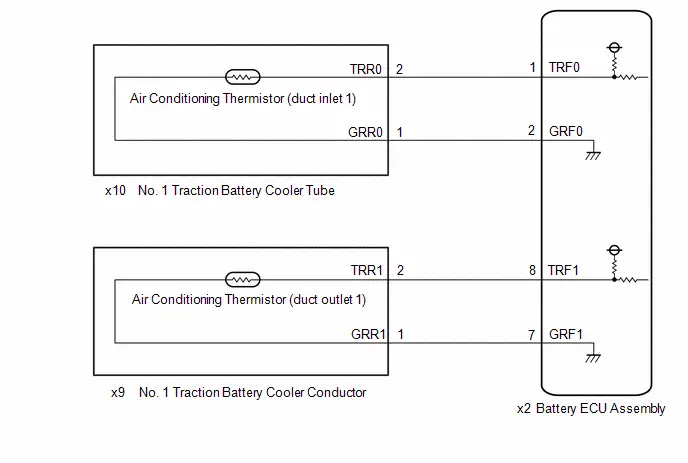

| x2 | 1 | TRF0 | Air conditioning thermistor assembly (Duct Inlet 1) |

| 2 | GRF0 | Air conditioning thermistor assembly (Duct Inlet 1) ground | |

| 3 | - | - | |

| 4 | - | - | |

| 5 | - | - | |

| 6 | - | - | |

| 7 | GRF1 | Air conditioning thermistor assembly (Duct Outlet 1) ground | |

| 8 | TRF1 | Air conditioning thermistor assembly (Duct Outlet 1) | |

| 9 | - | - | |

| 10 | - | - | |

| 11 | - | - | |

| 12 | - | - | |

| 13 | - | - | |

| 14 | - | - | |

| 15 | - | - | |

| 16 | - | - | |

| 17 | - | - | |

| 18 | - | - | |

| 19 | - | - | |

| 20 | - | - | |

| 21 | - | - | |

| 22 | - | - | |

| 23 | - | - | |

| 24 | - | - | |

| 25 | - | - | |

| 26 | - | - | |

| 27 | - | - | |

| 28 | - | - | |

| 29 | - | - | |

| 30 | - | - | |

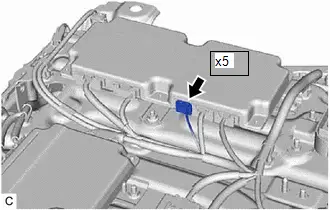

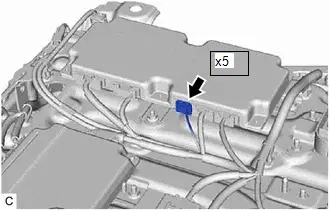

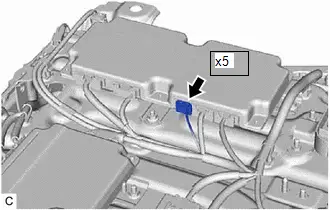

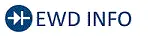

| x5 | 1 | - | - |

| 2 | - | - | |

| 3 | TBH0 | HV battery heater temperature sensor 0 | |

| 4 | GBH0 | HV battery heater temperature sensor 0 ground | |

| 5 | TBH1 | HV battery heater temperature sensor 1 | |

| 6 | GBH1 | HV battery heater temperature sensor 1 ground | |

| 7 | - | - | |

| 8 | - | - | |

| 9 | - | - | |

| 10 | - | - | |

| 11 | - | - | |

| 12 | - | - | |

| 13 | - | - | |

| 14 | - | - | |

| 15 | - | - | |

| 16 | - | - | |

| 17 | - | - | |

| 18 | - | - | |

| 19 | - | - | |

| 20 | - | - | |

| 21 | - | - | |

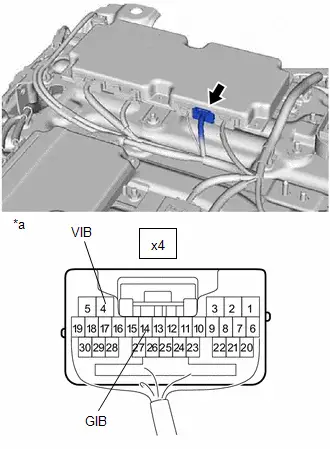

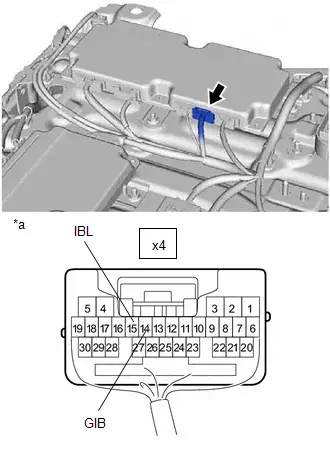

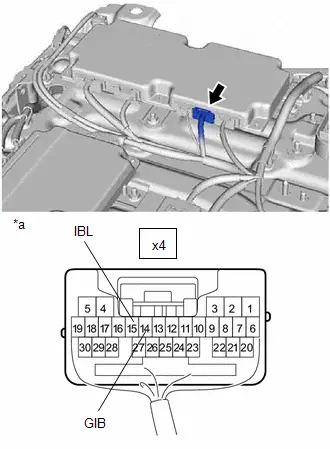

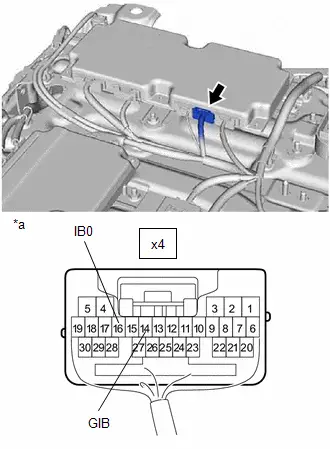

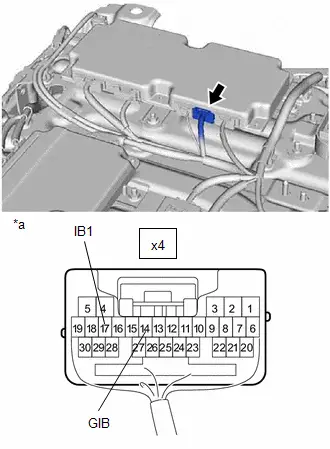

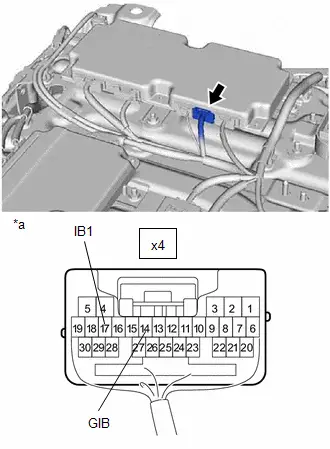

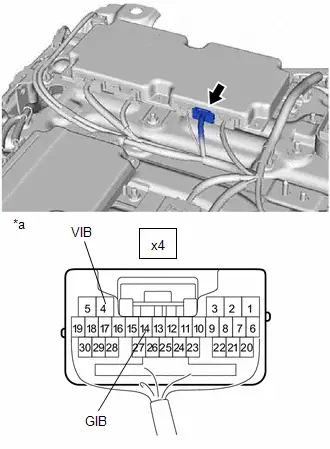

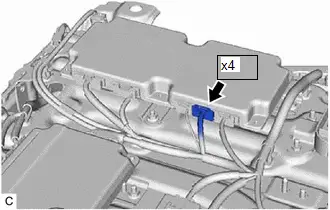

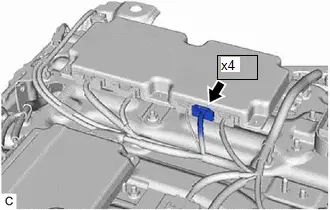

| x4 | 1 | - | - |

| 2 | - | - | |

| 3 | - | - | |

| 4 | VIB | Power source for battery current sensor | |

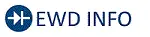

| 5 | VAS0 | Power source for air conditioning pressure sensor | |

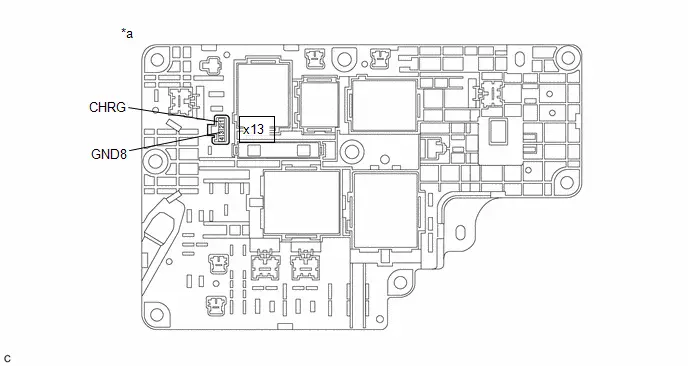

| 6 | CHRG | CHRG relay operation signal | |

| 7 | CHRP | CHRP relay operation signal | |

| 8 | CHRB | CHRB relay operation signal | |

| 9 | - | - | |

| 10 | - | - | |

| 11 | - | - | |

| 12 | BHRB | HV battery heater relay signal | |

| 13 | BHRG | HV battery heater relay ground | |

| 14 | GIB | Battery current sensor power source ground | |

| 15 | IBL | Battery current sensor signal (IBL) | |

| 16 | IB0 | Battery current sensor signal (IB0) | |

| 17 | IB1 | Battery current sensor signal (IB1) | |

| 18 | GAS0 | Air conditioning pressure sensor ground | |

| 19 | AS0 | Air conditioning pressure sensor signal | |

| 20 | SMA0 | Magnet valve signal | |

| 21 | SMB0 | Magnet valve signal | |

| 22 | SMC0 | Magnet valve signal | |

| 23 | SMD0 | Magnet valve signal | |

| 24 | - | - | |

| 25 | - | - | |

| 26 | - | - | |

| 27 | - | - | |

| 28 | - | - | |

| 29 | - | - | |

| 30 | - | - | |

| x3 | 1 | AM | Constant power source |

| 2 | - | - | |

| 3 | WCEN | Charging relay operation signal | |

| 4 | - | - | |

| 5 | IGCT | Power source | |

| 6 | - | - | |

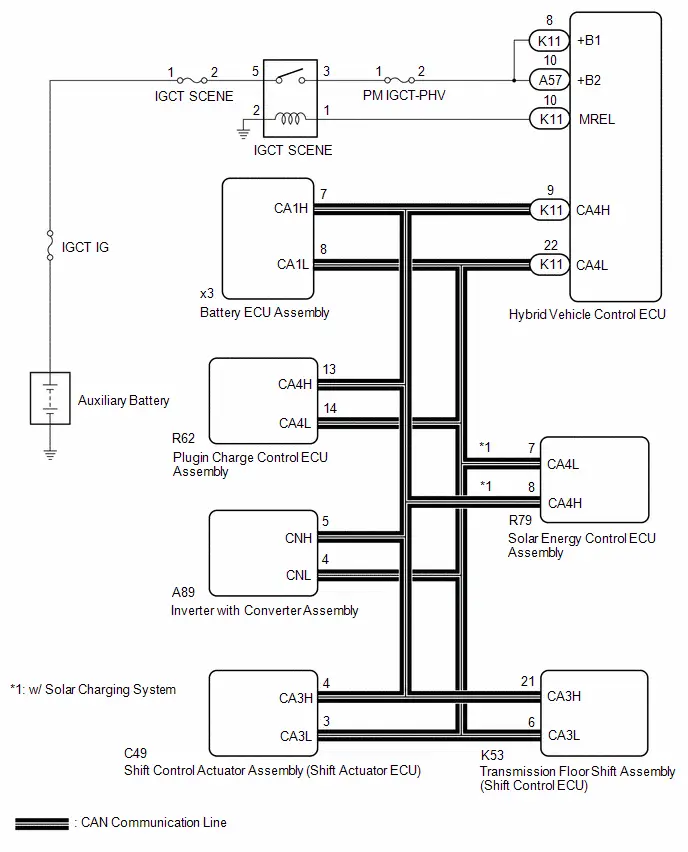

| 7 | CA1H | CAN communication line (battery local bus) | |

| 8 | CA1L | CAN communication line (battery local bus) | |

| 9 | - | - | |

| 10 | C2HB | CAN communication line (powertrain local bus) | |

| 11 | C2LB | CAN communication line (powertrain local bus) | |

| 12 | CA2H | CAN communication line (powertrain bus) | |

| 13 | CA2L | CAN communication line (powertrain bus) | |

| 14 | - | - | |

| 15 | - | - | |

| 16 | - | - | |

| 17 | - | ||

| 18 | IGC2 | Power source | |

| 19 | - | - | |

| 20 | - | - | |

| 21 | - | - | |

