Toyota Prius: Electric Expansion Valve (heating)

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during No. 2 cooler expansion valve removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedures | Effect/Inoperative Function When Necessary Procedures are not Performed | Link |

|---|---|---|---|

| *: Even when not replacing the part, it is necessary to perform the specified necessary procedures after installation. | |||

| Front bumper assembly* | Front television camera view adjustment | Panoramic View Monitor System |

|

| Advanced Park |

| ||

| Heating electric expansion valve (magnet valve assembly) |

| DTCs are stored |

|

CAUTION / NOTICE / HINT

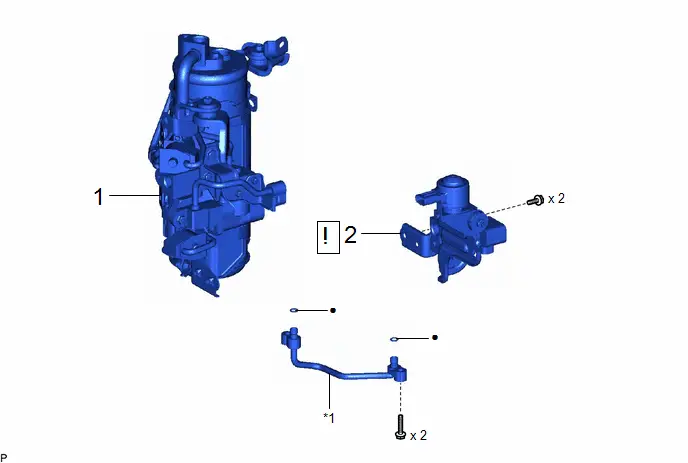

COMPONENTS (REMOVAL)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | ACCUMULATOR ASSEMBLY | 88470H | - | - | - |

| 2 | MAGNET VALVE ASSEMBLY | 88690K |

| - | - |

| *1 | NO. 3 LIQUID TUBE | - | - |

| ● | Non-reusable part | - | - |

PROCEDURE

1. REMOVE ACCUMULATOR ASSEMBLY

Click here

2. REMOVE MAGNET VALVE ASSEMBLY

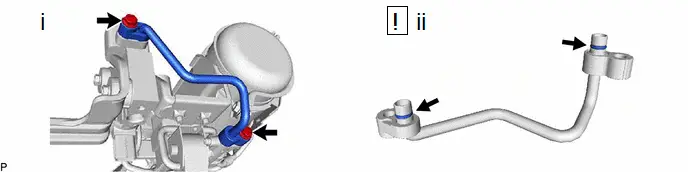

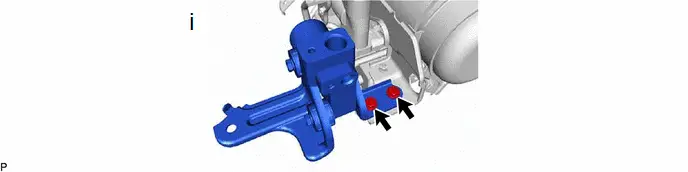

(1) Remove the 2 bolts and No. 3 liquid tube.

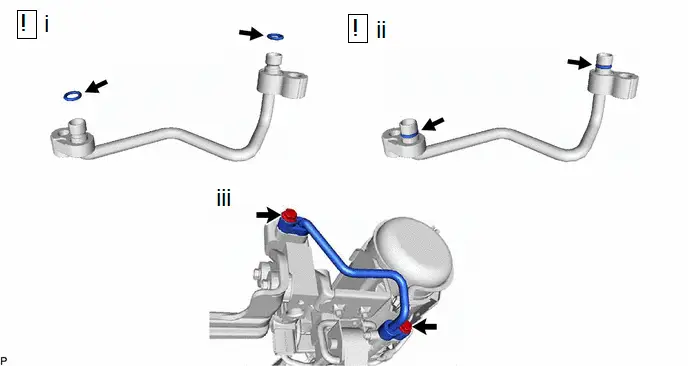

(2) Remove the 2 O-rings from the No. 3 liquid tube.

NOTICE:

Seal the openings of the removed parts using vinyl tape to prevent moisture and foreign matter from entering them.

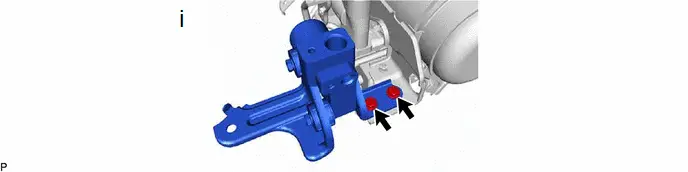

(1) Remove the 2 bolts and magnet valve assembly.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

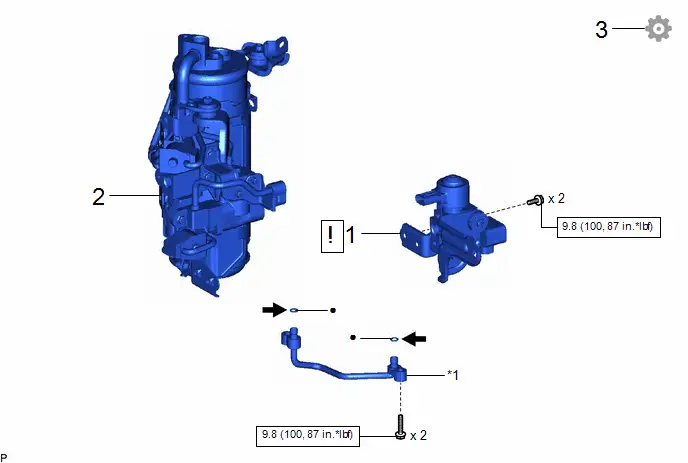

COMPONENTS (INSTALLATION)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | MAGNET VALVE ASSEMBLY | 88690K |

| - | - |

| 2 | ACCUMULATOR ASSEMBLY | 88470H | - | - | - |

| 3 | INITIALIZATION MAGNET VALVE ASSEMBLY | 88690K | - | - |

|

| *1 | NO. 3 LIQUID TUBE | - | - |

| N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

| Compressor oil ND-OIL 11 or equivalent | - | - |

PROCEDURE

1. INSTALL MAGNET VALVE ASSEMBLY

(1) Install the magnet valve assembly with the 2 bolts.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

(1) Remove the vinyl tape, and sufficiently apply compressor oil to 2 new O-rings and the fitting surface of the No. 3 liquid tube.

Compressor Oil:

ND-OIL 11 or equivalent

(2) Install the 2 O-rings to the No. 3 liquid tube.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(3) Install the No. 3 liquid tube with the 2 bolts.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

2. INSTALL ACCUMULATOR ASSEMBLY

Click here

3. INITIALIZATION MAGNET VALVE ASSEMBLY

Click here

Toyota Prius (XW60) 2023-2026 Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image