Toyota Prius: Smart Key System (for Start Function)

- Precaution

- Parts Location

- System Diagram

- How To Proceed With Troubleshooting

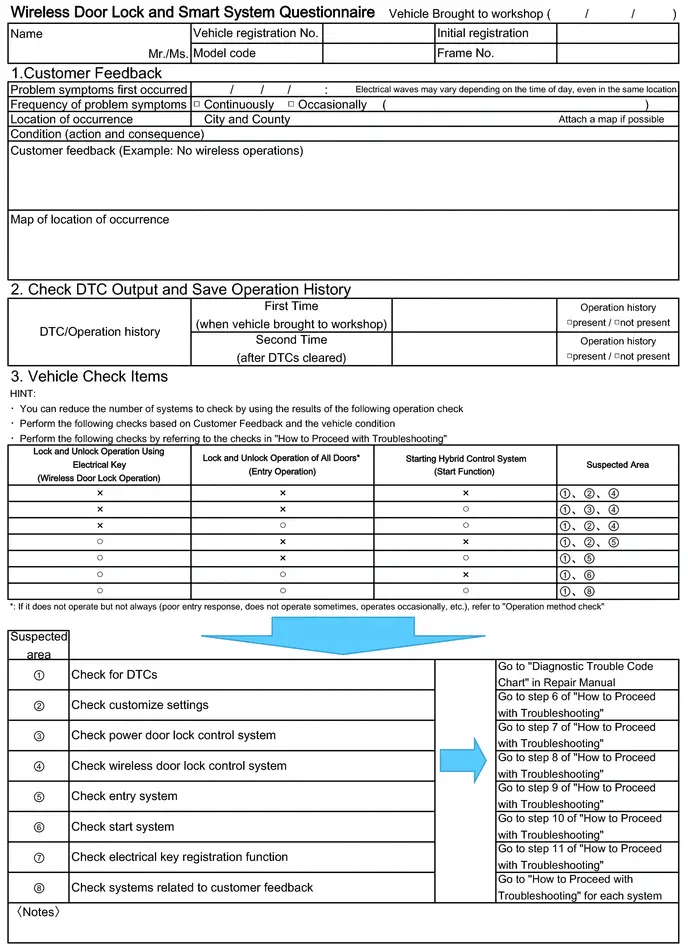

- Customer Problem Analysis Check

- Check For Intermittent Problems

- Operation Check

- Registration

- Customize Parameters

- Problem Symptoms Table

- Terminals Of Ecu

- Data List / Active Test

- Diagnostic Trouble Code Chart

- IG Circuit Short to Ground (B227111)

- ACC Circuit Short to Ground (B227411)

- Starter Circuit Short to Ground (B227511,B227512)

- Engine/Power Switch Signal Compare Failure (B227862)

- Vehicle Speed Signal Circuit Open (B228231,B228262)

- Steering Lock Position Signal Compare Failure (B228562)

- Battery Circuit or Ground Circuit Energization Malfunction (B228B00)

- Wireless Starter Component Internal Failure (B277A96)

- Steering Lock System Component Internal Failure (B278196,B278211,B278215,B279F1C)

- Antenna Coil Circuit Voltage Out of Range (B27841C)

- ID-BOX Component Internal Failure (B278D96)

- Immobiliser Amp Missing Message (B278E87)

- ID-BOX Calibration / Parameter Memory Failure (B279046)

- Engine Immobiliser System Signal (Some Circuit Quantity, Reported via Serial Data) Invalid (B279986)

- Engine Immobiliser System Circuit Short to Battery (B279A12)

- Engine Immobiliser System Incorrect Assembly (B279C95)

- Front Floor Electrical Key Oscillator Circuit Open (B27A513)

- Rear Floor 2 Electrical Key Oscillator Circuit Open (B27A713)

- Brake Switch "A" Signal Compare Failure (P057162)

- Lost Communication with Gear Shift Control Module "A" Missing Message (U010387,...,U113A87)

- Power Source Mode does not Change to ON (IG and ACC)

- Power Source Mode does not Change to ON (IG)

- Power Source Mode does not Change to ON (ACC)

- Power Source Mode does not Change to ON (READY)

- New Key cannot be Registered

- Additional Key cannot be Registered

- New Key Registration Warning Message is not Displayed

- System Malfunction Message is Displayed on the Multi-information Display

- Security Indicator Light Does not Blink

- Immobiliser System does not Operate Properly

Precaution

PRECAUTION

SYSTEM TYPE DETERMINATION

NOTICE:

For this vehicle, there are 2 types of certification ECU (smart key ECU assembly). Judgement can be performed by using the GTS to check if Data List items "Electrical Key 1 Low Battery History" to "Electrical Key 7 Low Battery History" are displayed or not.

(a) Descriptions for this repair manual are listed in the following table.

| Toyota Prius Vehicle Specification | Expression for this Repair Manual |

|---|---|

| Data List items from "Electrical Key 1 Low Battery History" to "Electrical Key 7 Low Battery History" are displayed on the GTS. | Type A |

| Only Data List items from "Electrical Key 1 Low Battery History" to "Electrical Key 4 Low Battery History" are displayed on the GTS. | Type B |

Type A:

Body Electrical > Smart Key > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Electrical Key 7 Low Battery History | Low battery transmission history (electronic key 7) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 6 Low Battery History | Low battery transmission history (electronic key 6) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 5 Low Battery History | Low battery transmission history (electronic key 5) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 4 Low Battery History | Low battery transmission history (electronic key 4) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 3 Low Battery History | Low battery transmission history (electronic key 3) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 2 Low Battery History | Low battery transmission history (electronic key 2) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 1 Low Battery History | Low battery transmission history (electronic key 1) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

Type B:

Body Electrical > Smart Key > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Electrical Key 4 Low Battery History | Low battery transmission history (electronic key 4) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 3 Low Battery History | Low battery transmission history (electronic key 3) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 2 Low Battery History | Low battery transmission history (electronic key 2) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

| Electrical Key 1 Low Battery History | Low battery transmission history (electronic key 1) | OFF or ON | OFF: Transmitter battery not depleted ON: Transmitter battery depleted | - |

CAUTION REGARDING INTERFERENCE WITH ELECTRONIC DEVICES

CAUTION:

As weak radio waves are emitted from the electrical key transmitter sub-assembly, if a pacemaker is being used, be sure to read the pacemaker instruction manual and the following.

-

People with implantable cardiac pacemakers, cardiac resynchronization therapy-pacemakers or implantable cardioverter defibrillators should keep away from the smart key system antennas. The radio waves may affect the operation of such devices. If necessary, the entry function can be disabled. Ask your dealer for details, such as the frequency of radio waves and timing of the emitted radio waves. Then, consult your doctor to see if you should disable the start function.

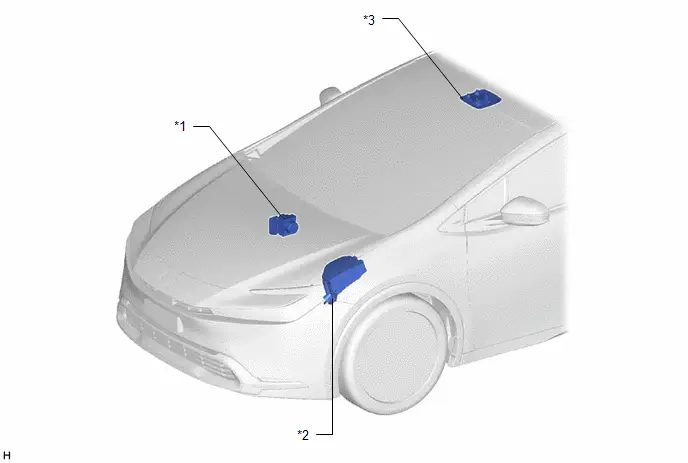

Smart key system antennas: Click here

Remote parking antenna: Click here

- User of any electrical medical device other than implantable cardiac pacemakers, cardiac resynchronization therapy-pacemakers or implantable cardioverter defibrillators should consult the manufacturer of the device for information about its operation under the influence of radio waves. Radio waves could have unexpected effects on the operation of such medical devices.

-

Ask your dealer for details for disabling the smart key system.

Exterior antenna

- Front door outside handle assembly (for Driver Door)

- Front door outside handle assembly (for Front Passenger Door)*1

- Electrical key antenna (outside luggage compartment)*1

- Remote parking antenna assembly*2

Interior antenna

- No. 1 indoor electrical key antenna assembly (front floor)

- No. 2 indoor electrical key antenna assembly (rear floor)

- *1: w/ Front Passenger Door Entry Function

- *2: w/ Advanced Park (Remote Controlled Function)

HINT:

The smart key system can be disabled by a customize setting.