| 22 | - | - | |

| 23 | - | - | |

| 24 | - | - | |

| 25 | GND | Ground | |

| 26 | GND1 | Ground | |

| 27 | GND2 | Ground |

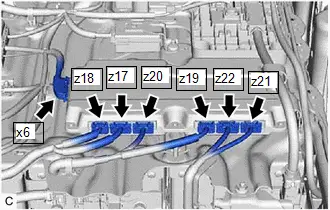

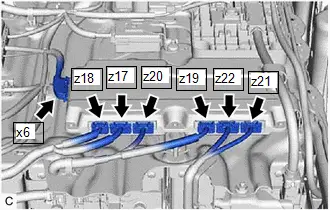

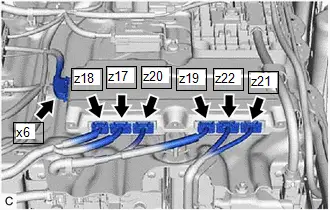

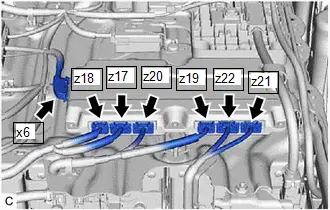

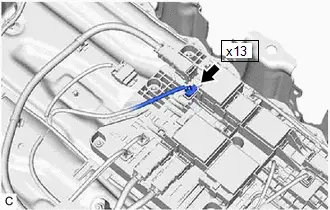

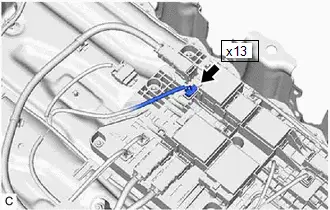

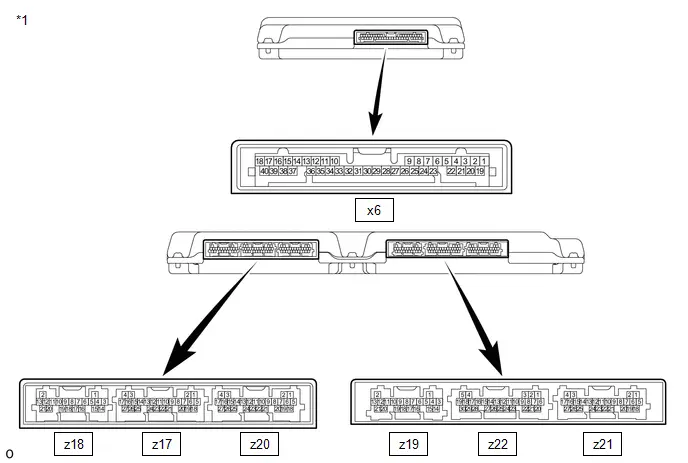

| *1 | Battery Voltage Sensor | - | - |

| Connector code | Terminal No. | Symbol | Terminal Description |

|---|---|---|---|

| x6 | 1 | VLKB | Isolation sensor signal |

| 2 | - | - | |

| 3 | - | - | |

| 4 | - | - | |

| 5 | GBB0 | Surge protection circuit | |

| 6 | - | - | |

| 7 | - | - | |

| 8 | - | - | |

| 9 | - | - | |

| 10 | SCIH | battery voltage sensor - battery ECU communication line | |

| 11 | SCOH | battery voltage sensor - battery ECU communication line | |

| 12 | VHS0 | Isolation sensor signal | |

| 13 | VBS2 | Stack selection signal 2 | |

| 14 | VBS1 | Stack selection signal 1 | |

| 15 | VBSG | Ground for shield | |

| 16 | GDV0 | Ground for battery voltage sensor 0 | |

| 17 | - | - | |

| 18 | VG0 | Power source for battery voltage sensor 0 | |

| 19 | - | - | |

| 20 | - | - | |

| 21 | VBB0 | Stack voltage sensor | |

| 22 | - | - | |

| 23 | - | - | |

| 24 | - | - | |

| 25 | VLKG | Isolation sensor ground | |

| 26 | - | - | |

| 27 | - | - | |

| 28 | - | - | |

| 29 | GGB0 | Surge protection circuit | |

| 30 | - | - | |

| 31 | - | - | |

| 32 | - | - | |

| 33 | SCIL | battery voltage sensor - battery ECU communication line | |

| 34 | SCOL | battery voltage sensor - battery ECU communication line | |

| 35 | VHS1 | Relay drive A Signal | |

| 36 | VDEN | Voltage sensor circuit control signal | |

| 37 | VBS0 | Stack selection signal 0 | |

| 38 | GDV1 | Battery voltage sensor 1 ground | |

| 39 | - | - | |

| 40 | VG1 | Power source for battery voltage sensor 1 | |

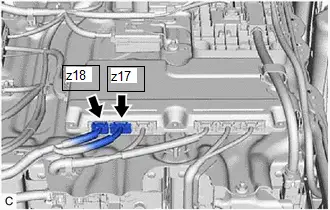

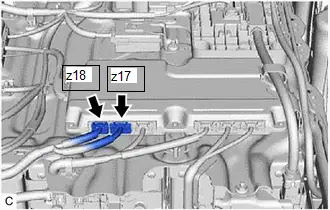

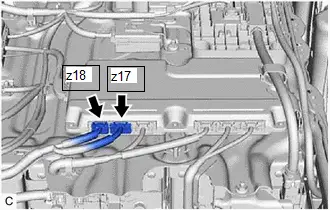

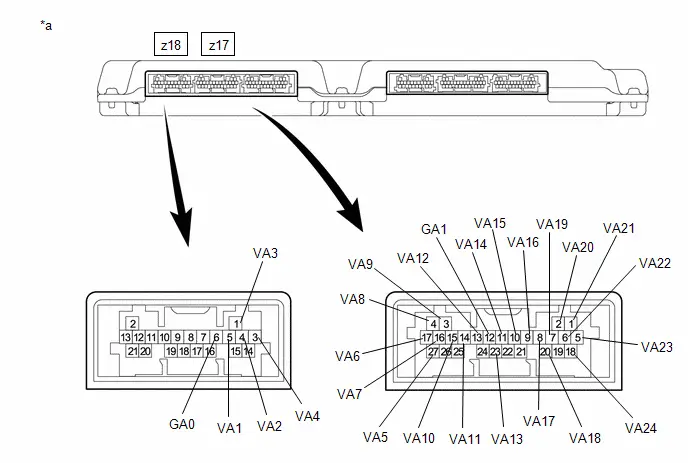

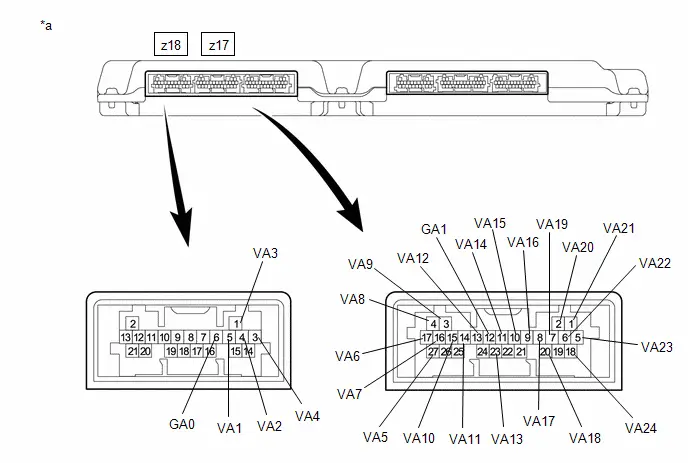

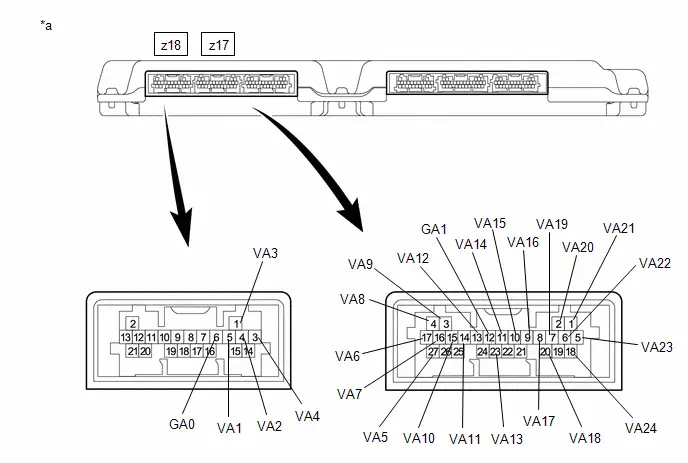

| z18 | 1 | VA3 | HV Battery Cell Voltage |

| 2 | - | - | |

| 3 | VA4 | HV Battery Cell Voltage | |

| 4 | VA2 | HV Battery Cell Voltage | |

| 5 | VA1 | HV Battery Cell Voltage | |

| 6 | GA0 | HV Battery Cell Voltage | |

| 7 | TB4 | HV battery temperature sensor 4 | |

| 8 | GB4 | HV battery temperature sensor 4 ground | |

| 9 | TB3 | HV battery temperature sensor 3 | |

| 10 | GB3 | HV battery temperature sensor 3 ground | |

| 11 | TB2 | HV battery temperature sensor 2 | |

| 12 | GB2 | HV battery temperature sensor 2 ground | |

| 13 | - | - | |

| 14 | - | - | |

| 15 | - | - | |

| 16 | - | - | |

| 17 | - | - | |

| 18 | GB1 | HV battery temperature sensor 1 ground | |

| 19 | TB1 | HV battery temperature sensor 1 | |

| 20 | GB0 | HV battery temperature sensor 0 ground | |

| 21 | TB0 | HV battery temperature sensor 0 | |

| z17 | 1 | VA21 | HV Battery Cell Voltage |

| 2 | VA20 | HV Battery Cell Voltage | |

| 3 | VA9 | HV Battery Cell Voltage | |

| 4 | VA8 | HV Battery Cell Voltage | |

| 5 | VA23 | HV Battery Cell Voltage | |

| 6 | VA22 | HV Battery Cell Voltage | |

| 7 | VA19 | HV Battery Cell Voltage | |

| 8 | VA17 | HV Battery Cell Voltage | |

| 9 | VA16 | HV Battery Cell Voltage | |

| 10 | VA15 | HV Battery Cell Voltage | |

| 11 | VA14 | HV Battery Cell Voltage | |

| 12 | GA1 | HV Battery Cell Voltage | |

| 13 | VA12 | HV Battery Cell Voltage | |

| 14 | VA11 | HV Battery Cell Voltage | |

| 15 | VA10 | HV Battery Cell Voltage | |

| 16 | VA7 | HV Battery Cell Voltage | |

| 17 | VA6 | HV Battery Cell Voltage | |

| 18 | VA24 | HV Battery Cell Voltage | |

| 19 | - | - | |

