Toyota Prius: Can Communication System (for Hev Model)

- Precaution

- Parts Location

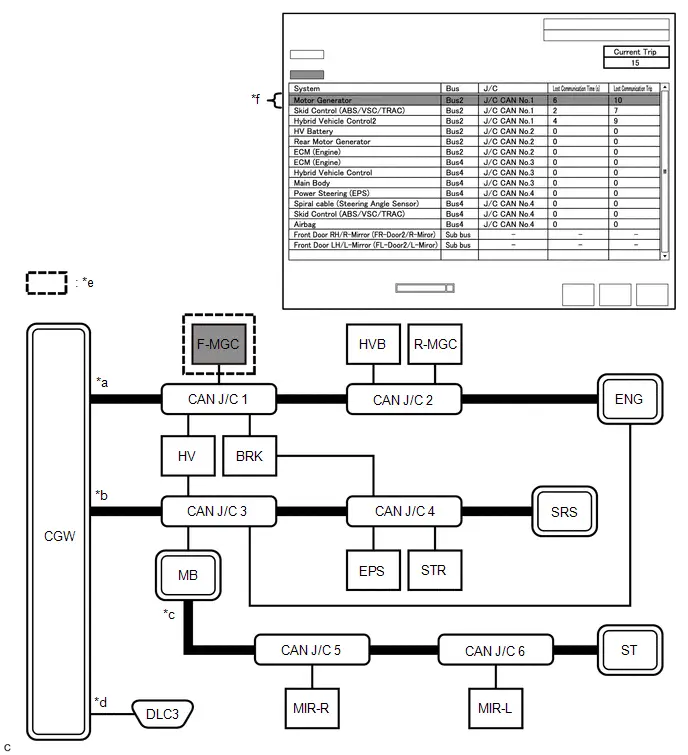

- System Diagram

- System Description

- How To Proceed With Troubleshooting

- Utility

- Terminals Of Ecu

- Diagnosis System

- Data List / Active Test

- Lost Communication with DC/DC Converter Control Module "C" Missing Message (U01BD87,U029100,U029187,U115087,U117687,U117B87)

- Lost Communication with ECM/PCM "A" (ch2) Missing Message (U111A87,U115000,U115087,U115487,U115987,U117008,U117087,U117D87,U11BC87)

- Check CAN Communication Connection

- Hybrid Vehicle Control ECU Communication Stop Mode

- Brake Booster (Skid Control ECU) Communication Stop Mode

- Clearance Warning ECU Communication Stop Mode

- Air Conditioning Amplifier Communication Stop Mode

- Power Steering ECU Communication Stop Mode

- Steering Angle Sensor Communication Stop Mode

- Shift Control ECU Communication Stop Mode

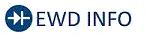

- Battery ECU Communication Stop Mode

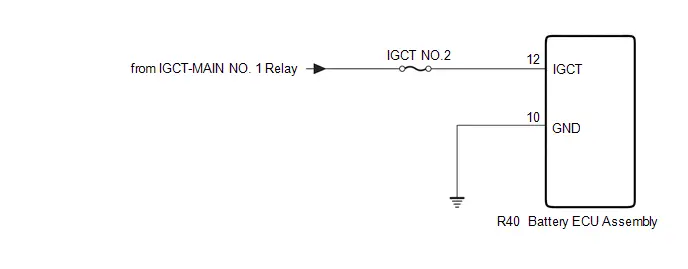

- Integration Control Supply Communication Stop Mode

- Main Body ECU Communication Stop Mode

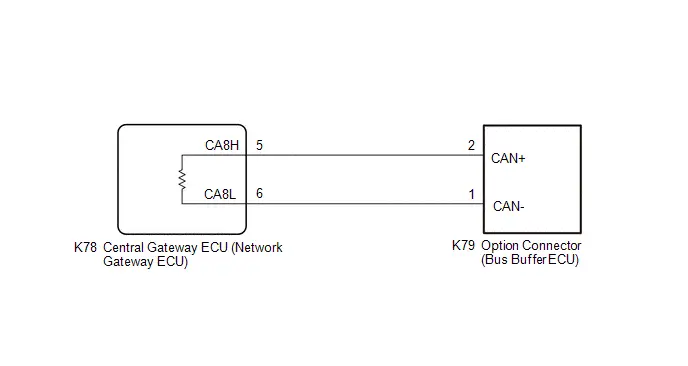

- Bus Buffer ECU Communication Stop Mode

- Rear Television Camera Communication Stop Mode

- Check Bus 1 Line

- Check Bus 2 Line

- Check Bus 3 Line

- Check Bus 4 Line

- Check Bus 5 Line

- Check Bus 6 Line

- Check Bus 7 Line

Precaution

PRECAUTION

PRECAUTIONS FOR DISCONNECTING CABLE FROM NEGATIVE (-) AUXILIARY BATTERY TERMINAL

NOTICE:

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

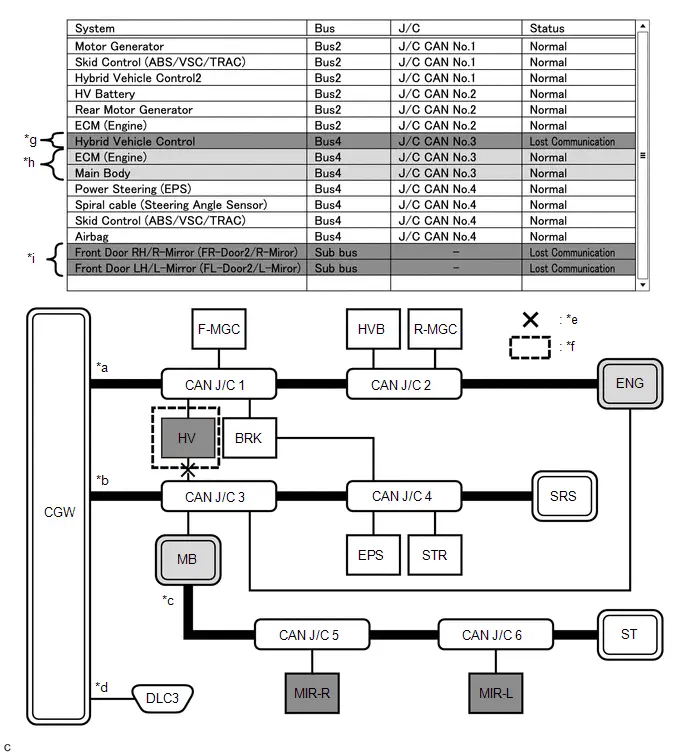

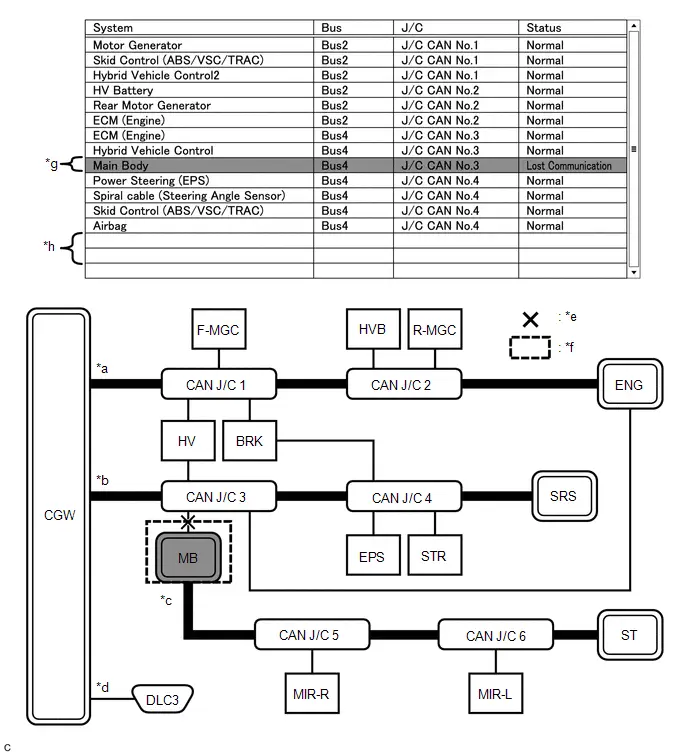

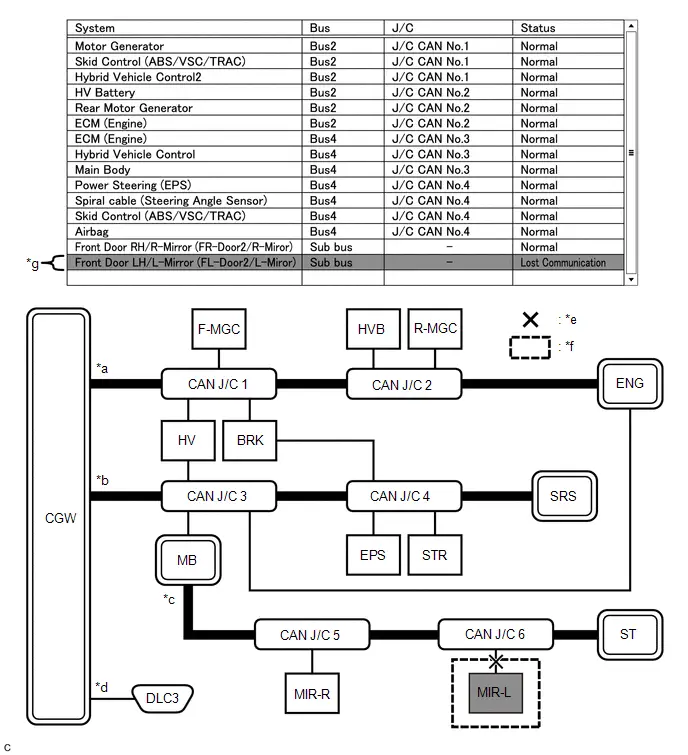

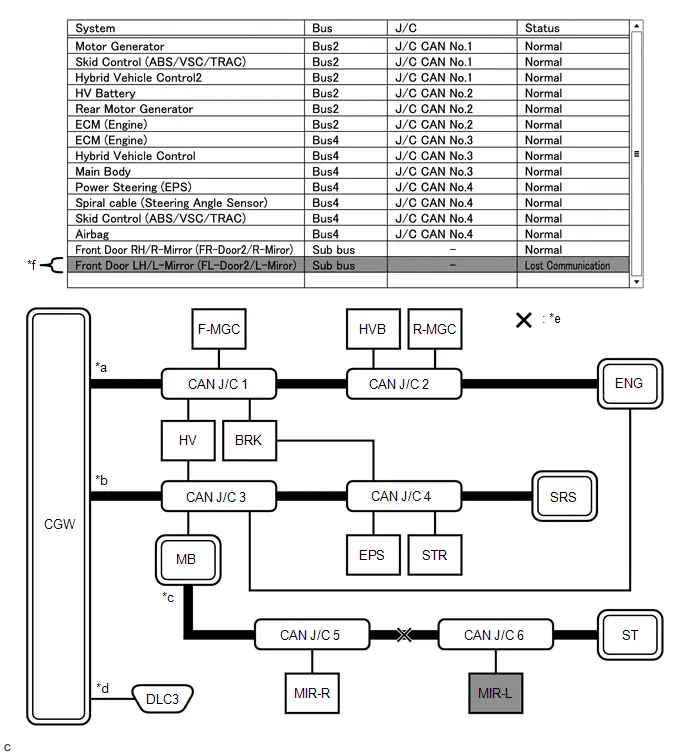

CAN COMMUNICATION SYSTEM TROUBLESHOOTING

(a) Because the order of diagnosis is important to allow correct diagnosis, make sure to begin troubleshooting using How to Proceed with Troubleshooting when CAN communication system related DTCs are output.

Click here

(b) Precaution for steering system handling

(1) Be careful when replacing parts. Incorrect replacement could affect the performance of the steering system and result in hazardous driving.

Click here

(c) Precaution for SRS airbag system handling

NOTICE:

This Toyota Prius vehicle is equipped with a Supplemental Restraint System (SRS) which includes parts such as airbags for the driver and front passenger. Failure to carry out service operations in the correct sequence could cause unexpected SRS deployment during servicing and may cause a serious accident. Before servicing (including removal or installation of parts, inspection or replacement), be sure to read Precaution for SRS.

Click here

(d) Precaution for when disconnecting a wire harness from a CAN junction connector

(1) When disconnecting a wire harness from a CAN junction connector, use tape or tags to identify each connector and make sure to reconnect each connector to its original location on the CAN junction connector.

HINT:

- Reconnecting a connector to a location other than its original location on the CAN junction connector will not affect system performance. However, reconnecting connectors to their original locations makes future maintenance easier and avoids negative effects on wire harnesses, such as excessive tension.

-

For information on how to identify the ECUs or sensors connected to the CAN junction connector, refer to Terminals of ECU.

Click here

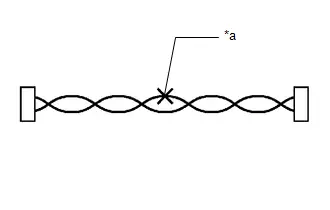

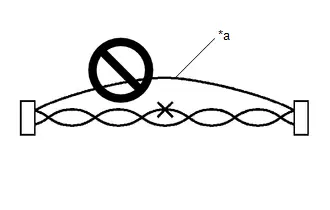

(e) Bus line repair

(1) After repairing a bus line with solder, wrap the repaired area with electrical tape.

| *a | Soldered Area to Be Wrapped with Electrical Tape |

NOTICE:

- When installing, make sure that these lines are twisted, because CAN bus lines are likely to be influenced by electrical noise if the bus lines are not twisted.

- Ensure that there is no gap between the CANH wire and CANL wire.

- Make sure that the distance between the first twist of the wires and the connector is less than 80 mm (3.15 in).

- When repairing the CAN bus lines, do not change the length of the lines. (Make sure that the length of the CANH bus line and CANL bus line are the same.)

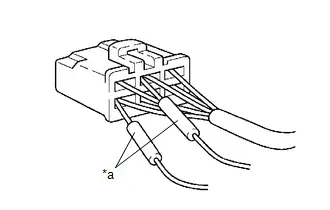

(2) Do not use bypass wiring between connectors.

| *a | Bypass Wire |

NOTICE:

- The ability of the twisted bus lines to resist interference will be lost if bypass wiring is used.

- Do not use a twisted pair of wires for bypass wiring.

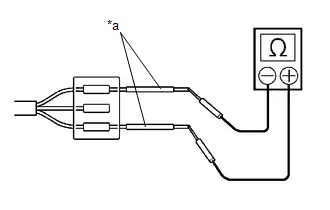

(f) Connector handling

(1) When checking resistance with a tester, insert the tester probes from the backside (harness side) of the connector.

| *a | Tester Probe |

(2) When it is not possible to insert the tester from the backside of the connector, using service wires, measure from the front side of the connector.

| *a | Service Wire |

(g) Precaution for when replacing a gateway function equipped ECU (sub bus monitoring ECU)

(1) When replacing a gateway equipped function ECU (sub bus monitoring ECU) with one which was installed to another Toyota Prius vehicle, perform initialization of the sub bus monitoring ECU in order to clear stored bus information.

Click here

NOTICE:

If the stored bus information does not match the current sub bus configuration, DTCs may be stored and fail-safe functions may operate.

HINT:

It is not necessary to perform initialization of a gateway monitoring ECU (sub bus monitoring ECU) when using a sub bus monitoring ECU which was installed to another Toyota Prius vehicle with the same sub bus configuration.

(h) Precautions for when a gateway function equipped ECU (sub bus monitor ECU) detects communication DTCs for ECUs not connected to the ECU

(1) Refer to precautions when replacing a gateway function equipped ECU (sub bus monitoring ECU) and initialize the connection information of the ECU.

Click here

(2) Clear the DTCs and check that no DTCs are output.

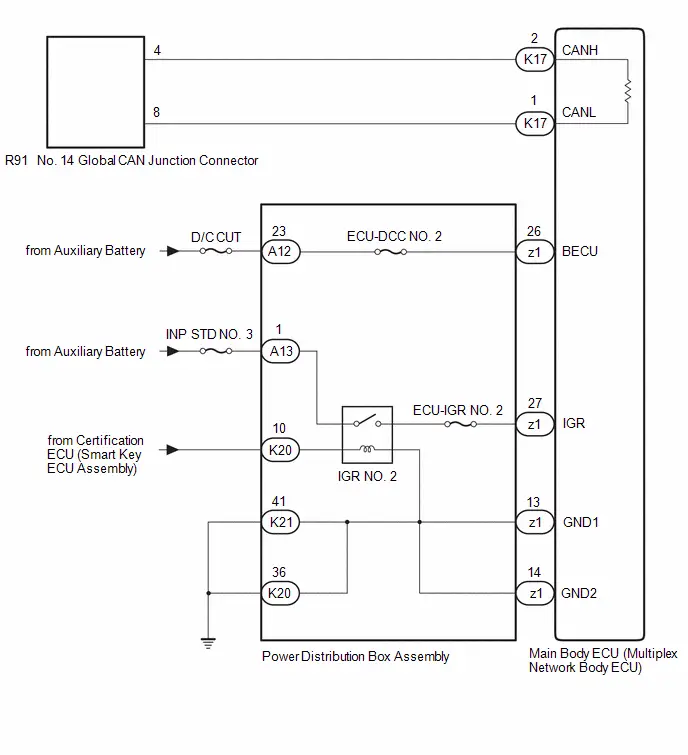

(i) Difference between genuine navigation receivers/radio and display receivers and optional navigation receivers/radio and display receivers

(1) Some optional navigation receivers/radio and display receivers are available as CAN compatible devices. Be aware that some optional navigation receivers/radio and display receivers do not have the same diagnostic features or characteristics of genuine navigation receivers/radio and display receivers.

NOTICE:

- Optional navigation receivers/radio and display receivers receive data from the CAN communication system. However, most optional navigation receivers/radio and display receivers do not send signals to the CAN bus main line.

- Most optional navigation receivers/radio and display receivers will not be displayed on the "CAN Bus Check" screen of the GTS.

- When checking for DTCs using the GTS, DTCs for optional navigation receivers/radio and display receivers will not be displayed on the GTS.