Click here

PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE (-) AUXILIARY BATTERY TERMINAL

NOTICE:

-

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

PRECAUTION WHEN USING GTS

(a) When using the GTS with the ignition switch off, perform lock and unlock operations using the door control switch of the multiplex network master switch assembly at intervals of 1.5 seconds or less until communication between the GTS and the Toyota Prius vehicle begins, and then select the vehicle model manually.

Then select Model Code "KEY REGIST" under manual mode and enter the following menus: Body Electrical / Smart Key(CAN). While using the GTS, periodically perform lock and unlock operations using the door control switch of the multiplex network master switch assembly at intervals of 1.5 seconds or less to maintain communication between the GTS and the Toyota Prius vehicle.

PRECAUTION FOR ACC CUSTOMIZE

(a) When performing an inspection, make sure that "ACC Customize" is set to "ON" using the multi-display.

Click here

HINT:

When "ACC Customize" is set to "ON" (ACC supply power enabled), the certification ECU (smart key ECU assembly) controls the ACC relay on and off. When "ACC Customize" is set to "OFF" (ACC supply power disabled), the certification ECU (smart key ECU assembly) and radio and display receiver assembly control the ACC relay on and off.

Therefore, inspection conditions and results may differ depending on whether "ACC customize" is set to ON or OFF when inspecting ACC related terminals or the Data List.

PRECAUTION FOR REGISTRATION

(a) If replacing any of the following parts, refer to Registration.

Click here

(1) Certification ECU (smart key ECU assembly)

(2) Hybrid Toyota Prius vehicle control ECU

(3) Electrical key transmitter sub-assembly

(4) ID code box (immobiliser code ECU)

(5) Main body ECU (multiplex network body ECU)

(6) DCM (telematics transceiver)*

- *: for Remote Connect Compatible Type

Parts Location

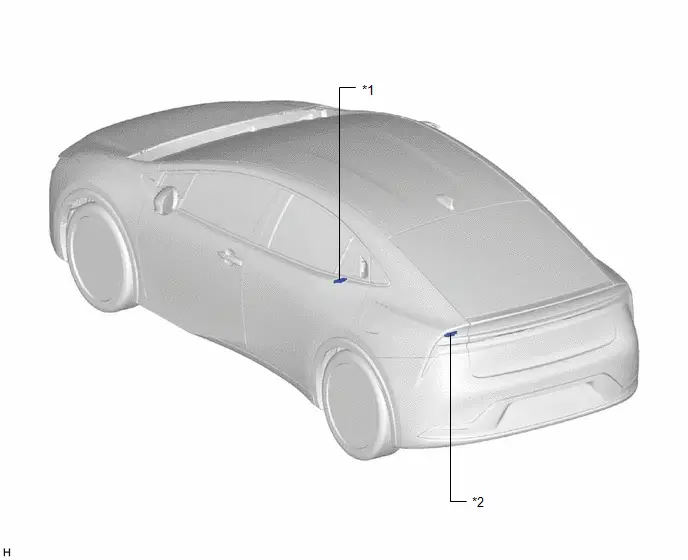

PARTS LOCATION

ILLUSTRATION

| *1 | BRAKE ACTUATOR ASSEMBLY - NO. 2 SKID CONTROL ECU | *2 | NO. 1 ENGINE ROOM RELAY BLOCK AND NO. 1 JUNCTION BLOCK ASSEMBLY - IGP RELAY |

| *3 | MAP LIGHT ASSEMBLY - SECURITY INDICATOR LIGHT | - | - |

ILLUSTRATION

| *1 | NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (FRONT FLOOR) | *2 | NO. 2 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (REAR FLOOR) |

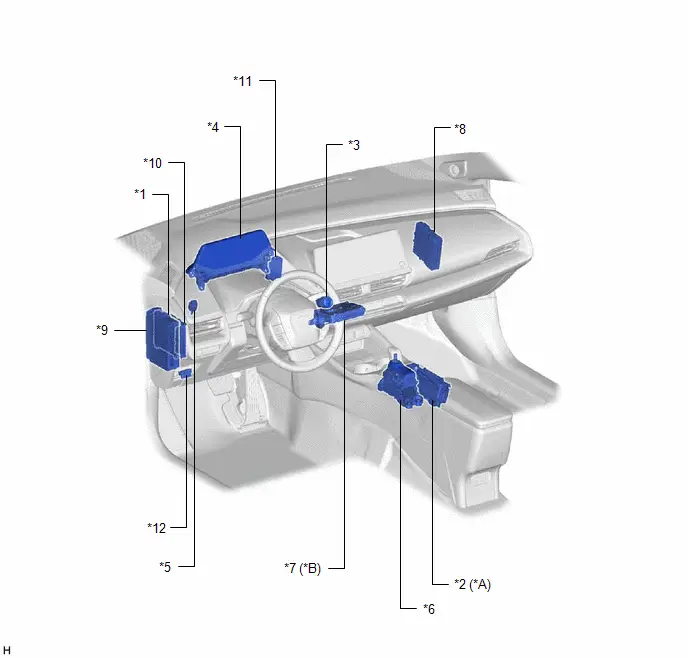

ILLUSTRATION

| *A | w/ Wireless Charging System | *B | for Remote Connect Compatible Type |

| *1 | MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) | *2 | MOBILE WIRELESS CHARGER CRADLE ASSEMBLY |

| *3 | POWER SWITCH | *4 | COMBINATION METER ASSEMBLY |

| *5 | STOP LIGHT SWITCH ASSEMBLY | *6 | TRANSMISSION FLOOR SHIFT ASSEMBLY |

| *7 | DCM (TELEMATICS TRANSCEIVER) | *8 | HYBRID Toyota Prius Vehicle CONTROL ECU |

| *9 | POWER DISTRIBUTION BOX ASSEMBLY - ACC RELAY - IGR NO. 1 RELAY - IGR NO. 2 RELAY - AM2 FUSE - STOP FUSE - ECU-ACC FUSE - ECU-IGR NO. 1 FUSE - ECU-IGR NO. 2 FUSE - BA RELAY - BA NO. 1 FUSE - BA NO. 2 FUSE | *10 | CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| *11 | ID CODE BOX (IMMOBILISER CODE ECU) | *12 | DLC3 |