| 20 | VA18 | HV Battery Cell Voltage | |

| 21 | - | - | |

| 22 | - | - | |

| 23 | VA13 | HV Battery Cell Voltage | |

| 24 | - | - | |

| 25 | - | - | |

| 26 | - | - | |

| 27 | VA5 | HV Battery Cell Voltage | |

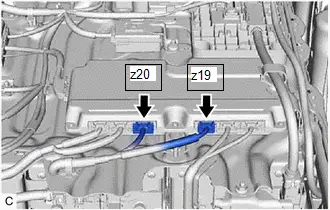

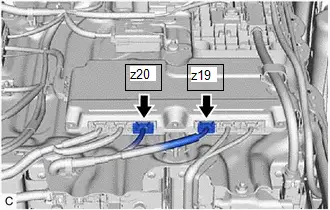

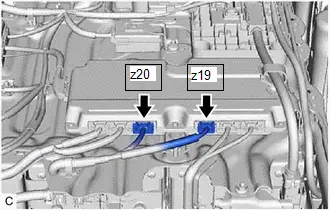

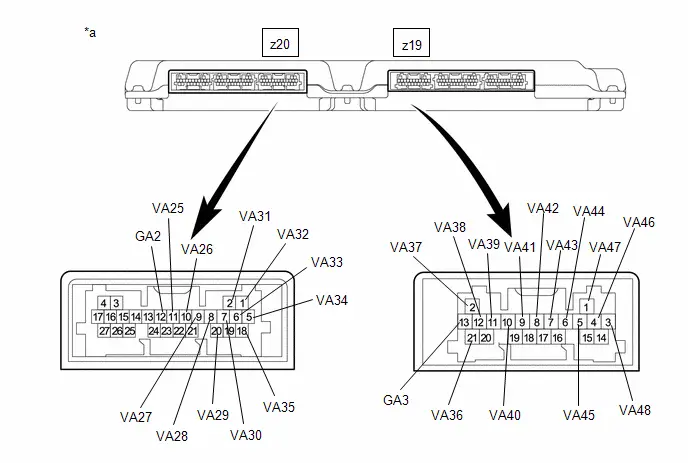

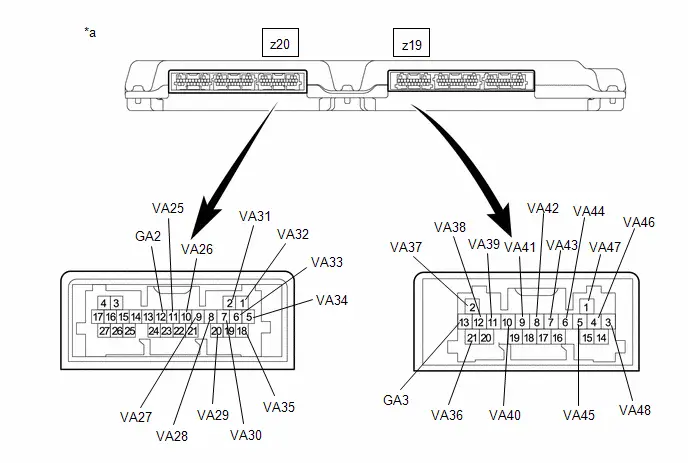

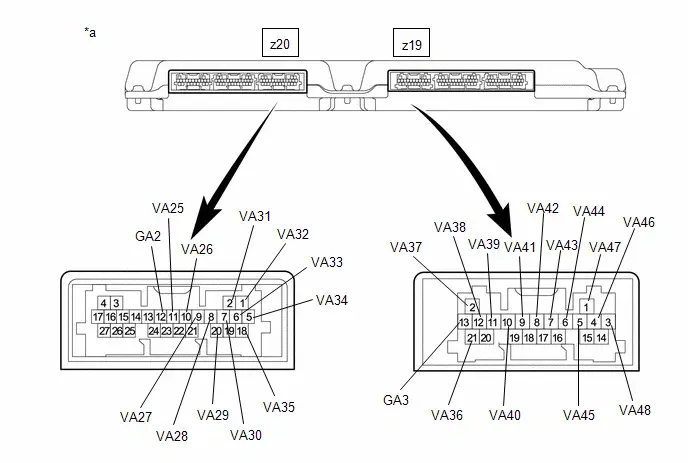

| z20 | 1 | VA32 | HV Battery Cell Voltage |

| 2 | VA31 | HV Battery Cell Voltage | |

| 3 | GB5 | HV battery temperature sensor 5 ground | |

| 4 | TB5 | HV battery temperature sensor 5 | |

| 5 | VA34 | HV Battery Cell Voltage | |

| 6 | VA33 | HV Battery Cell Voltage | |

| 7 | VA30 | HV Battery Cell Voltage | |

| 8 | VA28 | HV Battery Cell Voltage | |

| 9 | VA27 | HV Battery Cell Voltage | |

| 10 | VA26 | HV Battery Cell Voltage | |

| 11 | VA25 | HV Battery Cell Voltage | |

| 12 | GA2 | HV Battery Cell Voltage | |

| 13 | TB9 | HV battery temperature sensor 9 | |

| 14 | GB9 | HV battery temperature sensor 9 ground | |

| 15 | TB7 | HV battery temperature sensor 7 | |

| 16 | GB7 | HV battery temperature sensor 7 ground | |

| 17 | TB6 | HV battery temperature sensor 6 | |

| 18 | VA35 | HV Battery Cell Voltage | |

| 19 | - | - | |

| 20 | VA29 | HV Battery Cell Voltage | |

| 21 | - | - | |

| 22 | - | - | |

| 23 | - | - | |

| 24 | - | - | |

| 25 | TB8 | HV battery temperature sensor 8 | |

| 26 | GB8 | HV battery temperature sensor 8 ground | |

| 27 | GB6 | HV battery temperature sensor 6 ground | |

| z19 | 1 | VA47 | HV Battery Cell Voltage |

| 2 | VA37 | HV Battery Cell Voltage | |

| 3 | VA48 | HV Battery Cell Voltage | |

| 4 | VA46 | HV Battery Cell Voltage | |

| 5 | VA45 | HV Battery Cell Voltage | |

| 6 | VA44 | HV Battery Cell Voltage | |

| 7 | VA43 | HV Battery Cell Voltage | |

| 8 | VA42 | HV Battery Cell Voltage | |

| 9 | VA41 | HV Battery Cell Voltage | |

| 10 | VA40 | HV Battery Cell Voltage | |

| 11 | VA39 | HV Battery Cell Voltage | |

| 12 | VA38 | HV Battery Cell Voltage | |

| 13 | GA3 | HV Battery Cell Voltage | |

| 14 | - | - | |

| 15 | - | - | |

| 16 | - | - | |

| 17 | - | - | |

| 18 | - | - | |

| 19 | - | - | |

| 20 | - | - | |

| 21 | VA36 | HV Battery Cell Voltage | |

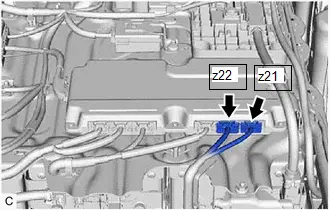

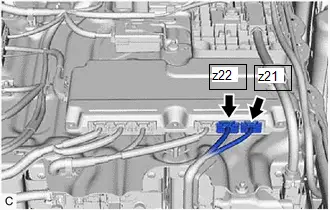

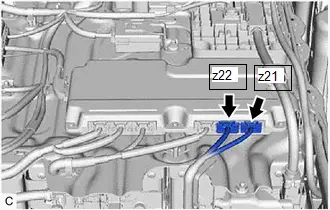

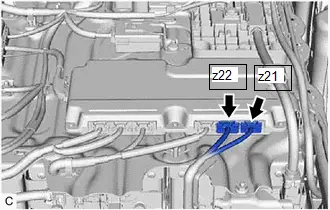

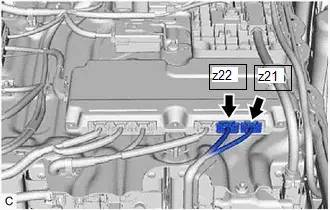

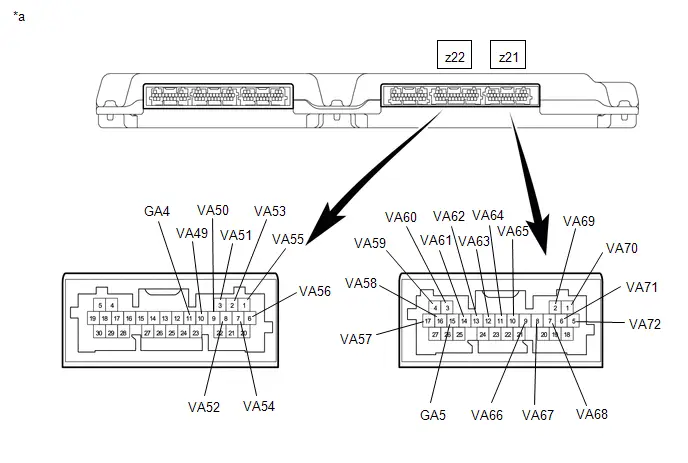

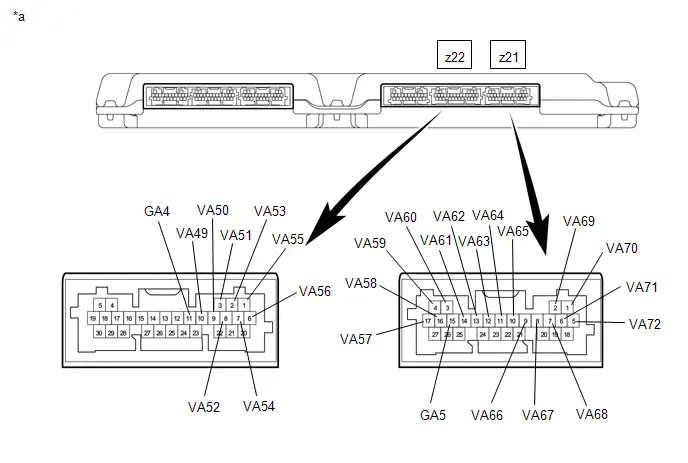

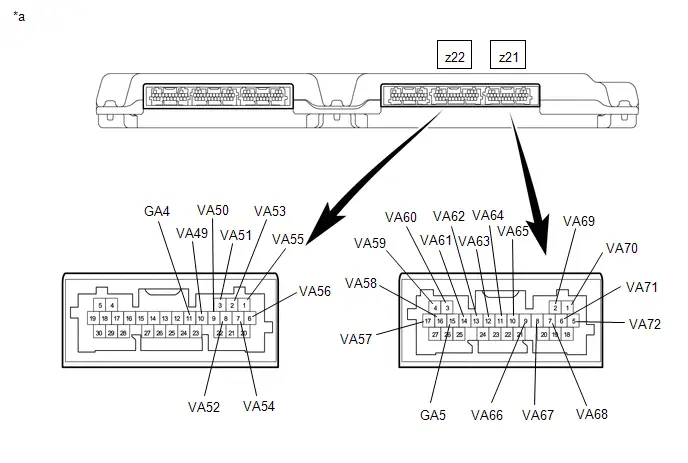

| z22 | 1 | VA55 | HV Battery Cell Voltage |

| 2 | VA53 | HV Battery Cell Voltage | |

| 3 | VA51 | HV Battery Cell Voltage | |

| 4 | - | - | |

| 5 | TB11 | HV battery temperature sensor 11 | |

| 6 | VA56 | HV Battery Cell Voltage | |

| 7 | VA54 | HV Battery Cell Voltage | |

| 8 | VA52 | HV Battery Cell Voltage | |

| 9 | VA50 | HV Battery Cell Voltage | |

| 10 | VA49 | HV Battery Cell Voltage | |

| 11 | GA4 | HV Battery Cell Voltage | |

| 12 | GB14 | HV battery temperature sensor 14 ground | |

| 13 | TB14 | HV battery temperature sensor 14 | |

| 14 | GB13 | HV battery temperature sensor 13 ground | |

| 15 | TB13 | HV battery temperature sensor 13 | |

| 16 | GB12 | HV battery temperature sensor 12 ground | |

| 17 | TB12 | HV battery temperature sensor 12 | |

| 18 | GB11 | HV battery temperature sensor 11 ground | |

| 19 | TB10 | HV battery temperature sensor 10 | |

| 20 | - | - | |

| 21 | - | - | |

| 22 | - | - | |

| 23 | - | - | |

| 24 | - | - | |

| 25 | - | - | |

| 26 | - | - | |

| 27 | - | - | |

| 28 | - | - | |

| 29 | - | - | |

| 30 | GB10 | HV battery temperature sensor 10 ground | |

| z21 | 1 | VA70 | HV Battery Cell Voltage |