SENSOR EXPRESSIONS

(a) The descriptions for the blind spot monitor sensors differ depending on the system. The expressions listed in the table below are used in this Repair Manual.

| Part Name | Actual Part Name |

|---|---|

| Blind spot monitor sensor LH (B) | Blind spot monitor sensor LH |

| Blind spot monitor sensor RH (A) | Blind spot monitor sensor RH |

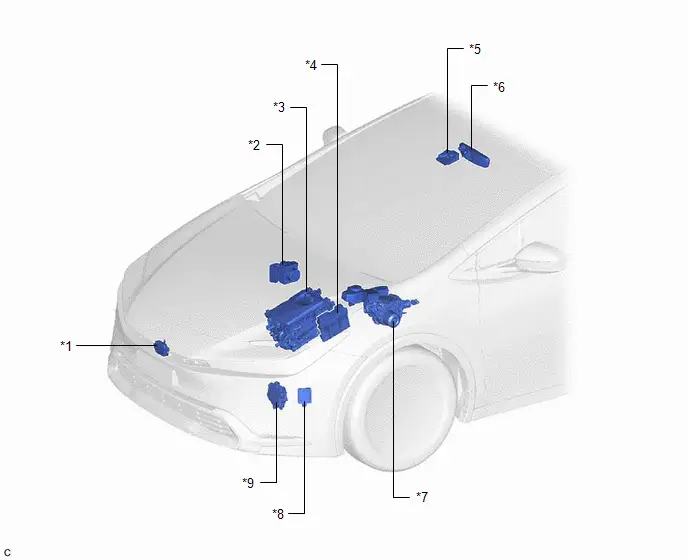

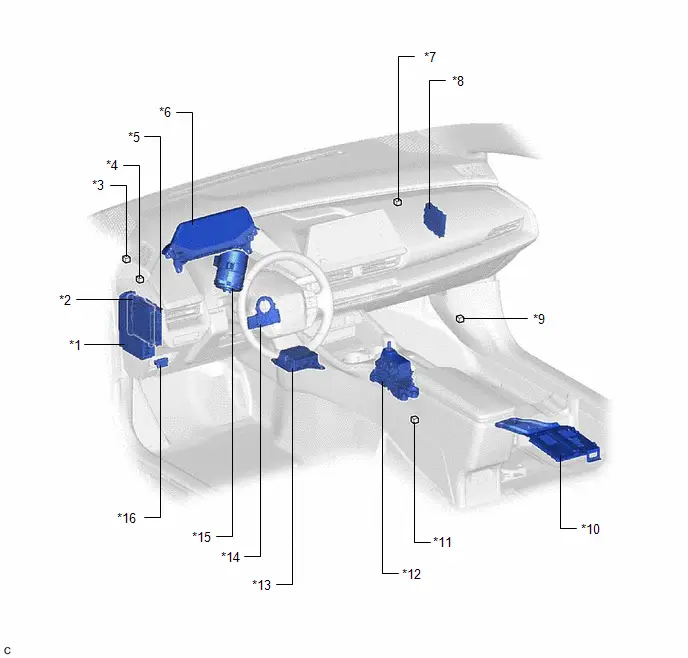

Parts Location

PARTS LOCATION

ILLUSTRATION

| *1 | MILLIMETER WAVE RADAR SENSOR ASSEMBLY | *2 | NO. 2 SKID CONTROL ECU (BRAKE ACTUATOR ASSEMBLY) |

| *3 | INVERTER WITH CONVERTER ASSEMBLY | *4 | ECM |

| *5 | FORWARD RECOGNITION CAMERA | *6 | INNER REAR VIEW MIRROR ASSEMBLY (w/ Digital Inner Mirror System) |

| *7 | NO. 1 SKID CONTROL ECU (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY) | *8 | FRONT SIDE RADAR SENSOR (A) (w/ Front Side Radar Sensor System) |

| *9 | SHIFT CONTROL ACTUATOR ASSEMBLY | - | - |

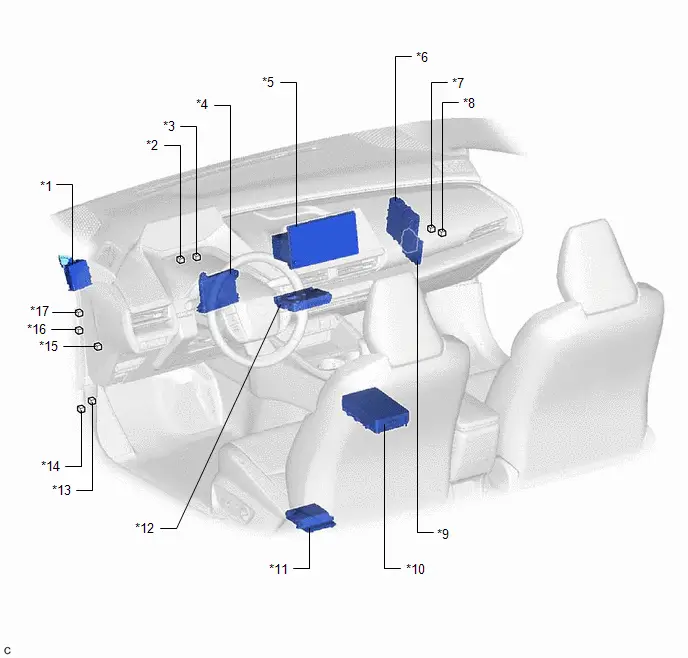

ILLUSTRATION

| *1 | POWER DISTRIBUTION BOX ASSEMBLY | *2 | MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| *3 | NO. 2 GLOBAL CAN JUNCTION CONNECTOR | *4 | NO. 4 GLOBAL CAN JUNCTION CONNECTOR |

| *5 | CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) | *6 | COMBINATION METER ASSEMBLY |

| *7 | NO. 5 GLOBAL CAN JUNCTION CONNECTOR | *8 | CENTRAL GATEWAY ECU (NETWORK GATEWAY ECU) |

| *9 | NO. 15 GLOBAL CAN JUNCTION CONNECTOR | *10 | PARKING ASSIST ECU (w/ Panoramic View Monitor System) |

| *11 | NO. 12 GLOBAL CAN JUNCTION CONNECTOR (w/ Panoramic View Monitor System) | *12 | TRANSMISSION FLOOR SHIFT ASSEMBLY |

| *13 | AIRBAG ECU ASSEMBLY | *14 | STEERING SENSOR |

| *15 | POWER STEERING ECU ASSEMBLY | *16 | DLC3 |

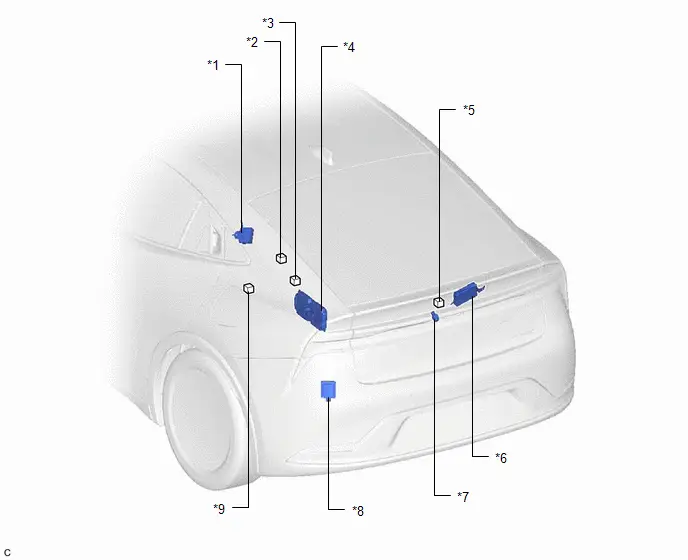

ILLUSTRATION

| *1 | Toyota Prius Vehicle APPROACHING SPEAKER CONTROLLER | *2 | NO. 10 GLOBAL CAN JUNCTION CONNECTOR |

| *3 | NO. 6 GLOBAL CAN JUNCTION CONNECTOR | *4 | AIR CONDITIONING AMPLIFIER ASSEMBLY |

| *5 | RADIO AND DISPLAY RECEIVER ASSEMBLY | *6 | HYBRID Toyota Prius Vehicle CONTROL ECU |

| *7 | NO. 1 CAN JUNCTION CONNECTOR | *8 | NO. 3 GLOBAL CAN JUNCTION CONNECTOR |

| *9 | CLEARANCE WARNING ECU ASSEMBLY (w/ Intuitive Parking Assist System) | *10 | INTEGRATION CONTROL SUPPLY |

| *11 | POSITION CONTROL ECU ASSEMBLY LH (w/ Seat Position Memory System) | *12 | DCM (TELEMATICS TRANSCEIVER) (w/ Telematics Transceiver) |

| *13 | NO. 13 GLOBAL CAN JUNCTION CONNECTOR | *14 | OPTION CONNECTOR (BUS BUFFER ECU) |

| *15 | NO. 7 GLOBAL CAN JUNCTION CONNECTOR | *16 | NO. 2 JUNCTION CONNECTOR |

| *17 | NO. 2 CAN JUNCTION CONNECTOR | - | - |

ILLUSTRATION

| *1 | TIRE PRESSURE WARNING ECU AND RECEIVER | *2 | NO. 14 GLOBAL CAN JUNCTION CONNECTOR |

| *3 | NO. 11 GLOBAL CAN JUNCTION CONNECTOR | *4 | BATTERY ECU ASSEMBLY |

| *5 | NO. 16 GLOBAL CAN JUNCTION CONNECTOR (w/ Parking Assist Monitor System) | *6 | MULTIPLEX NETWORK DOOR ECU (w/ Power Back Door System) |

| *7 | REAR TELEVISION CAMERA ASSEMBLY (w/ Parking Assist Monitor System) | *8 | BLIND SPOT MONITOR SENSOR LH (B) |

| *9 | NO. 2 CAN JUNCTION TERMINAL | - | - |

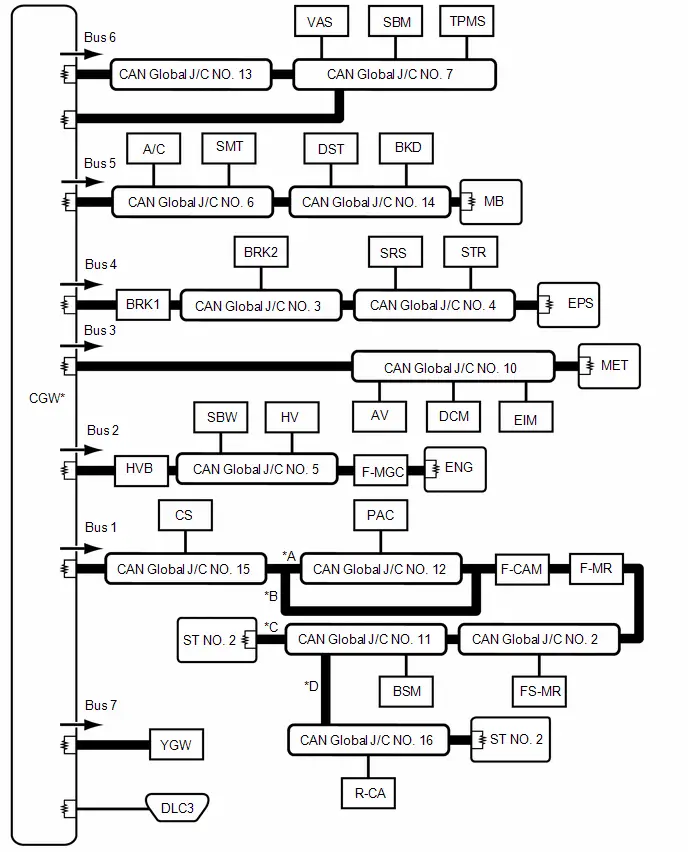

System Diagram

SYSTEM DIAGRAM

OVERALL CAN BUS DIAGRAM

| *A | w/ Panoramic View Monitor System | *B | w/o Panoramic View Monitor System |

| *C | w/o Parking Assist Monitor System | *D | w/ Parking Assist Monitor System |

| CAN Main Bus Line |

| Terminating Resistor |

| CAN Branch Line | * | Gateway Function Equipped ECU |

| Bus Monitoring Direction | - | - |

| Connected to | Code | ECU/Sensor Name | GTS Display | Applicability |

|---|---|---|---|---|

| - | CGW | Central Gateway ECU (Network Gateway ECU) | - | Installed on all Toyota Prius vehicles |

| - | DLC3 | DLC3 | - | Installed on all vehicles |

| Bus 1 | CS | Clearance Warning ECU Assembly | Clearance Warning (Intuitive Parking Assist) | w/ Intuitive Parking Assist System |

| F-CAM | Forward Recognition Camera | Front Camera Module | Installed on all Toyota Prius vehicles | |

| F-MR | Millimeter Wave Radar Sensor Assembly | Front Radar | Installed on all vehicles | |

| FS-MR | Front Side Radar Sensor (A) | Front Side Radar "A" | w/ Front Side Radar Sensor System | |

| PAC | Parking Assist ECU | Panoramic View Monitor / Circumference Monitoring Camera Control Module | w/ Panoramic View Monitor System | |

| BSM | Blind Spot Monitor Sensor LH (B) | Blind Spot Monitor "B" | Installed on all Toyota Prius vehicles | |

| R-CA | Rear Television Camera Assembly | Parking Assist Monitor System / Rear Camera | w/ Parking Assist Monitor System | |

| CAN Global J/C NO. 2 | No. 2 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| CAN Global J/C NO. 11 | No. 11 Global CAN Junction Connector | - | Installed on all vehicles | |

| CAN Global J/C NO. 12 | No. 12 Global CAN Junction Connector | - | w/ Panoramic View Monitor System | |

| CAN Global J/C NO. 15 | No. 15 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| CAN Global J/C NO. 16 | No. 16 Global CAN Junction Connector | - | w/ Parking Assist Monitor System | |

| ST NO. 2 | No. 2 CAN Junction Terminal | - | Installed on all Toyota Prius vehicles | |

| Bus 2 | HVB | Battery ECU Assembly | HV Battery | Installed on all Toyota Prius vehicles |

| SBW | Transmission Floor Shift Assembly | Transmission Control | Installed on all vehicles | |

| HV | Hybrid Toyota Prius Vehicle Control ECU | Hybrid Vehicle Control | Installed on all vehicles | |

| F-MGC | Inverter with Converter Assembly | Motor Generator | Installed on all Toyota Prius vehicles | |

| ENG | ECM | ECM (Engine) | Installed on all vehicles | |

| CAN Global J/C NO. 5 | No. 5 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| Bus 3 | DCM | DCM (Telematics Transceiver) | DCM | w/ Telematics Transceiver |

| EIM | Inner Rear View Mirror Assembly | Digital Rear-View Mirror | w/ Digital Inner Mirror System | |

| AV | Radio and Display Receiver Assembly | Display and Navigation (AVN) | Installed on all Toyota Prius vehicles | |

| MET | Combination Meter Assembly | Combination Meter | Installed on all vehicles | |

| CAN Global J/C NO. 10 | No. 10 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| Bus 4 | SRS | Airbag ECU Assembly | Airbag | Installed on all Toyota Prius vehicles |

| BRK2 | No. 2 Skid Control ECU (Brake Actuator Assembly) | Skid Control (ABS/VSC/TRAC) | Installed on all Toyota Prius vehicles | |

| BRK1 | No. 1 Skid Control ECU (Brake Booster with Master Cylinder Assembly) | Brake Booster | Installed on all Toyota Prius vehicles | |

| STR | Steering Sensor | Spiral cable (Steering Angle Sensor) | Installed on all vehicles | |

| EPS | Power Steering ECU Assembly | Power Steering (EPS) | Installed on all Toyota Prius vehicles | |

| CAN Global J/C NO. 3 | No. 3 Global CAN Junction Connector | - | Installed on all vehicles | |

| CAN Global J/C NO. 4 | No. 4 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| Bus 5 | A/C | Air Conditioning Amplifier Assembly | Air Conditioning Amplifier | Installed on all Toyota Prius vehicles |

| SMT | Certification ECU (Smart Key ECU Assembly) |

| Installed on all Toyota Prius vehicles | |

| DST | Position Control ECU Assembly LH | D-Seat | w/ Seat Position Memory System | |

| BKD | Multiplex Network Door ECU | Back Door | Installed on all Toyota Prius vehicles | |

| MB | Main Body ECU (Multiplex Network Body ECU) | Main Body | Installed on all vehicles | |

| CAN Global J/C NO. 6 | No. 6 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| CAN Global J/C NO. 14 | No. 14 Global CAN Junction Connector | - | Installed on all vehicles | |

| Bus 6 | VAS | Toyota Prius Vehicle Approaching Speaker Controller | Acoustic Vehicle Alerting System | Installed on all vehicles |

| TPMS | Tire Pressure Warning ECU and Receiver | Tire Pressure | Installed on all Toyota Prius vehicles | |

| SBM | Integration Control Supply | Sub Battery System | Installed on all vehicles | |

| CAN Global J/C NO. 7 | No. 7 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| CAN Global J/C NO. 13 | No. 13 Global CAN Junction Connector | - | Installed on all vehicles | |

| Bus 7 | YGW | Option Connector (Bus Buffer ECU) | Remote Engine Starter | w/ CAN Compatible Optional Devices |

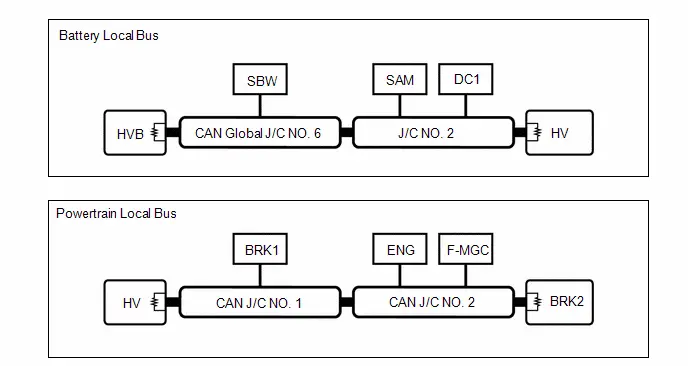

| Battery Local Bus | HVB | Battery ECU Assembly | - | Installed on all Toyota Prius vehicles |

| SBW | Transmission Floor Shift Assembly | - | Installed on all vehicles | |

| SAM | Shift Control Actuator Assembly | - | Installed on all Toyota Prius vehicles | |

| DC1 | Inverter with Converter Assembly | - | Installed on all vehicles | |

| HV | Hybrid Toyota Prius Vehicle Control ECU | - | Installed on all vehicles | |

| CAN Global J/C NO. 6 | No. 6 Global CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| J/C NO. 2 | No. 2 Junction Connector | - | Installed on all vehicles | |

| Powertrain Local Bus | BRK2 | No. 2 Skid Control ECU (Brake Actuator Assembly) | - | Installed on all Toyota Prius vehicles |

| ENG | ECM | - | Installed on all vehicles | |

| BRK1 | No. 1 Skid Control ECU (Brake Booster with Master Cylinder Assembly) | - | Installed on all Toyota Prius vehicles | |

| F-MGC | Inverter with Converter Assembly | - | Installed on all vehicles | |

| HV | Hybrid Toyota Prius Vehicle Control ECU | - | Installed on all vehicles | |

| CAN J/C NO. 1 | No. 1 CAN Junction Connector | - | Installed on all Toyota Prius vehicles | |

| CAN J/C NO. 2 | No. 2 CAN Junction Connector | - | Installed on all vehicles |

System Description

SYSTEM DESCRIPTION

BRIEF DESCRIPTION

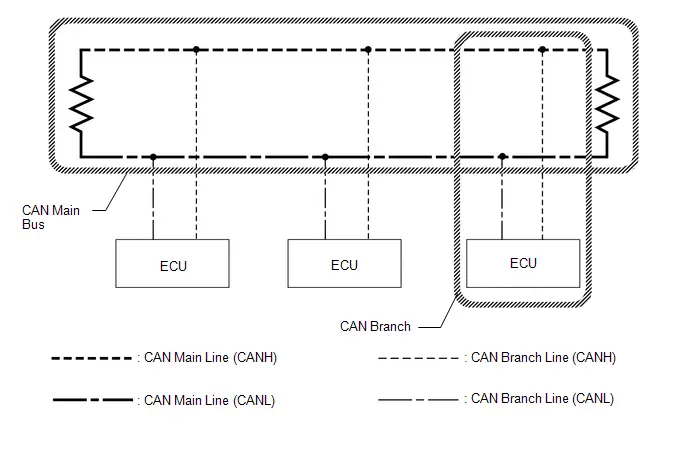

(a) The Controller Area Network (CAN) is a serial data communication system for real time application. It is a vehicle multiplex communication system which has a high communication speed and the ability to detect malfunctions.