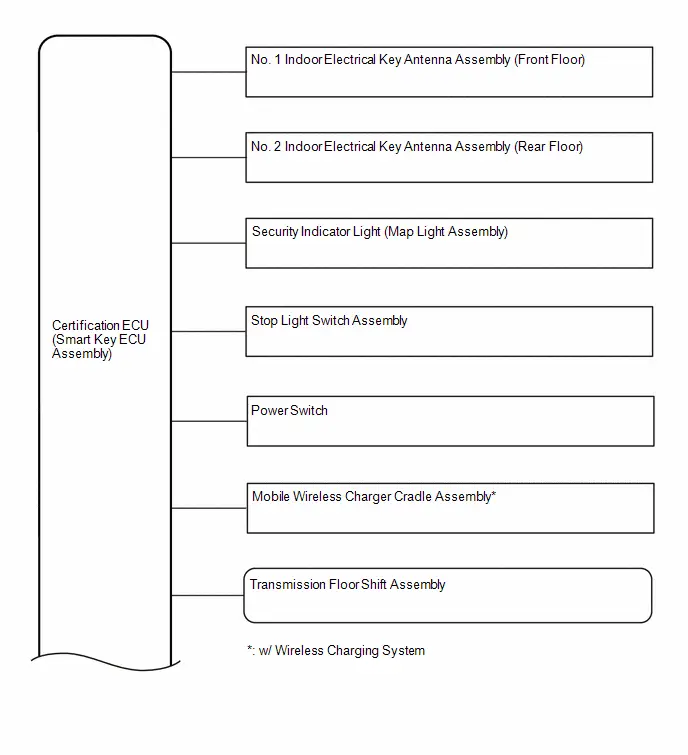

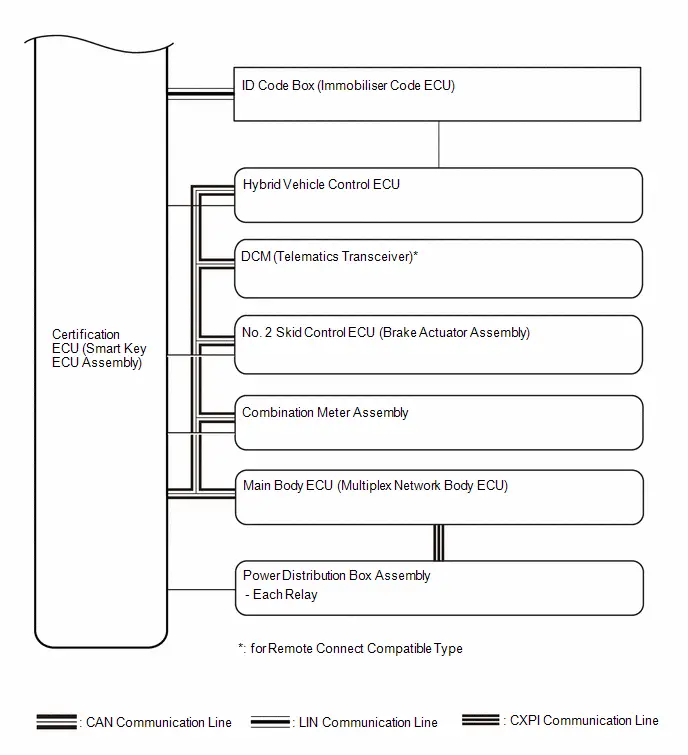

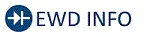

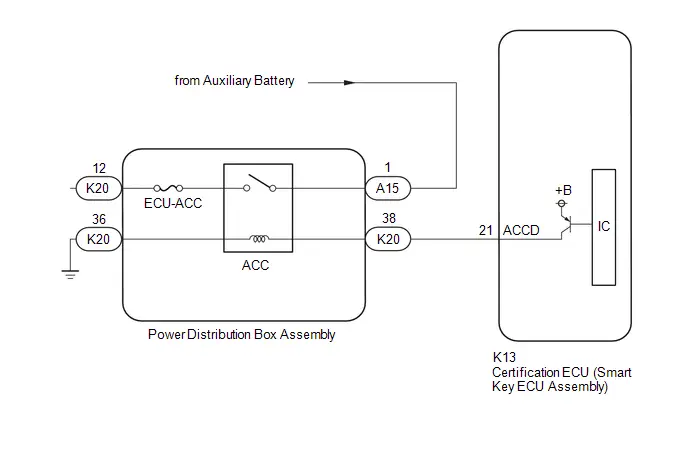

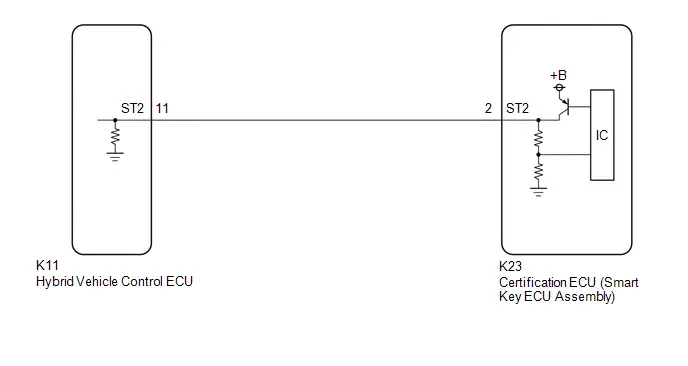

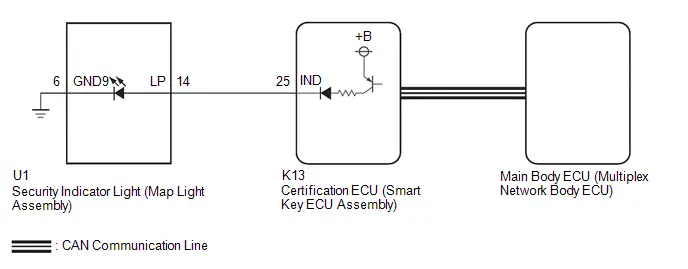

System Diagram

SYSTEM DIAGRAM

SMART KEY SYSTEM (for Start Function)

SMART KEY SYSTEM (for Entry Function)

Click here

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

NOTICE:

- Do not perform "Smart Code Reset" (all key ID erasure) until all malfunctions and symptoms have been confirmed and resolved. If all key ID erasure is performed without confirming or resolving malfunctions, key registration will be unable to be performed, resulting in unnecessary part replacement.

- Make sure that the smart key system has not been disabled by a customize setting.

HINT:

- Replace parts related to the wireless door lock control system and smart key system according to the inspection procedure.

- If the wireless door lock control system and smart key system do not operate, check the customize settings and make sure that the wireless door lock control system and smart key system are not disabled.

-

The wireless door lock control system and smart key system primarily use the following systems.

- Power door lock system

- Wireless door lock control system

- Smart key system (for Entry Function)

-

Smart key system (for Start Function)

- Immobiliser function

- If 2 or more electrical key transmitter sub-assemblies are registered to the system, make sure to perform troubleshooting with all of them.

PROCEDURE

| 1. | Toyota Prius Vehicle BROUGHT TO WORKSHOP |

(a) Confirm how the vehicle was brought to the workshop.

- Vehicle was driven.

- Vehicle was towed.

HINT:

The cause of the malfunction may be narrowed down by confirming whether the vehicle was driven or towed.

|

| 2. | CUSTOMER PROBLEM ANALYSIS |

HINT:

- In troubleshooting, confirm that the problem symptoms have been accurately identified. Preconceptions should be discarded in order to make an accurate judgment. To clearly understand what the problem symptoms are, it is extremely important to ask the customer about the problem and the conditions at the time the malfunction occurred.

- Gather as much information as possible for reference. Past malfunctions that seem unrelated may also help in some cases.

-

The following 5 items are important points for problem analysis:

What

Toyota Prius Vehicle model, system name

When

Date and time, frequency, whether the problem occurred recently or has been occurring for a long time

Where

Whether the problem occurs at specified location

Under what conditions?

Whether the doors were locked or unlocked, whether the ignition switch was ON, whether the hybrid control system was starting

How did it happen?

Ask the customer for details about the Toyota Prius vehicle operating conditions, environment and malfunction.

|

| 3. | BASIC CHECK |

(a) Measure the auxiliary battery voltage with the ignition switch off.

Standard Voltage:

11 to 14 V

HINT:

- A simple method to determine whether the auxiliary battery is depleted is to operate the horn.

- If the auxiliary battery voltage is below 11 V, recharge or replace the auxiliary battery.

(b) Check for blown fuses, open or shorted wire harnesses, improperly connected connectors and other problems in areas that can be visually inspected.

(c) Check the connection of each connector and check them for deformation or damage.

|

| 4. | CHECK DTCS AND SAVE OPERATION HISTORY |

(a) Using the GTS, enter the following menus: System Select / Health Check

HINT:

- If DTCs are output, perform troubleshooting for the DTCs.

- Save all output DTCs and operation history.

-

Operation history can also be checked using the Utility menu of the GTS.

Click here

| Result | Proceed to |

|---|---|

| No DTCs are output | A |

| Wireless door lock system and smart key system DTCs are output | B |

| DTCs other than wireless door lock system and smart key system DTCs are output | C |

| B |

| GO TO DIAGNOSTIC TROUBLE CODE CHART |

| C |

| GO TO DIAGNOSTIC TROUBLE CODE CHART |

|

| 5. | CHECK PROBLEM SYMPTOMS |

(a) Based on the customer problem analysis, check the problem symptoms.

Click here

| Result | Proceed to |

|---|---|

| The problem symptom can be confirmed | A |

| The problem symptom cannot be confirmed | B |

| B |

| GO TO CHECK FOR INTERMITTENT PROBLEMS |

|

| 6. | CHECK CUSTOMIZE ITEMS |

(a) Use the following customize setting methods to confirm that the smart key system is enabled.

- Using the GTS

- Using the multi-display

- Using manual operation

Check the customize settings.

Click here

(b) Use the following customize setting methods to confirm that the wireless door lock system is enabled.

- Using the GTS

- Using the multi-display

Check the customize settings.

Click here

HINT:

- Even when the smart key system is disabled by a customize setting, the hybrid control system can be started by an emergency key operation.

- If the smart key system or wireless door lock control system is disabled, all entry and start functions or wireless functions will not operate.

| Result | Proceed to |

|---|---|

| Wireless door lock control system and smart key system are enabled | A |

| Smart key system is disabled | B |

| Wireless door lock system is disabled | C |

| B |

| GO TO CUSTOMIZE PARAMETERS |

| C |

| GO TO CUSTOMIZE PARAMETERS |

|

| 7. | CHECK POWER DOOR LOCK SYSTEM |

(a) Check the power door lock system.