| 2 | VA69 | HV Battery Cell Voltage | |

| 3 | VA60 | HV Battery Cell Voltage | |

| 4 | VA59 | HV Battery Cell Voltage | |

| 5 | VA72 | HV Battery Cell Voltage | |

| 6 | VA71 | HV Battery Cell Voltage | |

| 7 | VA68 | HV Battery Cell Voltage | |

| 8 | VA67 | HV Battery Cell Voltage | |

| 9 | VA66 | HV Battery Cell Voltage | |

| 10 | VA65 | HV Battery Cell Voltage | |

| 11 | VA64 | HV Battery Cell Voltage | |

| 12 | VA63 | HV Battery Cell Voltage | |

| 13 | VA62 | HV Battery Cell Voltage | |

| 14 | VA61 | HV Battery Cell Voltage | |

| 15 | GA5 | HV Battery Cell Voltage | |

| 16 | VA58 | HV Battery Cell Voltage | |

| 17 | VA57 | HV Battery Cell Voltage | |

| 18 | - | - | |

| 19 | - | - | |

| 20 | - | - | |

| 21 | - | - | |

| 22 | - | - | |

| 23 | - | - | |

| 24 | - | - | |

| 25 | - | - | |

| 26 | - | - | |

| 27 | - | - |

Diagnosis System

DIAGNOSIS SYSTEM

DESCRIPTION

(a) The battery ECU assembly has a self-diagnosis system. If the computer, hybrid control system, or a component is not working properly, the ECU records the conditions that relate to the fault. The ECU also illuminates the master warning in the combination meter assembly and provides other appropriate messages on the multi-information display, such as the HV system warning message, HV battery warning message, or discharge warning message.

- When troubleshooting OBD II (On-Board Diagnostics) Toyota Prius vehicles, the GTS (complying with SAE J1978) must be connected to the DLC3 (Data Link Connector 3) of the vehicle. Various data in the vehicle ECM (Engine Control Module) can then be read.

-

OBD II regulations require that the vehicle's on-board computer illuminates the MIL (Malfunction Indicator Lamp) on the instrument panel when the computer detects a malfunction in:

- The emission control system components.

- The powertrain control components (which affect Toyota Prius vehicle emissions).

-

The computer itself.

In addition, the applicable DTCs prescribed by SAE J2012 are recorded in the battery ECU assembly memory. If the malfunction does not recur in 3 consecutive trips, the MIL turns off automatically but the DTCs remain recorded in the battery ECU assembly memory.

- To check for DTCs, connect the GTS to the DLC3. The GTS displays DTCs, freeze frame data, and a variety of hybrid control system data. The DTCs and freeze frame data can be cleared with the GTS. In order to enhance the OBD function on Toyota Prius vehicles and develop the off-board diagnosis system, Controller Area Network (CAN) communication is used in this system. CAN is a network which uses a pair of data transmission lines spanning multiple computers and sensors. It allows for high speed communications between the systems and simplification of the wire harness connections.

2 TRIP DETECTION LOGIC

- When a malfunction is first detected, the malfunction is temporarily stored in the battery ECU assembly memory (1st trip). If the same malfunction is detected during the next drive cycle, the MIL is illuminated (2nd trip).

FREEZE FRAME DATA

- The battery ECU assembly records Toyota Prius vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was moving or stationary, whether the engine was warmed up or not, as well as other data recorded at the time of a malfunction.

AUXILIARY BATTERY VOLTAGE

Standard Voltage:

| Switch Condition | Specified Condition |

|---|---|

| Ignition switch ON | 11 to 14 V |

-

If voltage is below 11 V, replace or recharge the auxiliary battery.

NOTICE:

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

MIL (Malfunction Indicator Lamp)

(a) The MIL is illuminated when the ignition switch is first turned to ON, before the READY light comes on.

(b) When the READY indicator turns on, the MIL should turn off. If the MIL remains illuminated, the diagnosis system has detected a malfunction or abnormality in the system.