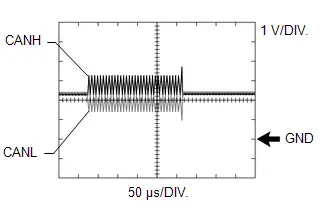

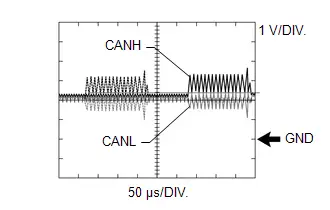

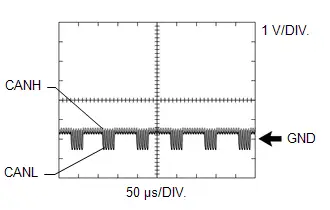

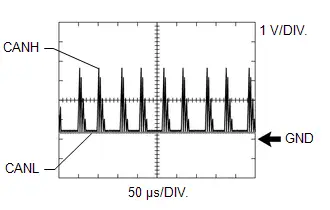

(b) Using the CANH and CANL bus lines as a pair, CAN communication is performed using a voltage differential. (A base voltage is applied to the pair of lines and a voltage differential is created when communicating.)

(c) Many ECUs or sensors installed to the Toyota Prius vehicle operate by sharing information and communicating with each other.

(d) 2 resistors which are necessary for communication are used in a CAN bus main line.

DEFINITION OF TERMS

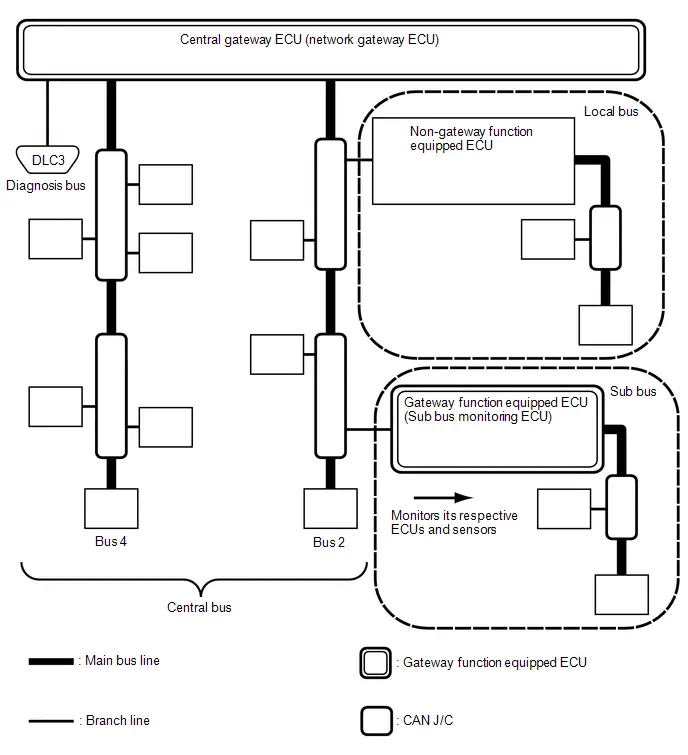

(a) Central bus

(1) The central bus is a term used to describe all buses directly connected to the central gateway ECU (network gateway ECU).

HINT:

A bus is displayed as Bus on the "Communication Bus Check" screen of the GTS.

(b) Sub bus

(1) A sub bus is a bus that has a gateway function equipped ECU in order to communicate with the central bus and other sub buses.

HINT:

- A sub bus is displayed as Sub bus on the "Communication Bus Check" screen of the GTS.

- When Sub bus is selected on the "Communication Bus Check" screen, ECUs and sensors connected to non-CAN networks such as LIN may also be displayed in addition to the ECUs and sensors connected to sub buses in the CAN network.

(c) Local bus

(1) A local bus is a bus that does not have the ability to communicate with other buses. ECUs and sensors on a local bus can only communicate with other ECUs and sensors on the same bus.

NOTICE:

Gateway function not equipped ECU is a generic name for ECUs not connected to the central gateway ECU (network gateway ECU) with a gateway function.

(d) CAN J/C

(1) A CAN junction connector is a connector that connects branch lines to a main bus.

(e) Main bus

(1) A main bus line is the wire harness that runs between the 2 terminating resistors of a bus.

(f) Branch

(1) A branch line is a wire harness that connects an ECU or sensor to a main bus line.

(g) Terminating resistors

(1) Terminating resistors which maintain a stable signal inside the CAN bus are installed. 2 resistors of 120 Ω each located at each end of the bus are necessary.

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

PRECAUTIONS WHEN TROUBLESHOOTING

NOTICE:

- Because the order of diagnosis is important to allow correct diagnosis, make sure to begin troubleshooting using How to Proceed with Troubleshooting when CAN communication system related DTCs are output.

-

If the CAN communication system is malfunctioning, check the contact pressure of the terminals in connectors, as insufficient terminal contact pressure may be the cause.

Click here

- Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the Toyota Prius vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) auxiliary battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

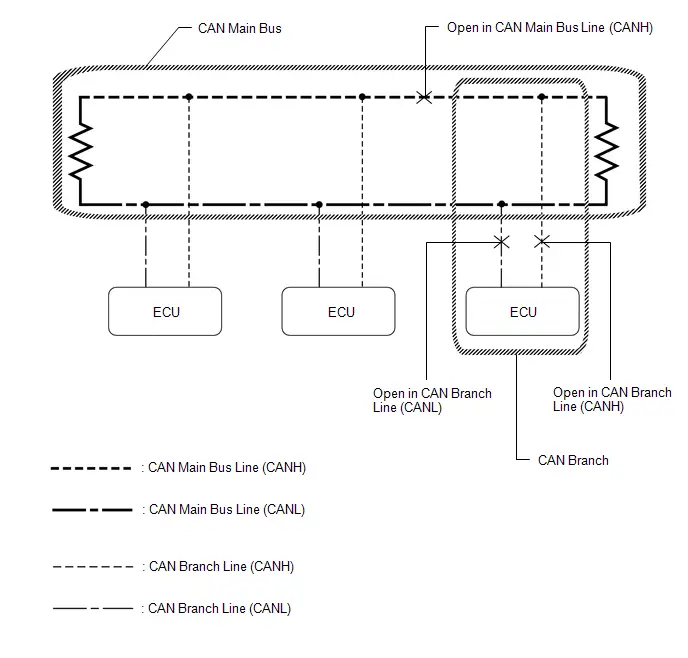

(a) CAN communication DTCs are output for CAN main bus and CAN branch malfunctions as well as for internal malfunctions or power source malfunctions of ECUs or sensors for systems using CAN communication. Therefore, when DTCs for internal malfunctions or power source malfunctions of corresponding systems are output at the same time as CAN communication DTCs, troubleshoot according to the internal malfunction and power source malfunction DTCs.

(b) The DLC3 inspection can only be used to detect malfunctions in the diagnosis bus (the bus which connects the DLC3 to the central gateway ECU (network gateway ECU)).

(c) An open in a branch for ECUs or sensors that are connected to the CAN main bus can be checked by performing a CAN bus check using the GTS. (This inspection is possible when all the main bus lines are normal.)