Click here

| Result | Proceed to |

|---|---|

| Power door lock system operates properly | A |

| Power door lock system does not operate properly | B |

| B |

| GO TO POWER DOOR LOCK SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING)

|

|

| 8. | CHECK WIRELESS DOOR LOCK CONTROL SYSTEM |

(a) Check the wireless door lock control system.

Click here

| Result | Proceed to |

|---|---|

| All functions operate properly | A |

| Wireless lock/unlock functions do not operate (entry and start functions also do not operate) | B |

| Wireless lock/unlock functions do not operate (entry and start functions operate) | C |

| Door ajar warning does not operate | D |

| Answer-back (buzzer sounds and hazard lights flash) function does not operate | E |

| B |

| GO TO SMART KEY SYSTEM (for Entry Function) (All Door Entry Lock/Unlock Functions and Wireless Functions do not Operate) |

| C |

| REPLACE ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

| D |

| GO TO LIGHTING SYSTEM (Door Courtesy Switch Circuit)

|

| E |

| GO TO WIRELESS DOOR LOCK CONTROL SYSTEM (No Answer-Back) |

|

| 9. | CHECK SMART KEY SYSTEM (for Entry Function) |

(a) Check the smart key system (for Entry Function).

Click here

| Result | Proceed to |

|---|---|

| All functions operate properly | A |

| Entry lock/unlock functions do not operate for all doors (wireless function also does not operate) | B |

| Entry lock/unlock functions do not operate for all doors (wireless function operates) | C |

| Entry lock/unlock functions do not operate only for driver side door | D |

| Entry lock/unlock functions do not operate only for front passenger side door | E |

| Entry lock/unlock functions do not operate only for back door | F |

| Entry lock function does not operate only for driver side door (unlock function operates) | G |

| Entry lock function does not operate only for passenger side door (unlock function operates) | H |

| Entry lock function does not operate only for back door (unlock function operates) | I |

| Entry unlock function does not operate only for driver side door (lock function operates) | J |

| Entry unlock function does not operate only for passenger side door (lock function operates) | K |

| Entry unlock function does not operate only from back door (lock function operates) | L |

| Smart key system exterior warning and answer-back buzzer do not sound | M |

| Smart key system interior warning does not sound | N |

| Touching unlock sensor for certain period of time does not unlock all doors | O |

| Entry lock function does not operate using close and lock Function* | P |

- *: w/ Power Back Door System

| B |

| GO TO SMART KEY SYSTEM (for Entry Function) (All Door Entry Lock/Unlock Functions and Wireless Functions do not Operate) |

| C |

| GO TO SMART KEY SYSTEM (for Entry Function) (All Door Entry Lock/Unlock Functions do not Operate, but Wireless Functions Operate) |

| D |

| GO TO SMART KEY SYSTEM (for Entry Function) (Driver Side Door Entry Lock and Unlock Functions do not Operate) |

| E |

| GO TO SMART KEY SYSTEM (for Entry Function) (Front Passenger Side Door Entry Lock and Unlock Functions do not Operate) |

| F |

| GO TO SMART KEY SYSTEM (for Entry Function) (Back Door Entry Lock and Unlock Functions do not Operate) |

| G |

| GO TO SMART KEY SYSTEM (for Entry Function) (Driver Side Door Entry Lock Function does not Operate) |

| H |

| GO TO SMART KEY SYSTEM (for Entry Function) (Front Passenger Side Door Entry Lock Function does not Operate) |

| I |

| GO TO SMART KEY SYSTEM (for Entry Function) (Back Door Entry Lock Function does not Operate) |

| J |

| GO TO SMART KEY SYSTEM (for Entry Function) (Driver Side Door Entry Unlock Function does not Operate) |

| K |

| GO TO SMART KEY SYSTEM (for Entry Function) (Front Passenger Side Door Entry Unlock Function does not Operate) |

| L |

| GO TO SMART KEY SYSTEM (for Entry Function) (Back Door Entry Unlock Function does not Operate) |

| M |

| GO TO SMART KEY SYSTEM (for Entry Function) (Entry Exterior Alarm and Answer-back Buzzer do not Sound) |

| N |

| GO TO SMART KEY SYSTEM (for Entry Function) (Entry Interior Alarm does not Sound)

|

| O |

| GO TO SMART KEY SYSTEM (for Entry Function) (Touching Unlock Sensor for Certain Period of Time does not Unlock All Doors) |

| P |

| GO TO SMART KEY SYSTEM (for Entry Function) (Entry Lock Function does not Operate Using Close & Lock Function) |

|

| 10. | CHECK SMART KEY SYSTEM (for Start Function) |

(a) Check the smart key system (for Start Function).

Click here

| Result | Proceed to |

|---|---|

| All functions operate properly | A |

| Power source mode changing function does not operate correctly (power source mode cannot be changed to ACC, but can be changed to ON) | B |

| Only BA power source mode does not operate correctly | C |

| Security indicator light does not blink | D |

| System malfunction message is displayed on the multi-information display | E |

| Result | Proceed to |

|---|---|

| Push-button start function does not operate | F |

| Immobiliser function does not operate | G |

| Power source mode changing function does not operate (power source mode cannot be changed to ACC or ON) | H |

| Power source mode changing function does not operate correctly (power source mode can be changed to on ACC, but not ON) | I |

| Immobiliser function does not operate (security indicator light does not turn off) | J |

| B |

| GO TO SMART KEY SYSTEM (for Start Function) (Power Source Mode does not Change to ON (ACC)) |

| C |

| GO TO PROBLEM SYMPTOMS TABLE (Only BA Power Source Mode Changing Function does not Operate correctly .) |

| D |

| GO TO SMART KEY SYSTEM (for Start Function) (Security Indicator Light Does not Blink) |

| E |

| GO TO SMART KEY SYSTEM (for Start Function) (System Malfunction Message is Displayed on the Multi-information Display) |

| F |

| GO TO SMART KEY SYSTEM (for Start Function) (Power Source Mode does not Change to ON (READY)) |

| G |

| GO TO SMART KEY SYSTEM (for Start Function) (Immobiliser System does not Operate Properly) |

| H |

| GO TO SMART KEY SYSTEM (for Start Function) (Power Source Mode does not Change to ON (IG and ACC)) |

| I |

| GO TO SMART KEY SYSTEM (for Start Function) (Power Source Mode does not Change to ON (IG)) |

| J |

| GO TO SMART KEY SYSTEM (for Start Function) (Immobiliser System does not Operate Properly) |

|

| 11. | CHECK ELECTRICAL KEY REGISTRATION FUNCTION |

(a) Check the electrical key registration function.

Click here

| Result | Proceed to |

|---|---|

| Electrical key registration function operates properly | A |

| Cannot register new keys | B |

| Cannot register additional keys | C |

| Additional key registration display is not displayed | D |

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| GO TO SMART KEY SYSTEM (for Start Function) (New Key cannot be Registered) |

| C |

| GO TO SMART KEY SYSTEM (for Start Function) (Additional Key cannot be Registered) |

| D |

| GO TO SMART KEY SYSTEM (for Start Function) (New Key Registration Warning Message is not Displayed) |

Customer Problem Analysis Check

CUSTOMER PROBLEM ANALYSIS CHECK

HINT:

Be sure to ask the customer in detail about the following points concerning the vehicle operating conditions, environment and problem, and then check for DTCs.

- If the entry unlock function does not operate.

- If the power source mode does not change even though the power switch was pressed (does not change to ACC).

- If the entry lock function does not operate.

- If the entry lock/unlock function does not operate for all doors.

- If both the entry lock and unlock functions do not operate.

- If the wireless lock and unlock functions do not operate.

- If the hybrid control system cannot be started the push-button start function.

- If a hybrid control system start was attempted by holding the electrical key transmitter sub-assembly near the power switch and then pressing the power switch.

- If the warning buzzers inside the Toyota Prius vehicle do not sound.

- If the warning buzzers outside the vehicle do not sound.

If it is suspected that wave interference is likely, be sure to ask the customer in detail about the following points concerning the vehicle operating conditions, environment and problem.

- Specific locations where the system does not operate (such as near TV towers, large video displays, wireless garage door opener systems, wireless security cameras, home security systems, etc.).

- Specific times when the system does not operate.

- If the symptoms occurred immediately after purchase or only recently.

- If the system does not operate only when near specific Toyota Prius vehicles (there may be wave interference from the wireless systems of other vehicles).