HINT:

If the MIL is not illuminated when the ignition switch is first turned to ON, check the MIL circuit.

for SFI System: Click here

Dtc Check / Clear

DTC CHECK / CLEAR

CHECK FOR DTCS

(a) Check the DTCs and freeze frame data, and then write them down.

Powertrain > HV Battery > Trouble Codes(b) Check the details of the DTCs.

| Display Item | Description |

|---|---|

| Test Failed | Shows the malfunction judgment results during the current trip. |

| Pending | Shows the malfunction judgment results up to now. (Indicates the possibility of a malfunction when no DTC is confirmed.) |

| Confirmed | Shows the DTCs confirmed up to now. (The number of current trips differs for each DTC.) |

- A pending DTC is a DTC that is stored in the battery ECU assembly during the 1st trip when the 2 trip detection logic is used.

- Freeze frame data is stored for each of the latest result DTCs, pending DTCs and confirmed DTCs.

(1) Check items on the display and press "Next".

Powertrain > HV Battery > Utility| Tester Display |

|---|

| Check Mode |

NOTICE:

- All the stored DTCs and freeze frame data are cleared if the battery ECU assembly is changed from normal mode to check mode. Before changing modes, always check and note any DTCs and freeze frame data.

- Changing from normal mode to check mode function is not available when the ignition switch is turned to ON (READY).

- If a DTC is stored, check and note the DTC and freeze frame data following the GTS display, then change from normal mode to check mode.

CHECK FREEZE FRAME DATA

(a) If a DTC is present, select it in order to display its freeze frame data.

(b) Read the freeze frame data recorded when the DTC was stored.

CHECK TIME STAMP

HINT:

By checking Time Stamp, the time and order in which DTCs were stored in an ECU can be checked.

(a) Enter the following menus: Health Check.

(b) Perform the following steps when the data setting screen is displayed.

(c) Select the systems for which to perform Health Check and check for time stamp data.

- Powertrain

- Chassis

- Body

- Store All Data

(d) Select "Yes" when "Do you want to store time stamp data?" is displayed.

HINT:

If "Yes" is not selected, time stamp data will not be stored.

(e) After Health Check has completed, select "Time Stamp Data" to display the Time Stamp screen.

(f) Select the desired system from the drop-down list on the bottom of the Time Stamp screen.

(g) Check the order and time which DTCs were stored for the selected system.

CHECK FOR DTCS (SYSTEMS EXCEPT BATTERY ECU ASSEMBLY)

HINT:

The battery ECU assembly maintains communication with other computers, including the electric Toyota Prius vehicle charger assembly, the ECM, and hybrid vehicle control ECU. Therefore, if the battery ECU assembly outputs a warning, it is necessary to check and record the DTCs of all systems.

(a) If DTCs are stored, check the relevant systems.

HINT:

If DTCs for the CAN communication system are stored in addition to other DTCs, first troubleshoot and repair any malfunctions in the CAN communication system.

CLEAR DTCS

NOTICE:

Clearing the DTCs will also clear the freeze frame data.

(a) Enter the following menus: Powertrain / HV battery / Trouble Codes.

Powertrain > HV Battery > Trouble Codes(b) Clear DTCs and freeze frame data.

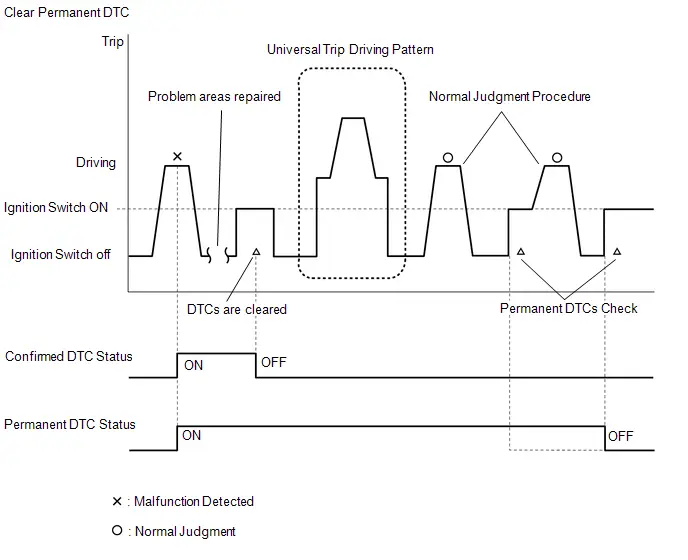

Powertrain > HV Battery > Clear DTCs- After clearing current DTCs using the GTS (or by disconnecting the cable from the negative (-) auxiliary battery terminal), permanent DTCs can be cleared when the universal trip is performed and then the system is determined to be normal for the relevant DTCs. The driving pattern to obtain a normal judgment is described under the "Confirmation Driving Pattern" for the respective DTC.