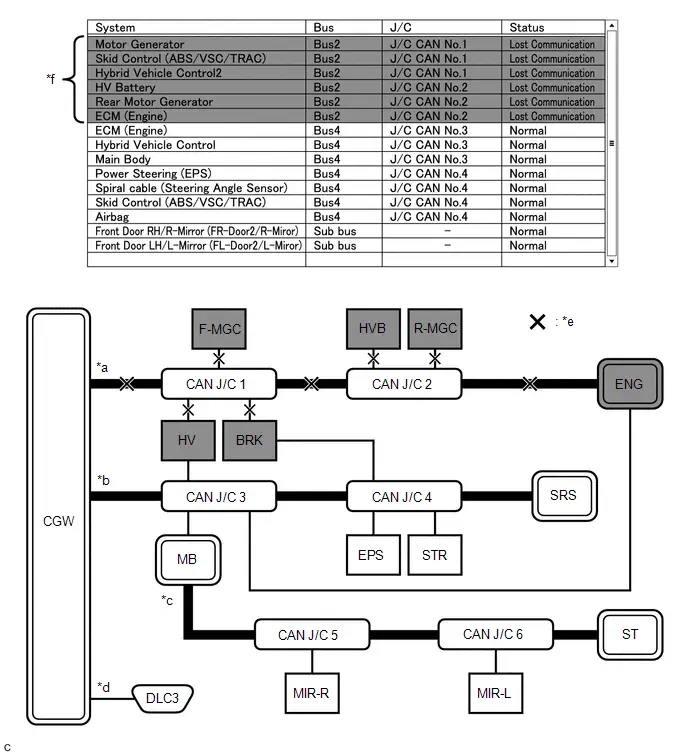

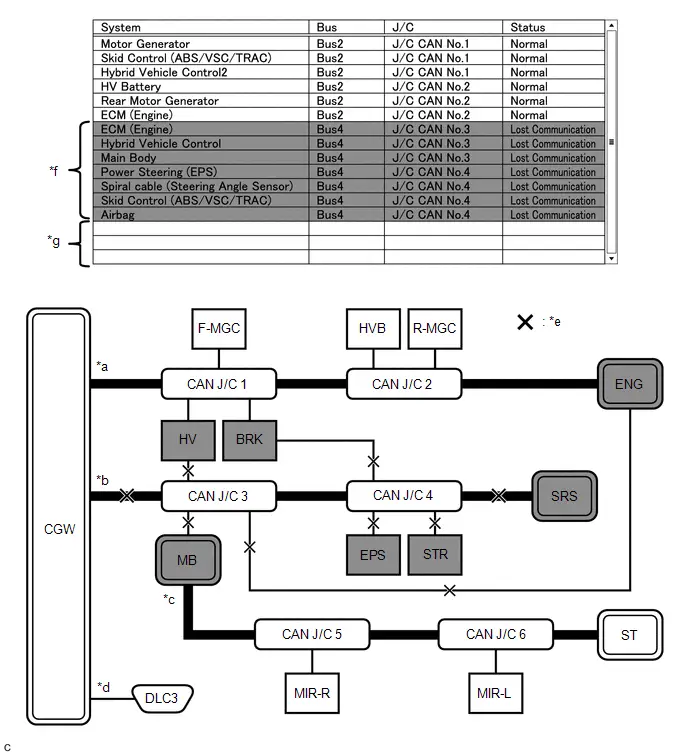

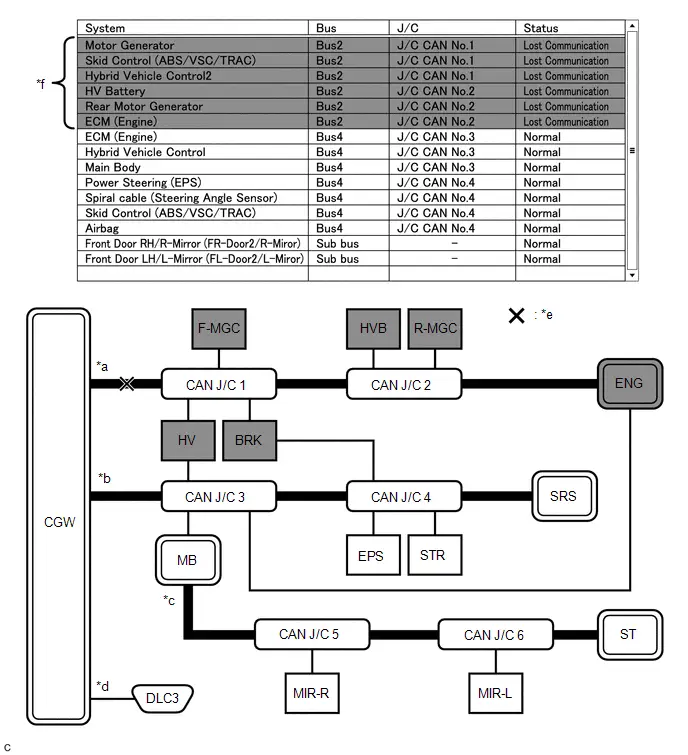

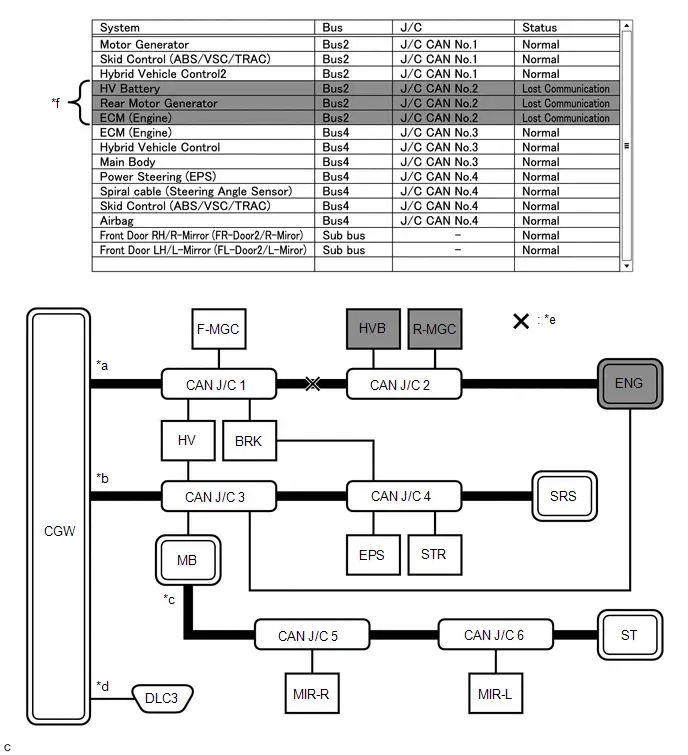

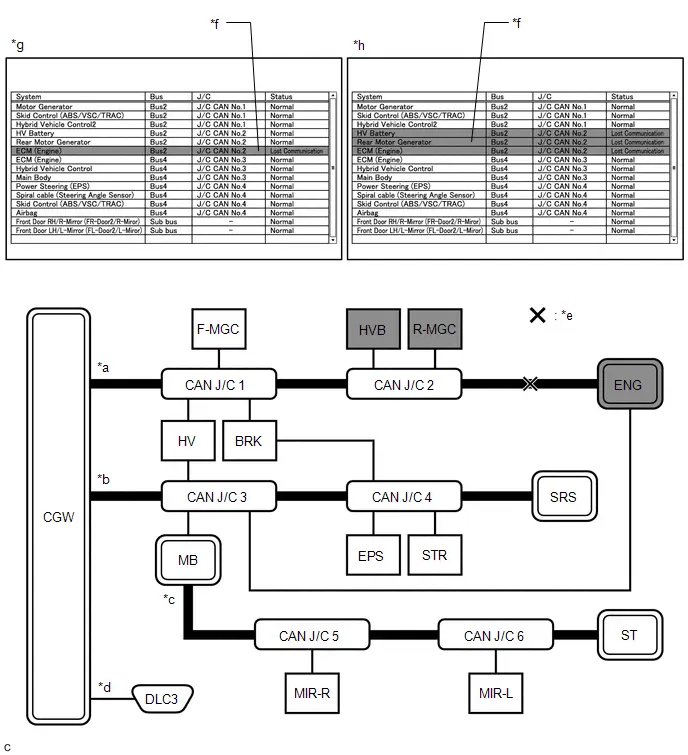

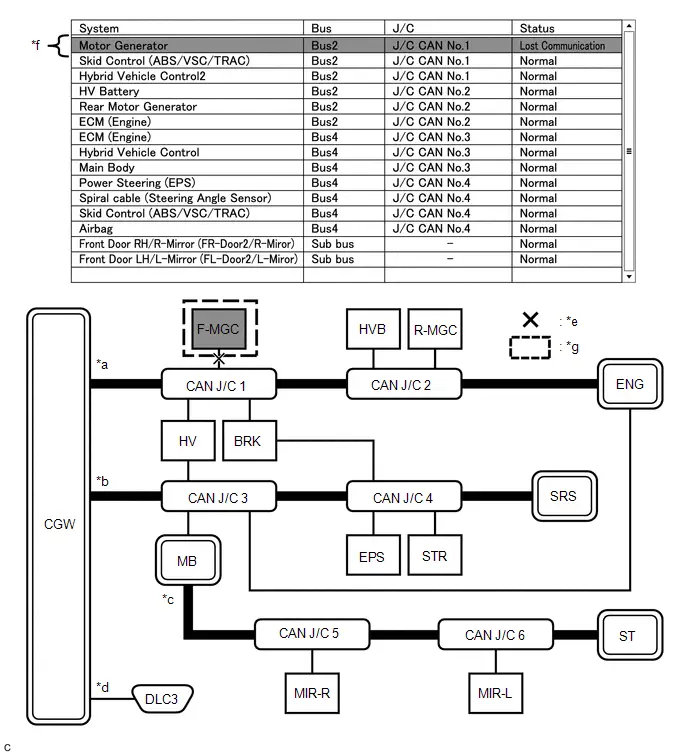

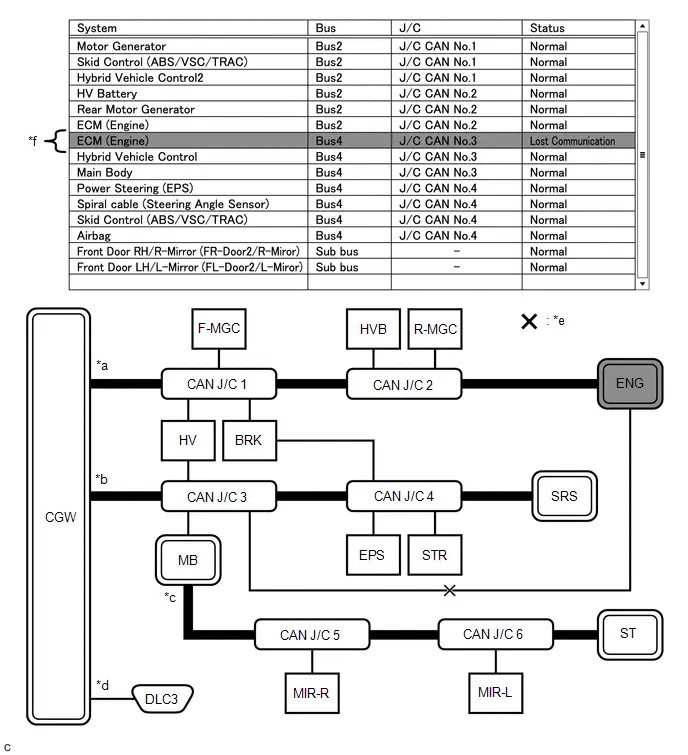

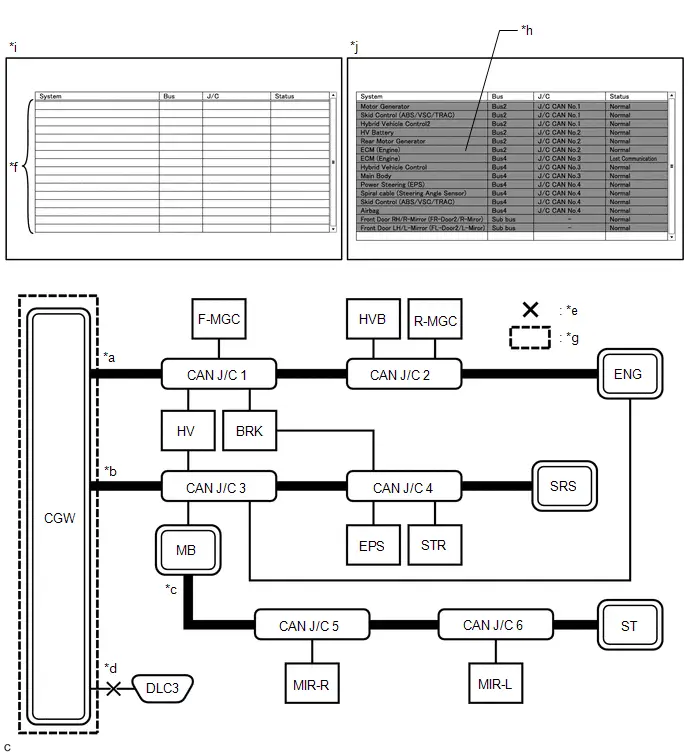

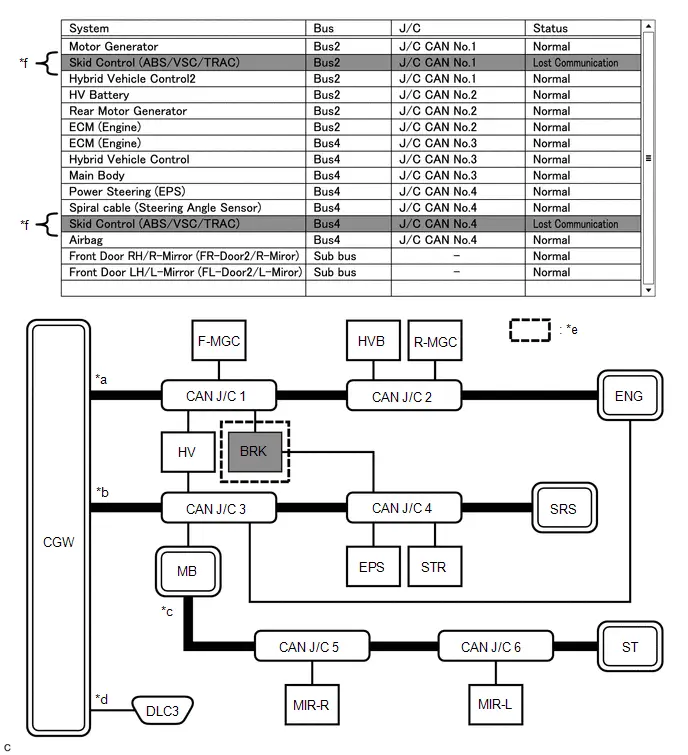

(d) In the event of communication error history in the central bus, identify the ECUs or sensors which were not communicating by analyzing the combination of stored DTCs or by performing Communication Bus Check (Detail).

(e) If a sub bus has a communication error, the gateway function equipped ECU (sub bus monitor ECU) detects it and stores DTCs related to the error.

HINT:

On the GTS, gateway function equipped ECUs display DTCs for ECUs connected to the sub bus.

(f) When an open circuit is detected, before disconnecting related connectors for inspection, push in on the connector body to check that the connector is not loose or disconnected.

(g) When a connector is disconnected, check that the terminals and connector body are not cracked, deformed or corroded.

PROCEDURE

| 1. | Toyota Prius Vehicle BROUGHT TO WORKSHOP |

HINT:

- If the ignition switch can be turned to ON (the power source mode can be changed to on) when the vehicle is brought in for repair, check for DTCs and check the illumination condition of the indicators in the combination meter assembly and the basic operation of the Toyota Prius vehicle (such as steering operation) promptly.

- Do not turn the ignition switch off until the inspection of the vehicle is finished, as some fail-safe functions are canceled when the ignition switch is turned off.

-

If the ignition switch cannot be turned to ON (the power source mode cannot be changed to on) even though the auxiliary battery voltage is normal, repair this malfunction before performing troubleshooting.

Click here

- When the ignition switch cannot be turned to ON, data can be read from ECUs that can communicate with the ignition switch off by connecting the GTS to the Toyota Prius vehicle and turning a courtesy light switch on and off at intervals of 1.5 seconds or less until communication starts.

|

| 2. | CUSTOMER PROBLEM ANALYSIS |

HINT:

- When troubleshooting, confirm that the problem symptoms have been accurately identified. Preconceptions should be discarded in order to make an accurate judgment. To clearly understand what the problem symptoms are, it is extremely important to ask the customer about the problem and the conditions at the time the malfunction occurred.

- Ask the customer if the Toyota Prius vehicle is/was equipped with additional devices such as a theft deterrent device or monitor. (If equipped, explain to the customer that the additional devices will be removed before performing troubleshooting as the malfunction cannot be checked properly.)

- Examples of points to be confirmed are shown below.

(a) It is useful to confirm the symptoms and the conditions in which the Toyota Prius vehicle was operating at the time when a malfunction occurred. This helps to narrow down the malfunctioning part.

HINT:

- What was affected (system, part or meter warning indicators)

- What happened (details of the malfunction)

- When (occurrence date and time, frequency and if it recurs or not)

- Under what kind of situation did the problem occur (driving and operating condition at the occurrence and weather)

- Road type or condition (city, suburb, paved road, unpaved road, highway, etc.)

- Conditions when Toyota Prius vehicle returned to normal (ignition switch was turned off, etc.)

| Symptom |

|

| Meter warning lights |

|

|

| 3. | PRE-CHECK |

(a) Measure the auxiliary battery voltage with the ignition switch off.

Standard Voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the auxiliary battery before proceeding to the next step.

HINT:

If the ignition switch cannot be turned to ON, measure the voltage of the auxiliary battery. If it is below 11 V, perform inspection after replacing or recharging the auxiliary battery.

| NG |

| CHARGE OR REPLACE AUXILIARY BATTERY |

|

| 4. | CHECK GTS OPERATION |

HINT:

Read the GTS operator's manual before use.

Click here

(a) Connect the GTS to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the GTS on.

(d) Check that the GTS and ECUs can communicate with the ignition switch ON.

HINT:

- ECUs and sensors are not displayed on the "Communication Bus Check" screen when the GTS cannot communicate with the Toyota Prius vehicle.

- If communication between the GTS and ECUs is not possible, either the GTS or vehicle has a malfunction.

- If communication between the GTS and ECUs is still not possible even when the GTS is connected to another vehicle, the GTS has a malfunction. Perform the self tests described in the GTS operator's manual. (The GTS may be malfunctioning or its battery may be discharged.)

| NG |

| GO TO Check CAN Communication Connection |

|

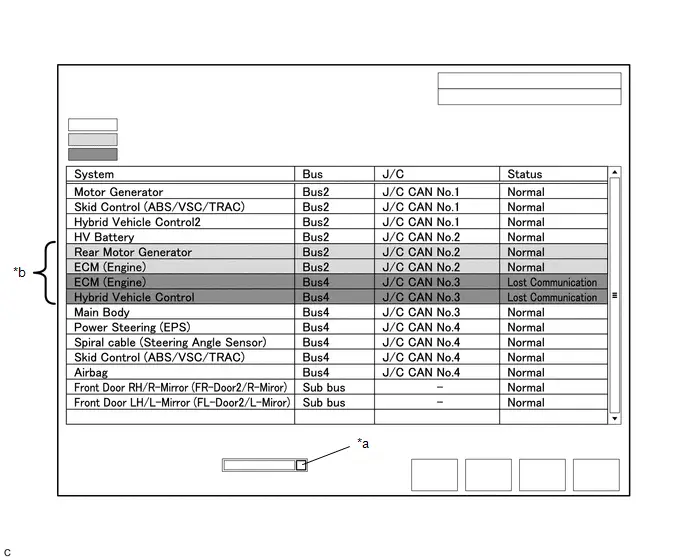

| 5. | BUS INSPECTION (CHECK CONNECTED ECUS AND SENSORS USING GTS) |

(a) Based on the Toyota Prius vehicle equipment and specifications, confirm the systems that use CAN communication.

Click here

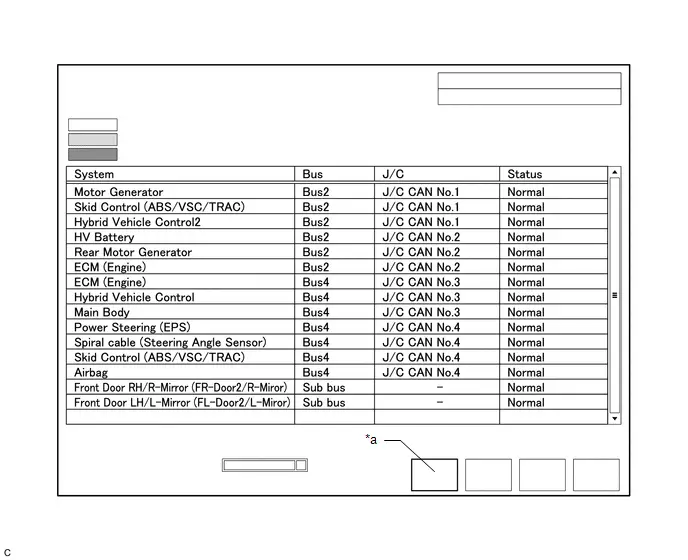

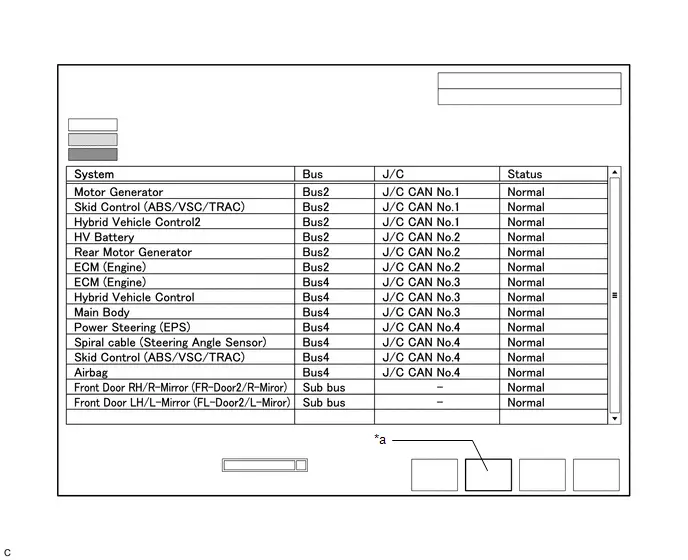

(b) Select "CAN Bus Check" from the screen on the GTS.

CAN Bus Check(c) Observe the screen for approximately 2 minutes to check the ECUs and sensors displayed on the screen.

(d) Check for ECUs or sensors displayed as not communicating on the "Communication Bus Check" screen (indicated by a red background color or a background color that changes from red to yellow).

NOTICE:

- A sub bus monitoring ECU outputs DTCs for its respective ECUs and sensors. Identify the malfunctioning ECU or sensor using the output DTCs.

- ECUs or sensors that are not installed to the Toyota Prius vehicle will not be displayed. Do not mistake these for ECUs or sensors that are not communicating.

- When using the combo box, it may be possible to select a sub bus from the drop down list that does not have any connected ECUs or sensors. This is not a malfunction and occurs when there is no optional device connected to a sub bus which is monitored by a sub bus monitoring ECU (gateway function equipped ECU).

HINT:

-

For details on how to read the "Communication Bus Check" screen, refer to Description of "Communication Bus Check" screen.

Click here

- If there is an ECU or sensor whose connection status changes intermittently while checking the "Communication Bus Check" screen, there may be an open circuit in one of the wires of a branch line of an ECU or sensor in the bus. If an open occurs in one of the wires of a CAN branch line, it may interfere with the communication of other ECUs or sensors resulting in an incorrect state being displayed.

- The central gateway ECU (network gateway ECU) displays the connection status of ECUs and sensors connected to the central bus on the GTS.

- Sub bus monitoring ECUs display the connection status of ECUs and sensors connected to their respective sub bus on the GTS.

-

If a CAN commutation DTC is output for an ECU connected to the sub bus, refer to the corresponding diagnostic procedure.

Click here

| Result | Proceed to |

|---|---|

| No ECUs or sensors are displayed as not communicating | A |

| ECUs or sensors are displayed as not communicating | B |

| B |

| GO TO STEP 8 |

|

| 6. | CHECK DTC (HEALTH CHECK) |

(a) Using the GTS, perform Health Check to read current and history DTCs and record them.

NOTICE:

- CAN communication DTCs are output when there is an open or short in any of the communication lines. Any problems with the power source of a corresponding ECU or sensor, or problems in the ECU or sensor itself also cause these DTCs to be output.

- If a CAN communication line connector is disconnected with the ignition switch ON or ACC, the ECUs of the corresponding system and related systems store a DTC.

HINT:

If an open occurs in just one of the wires of a CAN branch line, DTCs which are not related to malfunctioning parts may be output (DTCs may be displayed randomly), or a message indicating a communication error may be displayed.

| Result | Proceed to |

|---|---|

| DTCs are not output. | A |

| Output DTCs are listed in the Diagnostic Trouble Code Chart for CAN Communication System. | B |

| Output DTCs are not listed in the Diagnostic Trouble Code Chart for CAN Communication System. | C |

| B |

| GO TO DTC CHART |

| C |

| GO TO PERFORM DIAGNOSIS FOR RESPECTIVE SYSTEM |

|

| 7. | BUS INSPECTION (DETAIL) (CHECK CONNECTED ECUS AND SENSORS USING GTS) |

(a) Using the GTS, perform "Initialization".

Body Electrical > Central Gateway > Utility| Tester Display |

|---|

| Initialization |

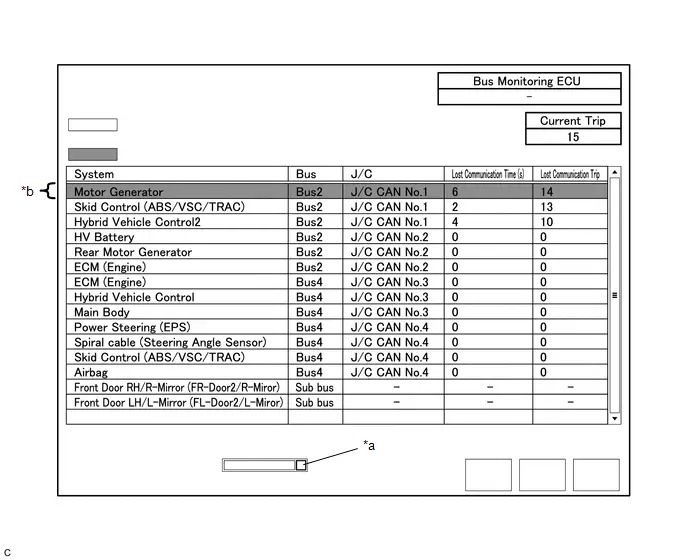

(b) Using the GTS, display the "Communication Bus Check (Detail)" screen.

HINT:

For details on how to inspect buses using the "Communication Bus Check (Detail)" screen, refer to Description of "Communication Bus Check" Screen.

Click here

(c) Check if ECUs or sensors with a Lost Communication Time (s) of 2 seconds or more are displayed.

| Result | Proceed to |

|---|---|

| No ECUs or sensors with a Lost Communication Time (s) of 2 seconds or more are displayed | A |

| ECUs or sensors with a Lost Communication Time (s) of 2 seconds or more are displayed | B |

| A |

| INSPECT FOR INTERMITTENT PROBLEMS |

| B |

| GO TO DIAGNOSIS PROCEDURE FOR RESPECTIVE BUS

|

| 8. | CAN BUS INSPECTION (DETERMINE CAUSE OF PROBLEM SYMPTOM) |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Measure the resistance of the CAN bus for which a malfunction is confirmed from the connector on the central gateway ECU (network gateway ECU) side.

HINT:

-

For details on the terminal arrangement of the central gateway ECU (network gateway ECU), refer to Terminals of ECU.

Click here

-

If the CAN bus main line is normal and there is an ECU or sensor whose connection status changes intermittently while checking the "Communication Bus Check" screen, there may be an open circuit in one of the wires of a branch line of an ECU or sensor in the bus. If an open occurs in one of the wires of a CAN branch line, it may interfere with the communication of other ECUs or sensors resulting in an incorrect state being displayed.

Performing the bus inspection again may help in determining the suspected area.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| CANH - CANL of a suspected bus | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| CANH - body ground of a suspected bus | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| CANL - body ground of a suspected bus | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| CANH - B of a suspected bus | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| CANL - B of a suspected bus | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| OK |

| GO TO DIAGNOSIS PROCEDURE FOR RESPECTIVE COMMUNICATION STOP

|

| NG |

| GO TO DIAGNOSIS PROCEDURE FOR RESPECTIVE BUS

|

Utility

UTILITY

INITIALIZE THE CONNECTION INFORMATION OF A GATEWAY FUNCTION EQUIPPED ECU (BUS MONITOR ECU)

(a) Initialize the ECU.

Body Electrical > Central Gateway > Utility| Tester Display |

|---|

| Initialization |

| Tester Display |

|---|

| Initialization |

Terminals Of Ecu

TERMINALS OF ECU

NOTICE:

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

-

When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

- Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the Toyota Prius vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) auxiliary battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

- This section describes the standard values for all CAN related components.

HINT:

-

The systems (ECUs and sensors) that use CAN communication vary depending on the Toyota Prius vehicle and optional equipment. Check which systems (ECUs and sensors) are installed to the vehicle.

Click here

- Operating the ignition switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

- Even after DTCs are cleared, if a DTC is stored again after driving the Toyota Prius vehicle for a while, the malfunction may be occurring due to vibration of the vehicle. In such a case, wiggling the ECUs or wire harness while performing the inspection below may help determine the cause of the malfunction.