- If the system operates intermittently.

- If the electrical key transmitter sub-assembly is bundled together with other items.

- If the electrical key transmitter sub-assembly is carried together with other electronic devices, such as cell phones, personal computers, portable music players, other electrical key transmitter sub-assemblies, etc. (make sure to keep the electrical key transmitter sub-assembly at least 0.1 m (0.328 ft.) away from such items).

- Where the electrical key transmitter sub-assembly is being kept when not in use: If the electrical key transmitter sub-assembly is being placed within 1 m (3.28 ft.) of items such as TVs, DVD recorders, induction cookers, rice cookers, dishwashers, modems, cell phones, personal computers, microwave ovens, desk or floor lamps, cordless telephones, etc.

- If there are electronic devices that transmit radio waves placed in the Toyota Prius vehicle.

-

When the transmitter battery was last replaced. The transmitter battery capacity can be approximated using the Key Low Battery Data List item.

Click here

- If the customer installed any optional components (theft deterrent devices, wireless fog lights, etc.) to the Toyota Prius vehicle.

Check For Intermittent Problems

CHECK FOR INTERMITTENT PROBLEMS

NOTICE:

- Operation history is stored in the RAM or EEPROM of the certification ECU (smart key ECU assembly). As the cause of a malfunction stored in the RAM will be cleared when the cable is disconnected from the negative (-) auxiliary battery terminal, do not disconnect the cable from the negative (-) auxiliary battery terminal before checking and recording are complete.

- If the Toyota Prius vehicle or vehicle controls are operated (for example, during initial inspection when the vehicle is brought in for repair) before operation history has been read and saved, the operation history information could be lost.

- The operation history function uses the current system time of the GTS and the time counter inside the controlling ECU to calculate the time shown in the operation history. For this reason, before reading the operation history, first make sure that the GTS system clock is accurately set to the current time.

Toyota Prius Vehicle CONTROL HISTORY (ROB)

HINT:

The certification ECU (smart key ECU assembly) stores the vehicle control history (RoB) of the smart key system and it can be read using the GTS.

(a) Read the Vehicle Control History (RoB) according to the display on the GTS.

Body Electrical > Smart Key > Utility| Tester Display |

|---|

| Toyota Prius Vehicle Control History (RoB) |

| Code | Item List | Item Description | Note |

|---|---|---|---|

| X0A10 | Auto Entry Mode Switch History | The certification ECU mode changed when the GTS was connected. | - |

| X0A11 | Customize (Auto Entry Cancel) | The smart functionality was canceled via customization. | - |

| X0A12 | Engine Start (Inactive) | Hybrid control system could not be started because steering lock status was unlock not confirmed. | - |

| X0A13 | Engine Start | Hybrid control system could not be started because immobiliser was set. | - |

| X0A14 | Radio Wave Interference (RF Reception Not Available) | An attempt was made to start the hybrid control system without a key. | - |

| X0A15 | Engine Start Inactive (Steering Lock System) | Hybrid control system could not be started because steering lock lever was engaged. | - |

| X0A18 | Auto Entry Wireless Operation History (Lock/Unlock) | Lock/unlock was performed by wireless operation. | - |

| X0A19 | Auto Entry Wireless Operation History (Open/Close) | Power slide door/back door was opened/closed by wireless operation. | - |

| X0A1A | Warning Operation History | Warning operation was performed by a function of the certification ECU. | - |

| X0A1B | Registration Function (Reason for Non-operation) | The reason that key registration failed. | - |

| X0A1C | Radio Wave Interference (RF Signal Received) | Smart system did not operate due to effects of radio frequency interference. | - |

| X0A1D | Auto Entry Lock (Inactive) | The reason that entry lock did not operate. | - |

| X0A1E | Auto Entry Unlock (Inactive) | The reason that operations other than entry lock operation did not operate correctly. | - |

HINT:

Some items may not be displayed depending on the specifications of the Toyota Prius vehicle.

(b) Read the Vehicle Control History (RoB) according to the display on the GTS.

Body Electrical > Power Source Control > Utility| Tester Display |

|---|

| Vehicle Control History (RoB) |

| Code | Item List | Item Description | Note |

|---|---|---|---|

| X0A00 | Cause Details of Engine Start / READY ON Failure | The reason that hybrid control system did not start or system did not enter READY ON. | - |

| X0A01 | Cause Details of Engine Stop / READY OFF in IG ON | The reason that hybrid control system stalled or hybrid control system stopped. | - |

| X0A02 | Cause Details of Leave ACC ON / IG ON | The reason that Toyota Prius vehicle power source turned off automatically. | - |

HINT:

Some items may not be displayed depending on the specifications of the vehicle.

SYMPTOM SIMULATION

Click here

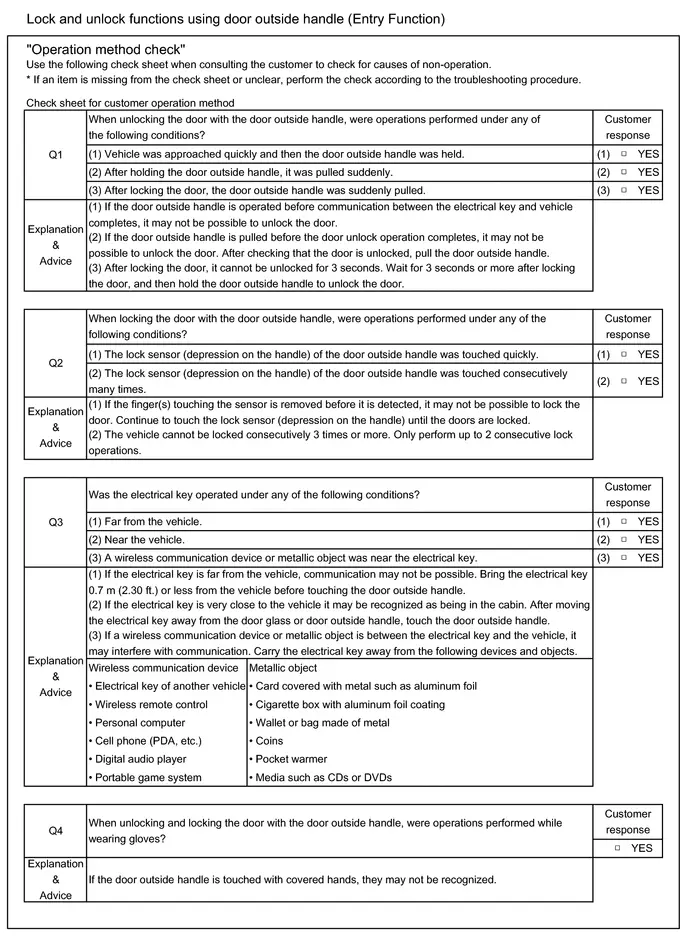

Operation Check

OPERATION CHECK

CHECK CUSTOMIZE PARAMETERS

(a) The operation check below is based on the non-customized initial condition of the vehicle. (However, make sure that "ACC Customize" is set to "ON" using the multi-display.)

Click here

CHECK PUSH-BUTTON START FUNCTION

(a) Check the push-button start function:

(1) Get into the Toyota Prius vehicle while carrying the electrical key transmitter sub-assembly with the ignition switch off. With the shift position in P, check that the key indicator display is displayed when the brake pedal is depressed. Check that the hybrid control system starts when the power switch is pressed after the key indicator display is displayed on the multi-information display.

(2) While carrying the electrical key transmitter sub-assembly, check that the power source mode changes in the following order when the power switch is pressed with the brake pedal released: off → ACC* → ON → off.

- *: When "ACC Customize" is set to "ON" using the multi-display

HINT:

If the power switch is pressed with the ignition switch ON and the shift position not in P, the power source mode will change to off, and shift position will change to P.

(3) Check the push-button start function operation range for the front side. Place the electrical key transmitter sub-assembly at either inspection point so that it is facing the direction shown in the illustration, and then check that the hybrid control system can be started.

NOTICE:

Even if the electrical key transmitter sub-assembly is in a Toyota Prius vehicle interior detection area, it may not be properly detected if it is on the instrument panel, in the glove box or on the floor.

HINT:

-

Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the No. 1 indoor electrical key antenna assembly (front floor).

Click here

- Perform this inspection for both inspection points.

| *a | Electrical Key Transmitter Sub-assembly Inspection Point |

The illustrations shown are examples only.