-

To clear permanent DTCs, all of the following conditions must be are met:

- There is a history that universal trip driving was performed.

- The Toyota Prius vehicle has been judged as normal for 2 trips. (Normal judgment does not have to be performed in 2 consecutive trip, but normal judgment should occur in the latest trip.)

- No malfunctions are detected.

CLEAR PERMANENT DTC

(a) Enter the following menus: Powertrain / HV Battery / Trouble Codes.

Powertrain > HV Battery > Trouble CodesHINT:

If "YES" is displayed for the value of "PERMANENT" at the top right of the GTS screen, permanent DTCs are stored.

(b) Select the "Generic" tab.

(c) Check if permanent DTCs are stored.

HINT:

If permanent DTCs are not output, it is not necessary to continue this procedure.

(d) Clear the DTCs.

Powertrain > HV Battery > Clear DTCsNOTICE:

Do not clear the DTCs or disconnect the cable from the auxiliary battery terminal after performing this step.

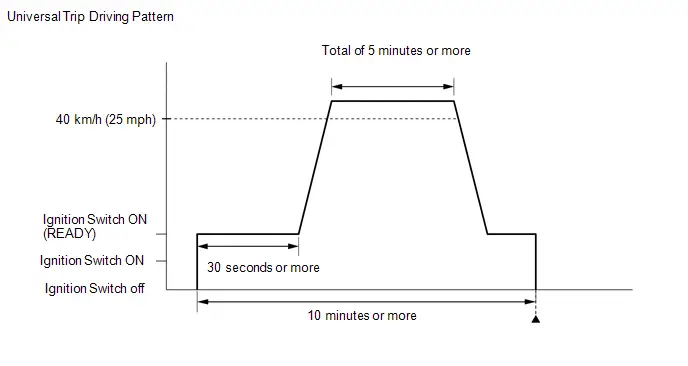

(e) Perform the universal trip.

CAUTION:

When performing the driving pattern, obey all speed limits and traffic laws.

HINT:

The universal trip driving pattern and normal judgment procedure can be performed consecutively in the same driving cycle.

(1) Turn the ignition switch to ON (READY) and wait for 30 seconds or more.

(2) Drive the Toyota Prius vehicle at 40 km/h (25 mph) or more for a total of 5 minutes or more.

HINT:

It is possible to complete the drive pattern even if the vehicle decelerates to less than 40 km/h (25 mph) during the driving cycle provided that the vehicle is driven at 40 km/h (25 mph) or more for a total of 5 minutes.

(3) Allow 10 minutes or more to elapse from the time the ignition switch turned to ON (READY).

(f) Turn the ignition switch off and wait for 2 minutes or more.

(g) Perform the normal judgment procedure in the respective confirmation driving pattern of each output DTC.

HINT:

Do not turn the ignition switch off by mistake during this step.

(h) With ignition switch ON (READY) and wait for 5 seconds or more.

(i) Turn the ignition switch off and wait for 2 minutes or more.

(j) Turn the ignition switch to ON.

(k) Enter the following menus: Powertrain / HV Battery / Trouble Codes.

Powertrain > HV Battery > Trouble Codes(l) Check that the permanent DTCs have been cleared.

HINT:

If permanent DTCs are not output, it is not necessary to continue this procedure.

(m) Perform the normal judgment procedure in the respective confirmation driving pattern of each output DTC.

HINT:

Do not turn the ignition switch off by mistake during this step.

(n) With ignition switch ON (READY) and wait for 5 seconds or more.

(o) Turn the ignition switch off and wait for 2 minutes or more.

(p) Turn the ignition switch to ON.

(q) Enter the following menus: Powertrain / HV Battery / Trouble Codes.

Powertrain > HV Battery > Clear DTCs(r) Check that the permanent DTCs have been cleared.

HINT:

- Permanent DTCs will be cleared if a normal judgment is obtained during 3 consecutive driving cycles with the MIL illuminated.

- The permanent DTCs are cleared when the universal trip is completed.

- If permanent DTCs are still present after the universal trip, turn the ignition switch off and wait for a while. Then, confirm that the permanent DTCs have been cleared.

Freeze Frame Data

FREEZE FRAME DATA

FREEZE FRAME DATA

HINT:

The battery ECU assembly records vehicle and driving condition information as freeze frame data the moment a DTC is stored. It can be used for estimating or duplicating the vehicle conditions that were present when the malfunction occurred. To confirm the details of the hybrid battery system, check the detailed information for the DTC information code in the Data List (INF code).

(a) Select a DTC in order to display its freeze frame data.

(b) Check the freeze frame information recorded with the DTC.