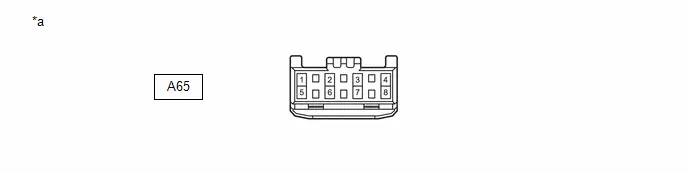

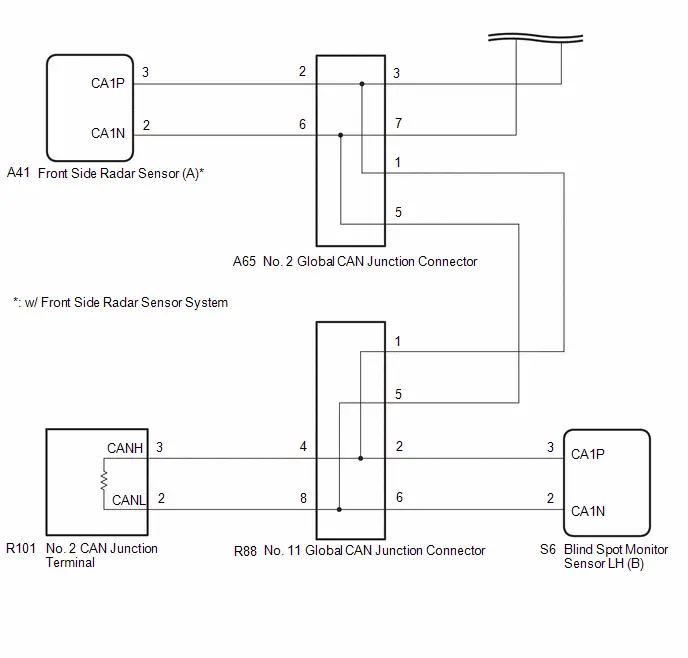

NO. 2 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 2 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 2 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 2 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| A65-1 (CANH) | LG | No. 11 global CAN junction connector (for Bus 1) |

| A65-5 (CANL) | W | |

| A65-2 (CANH) | L | Front side radar sensor (A)* (for Bus 1) |

| A65-6 (CANL) | W | |

| A65-3 (CANH) | R | Millimeter wave radar sensor assembly (for Bus 1) |

| A65-7 (CANL) | W |

- *: w/ Front Side Radar Sensor System

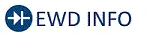

NO. 3 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 3 global CAN junction connector.

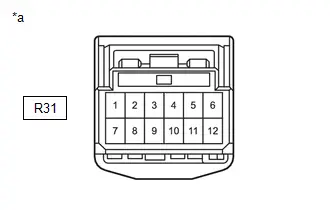

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 3 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 3 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| A17-1 (CANH) | G | No. 2 skid control ECU (brake actuator assembly) (for Bus 4) |

| A17-12 (CANL) | W | |

| A17-2 (CANH) | L | No. 1 skid control ECU (brake booster with master cylinder assembly) (for Bus 4) |

| A17-13 (CANL) | W | |

| A17-3 (CANH) | B | No. 4 global CAN junction connector (for Bus 4) |

| A17-14 (CANL) | W |

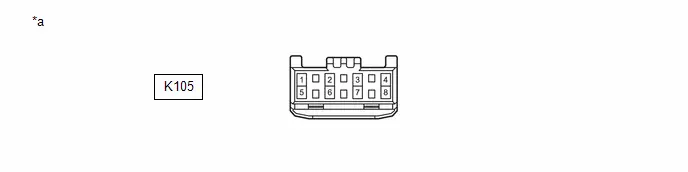

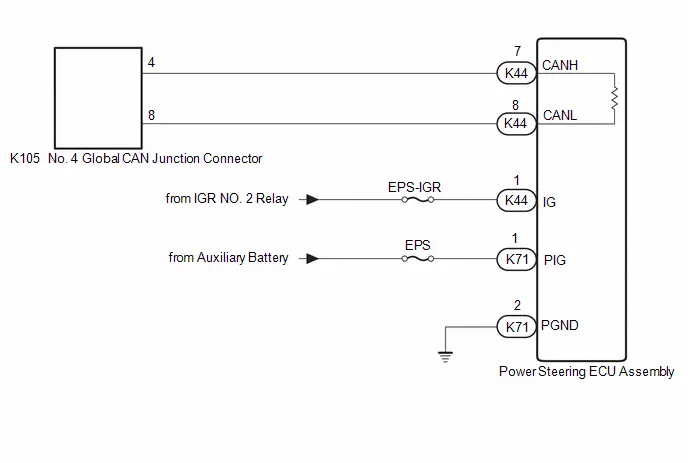

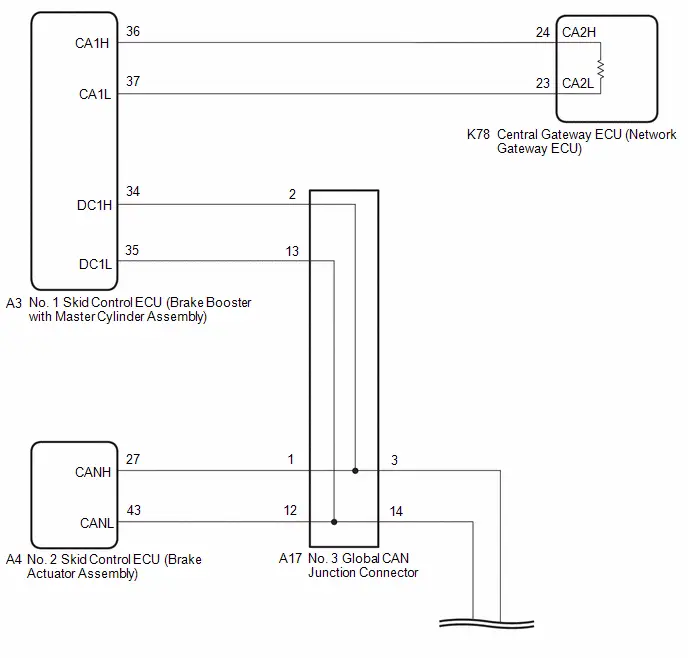

NO. 4 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 4 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 4 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 4 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| K105-1 (CANH) | R | Airbag ECU assembly (for Bus 4) |

| K105-5 (CANL) | W | |

| K105-2 (CANH) | B | No. 3 global CAN junction connector (for Bus 4) |

| K105-6 (CANL) | W | |

| K105-3 (CANH) | LG | Steering sensor (for Bus 4) |

| K105-7 (CANL) | W | |

| K105-4 (CANH) | G | Power steering ECU assembly (for Bus 4) |

| K105-8 (CANL) | W |

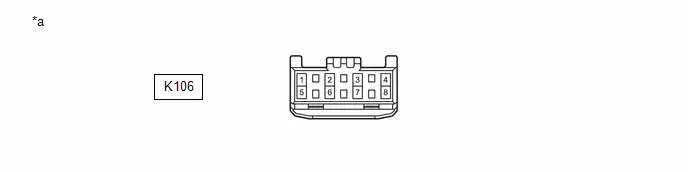

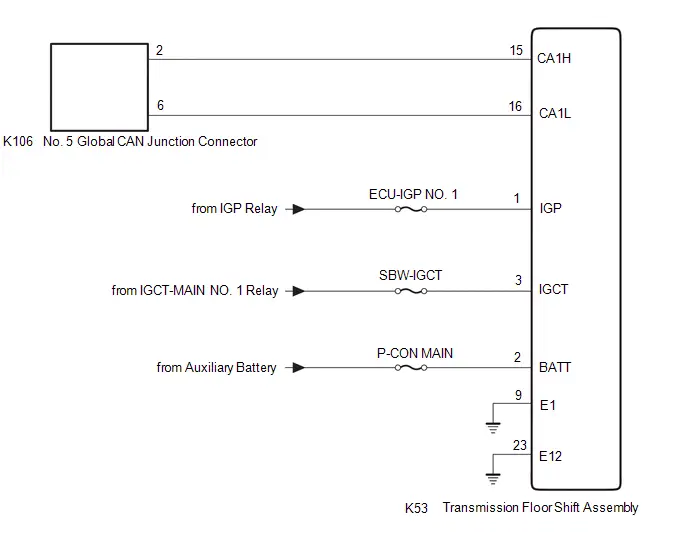

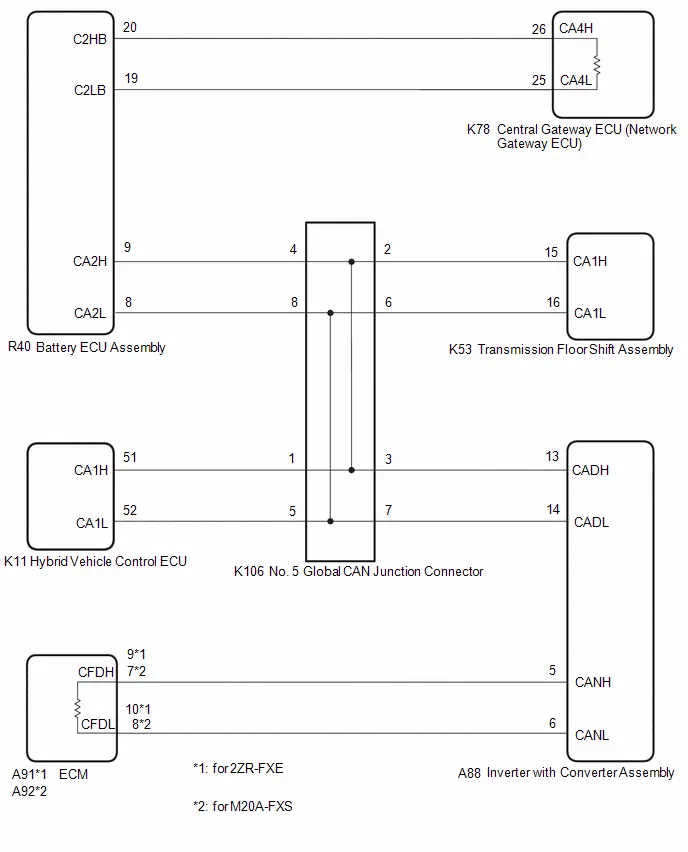

NO. 5 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 5 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 5 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 5 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| K106-1 (CANH) | R | Hybrid Toyota Prius vehicle control ECU (for Bus 2) |

| K106-5 (CANL) | W | |

| K106-2 (CANH) | L | Transmission floor shift assembly (for Bus 2) |

| K106-6 (CANL) | W | |

| K106-3 (CANH) | LG | Inverter with converter assembly (for Bus 2) |

| K106-7 (CANL) | W | |

| K106-4 (CANH) | BR | Battery ECU assembly (for Bus 2) |

| K106-8 (CANL) | W |

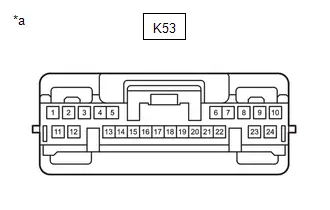

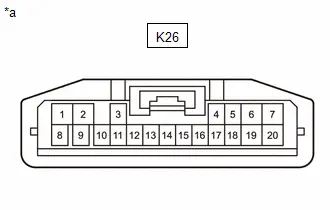

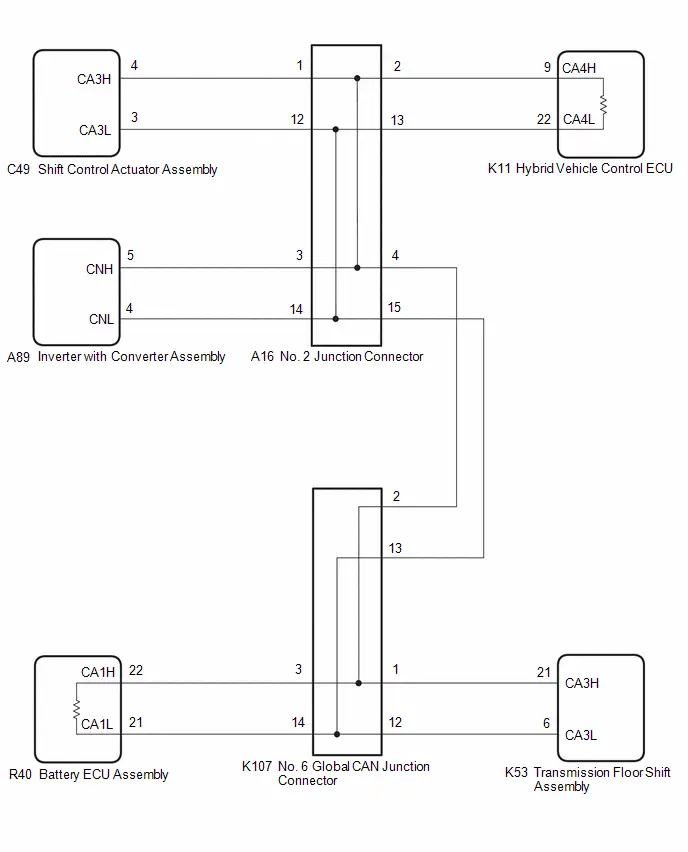

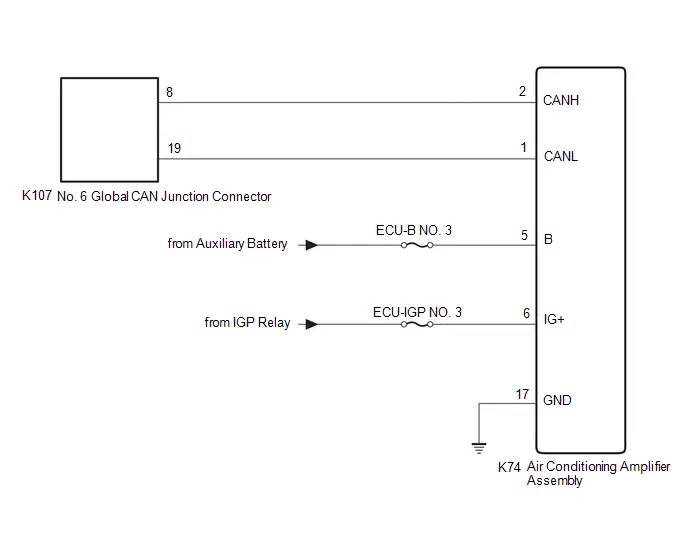

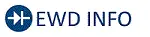

NO. 6 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 6 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 6 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 6 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| K107-1 (CANH) | LG | Transmission floor shift assembly (for Battery Local Bus) |

| K107-12 (CANL) | W | |

| K107-2 (CANH) | B | No. 2 junction connector (for Battery Local Bus) |

| K107-13 (CANL) | W | |

| K107-3 (CANH) | P | Battery ECU assembly (for Battery Local Bus) |

| K107-14 (CANL) | W | |

| K107-7 (CANH) | R | Certification ECU (smart key ECU assembly) (for Bus 5) |

| K107-18 (CANL) | W | |

| K107-8 (CANH) | L | Air conditioning amplifier assembly (for Bus 5) |

| K107-19 (CANL) | W | |

| K107-9 (CANH) | V | Central gateway ECU (network gateway ECU) (for Bus 5) |

| K107-20 (CANL) | W | |

| K107-10 (CANH) | G | No. 14 global CAN junction connector (for Bus 5) |

| K107-21 (CANL) | W |

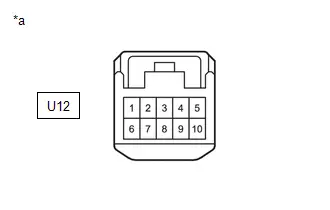

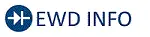

NO. 7 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 7 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 7 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 7 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| K108-1 (CANH) | L | Integration control supply (for Bus 6) |

| K108-12 (CANL) | W | |

| K108-2 (CANH) | G | Toyota Prius Vehicle approaching speaker controller (for Bus 6) |

| K108-13 (CANL) | W | |

| K108-3 (CANH) | LG | Central gateway ECU (network gateway ECU) (for Bus 6) |

| K108-14 (CANL) | W | |

| K108-4 (CANH) | P | No. 13 global CAN junction connector (for Bus 6) |

| K108-15 (CANL) | W | |

| K108-5 (CANH) | L | Tire pressure warning ECU and receiver (for Bus 6) |

| K108-16 (CANL) | W |

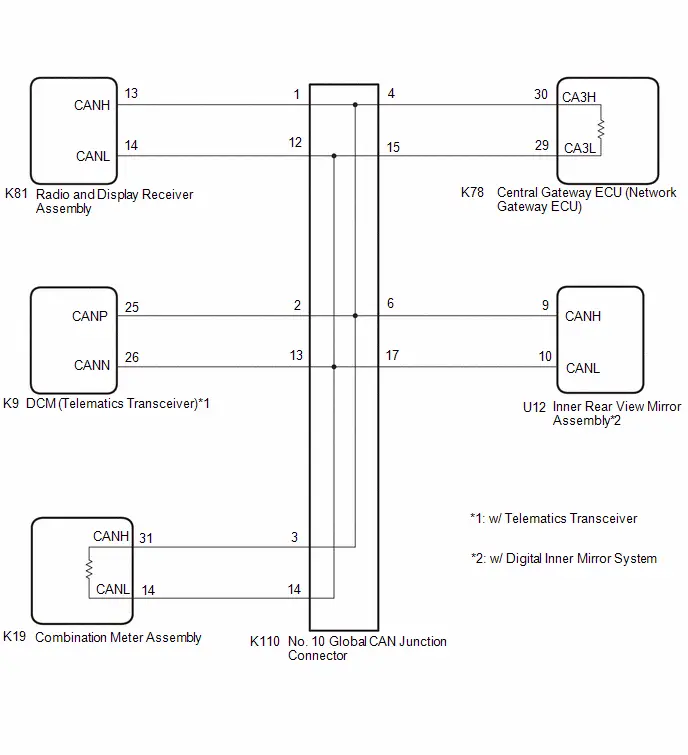

NO. 10 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 10 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 10 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 10 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| K110-1 (CANH) | L | Radio and display receiver assembly (for Bus 3) |

| K110-12 (CANL) | W | |

| K110-2 (CANH) | GR | DCM(telematics transceiver)*1 (for Bus 3) |

| K110-13 (CANL) | W | |

| K110-3 (CANH) | V | Combination meter assembly (for Bus 3) |

| K110-14 (CANL) | W | |

| K110-4 (CANH) | G | Central gateway ECU (network gateway ECU) (for Bus 3) |

| K110-15 (CANL) | W | |

| K110-6 (CANH) | R | Inner rear view mirror assembly*2 (for Bus 3) |

| K110-17 (CANL) | W |

- *1: w/ Telematics Transceiver

- *2: w/ Digital Inner Mirror System

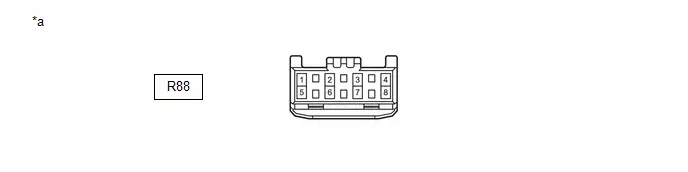

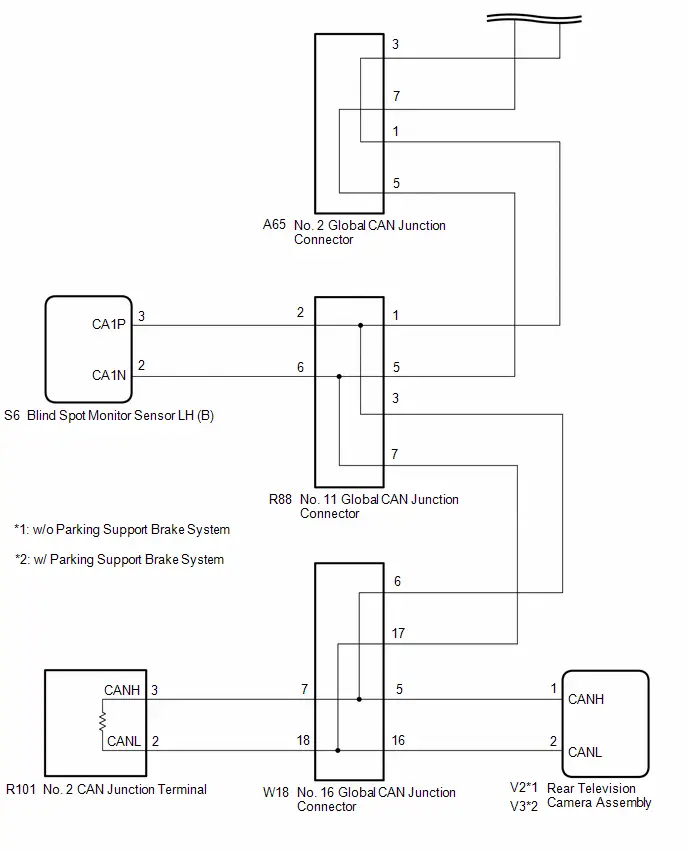

NO. 11 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 11 global CAN junction connector.