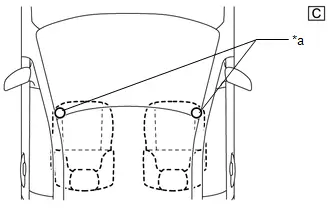

(4) Check the push-button start function operation range for the luggage compartment. Place the electrical key transmitter sub-assembly at either inspection point so that it is facing the direction shown in the illustration, and then check that the hybrid control system can be started.

NOTICE:

Even if the electrical key transmitter sub-assembly is in a Toyota Prius vehicle interior detection area, it may not be properly detected if it is on the instrument panel, in the glove box or on the floor.

HINT:

-

Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the center of the No. 2 indoor electrical key antenna assembly (rear floor).

Click here

- Perform this inspection for both inspection points.

| *a | Electrical Key Transmitter Sub-assembly Inspection Point |

The illustrations shown are examples only.

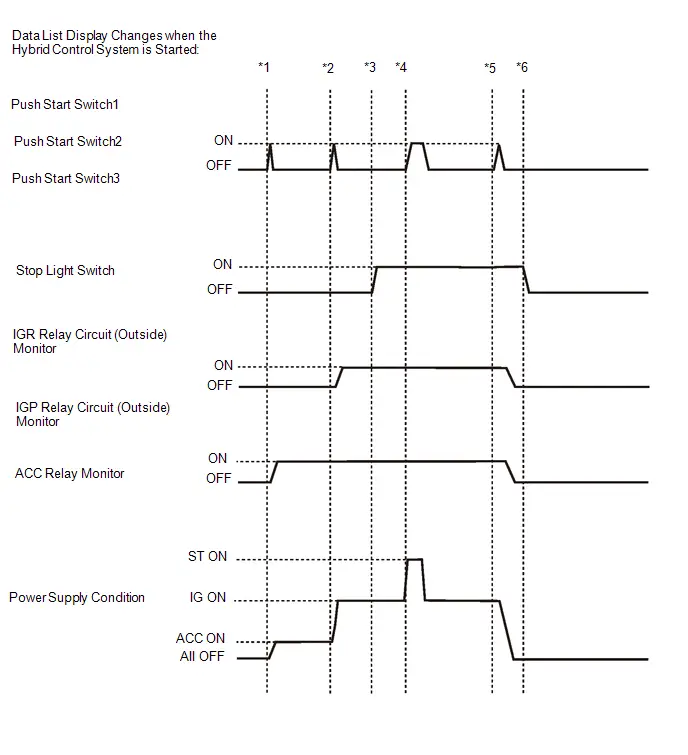

CHECK POWER SOURCE MODE CHANGING FUNCTION

NOTICE:

-

When "ACC customize" is set to "OFF" using the multi-display, ACC supply power can be disabled.

Click here

- When "ACC Customize" is set to "OFF" using the multi-display, make sure to return the setting to its original state after completing the inspection.

(a) Check the power switch. (ACC customize "ON")

(1) Check that the power source mode changes according to the chart below.

| Shift Position | Brake Pedal | Power Source Mode when Power Switch Pressed |

|---|---|---|

| P | Released | Off → ACC → ON → off |

| P | Released | ON (READY) → off |

| P | Depressed | Off → ON (READY) |

| P | Depressed | ACC → ON (READY) |

| P | Depressed | ON → ON (READY) |

| P | Depressed | ON (READY) → off |

| Not P | Released | ON → off |

| Not P | Released | ON (READY) → off |

| Not P | Depressed | ON → off |

| Not P | Depressed | ON (READY) → off |

(b) Check the power switch. (ACC customize "OFF")

(1) Check that the power source mode changes according to the chart below.

| Shift Position | Brake Pedal | Power Source Mode when Power Switch Pressed |

|---|---|---|

| P | Released | Off → ON → off |

| P | Released | ON (READY) → off |

| P | Depressed | Off → ON (READY) |

| P | Depressed | ON → ON (READY) |

| P | Depressed | ON (READY) → off |

| Not P | Released | ON → off |

| Not P | Released | ON (READY) → off |

| Not P | Depressed | ON → off |

| Not P | Depressed | ON (READY) → off |

CHECK BA POWER SOURCE MODE CHANGING FUNCTION

(a) Check the BA power source:

(1) With all of the doors closed, lock the doors using the entry lock function or wireless function.

(2) After 3 minutes or more have elapsed, unlock the doors using the entry lock function or wireless function.

(3) Open the driver door, enter the Toyota Prius vehicle and close the driver door.

(4) Check that the multi-information display in the combination meter assembly starts up.

(5) Operate the multimedia switch and check that the multi display starts.

CHECK TRANSMITTER BATTERY SAVING MODE FUNCTION

(a) Check the transmitter battery saving mode function:

(1) Press the unlock switch of the electrical key transmitter sub-assembly twice while pressing the lock switch and check that the electrical key transmitter sub-assembly LED blinks 4 times and enters transmitter battery saving mode.

(2) Check that the smart key system does not operate while in transmitter battery saving mode.

HINT:

To cancel transmitter battery saving mode, press a switch of the electrical key transmitter sub-assembly.

CHECK ENTRY CANCEL FUNCTION

(a) Disable the smart key system and check that all functions of the smart key system no longer operate.

Click here

HINT:

When the smart key system is disabled, it is possible to lock and unlock the doors with the wireless function, and the hybrid control system can be started by holding the electrical key transmitter sub-assembly near the power switch.

CHECK KEY DIAGNOSTIC MODE

Click here

Registration

REGISTRATION

PROCEDURE

1. REPAIR INSTRUCTION

CAUTION:

As weak radio waves are emitted from the electrical key transmitter sub-assembly, if a pacemaker is being used, be sure to read the pacemaker instruction manual and the following.

-

People with implantable cardiac pacemakers, cardiac resynchronization therapy-pacemakers or implantable cardioverter defibrillators should keep away from the smart key system antennas. The radio waves may affect the operation of such devices. If necessary, the entry function can be disabled. Ask your dealer for details, such as the frequency of radio waves and timing of the emitted radio waves. Then, consult your doctor to see if you should disable the entry function.

Click here

- User of any electrical medical device other than implantable cardiac pacemakers, cardiac resynchronization therapy-pacemakers or implantable cardioverter defibrillators should consult the manufacturer of the device for information about its operation under the influence of radio waves. Radio waves could have unexpected effects on the operation of such medical devices.

-

Ask your dealer for details for disabling the entry function.

Click here

NOTICE:

PRECAUTION WHEN REPLACING PARTS

-

Code registration is necessary when any of the following parts is replaced with a new one. After replacing a part, any part that has performed registration cannot be returned.

- Certification ECU (smart key ECU assembly)

- ID code box (immobiliser code ECU)

- Electrical key transmitter sub-assembly

- Main body ECU (multiplex network body ECU)

- DCM (telematics transceiver)*1

- Digital key ECU assembly*2

- BLE door digital key receiver assembly*2

- BLE luggage digital key receiver assembly*2

-

BLE indoor digital key receiver assembly*2

- *1: for Remote Connect Compatible Type

- *2: w/ Digital Key System

- Make sure to make a note of the ACC customize setting before replacing the certification ECU (smart key ECU assembly) as ACC customize defaults to ON after replacing the certification ECU (smart key ECU assembly). Then make sure to return the setting to the noted value after replacement.

PRECAUTION FOR REGISTRATION

- Make sure that only 1 electrical key transmitter sub-assembly is in the cabin during registration procedures. If 2 or more electrical key transmitter sub-assemblies are in the cabin simultaneously, the electric waves will interfere with each other, preventing normal registration.

- A maximum of 7 electrical key transmitter sub-assemblies can be registered (this includes any electrical key transmitter sub-assemblies registered when the Toyota Prius vehicle was purchased).

- If the battery is depleted during the electrical key transmitter sub-assembly registration procedure, there may be cases in which the electrical key transmitter sub-assembly cannot be registered again. Therefore, make sure to perform work with a sufficiently charged battery.

- If any of the work times are exceeded, finish the procedure.

- Do not disconnect the battery during the Registration.

- Do not perform operations that create an electrical load such as operating the power windows.

-

If Smart Key System is canceled, registration cannot be performed.

Click here

-

If the digital key system is canceled, registration cannot be performed.