Powertrain > HV Battery| Tester Display |

|---|

| Toyota Prius Vehicle Speed |

| Target Engine Power |

| Engine Speed |

| Calculate Load |

| Coolant Temperature |

| Engine Run Time |

| Accelerator Position |

| Throttle Position Sensor No.1 Voltage % |

| Shift Position |

| Atmospheric Pressure |

| Ambient Temperature |

| BATT Voltage |

| Smoothed Value of BATT Voltage |

| Warmup Cycle Cleared DTC |

| Distance from DTC Cleared |

| Time after DTC Cleared |

| Running Time from MIL ON |

| Total Distance Traveled |

| Total Distance Traveled - Unit |

| MIL ON Run Distance |

| IGB Signal Status |

| IG2 Signal Status |

| Ready Signal |

| Ready ON Prevention Status |

| IG OFF Time of Last Trip |

| HV/EV Activate Condition |

| SMRG Control Status |

| SMRB Control Status |

| SMRP Control Status |

| WIN Control Limit Power |

| WOUT Control Limit Power |

| A/C Consumption Power |

| A/C System Status |

| Stop Light Switch |

| Airbag Status (Collision) |

| Airbag Status (Safing) |

| Airbag Status (Normal) |

| Generator Revolution |

| Target Generator Torque |

| Motor Revolution |

| Target Motor Torque |

| Request Motor Regenerative Brake Torque |

| Motor Regenerate Brake Execution Torque |

| Generator Carrier Frequency |

| Motor Carrier Frequency |

| Boosting Converter Carrier Frequency |

| VL-Voltage before Boosting |

| VH-Voltage after Boosting |

| Boost Ratio |

| Hybrid/EV Battery SOC |

| Delta SOC |

| Hybrid/EV Battery SOC just after IG-ON |

| Hybrid/EV Battery Maximum SOC |

| Hybrid/EV Battery Minimum SOC |

| Hybrid/EV Battery Voltage |

| Hybrid/EV Battery Current |

| Hybrid/EV Battery Current for Hybrid/EV Battery Control |

| Hybrid/EV Battery Current for Hybrid/EV Battery Control (Sub) |

| Hybrid/EV Battery Current for Driving Control |

| Hybrid/EV Battery Current (IBL) |

| Hybrid/EV Battery Current Sensor Voltage for Hybrid/EV Battery Control |

| Hybrid/EV Battery Current Sensor Voltage for Hybrid/EV Battery Control (Sub) |

| Hybrid/EV Battery Current Sensor Voltage (IBL) |

| Hybrid/EV Battery Control Mode |

| Hybrid/EV Battery Current Sensor Power Supply Voltage |

| Hybrid/EV Battery Current Sensor Offset Learning Value |

| Hybrid/EV Battery Current Sensor Offset |

| Hybrid/EV Battery Current Sensor Offset Learning Value (Sub) |

| Hybrid/EV Battery Current Sensor Offset (Sub) |

| Hybrid/EV Battery Current Sensor Offset Learning Value (IBL) |

| Hybrid/EV Battery Current Sensor Offset (IBL) |

| Short Wave Highest Value |

| Hybrid/EV Battery Cell Circuit Open Information for Monitoring IC 1 |

| Hybrid/EV Battery Cell Circuit Open Information for Monitoring IC 2 |

| Hybrid/EV Battery Cell Circuit Open Information for Monitoring IC 3 |

| Lost Communication with Hybrid/EV Battery Monitoring IC |

| Hybrid/EV Battery Monitoring IC 1 Internal Malfunction (Determinable) |

| Hybrid/EV Battery Monitoring IC 2 Internal Malfunction (Determinable) |

| Hybrid/EV Battery Monitoring IC 3 Internal Malfunction (Determinable) |

| Hybrid/EV Battery Monitoring IC Internal Malfunction (Unidentifiable) |

| Hybrid/EV Battery Monitoring IC 1 Power Supply Malfunction |

| Hybrid/EV Battery Monitoring IC 2 Power Supply Malfunction |

| Hybrid/EV Battery Monitoring IC 3 Power Supply Malfunction |

| Hybrid/EV Battery Monitoring IC 1 Cell Voltage Detection Malfunction |

| Hybrid/EV Battery Monitoring IC 2 Cell Voltage Detection Malfunction |

| Hybrid/EV Battery Monitoring IC 3 Cell Voltage Detection Malfunction |

| Hybrid/EV Battery Stack 1 Cell Average Voltage |

| Hybrid/EV Battery Stack 2 Cell Average Voltage |

| Hybrid/EV Battery Stack 3 Cell Average Voltage |

| Hybrid/EV Battery Block 1 Cell Average Voltage |

| Hybrid/EV Battery Block 2 Cell Average Voltage |

| Hybrid/EV Battery Block 3 Cell Average Voltage |

| Hybrid/EV Battery Cell Maximum Voltage Up to 1 trip before |

| Hybrid/EV Battery Cell Minimum Voltage Up to 1 trip before |

| Hybrid/EV Battery Cell 1 Voltage |

| Hybrid/EV Battery Cell 2 Voltage |

| Hybrid/EV Battery Cell 3 Voltage |

| Hybrid/EV Battery Cell 4 Voltage |

| Hybrid/EV Battery Cell 5 Voltage |

| Hybrid/EV Battery Cell 6 Voltage |

| Hybrid/EV Battery Cell 7 Voltage |

| Hybrid/EV Battery Cell 8 Voltage |

| Hybrid/EV Battery Cell 9 Voltage |

| Hybrid/EV Battery Cell 10 Voltage |

| Hybrid/EV Battery Cell 11 Voltage |

| Hybrid/EV Battery Cell 12 Voltage |

| Hybrid/EV Battery Cell 13 Voltage |

| Hybrid/EV Battery Cell 14 Voltage |

| Hybrid/EV Battery Cell 15 Voltage |

| Hybrid/EV Battery Cell 16 Voltage |

| Hybrid/EV Battery Cell 17 Voltage |

| Hybrid/EV Battery Cell 18 Voltage |

| Hybrid/EV Battery Cell 19 Voltage |

| Hybrid/EV Battery Cell 20 Voltage |

| Hybrid/EV Battery Cell 21 Voltage |

| Hybrid/EV Battery Cell 22 Voltage |

| Hybrid/EV Battery Cell 23 Voltage |

| Hybrid/EV Battery Cell 24 Voltage |

| Hybrid/EV Battery Cell 25 Voltage |

| Hybrid/EV Battery Cell 26 Voltage |

| Hybrid/EV Battery Cell 27 Voltage |

| Hybrid/EV Battery Cell 28 Voltage |

| Hybrid/EV Battery Cell 29 Voltage |

| Hybrid/EV Battery Cell 30 Voltage |

| Hybrid/EV Battery Cell 31 Voltage |

| Hybrid/EV Battery Cell 32 Voltage |

| Hybrid/EV Battery Cell 33 Voltage |

| Hybrid/EV Battery Cell 34 Voltage |

| Hybrid/EV Battery Cell 35 Voltage |

| Hybrid/EV Battery Cell 36 Voltage |

| Hybrid/EV Battery Cell 37 Voltage |

| Hybrid/EV Battery Cell 38 Voltage |

| Hybrid/EV Battery Cell 39 Voltage |

| Hybrid/EV Battery Cell 40 Voltage |

| Hybrid/EV Battery Cell 41 Voltage |

| Hybrid/EV Battery Cell 42 Voltage |

| Hybrid/EV Battery Cell 43 Voltage |

| Hybrid/EV Battery Cell 44 Voltage |

| Hybrid/EV Battery Cell 45 Voltage |

| Hybrid/EV Battery Cell 46 Voltage |

| Hybrid/EV Battery Cell 47 Voltage |

| Hybrid/EV Battery Cell 48 Voltage |

| Hybrid/EV Battery Cell 49 Voltage |

| Hybrid/EV Battery Cell 50 Voltage |

| Hybrid/EV Battery Cell 51 Voltage |

| Hybrid/EV Battery Cell 52 Voltage |

| Hybrid/EV Battery Cell 53 Voltage |

| Hybrid/EV Battery Cell 54 Voltage |

| Hybrid/EV Battery Cell 55 Voltage |

| Hybrid/EV Battery Cell 56 Voltage |

| Hybrid/EV Battery Cell 57 Voltage |

| Hybrid/EV Battery Cell 58 Voltage |

| Hybrid/EV Battery Cell 59 Voltage |

| Hybrid/EV Battery Cell 60 Voltage |

| Hybrid/EV Battery Cell 61 Voltage |

| Hybrid/EV Battery Cell 62 Voltage |

| Hybrid/EV Battery Cell 63 Voltage |

| Hybrid/EV Battery Cell 64 Voltage |

| Hybrid/EV Battery Cell 65 Voltage |

| Hybrid/EV Battery Cell 66 Voltage |

| Hybrid/EV Battery Cell 67 Voltage |

| Hybrid/EV Battery Cell 68 Voltage |

| Hybrid/EV Battery Cell 69 Voltage |

| Hybrid/EV Battery Cell 70 Voltage |

| Hybrid/EV Battery Cell 71 Voltage |

| Hybrid/EV Battery Cell 72 Voltage |

| Hybrid/EV Battery Temperature 1 |

| Hybrid/EV Battery Temperature 2 |

| Hybrid/EV Battery Temperature 3 |

| Hybrid/EV Battery Temperature 4 |

| Hybrid/EV Battery Temperature 5 |

| Hybrid/EV Battery Temperature 6 |

| Hybrid/EV Battery Temperature 7 |

| Hybrid/EV Battery Temperature 8 |

| Hybrid/EV Battery Temperature 9 |

| Hybrid/EV Battery Temperature 10 |

| Hybrid/EV Battery Temperature 11 |

| Hybrid/EV Battery Temperature 12 |

| Hybrid/EV Battery Temperature 13 |

| Hybrid/EV Battery Temperature 14 |

| Hybrid/EV Battery Temperature 15 |

| Hybrid/EV Battery Temperature Sensor Voltage 1 |

| Hybrid/EV Battery Temperature Sensor Voltage 2 |

| Hybrid/EV Battery Temperature Sensor Voltage 3 |

| Hybrid/EV Battery Temperature Sensor Voltage 4 |

| Hybrid/EV Battery Temperature Sensor Voltage 5 |

| Hybrid/EV Battery Temperature Sensor Voltage 6 |

| Hybrid/EV Battery Temperature Sensor Voltage 7 |

| Hybrid/EV Battery Temperature Sensor Voltage 8 |

| Hybrid/EV Battery Temperature Sensor Voltage 9 |

| Hybrid/EV Battery Temperature Sensor Voltage 10 |

| Hybrid/EV Battery Temperature Sensor Voltage 11 |

| Hybrid/EV Battery Temperature Sensor Voltage 12 |

| Hybrid/EV Battery Temperature Sensor Voltage 13 |

| Hybrid/EV Battery Temperature Sensor Voltage 14 |

| Hybrid/EV Battery Temperature Sensor Voltage 15 |

| Hybrid/EV Battery Cooling Fan Low Speed Request |

| Hybrid/EV Battery Heater 1 Temperature |

| Hybrid/EV Battery Heater 2 Temperature |

| Hybrid/EV Battery Heater 1 Temperature Sensor Voltage |

| Hybrid/EV Battery Heater 2 Temperature Sensor Voltage |

| Hybrid/EV Battery Heater Relay |

| Hybrid/EV Battery Cooling Request Level |

| Hybrid/EV Battery Cooling Status (A/C) |

| Hybrid/EV Battery Refrigerant Temperature (Duct Inlet 1) |

| Hybrid/EV Battery Refrigerant Temperature (Duct Outlet 1) |

| Hybrid/EV Battery Refrigerant Temperature Sensor Voltage (Duct Inlet 1) |

| Hybrid/EV Battery Refrigerant Temperature Sensor Voltage (Duct Outlet 1) |

| Hybrid/EV Battery Refrigerant Pressure 1 |

| Hybrid/EV Battery Refrigerant Pressure Sensor 1 Voltage |

| Target Hybrid/EV Battery Refrigerant Cooling Expansion Valve 1 Position |

| Actual Hybrid/EV Battery Refrigerant Cooling Expansion Valve 1 Position |

| Hybrid/EV Battery Refrigerant Cooling Expansion Valve 1 Drive Status |

| Hybrid/EV Battery Refrigerant Cooling Expansion Valve 1 IC Malfunction |

| Hybrid/EV Battery Refrigerant Cooling Expansion Valve 1 Circuit Open |

| Hybrid/EV Battery Refrigerant Cooling Expansion Valve 1 Overcurrent |

| AC Charging Negative Relay Drive Request |

| AC Charging Positive Relay Drive Request |

| AC Charging Precharge Relay Drive Request |

| AC Charging Negative Relay Status |

| AC Charging Positive Relay Status |

| AC Charging Precharge Relay Status |

| AC Charging Relay Permission Signal Status |

Vehicle Behavior Chart

VEHICLE BEHAVIOR CHART

VEHICLE BEHAVIOR CHART

(a) Vehicle behavior categorized by DTC

If a DTC is output, the vehicle behaves as follows.