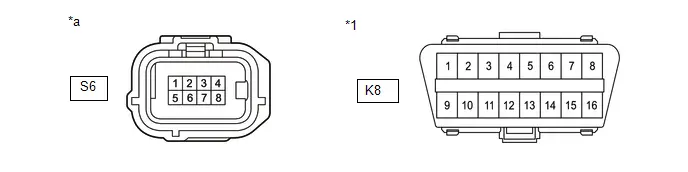

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 11 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 11 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| R88-1 (CANH) | LG | No. 2 global CAN junction connector (for Bus 1) |

| R88-5 (CANL) | W | |

| R88-2 (CANH) | R | Blind spot monitor sensor LH (B) (for Bus 1) |

| R88-6 (CANL) | W | |

| R88-3 (CANH) | GR | No. 16 global CAN junction connector*1 (for Bus 1) |

| R88-7 (CANL) | W | |

| R88-4 (CANH) | L | No. 2 CAN junction terminal*2 (for Bus 1) |

| R88-8 (CANL) | W |

- *1: w/ Parking Assist Monitor System

- *2: w/o Parking Assist Monitor System

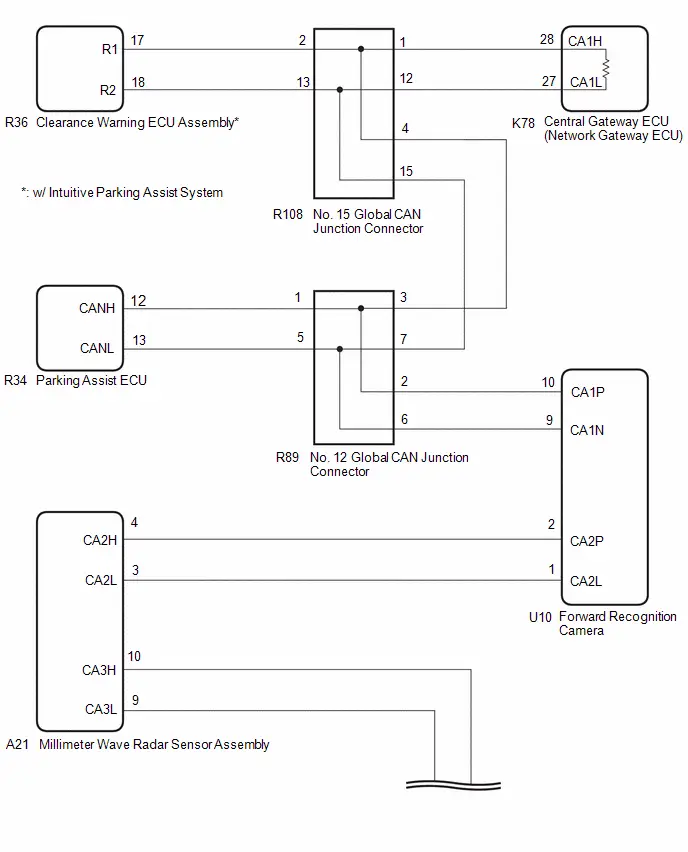

NO. 12 GLOBAL CAN JUNCTION CONNECTOR (w/ Panoramic View Monitor System)

(a) Check the No. 12 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 12 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 12 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| R89-1 (CANH) | G | Parking assist ECU (for Bus 1) |

| R89-5 (CANL) | W | |

| R89-2 (CANH) | R | Forward recognition camera (for Bus 1) |

| R89-6 (CANL) | W | |

| R89-3 (CANH) | B | No. 15 global CAN junction connector (for Bus 1) |

| R89-7 (CANL) | W |

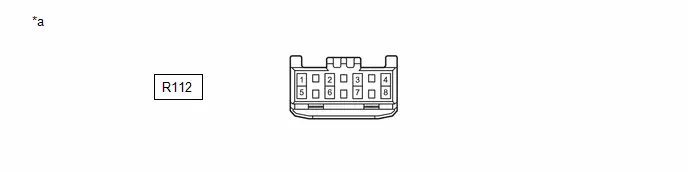

NO. 13 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 13 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 13 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 13 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| R112-1 (CANH) | G | No. 7 global CAN junction connector (for Bus 6) |

| R112-5 (CANL) | W | |

| R112-2 (CANH) | R | Central gateway ECU (network gateway ECU) (for Bus 6) |

| R112-6 (CANL) | W |

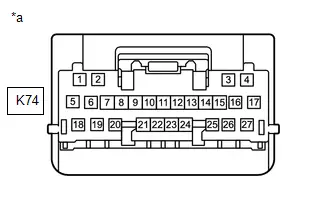

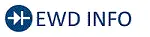

NO. 14 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 14 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 14 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 14 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| R91-1 (CANH) | L | Position control ECU assembly LH*1 (for Bus 5) |

| R91-5 (CANL) | W | |

| R91-2 (CANH) | V | Multiplex network door ECU*2 (for Bus 5) |

| R91-6 (CANL) | W | |

| R91-3 (CANH) | G | No. 6 global CAN junction connector (for Bus 5) |

| R91-7 (CANL) | W | |

| R91-4 (CANH) | R | Main body ECU (multiplex network body ECU) (for Bus 5) |

| R91-8 (CANL) | W |

- *1: w/ Seat Position Memory System

- *2: w/ Power Back Door System

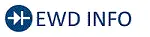

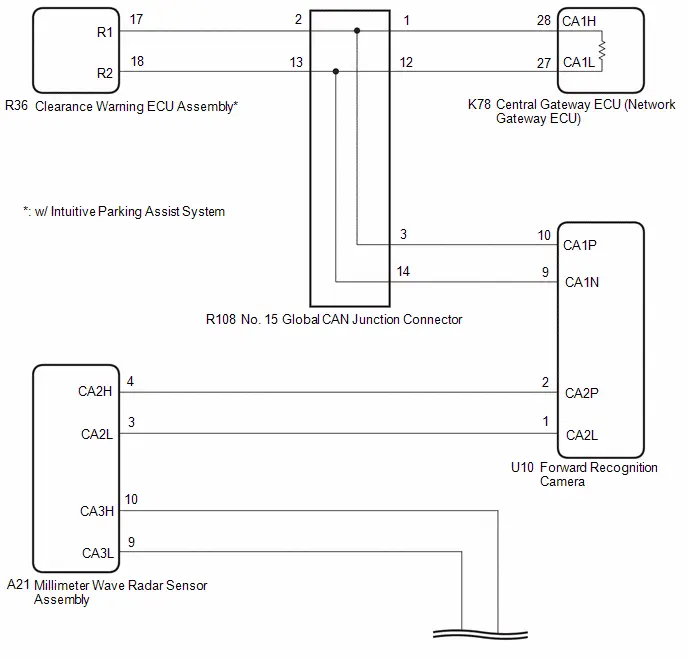

NO. 15 GLOBAL CAN JUNCTION CONNECTOR

(a) Check the No. 15 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 15 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 15 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| R108-1 (CANH) | B | Central gateway ECU (network gateway ECU) (for Bus 1) |

| R108-12 (CANL) | W | |

| R108-2 (CANH) | L | Clearance warning ECU assembly*1 (for Bus 1) |

| R108-13 (CANL) | W | |

| R108-3 (CANH) | SB | Forward recognition camera*2 (for Bus 1) |

| R108-14 (CANL) | W | |

| R108-4 (CANH) | B | No. 12 global CAN junction connector*3 (for Bus 1) |

| R108-15 (CANL) | W |

- *1: w/ Intuitive Parking Assist System

- *2: w/o Panoramic View Monitor System

- *3: w/ Panoramic View Monitor System

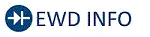

NO. 16 GLOBAL CAN JUNCTION CONNECTOR (w/ Parking Assist Monitor System)

(a) Check the No. 16 global CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 16 Global CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 16 global CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| W18-5 (CANH) | LG | Rear television camera assembly (for Bus 1) |

| W18-16 (CANL) | W | |

| W18-6 (CANH) | L | No. 11 global CAN junction connector (for Bus 1) |

| W18-17 (CANL) | W | |

| W18-7 (CANH) | P | No. 2 CAN junction terminal (for Bus 1) |

| W18-18 (CANL) | W |

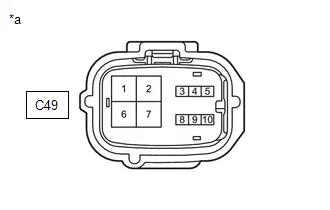

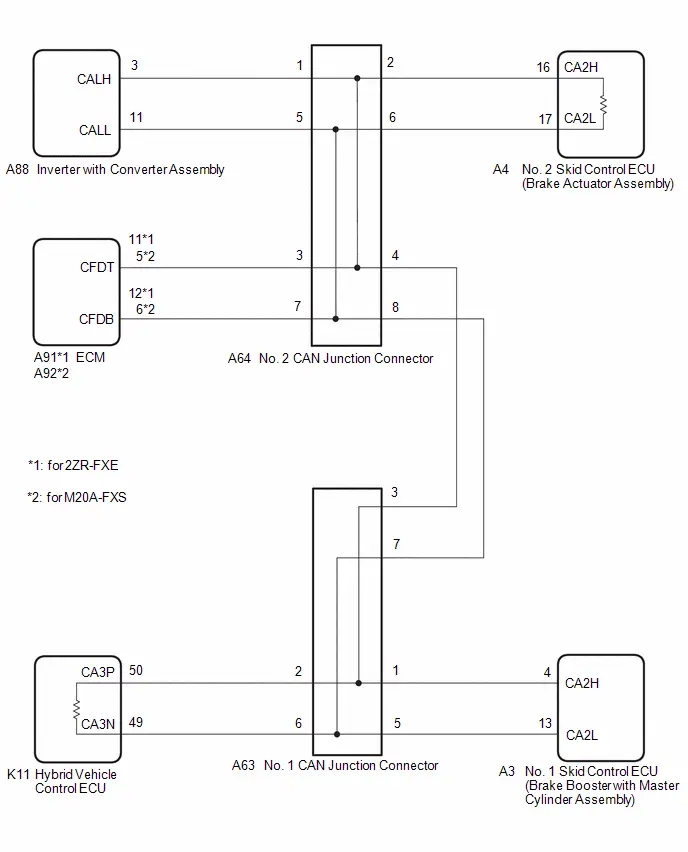

NO. 1 CAN JUNCTION CONNECTOR

(a) Check the No. 1 CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 1 CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 1 CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| A63-1 (CANH) | BE | No. 1 skid control ECU (brake booster with master cylinder assembly) (for Powertrain Local Bus) |

| A63-5 (CANL) | W | |

| A63-2 (CANH) | P | Hybrid Toyota Prius vehicle control ECU (for Powertrain Local Bus) |

| A63-6 (CANL) | W | |

| A63-3 (CANH) | L | No. 2 CAN junction connector (for Powertrain Local Bus) |

| A63-7 (CANL) | W |

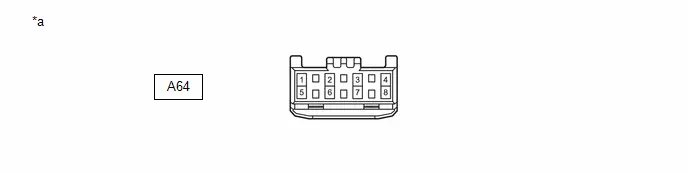

NO. 2 CAN JUNCTION CONNECTOR

(a) Check the No. 2 CAN junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 2 CAN Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 2 CAN junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| A64-1 (CANH) | G | Inverter with converter assembly (for Powertrain Local Bus) |

| A64-5 (CANL) | W | |

| A64-2 (CANH) | V | No. 2 skid control ECU (brake actuator assembly) (for Powertrain Local Bus) |

| A64-6 (CANL) | W | |

| A64-3 (CANH) | B | ECM (for Powertrain Local Bus) |

| A64-7 (CANL) | W | |

| A64-4 (CANH) | L | No. 1 CAN junction connector (for Powertrain Local Bus) |

| A64-8 (CANL) | W |

NO. 2 JUNCTION CONNECTOR

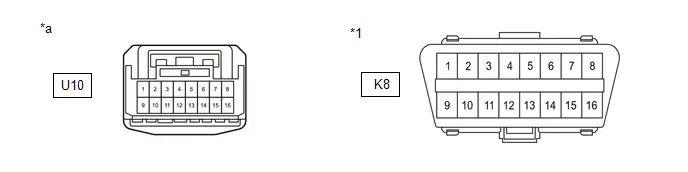

(a) Check the No. 2 junction connector.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 2 Junction Connector) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 2 junction connector.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| A16-1 (CANH) | G | Shift control actuator assembly (for Battery Local Bus) |

| A16-12 (CANL) | W | |

| A16-2 (CANH) | SB | Hybrid Toyota Prius vehicle control ECU (for Battery Local Bus) |

| A16-13 (CANL) | W | |

| A16-3 (CANH) | R | Inverter with converter assembly (for Battery Local Bus) |

| A16-14 (CANL) | W | |

| A16-4 (CANH) | B | No. 6 global CAN junction connector (for Battery Local Bus) |

| A16-15 (CANL) | W |

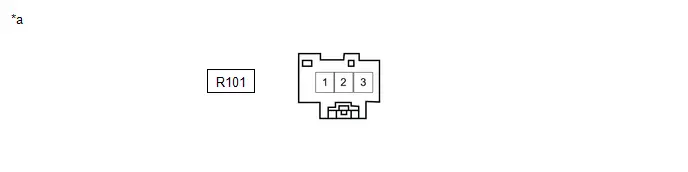

NO. 2 CAN JUNCTION TERMINAL

(a) Check the No. 2 CAN junction terminal.

(1) Connection diagram

| *a | Front view of wire harness connector (to No. 2 CAN Junction Terminal) | - | - |

(2) Check the connection diagram of the components which are connected to the No. 2 CAN junction terminal.

| Terminal No. (Symbol) | Wiring Color | Connected to |

|---|---|---|

| R101-3 (CANH) | L | No. 11 global CAN junction connector*1 (for Bus 1) |

| R101-2 (CANL) | W | |

| R101-3 (CANH) | L | No. 16 global CAN junction connector*2 (for Bus 1) |

| R101-2 (CANL) | W |

- *1: w/o Parking Assist Monitor System

- *2: w/ Parking Assist Monitor System

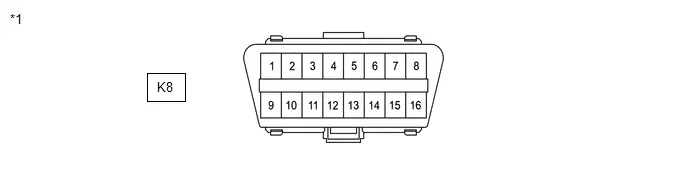

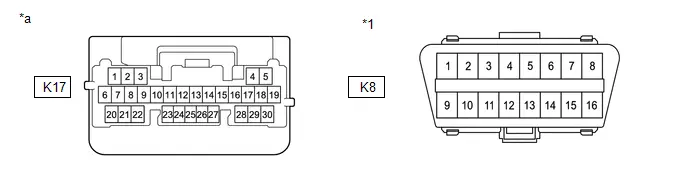

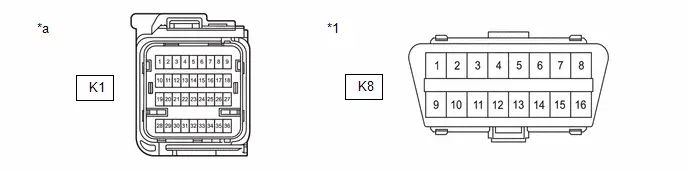

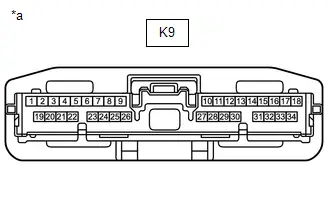

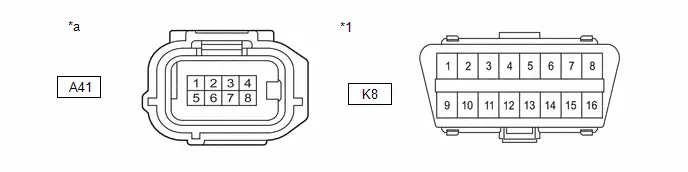

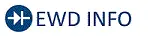

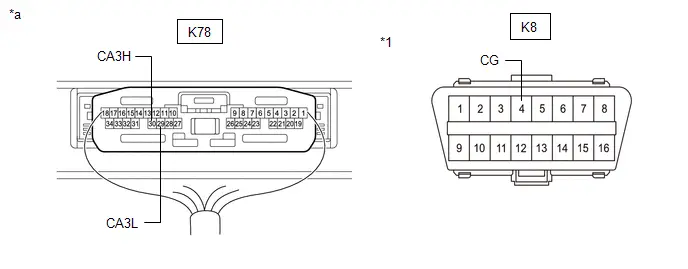

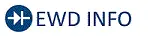

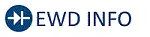

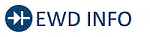

DLC3

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Measure the resistance according to the value(s) in the table below.