Click here

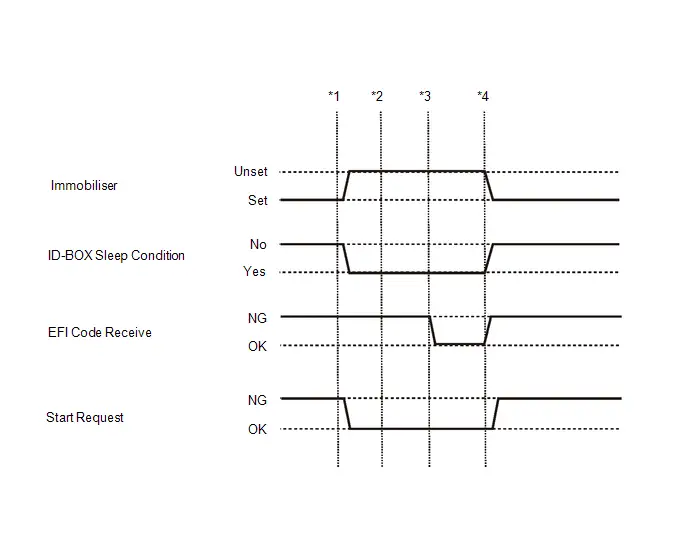

2. EXPLANATION OF IMMOBILISER KEY ID REGISTRATION PROCEDURE

(a) Addressing customer requests (perform work in chart below in order starting from left)

NOTICE:

If All keys ID erasure (Smart code reset) is performed, the code between the certification ECU (smart key ECU assembly) and the digital key ECU assembly is cleared and the digital key system will not function.

| Customer Request/Condition | Undesignated key permanent erasure | All keys ID erasure (Smart code reset) | New key ID registration | Additional key ID registration | Digital key (owner key) registration |

|---|---|---|---|---|---|

| Refer to PROCEDURE | "5" | "6" | "3" | "4" | * |

| All electrical key transmitter sub-assemblies are lost | - |

|

| - |

|

| Registering additional electrical key transmitter sub-assembly | - | - | - |

| - |

| Making a lost electrical key transmitter sub-assembly unusable |

| - | - | - | - |

- *: Refer to the digital key application procedure then perform the registration procedure.

(b) Addressing customer requests (perform work in chart below in order starting from left) (w/ Digital Key System)

| Customer Request | Condition | All digital keys clearance | Digital key (owner key) registration | All digital keys (share key) clearance |

|---|---|---|---|---|

| Refer to PROCEDURE | "12" | * | "13" | |

| Registering digital key (owner key) | Digital key registered | - |

| - |

| Digital key not registered | - |

| - | |

| Digital key (owner key) lost |

|

| - | |

| Clear all digital keys (share key) | - | - |

| |

- *: Refer to the digital key application procedure then perform the registration procedure.

(c) Addressing malfunctions 1 (perform work in chart below in order starting from left)

Certification ECU (smart key ECU assembly) malfunction| Condition (The number of the electrical key transmitter sub-assemblies customer has brought) | Undesignated key permanent erasure | Replace certification ECU (smart key ECU assembly) | Replace ID code box (immobiliser code ECU) | Replace digital key ECU assembly*1 | - |

|---|---|---|---|---|---|

| Refer to PROCEDURE | "5" | HINT:

| HINT:

| HINT:

| - |

| All electrical key transmitter sub-assemblies | - |

| - | - | Continue to the table below |

| At least 1 electrical key transmitter sub-assembly (Key ID codes can be registered and cleared) |

|

| - | - | Continue to the table below |

| At least 1 electrical key transmitter sub-assembly (Key ID codes cannot be either registered or cleared) | - |

|

|

| Continue to the table below |

| All electrical key transmitter sub-assemblies are lost | - |

|

|

| Continue to the table below |

| Condition (The number of the electrical key transmitter sub-assemblies customer has brought) | New key ID registration | ECU communication ID registration | Remote engine start and stop registration*2 | VIN / digital key ECU serial number registration*1 | Digital key (owner key) registration using the digital key application*1 |

|---|---|---|---|---|---|

| Refer to PROCEDURE | "3" | "8" | "10" | "11" | *3 |

| All electrical key transmitter sub-assemblies |

| - |

| - | - |

| At least 1 electrical key transmitter sub-assembly (Key ID codes can be registered and cleared) |

| - |

| - | - |

| At least 1 electrical key transmitter sub-assembly (Key ID codes cannot be either registered or cleared) |

|

|

|

|

|

| All electrical key transmitter sub-assemblies are lost |

|

|

|

|

|

- *1: w/ Digital Key System

- *2: for Remote Connect Compatible Type

- *3: Refer to the digital key application procedure then perform the registration procedure.

(d) Addressing malfunctions 2 (perform work in chart below in order starting from left)

ID code box (immobiliser code ECU) malfunction| Condition (The number of the electrical key transmitter sub-assemblies customer has brought) | Replace certification ECU (smart key ECU assembly) | Replace ID code box (immobiliser code ECU) | Replace digital key ECU assembly*1 | New key ID registration | - |

|---|---|---|---|---|---|

| Refer to PROCEDURE | HINT:

| HINT:

| HINT:

| "3" | - |

| At least 1 electrical key transmitter sub-assembly | - |

| - | - | Continue to the table below |

| All electrical key transmitter sub-assemblies are lost |

|

|

|

| Continue to the table below |

| Condition (The number of the electrical key transmitter sub-assemblies customer has brought) | ECU code registration | ECU communication ID registration | Remote engine start and stop registration*2 | VIN / digital key ECU serial number registration*1 | Digital key (owner key) registration using the digital key application*1 |

|---|---|---|---|---|---|

| Refer to PROCEDURE | "7" | "8" | "10" | "11" | *3 |

| At least 1 electrical key transmitter sub-assembly |

|

| - | - | - |

| All electrical key transmitter sub-assemblies are lost | - |

|

|

|

|

- *1: w/ Digital Key System

- *2: for Remote Connect Compatible Type

- *3: Refer to the digital key application procedure then perform the registration procedure.

(e) Addressing malfunctions 3 (perform work in chart below in order starting from left)

NOTICE:

If All keys ID erasure (Smart code reset) is performed, the code between the certification ECU (smart key ECU assembly) and the digital key ECU assembly is cleared and the digital key system will not function.

Electrical key transmitter sub-assemblies malfunction| Condition (The number of the electrical key transmitter sub-assemblies customer has brought) | Undesignated key permanent erasure | All keys ID erasure (Smart code reset) | New key ID registration | Additional key ID registration | Digital key (owner key) registration |

|---|---|---|---|---|---|

| Refer to PROCEDURE | "5" | "6" | "3" | "4" | * |

| One or more electrical key transmitter sub-assembly that operates normally |

| - | - |

| - |

| All electrical key transmitter sub-assembly lost or any electrical key transmitter sub-assembly does not operate normally | - |

|

| - |

|

- *: Refer to the digital key application procedure then perform the registration procedure.

(f) Addressing malfunctions 4 (perform work in chart below in order starting from left) (w/ Digital Key System)

Digital key ECU assembly malfunction| Condition (The number of the electrical key transmitter sub-assemblies customer has brought) | All digital keys clearance using the digital key or multi-display | Replace certification ECU (smart key ECU assembly) | Replace ID code box (immobiliser code ECU) | Replace digital key ECU assembly | - |

|---|---|---|---|---|---|

| Refer to PROCEDURE | HINT:

| HINT:

| HINT:

| HINT:

| - |

| At least 1 electrical key transmitter sub-assembly |

| - | - |

| Continue to the table below |

| All electrical key transmitter sub-assemblies are lost | - |

|

|

| Continue to the table below |

| Condition (The number of the electrical key transmitter sub-assemblies customer has brought) | New key ID registration | ECU code registration | ECU communication ID registration | Remote engine start and stop registration*1 | VIN / digital key ECU serial number registration | Digital key (owner key) registration |

|---|---|---|---|---|---|---|

| Refer to PROCEDURE | "3" | "7" | "8" | "10" | "11" | *2 |

| At least 1 electrical key transmitter sub-assembly | - |

| - | - |

|

|

| All electrical key transmitter sub-assemblies are lost |

| - |

|

|

|

|

- *1: for Remote Connect Compatible Type

- *2: Refer to the digital key application procedure then perform the registration procedure.