| DTC No. | Detection Item | Toyota Prius Vehicle Behavior when DTC is Output |

|---|---|---|

| P056014 | System Voltage (BATT) Circuit Short to Ground or Open | Normal driving |

| P060629 | Hybrid/EV Battery Energy Control Module Processor to Monitoring Processor Signal Invalid |

|

| P060687 | Hybrid/EV Battery Energy Control Module Processor to Monitoring Processor Missing Message |

|

| P060A47 | Hybrid/EV Battery Energy Control Module Monitoring Processor Watchdog / Safety MCU Failure |

|

| P060A87 | Hybrid/EV Battery Energy Control Module Processor from Monitoring Processor Missing Message |

|

| P060B49 | Hybrid/EV Battery Energy Control Module A/D Processing Internal Electronic Failure |

|

| P062F44 | Hybrid/EV Battery Energy Control Module EEPROM Data Memory Failure | Normal driving |

| P062F46 | Hybrid/EV Battery Energy Control Module EEPROM Calibration / Parameter Memory Failure | Normal driving |

| P0A1D94 | Hybrid/EV Powertrain Control Module Unexpected Operation | Hybrid system stopped |

| P0A9563 | High Voltage Fuse Accumulated Load History | Normal driving |

| P0A9B11 | Hybrid/EV Battery Temperature Sensor "A" Circuit Short to Ground | Normal driving |

| P0A9B15 | Hybrid/EV Battery Temperature Sensor "A" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0A9B1C | Hybrid/EV Battery Temperature Sensor "A" Voltage Out of Range | Normal driving |

| P0A9B2A | Hybrid/EV Battery Temperature Sensor "A" Signal Stuck In Range | Normal driving |

| P0AA749 | Hybrid/EV Battery Voltage Isolation Sensor Circuit Internal Electronic Failure | Normal driving |

| P0ABF11 | Hybrid/EV Battery Current Sensor "A" Circuit Short to Ground |

|

| P0ABF15 | Hybrid/EV Battery Current Sensor "A" Circuit Short to Auxiliary Battery or Open |

|

| P0ABF28 | Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure |

|

| P0ABF2A | Hybrid/EV Battery Current Sensor "A" Signal Stuck In Range |

|

| P0AC511 | Hybrid/EV Battery Temperature Sensor "B" Circuit Short to Ground | Normal driving |

| P0AC515 | Hybrid/EV Battery Temperature Sensor "B" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0AC51C | Hybrid/EV Battery Temperature Sensor "B" Voltage Out of Range | Normal driving |

| P0AC52A | Hybrid/EV Battery Temperature Sensor "B" Signal Stuck In Range | Normal driving |

| P0ACA11 | Hybrid/EV Battery Temperature Sensor "C" Circuit Short to Ground | Normal driving |

| P0ACA15 | Hybrid/EV Battery Temperature Sensor "C" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0ACA1C | Hybrid/EV Battery Temperature Sensor "C" Voltage Out of Range | Normal driving |

| P0ACA2A | Hybrid/EV Battery Temperature Sensor "C" Signal Stuck In Range | Normal driving |

| P0AE811 | Hybrid/EV Battery Temperature Sensor "D" Circuit Short to Ground | Normal driving |

| P0AE815 | Hybrid/EV Battery Temperature Sensor "D" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0AE81C | Hybrid/EV Battery Temperature Sensor "D" Voltage Out of Range | Normal driving |

| P0AE82A | Hybrid/EV Battery Temperature Sensor "D" Signal Stuck In Range | Normal driving |

| P0B0E11 | Hybrid/EV Battery Current Sensor "B" Circuit Short to Ground |

|

| P0B0E15 | Hybrid/EV Battery Current Sensor "B" Circuit Short to Auxiliary Battery or Open |

|

| P0B1362 | Hybrid/EV Battery Current Sensor "A"/"B" Signal Compare Failure |

|

| P0BC211 | Hybrid/EV Battery Temperature Sensor "E" Circuit Short to Ground | Normal driving |

| P0BC215 | Hybrid/EV Battery Temperature Sensor "E" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0BC21C | Hybrid/EV Battery Temperature Sensor "E" Voltage Out of Range | Normal driving |

| P0BC22A | Hybrid/EV Battery Temperature Sensor "E" Signal Stuck In Range | Normal driving |

| P0C3000 | Hybrid/EV Battery State of Charge High |

|

| P0C3200 | Hybrid/EV Battery Cooling System "A" Performance | Toyota Prius Vehicle behaves as follows when HV battery temperature is the specified value or higher:

|

| P0C3311 | Hybrid/EV Battery Temperature Sensor "F" Circuit Short to Ground | Normal driving |

| P0C3315 | Hybrid/EV Battery Temperature Sensor "F" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C331C | Hybrid/EV Battery Temperature Sensor "F" Voltage Out of Range | Normal driving |

| P0C332A | Hybrid/EV Battery Temperature Sensor "F" Signal Stuck In Range | Normal driving |

| P0C4211 | Hybrid/EV Battery Pack Coolant Temperature Sensor "A" Circuit Low Circuit Short to Ground | Normal driving |

| P0C4215 | Hybrid/EV Battery Pack Coolant Temperature Sensor "A" Circuit High Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C7C11 | Hybrid/EV Battery Temperature Sensor "G" Circuit Short to Ground | Normal driving |

| P0C7C15 | Hybrid/EV Battery Temperature Sensor "G" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C7C1C | Hybrid/EV Battery Temperature Sensor "G" Voltage Out of Range | Normal driving |

| P0C7C2A | Hybrid/EV Battery Temperature Sensor "G" Signal Stuck In Range | Normal driving |

| P0C8111 | Hybrid/EV Battery Temperature Sensor "H" Circuit Short to Ground | Normal driving |

| P0C8115 | Hybrid/EV Battery Temperature Sensor "H" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C811C | Hybrid/EV Battery Temperature Sensor "H" Voltage Out of Range | Normal driving |

| P0C812A | Hybrid/EV Battery Temperature Sensor "H" Signal Stuck In Range | Normal driving |

| P0C8811 | Hybrid/EV Battery Temperature Sensor "I" Circuit Short to Ground | Normal driving |

| P0C8815 | Hybrid/EV Battery Temperature Sensor "I" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C881C | Hybrid/EV Battery Temperature Sensor "I" Voltage Out of Range | Normal driving |

| P0C882A | Hybrid/EV Battery Temperature Sensor "I" Signal Stuck In Range | Normal driving |

| P0C8D11 | Hybrid/EV Battery Temperature Sensor "J" Circuit Short to Ground | Normal driving |

| P0C8D15 | Hybrid/EV Battery Temperature Sensor "J" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C8D1C | Hybrid/EV Battery Temperature Sensor "J" Voltage Out of Range | Normal driving |

| P0C8D2A | Hybrid/EV Battery Temperature Sensor "J" Signal Stuck In Range | Normal driving |

| P0C9211 | Hybrid/EV Battery Temperature Sensor "K" Circuit Short to Ground | Normal driving |

| P0C9215 | Hybrid/EV Battery Temperature Sensor "K" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C921C | Hybrid/EV Battery Temperature Sensor "K" Voltage Out of Range | Normal driving |

| P0C922A | Hybrid/EV Battery Temperature Sensor "K" Signal Stuck In Range | Normal driving |

| P0C9711 | Hybrid/EV Battery Temperature Sensor "L" Circuit Short to Ground | Normal driving |

| P0C9715 | Hybrid/EV Battery Temperature Sensor "L" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0C971C | Hybrid/EV Battery Temperature Sensor "L" Voltage Out of Range | Normal driving |

| P0C972A | Hybrid/EV Battery Temperature Sensor "L" Signal Stuck In Range | Normal driving |

| P0CA811 | Hybrid/EV Battery Temperature Sensor "M" Circuit Short to Ground | Normal driving |

| P0CA815 | Hybrid/EV Battery Temperature Sensor "M" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0CA81C | Hybrid/EV Battery Temperature Sensor "M" Voltage Out of Range | Normal driving |

| P0CA82A | Hybrid/EV Battery Temperature Sensor "M" Signal Stuck In Range | Normal driving |

| P0CAD11 | Hybrid/EV Battery Temperature Sensor "N" Circuit Short to Ground | Normal driving |

| P0CAD15 | Hybrid/EV Battery Temperature Sensor "N" Circuit Short to Auxiliary Battery or Open | Normal driving |

| P0CAD1C | Hybrid/EV Battery Temperature Sensor "N" Voltage Out of Range | Normal driving |

| P0CAD2A | Hybrid/EV Battery Temperature Sensor "N" Signal Stuck In Range | Normal driving |

| P0CB211 | Hybrid/EV Battery Temperature Sensor "O" Circuit Short to Ground | Normal driving |

| P0CB215 | Hybrid/EV Battery Temperature Sensor "O" Circuit Short to Auxiliary Battery or Open | Normal driving |