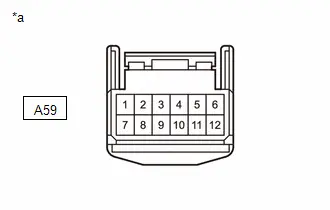

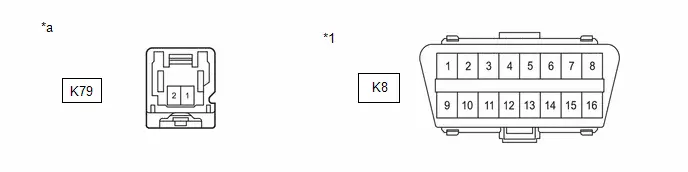

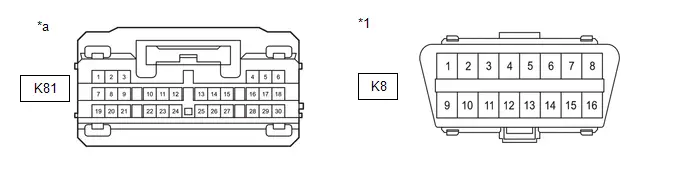

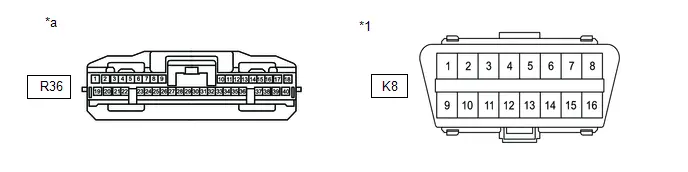

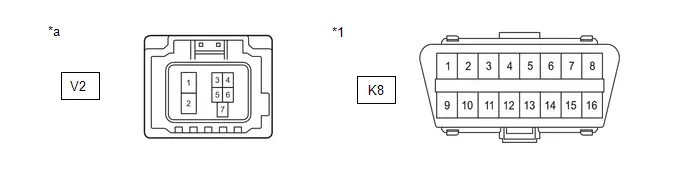

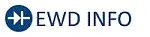

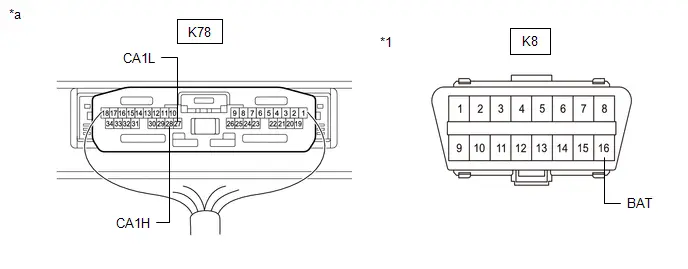

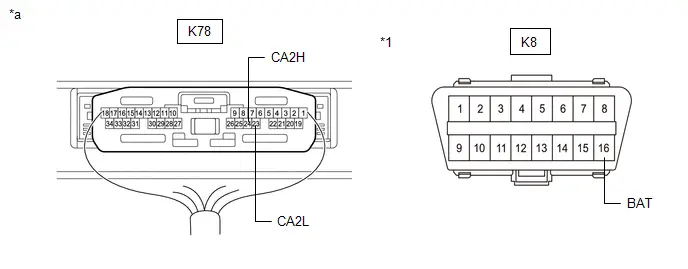

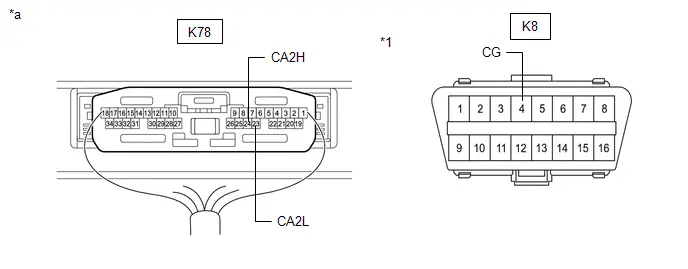

| *1 | DLC3 | - | - |

Standard Resistance:

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K8-6 (CANH) - K8-14 (CANL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| K8-6 (CANH) - K8-4 (CG) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K8-14 (CANL) - K8-4 (CG) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K8-6 (CANH) - K8-16 (BAT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K8-14 (CANL) - K8-16 (BAT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

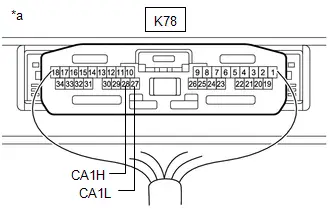

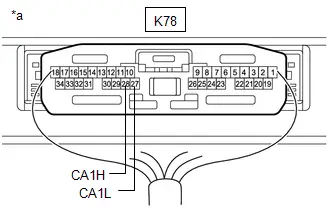

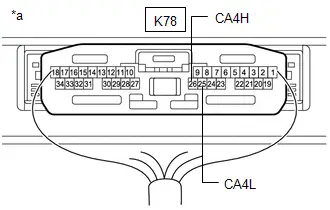

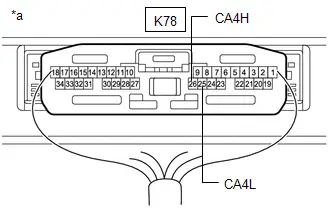

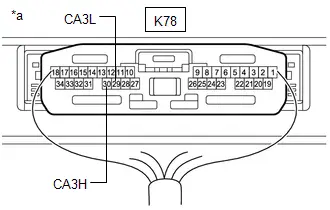

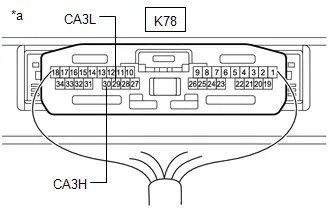

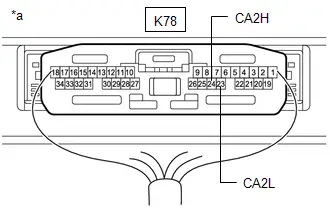

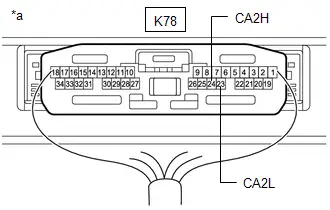

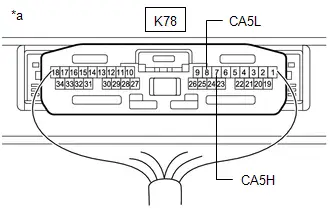

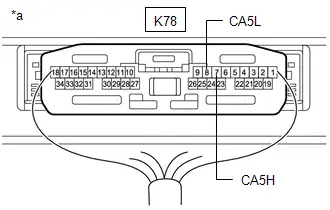

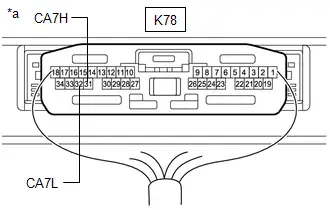

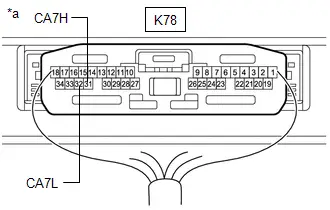

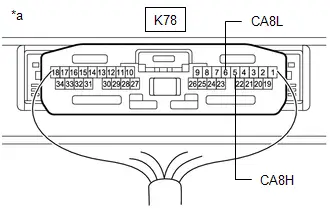

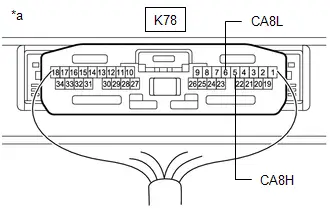

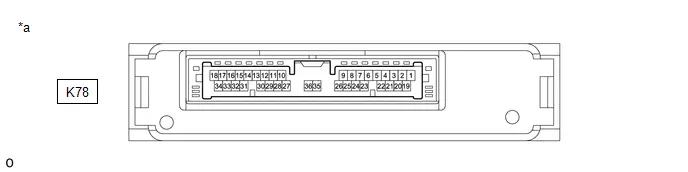

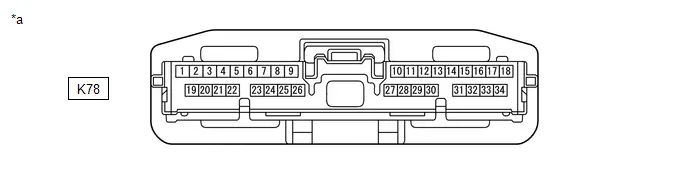

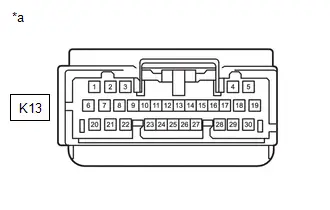

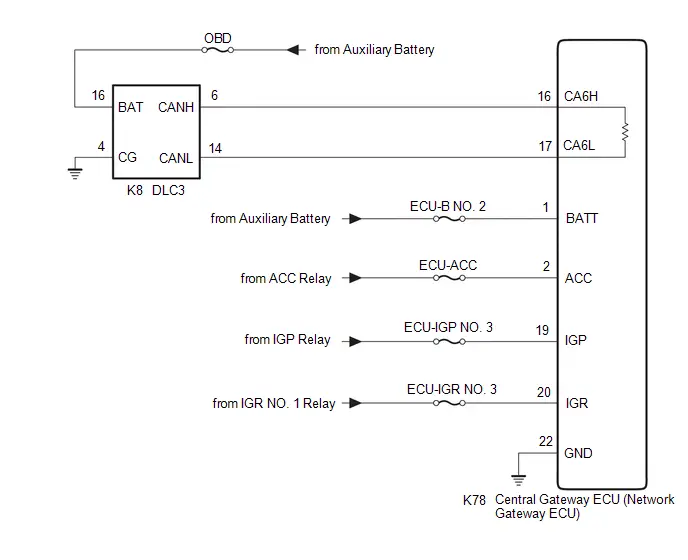

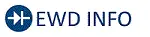

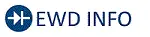

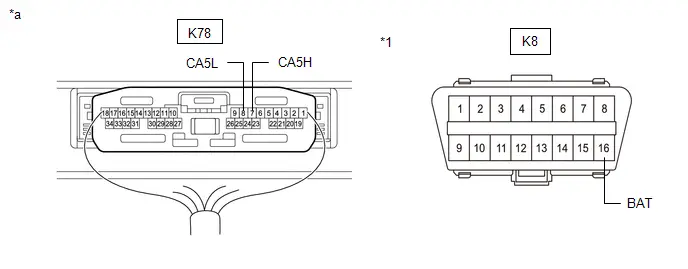

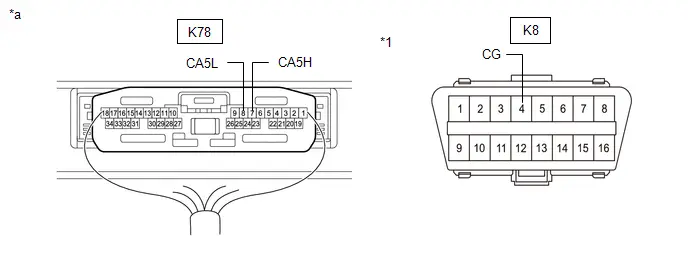

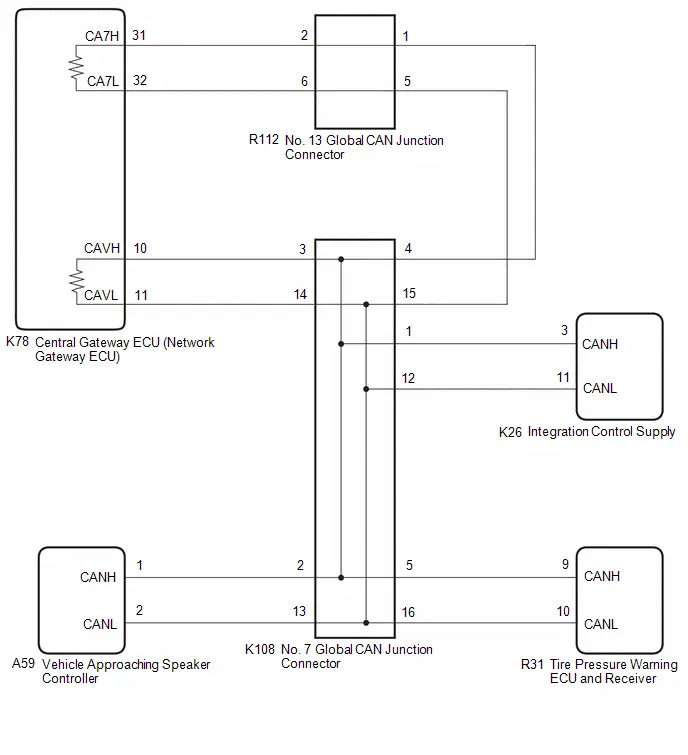

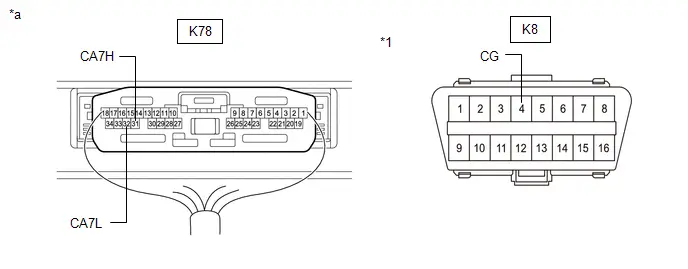

CENTRAL GATEWAY ECU (NETWORK GATEWAY ECU)

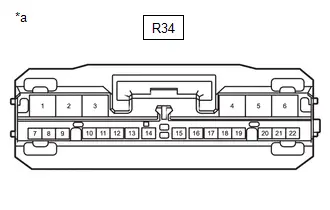

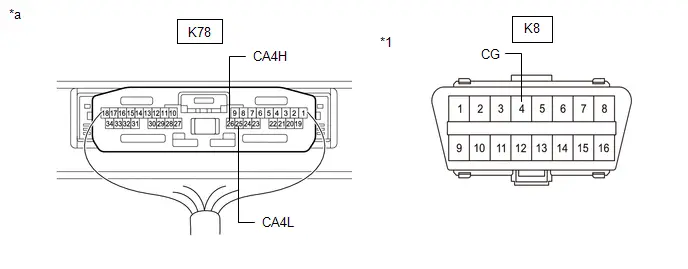

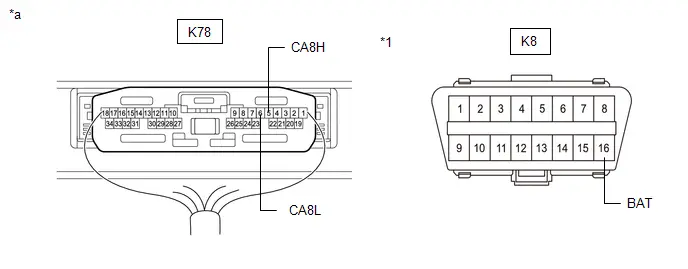

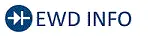

| *a | Component without harness connected (Central Gateway ECU (Network Gateway ECU)) | - | - |

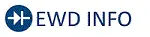

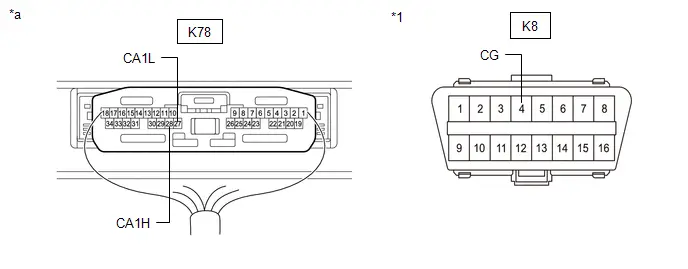

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the K78 central gateway ECU (network gateway ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

| *a | Front view of wire harness connector (to Central Gateway ECU (Network Gateway ECU)) | - | - |

Standard Resistance:

Diagnosis Bus Branch Lines (DLC3 - Central gateway ECU (network gateway ECU))| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-16 (CA6H) - K78-17 (CA6L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 1 MΩ or higher |

| K78-16 (CA6H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-17 (CA6L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-16 (CA6H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-17 (CA6L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-28 (CA1H) - K78-27 (CA1L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K78-28 (CA1H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-27 (CA1L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-28 (CA1H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-27 (CA1L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-26 (CA4H) - K78-25 (CA4L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K78-26 (CA4H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-25 (CA4L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-26 (CA4H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-25 (CA4L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-30 (CA3H) - K78-29 (CA3L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K78-30 (CA3H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-29 (CA3L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-30 (CA3H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-29 (CA3L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-24 (CA2H) - K78-23 (CA2L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K78-24 (CA2H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-23 (CA2L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-24 (CA2H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-23 (CA2L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-7 (CA5H) - K78-8 (CA5L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K78-7 (CA5H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-8 (CA5L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-7 (CA5H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-8 (CA5L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-31 (CA7H) - K78-10 (CAVH) | HIGH-level CAN bus line - HIGH-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | Below 1 Ω |

| K78-32 (CA7L) - K78-11 (CAVL) | LOW-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | Below 1 Ω |

| K78-31 (CA7H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-32 (CA7L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-31 (CA7H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-32 (CA7L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K78-5 (CA8H) - K78-6 (CA8L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K78-5 (CA8H) - K78-22 (GND) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-6 (CA8L) - K78-22 (GND) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K78-5 (CA8H) - K78-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K78-6 (CA8L) - K78-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

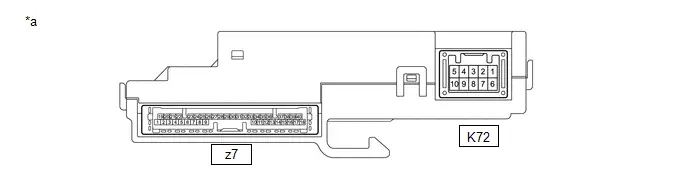

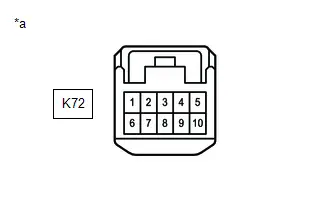

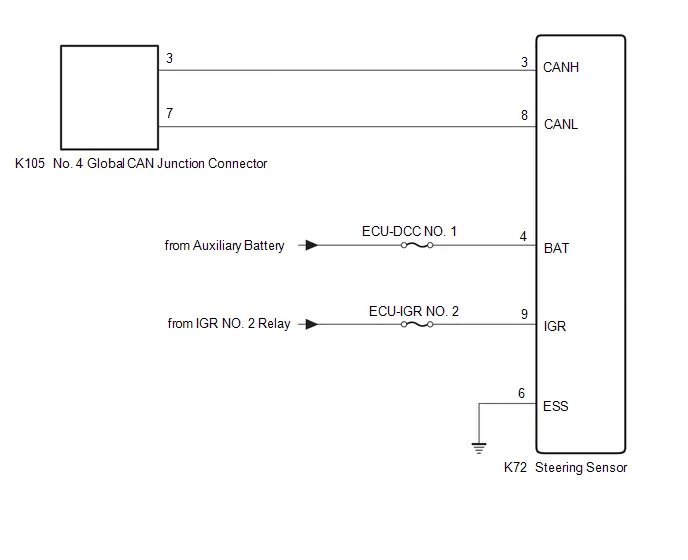

STEERING SENSOR

| *a | Component without harness connected (Steering Sensor) | - | - |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the K72 steering sensor connector.

