Toyota Prius: Heated Oxygen Sensor

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during heated oxygen sensor removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Gas leak from exhaust system is repaired | Inspection after repair |

|

|

CAUTION:

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

CAUTION / NOTICE / HINT

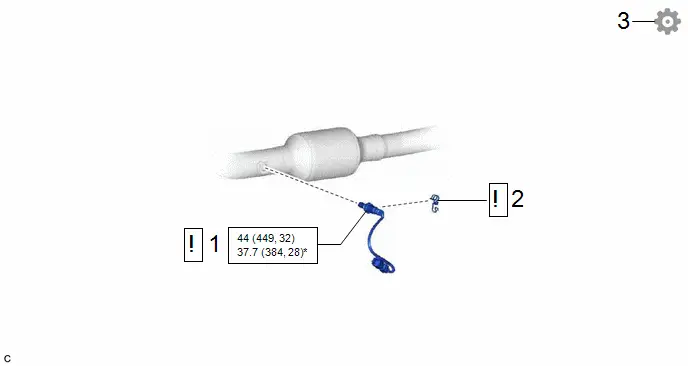

COMPONENTS (REMOVAL)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

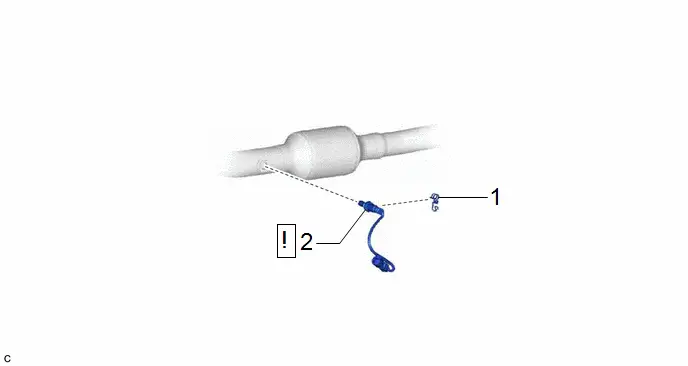

| 1 | WIRING HARNESS CLAMP BRACKET | 82715W | - | - | - |

| 2 | HEATED OXYGEN SENSOR | 89465 |

| - | - |

PROCEDURE

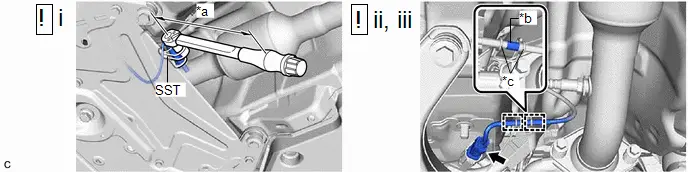

1. REMOVE WIRING HARNESS CLAMP BRACKET

2. REMOVE HEATED OXYGEN SENSOR

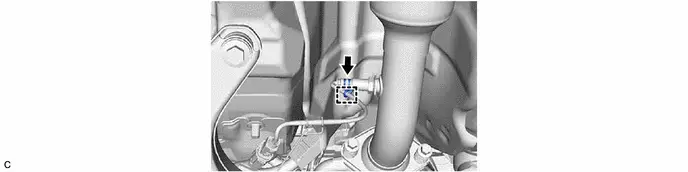

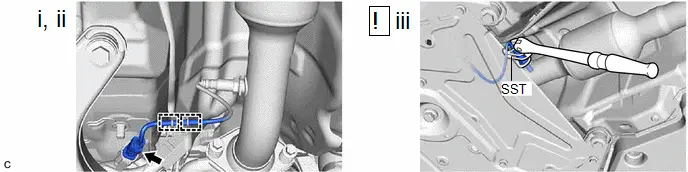

(1) Disconnect the heated oxygen sensor connector.

(2) Disengage the 2 wire harness clamps.

(3) Using SST, remove the heated oxygen sensor from the front exhaust pipe assembly.

SST: 09224-00012

NOTICE:

If the heated oxygen sensor has been struck or dropped, replace it.

Inspection

INSPECTION

PROCEDURE

1. INSPECT HEATED OXYGEN SENSOR

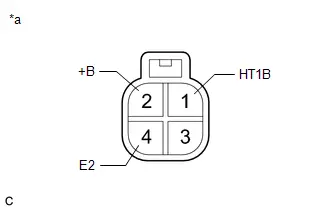

| *a | Component without harness connected (Heated Oxygen Sensor) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition | Result |

|---|---|---|---|

| 1 (HT1B) - 2 ( B) | 20°C (68°F) | 5 to 10 Ω | Ω |

| 1 (HT1B) - 4 (E2) | Always | 10 kΩ or higher | kΩ |

If the result is not as specified, replace the heated oxygen sensor.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | HEATED OXYGEN SENSOR | 89465 |

| - | - |

| 2 | WIRING HARNESS CLAMP BRACKET | 82715W |

| - | - |

| 3 | INSPECT FOR EXHAUST GAS LEAK | - | - | - |

|

| N*m (kgf*cm, ft.*lbf): Specified torque | * | For use with SST |

PROCEDURE

1. INSTALL HEATED OXYGEN SENSOR

| *a | Torque Wrench Fulcrum Length | *b | Tube |

| *c | Wire Harness Clamp | - | - |

(1) Using SST, install the heated oxygen sensor to the front exhaust pipe assembly.

SST: 09224-00012

Torque:

Specified tightening torque :

44 N·m {449 kgf·cm, 32 ft·lbf}

NOTICE:

If the heated oxygen sensor has been struck or dropped, replace it.

HINT:

-

Calculate the torque wrench reading when changing the fulcrum length of the torque wrench.

Click here

-

When using SST (fulcrum length of 30 mm (1.18 in.)) torque wrench (fulcrum length of 180 mm (7.09 in.)):

37.7 N*m (384 kgf*cm, 28 ft.*lbf)

(2) Engage the 2 wire harness clamps so that the tube is positioned as shown in the illustration.

(3) Connect the heated oxygen sensor connector.

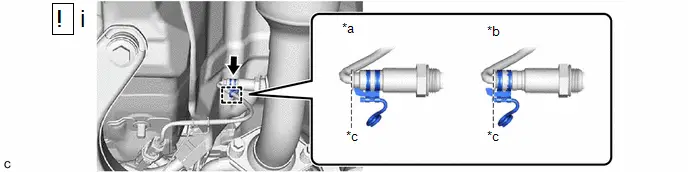

2. INSTALL WIRING HARNESS CLAMP BRACKET

| *a | Correct | *b | Incorrect |

| *c | Standard Position | - | - |

(1) Install the wiring harness clamp bracket to the heated oxygen sensor.

NOTICE:

Align the edge of the wiring harness clamp bracket and heated oxygen sensor as shown in the illustration.

3. INSPECT FOR EXHAUST GAS LEAK

Click here

Toyota Prius (XW60) 2023-2026 Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image