(c) Measure the resistance according to the value(s) in the table below.

| *a | Front view of wire harness connector (to Steering Sensor) |

Standard Resistance:

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K72-3 (CANH) - K72-8 (CANL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| K72-3 (CANH) - K72-6 (ESS) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K72-8 (CANL) - K72-6 (ESS) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K72-3 (CANH) - K72-4 (BAT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K72-8 (CANL) - K72-4 (BAT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

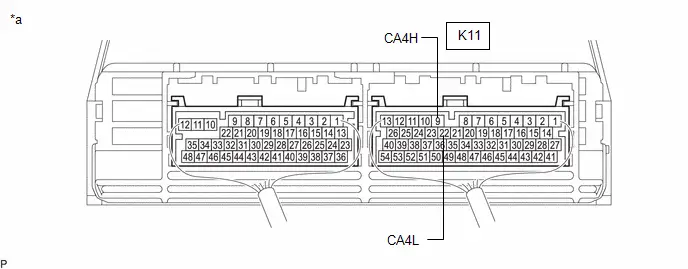

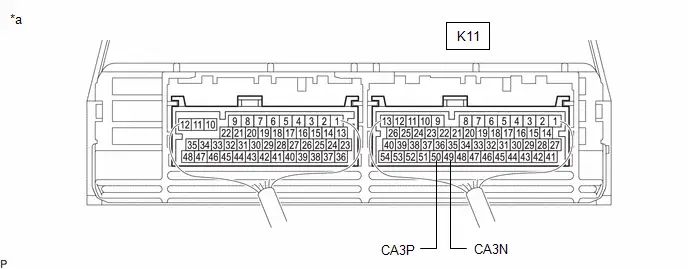

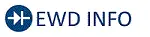

HYBRID Toyota Prius Vehicle CONTROL ECU

Refer to Terminals of ECU.

-

for M20A-FXS

Click here

-

for 2ZR-FXE:

Click here

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

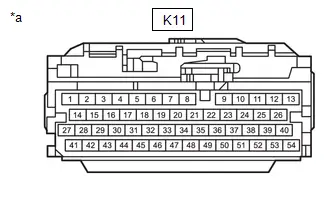

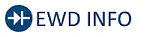

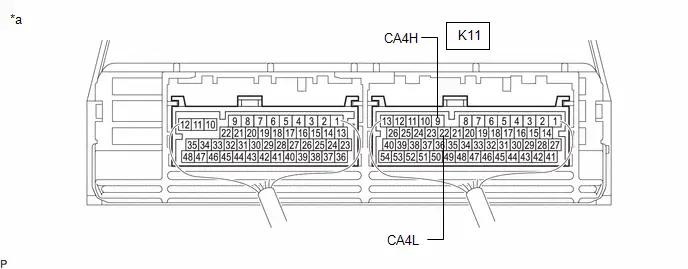

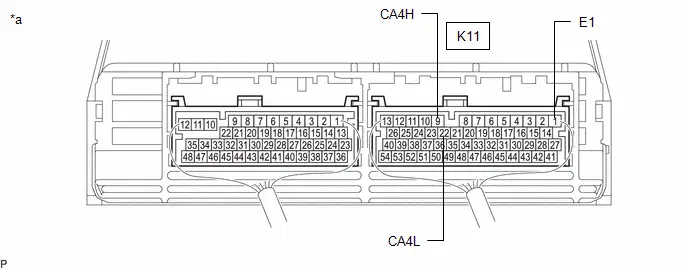

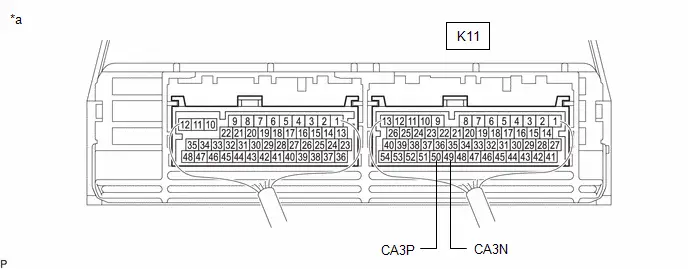

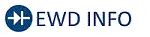

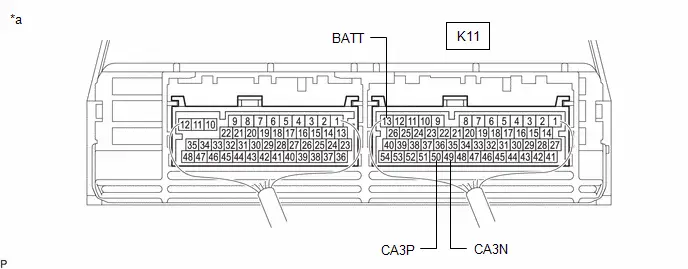

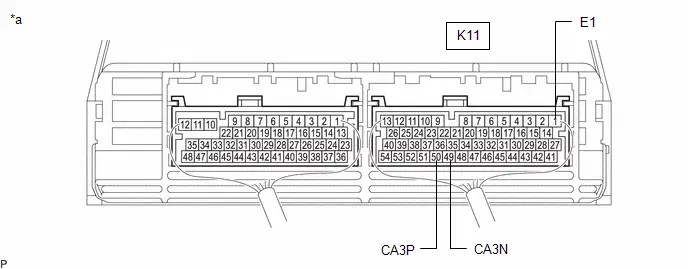

(b) Disconnect the K11 hybrid Toyota Prius vehicle control ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Bus 2 Branch Lines| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K11-51 (CA1H) - K11-52 (CA1L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| K11-51 (CA1H) - K11-1 (E1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K11-52 (CA1L) - K11-1 (E1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K11-51 (CA1H) - K11-13 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K11-52 (CA1L) - K11-13 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K11-9 (CA4H) - K11-22 (CA4L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K11-9 (CA4H) - K11-1 (E1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K11-22 (CA4L) - K11-1 (E1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K11-9 (CA4H) - K11-13 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K11-22 (CA4L) - K11-13 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K11-50 (CA3P) - K11-49 (CA3N) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K11-50 (CA3P) - K11-1 (E1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K11-49 (CA3N) - K11-1 (E1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K11-50 (CA3P) - K11-13 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K11-49 (CA3N) - K11-13 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| *a | Front view of wire harness connector (to Hybrid Toyota Prius Vehicle Control ECU) |

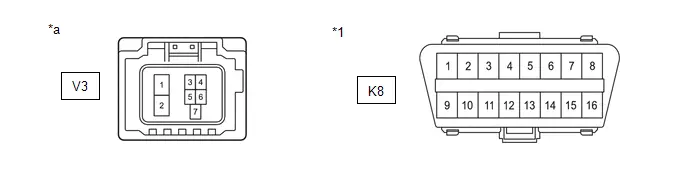

INVERTER WITH CONVERTER ASSEMBLY

Refer to Terminals of ECU.

-

for M20A-FXS:

Click here

-

for 2ZR-FXE:

Click here

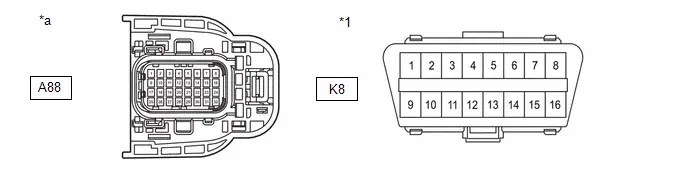

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the A88 inverter with converter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

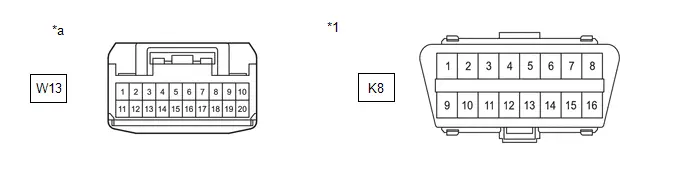

| *1 | DLC3 | - | - |

| *a | Front view of wire harness connector (to Inverter with Converter Assembly) | - | - |

Standard Resistance:

Bus 2 Main Lines| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A88-5 (CANH) - A88-6 (CANL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| A88-5 (CANH) - K8-4 (CG) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A88-6 (CANL) - K8-4 (CG) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A88-5 (CANH) - K8-16 (BAT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A88-6 (CANL) - K8-16 (BAT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A88-13 (CADH) - A88-14 (CADL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| A88-13 (CADH) - K8-4 (CG) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A88-14 (CADL) - K8-4 (CG) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A88-13 (CADH) - K8-16 (BAT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A88-14 (CADL) - K8-16 (BAT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A88-3 (CALH) - A88-11 (CALL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| A88-3 (CALH) - K8-4 (CG) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A88-11 (CALL) - K8-4 (CG) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A88-3 (CALH) - K8-16 (BAT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A88-11 (CALL) - K8-16 (BAT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

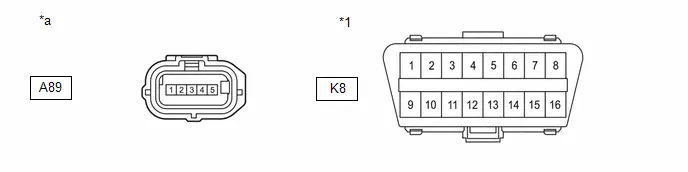

(d) Disconnect the A89 inverter with converter assembly connector.

(e) Measure the resistance according to the value(s) in the table below.

| *1 | DLC3 | - | - |

| *a | Front view of wire harness connector (to Inverter with Converter Assembly) | - | - |

Standard Resistance:

Battery Local Bus Branch Lines| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A89-5 (CNH) - A89-4 (CNL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| A89-5 (CNH) - K8-4 (CG) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A89-4 (CNL) - K8-4 (CG) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A89-5 (CNH) - K8-16 (BAT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A89-4 (CNL) - K8-16 (BAT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

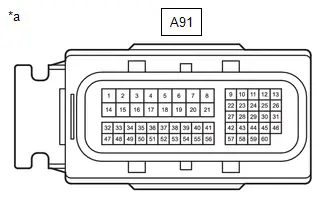

ECM (for 2ZR-FXE)

Refer to Terminals of ECU.

Click here

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the A91 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

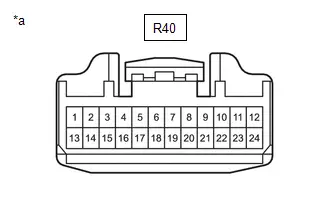

| *a | Front view of wire harness connector (to ECM) |

Standard Resistance:

Bus 2 Main Lines| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A91-9 (CFDH) - A91-10 (CFDL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| A91-9 (CFDH) - A91-17 (E1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A91-10 (CFDL) - A91-17 (E1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A91-9 (CFDH) - A91-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A91-10 (CFDL) - A91-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A91-11 (CFDT) - A91-12 (CFDB) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| A91-11 (CFDT) - A91-17 (E1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A91-12 (CFDB) - A91-17 (E1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A91-11 (CFDT) - A91-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A91-12 (CFDB) - A91-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

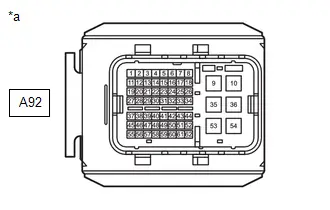

ECM (for M20A-FXS)

Refer to Terminals of ECU.

Click here

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the A92 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

| *a | Front view of wire harness connector (to ECM) |

Standard Resistance:

Bus 2 Main Lines| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A92-7 (CFDH) - A92-8 (CFDL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| A92-7 (CFDH) - A92-10 (E1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A92-8 (CFDL) - A92-10 (E1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A92-7 (CFDH) - A92-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A92-8 (CFDL) - A92-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A92-5 (CFDT) - A92-6 (CFDB) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| A92-5 (CFDT) - A92-10 (E1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A92-6 (CFDB) - A92-10 (E1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A92-5 (CFDT) - A92-1 (BATT) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A92-6 (CFDB) - A92-1 (BATT) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

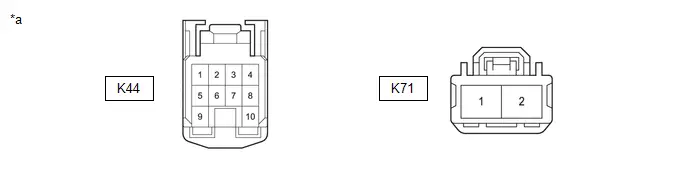

COMBINATION METER ASSEMBLY

Refer to Terminals of ECU.

Click here

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

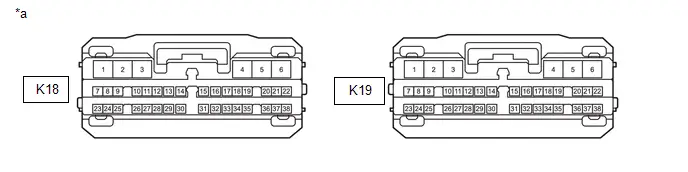

(b) Disconnect the K18 and K19 combination meter assembly connectors.

(c) Measure the resistance according to the value(s) in the table below.

| *a | Front view of wire harness connector (to Combination Meter Assembly) | - | - |

Standard Resistance:

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| K19-31 (CANH) - K19-14 (CANL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| K19-31 (CANH) - K18-2 (ES) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K19-14 (CANL) - K18-2 (ES) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| K19-31 (CANH) - K19-2 (B) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| K19-14 (CANL) - K19-2 (B) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

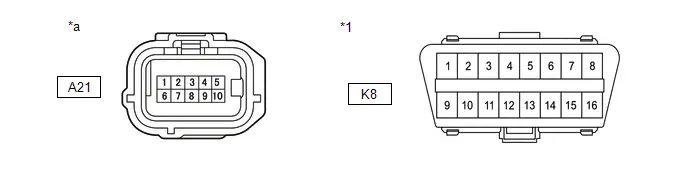

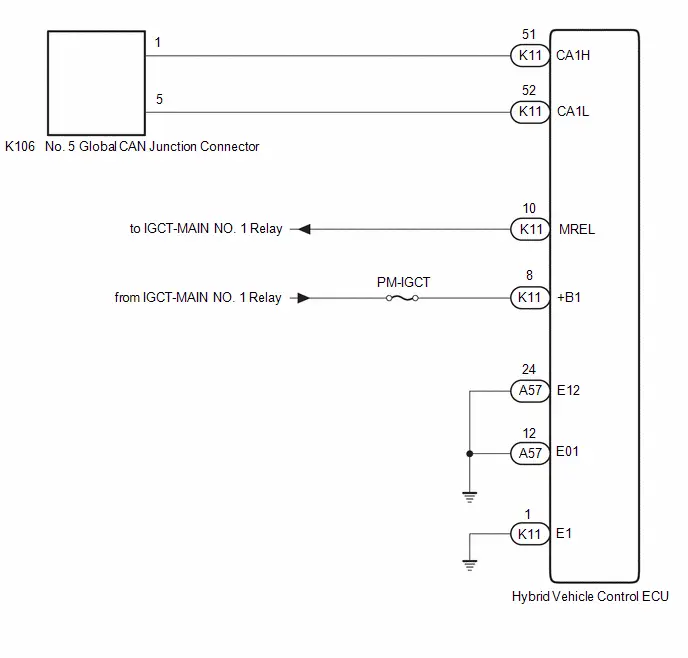

NO. 1 SKID CONTROL ECU (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY)

Refer to Terminals of ECU.

Click here

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

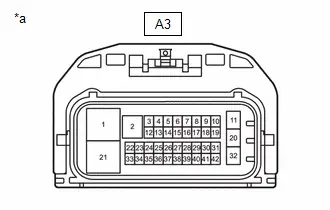

(b) Disconnect the A3 No. 1 skid control ECU (brake booster with master cylinder assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

| *a | Front view of wire harness connector (to No. 1 Skid Control ECU (Brake Booster with Master Cylinder Assembly)) |

Standard Resistance:

Bus 4 Main Lines| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A3-36 (CA1H) - A3-37 (CA1L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| A3-36 (CA1H) - A3-21 (GND2) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A3-37 (CA1L) - A3-21 (GND2) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A3-36 (CA1H) - A3-11 (BS) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A3-37 (CA1L) - A3-11 (BS) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A3-34 (DC1H) - A3-35 (DC1L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 108 to 132 Ω |

| A3-34 (DC1H) - A3-21 (GND2) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A3-35 (DC1L) - A3-21 (GND2) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A3-34 (DC1H) - A3-11 (BS) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A3-35 (DC1L) - A3-11 (BS) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A3-4 (CA2H) - A3-13 (CA2L) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| A3-4 (CA2H) - A3-21 (GND2) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A3-13 (CA2L) - A3-21 (GND2) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A3-4 (CA2H) - A3-11 (BS) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A3-13 (CA2L) - A3-11 (BS) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

NO. 2 SKID CONTROL ECU (BRAKE ACTUATOR ASSEMBLY)

Refer to Terminals of ECU.

Click here

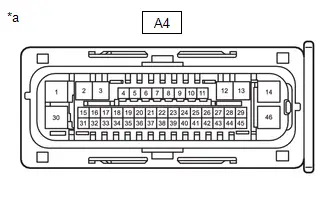

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the A4 No. 2 skid control ECU (brake actuator assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

| *a | Front view of wire harness connector (to No. 2 Skid Control ECU (Brake Actuator Assembly)) |

Standard Resistance:

Bus 4 Branch Lines| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition |

|---|---|---|---|

| A4-27 (CANH) - A4-43 (CANL) | HIGH-level CAN bus line - LOW-level CAN bus line | Cable disconnected from negative (-) auxiliary battery terminal | 54 to 69 Ω |

| A4-27 (CANH) - A4-1 (GND1) | HIGH-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A4-43 (CANL) - A4-1 (GND1) | LOW-level CAN bus line - Ground | Cable disconnected from negative (-) auxiliary battery terminal | 200 Ω or higher |

| A4-27 (CANH) - A4-14 ( BS) | HIGH-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |

| A4-43 (CANL) - A4-14 ( BS) | LOW-level CAN bus line - Auxiliary battery positive ( ) | Cable disconnected from negative (-) auxiliary battery terminal | 6 kΩ or higher |