(g) Addressing malfunctions 5 (perform work in chart below in order starting from left)

| Malfunctioning ECU | Condition | Replace hybrid Toyota Prius vehicle control ECU | Replace main body ECU (multiplex network body ECU) | Replace DCM (telematics transceiver)*1 | Replace BLE digital key receiver*2 | - |

|---|---|---|---|---|---|---|

| Refer to PROCEDURE | HINT:

| HINT:

| HINT:

| HINT:

| - | |

| Hybrid Toyota Prius vehicle control ECU | When replacing a new one |

| - | - | - | Continue to the table below |

| Main body ECU (multiplex network body ECU) | When replacing a new one | - |

| - | - | Continue to the table below |

| DCM (telematics transceiver)*1 | When replacing a new one | - | - |

| - | Continue to the table below |

| BLE digital key receiver assembly*2 | When replacing a new one | - | - | - |

| Continue to the table below |

| When replacing a used one | - | - | - |

| Continue to the table below | |

| Malfunctioning ECU | Condition | ECU code registration | Remote door lock and unlock registration*1 | Remote engine start and stop registration*1 |

|---|---|---|---|---|

| Refer to PROCEDURE | "7" | "9" | "10" | |

| Hybrid Toyota Prius vehicle control ECU | When replacing a new one | - | - | - |

| Main body ECU (multiplex network body ECU) | When replacing a new one |

|

| - |

| DCM (telematics transceiver)*1 | When replacing a new one | - |

|

|

| BLE digital key receiver assembly*2 | When replacing a new one |

| - | - |

| When replacing a used one |

| - | - | |

- *1: for Remote Connect Compatible Type

- *2: w/ Digital Key System

- *3: for BLE door digital key receiver assembly

- *4: for BLE luggage key receiver assembly

- *5: for BLE indoor digital key receiver assembly

3. NEW KEY ID REGISTRATION

NOTICE:

- When the certification ECU (smart key ECU assembly) is replaced, register all electrical key transmitter sub-assemblies used by the customer.

- Registered electrical key transmitter sub-assemblies other than those registered during the certification ECU (smart key ECU assembly) replacement cannot be re-registered, and therefore they can no longer be used.

- Immediately after replacing the certification ECU (smart key ECU assembly), the GTS item "Number of Registered Codes" should change to "0". If this item does not change to "0", the certification ECU (smart key ECU assembly) may be registered to another Toyota Prius vehicle. A certification ECU (smart key ECU assembly) which is registered to another vehicle cannot be used.

| Process | Procedure | Time limit (seconds) |

|---|---|---|

| 1. Start of registration |

| - |

| 2. Get Pass-Code |

| - |

| 3. Confirmation of all registered electrical key transmitter sub-assemblies (When only the certification ECU (smart key ECU assembly) is replaced) |

HINT: When performing the electrical key transmitter sub-assembly confirmation procedure the security indicator light comes on and remains on until all the electrical key transmitter sub-assemblies are confirmed. | 30 |

| 4. Verification of unregistered electrical key transmitter sub-assembly |

| 30 |

| 5. End of registration | Finish new key ID code registration. | - |

4. ADDITIONAL KEY ID REGISTRATION

NOTICE:

If an electrical key transmitter sub-assembly has recently been registered, the new key registration warning message will be displayed on the multi-information display and cannot be cleared for 10 days.*

This message is displayed to inform the user that an electrical key transmitter sub-assembly has been registered and help prevent the Toyota Prius vehicle from being stolen if the registration was unauthorized.

-

*: Display of the warning message will be suspended when any of the following conditions is met:

- The warning message has been displayed for 60 seconds.

- All of the doors are closed and locked.

- Ignition switch is turned to ON.

| Process | Procedure | Time limit (seconds) |

|---|---|---|

| 1. Start of registration |

| - |

| 2. Get Pass-Code |

| - |

| 3. Confirmation of registered electrical key transmitter sub-assemblies |

HINT: When checking registered electrical key transmitter sub-assemblies, check using an electrical key transmitter sub-assembly that is registered to the Toyota Prius vehicle. | 30 |

| 4. Verification of unregistered electrical key transmitter sub-assembly |

| 30 |

| 5. End of registration | Finish additional key ID code registration. | - |

5. UNDESIGNATED KEY PERMANENT ERASURE

NOTICE:

- If Undesignated Key Permanent Erasure is performed, previously registered electrical key transmitter sub-assemblies cannot be re-registered, and therefore they can no longer be used.

- Do not erase all registered key codes except one electrical key transmitter sub-assembly (for card type) while the smart key system cancel is activated. By doing so, the smart key system cannot be returned to its original condition using the cancel operation. In addition, the entry unlock switching function cannot be used. However, erasing all registered key codes except one electrical key transmitter sub-assembly (for card type) will not cause problems if registering additional electrical key transmitter sub-assemblies (for standard type).

HINT:

Undesignated Key Permanent Erasure can be used to delete and disable all key IDs other than the electrical key transmitter sub-assemblies selected during "confirmation of registered electrical key transmitter sub-assemblies to keep (process No. 3)".

| Process | Procedure | Time limit (seconds) |

|---|---|---|

| 1. Start of erasure |

| - |

| 2. Get Pass-Code |

| - |

| 3. Confirmation of registered electrical key transmitter sub-assemblies to keep |

HINT: The security indicator light illuminates when all the registered electrical key transmitter sub-assemblies to keep are confirmed. | 30 |

| 4. Erasure of key ID |

| - |

| 5. Confirmation of ECU code |

HINT: The security indicator light goes off when confirmation of ECU code is completed. | - |

| 6. Erasure of ID code |

| - |

| 7. End of erasure | Finish key ID erasure. | - |

6. ALL KEYS ID ERASURE (SMART CODE RESET)

NOTICE:

Do not perform "Smart Code Reset" (all key ID erasure) until all of the malfunctions and symptoms have been confirmed and resolved. If all key ID erasure is performed without confirming or resolving malfunctions, key registration will be unable to be performed, resulting in unnecessary part replacement.

| Process | Procedure | Time limit (seconds) |

|---|---|---|

| 1. Start of erasure |

| - |

| 2. Get Pass-Code |

NOTICE: After obtaining the Pass-Code, do not turn off the GTS until erasure is completed. If the GTS is turned off before erasure is completed, obtain the Pass-Code once more. | - |

| 3. Erasure of ID code |

| - |

| 4. End of erasure | Finish key ID code erasure. | - |

7. ECU CODE REGISTRATION

| Process | Procedure | Time limit (seconds) |

|---|---|---|

| 1. Start of registration |

| - |

| 2. Confirmation of registered electrical key transmitter sub-assemblies |

HINT: When checking registered electrical key transmitter sub-assemblies, check using an electrical key transmitter sub-assembly that is registered to the Toyota Prius vehicle. | 30 |

| 3. Registration of ECU code |

| - |

| 4. End of registration | Finish ECU code registration. | - |

8. ECU COMMUNICATION ID REGISTRATION

NOTICE:

Do not open or close the driver door during registration. If the driver door is opened or closed, restart from step 1 of "Start of registration".

| Process | Procedure |

|---|---|

| 1. Start of registration |

|

| 2. ECU communication ID registration |

|

| 3. Confirmation of registration |

|

| 4. Clear DTC |

|

| 5. End of registration | Finish ECU communication ID registration. |

9. REMOTE DOOR LOCK AND UNLOCK REGISTRATION

| Process | Procedure |

|---|---|

| 1. Start of registration |

|

| 2. Registration of remote door lock and unlock |

|

| 3. End of registration | Finish remote door lock and unlock registration. |

10. REMOTE ENGINE START AND STOP REGISTRATION

| Process | Procedure |

|---|---|

| 1. Start of registration |

|

| 2. Registration of remote engine start and stop |

|

| 3. End of registration | Finish remote engine start and stop registration. |

11. VIN / DIGITAL KEY ECU SERIAL NO. REGISTRATION TO SERVER

| Process | Procedure |

|---|---|

| 1. Start of registration |

|

| 2. Registration to server |

HINT: After the GTS operation completes and the ignition switch is turned off, the digital key ECU serial No. and VIN will be sent to the center via the telematics system and registered to the dedicated server 30 seconds after the ignition switch is turned to ON (IG) for the first time. |

| 3. Confirmation of server registration completion |

|

| 4. End of registration | Finish VIN / digital key ECU serial No. registration to server. |

12. ALL DIGITAL KEYS CLEARANCE

| Process | Procedure | Time limit (seconds) |

|---|---|---|

| 1. Start of erasure |

| - |

| 2. Get Pass-Code |

NOTICE: After obtaining the Pass-Code, do not turn off the GTS until erasure is completed. If the GTS is turned off before erasure is completed, obtain the Pass-Code once more. | - |

| 3. Confirmation of registered electrical key transmitter sub-assemblies |

HINT: When checking registered electrical key transmitter sub-assemblies, check using an electrical key transmitter sub-assembly that is registered to the Toyota Prius vehicle. | 30 |

| 4. End of erasure | Finish all digital keys clearance. | - |

13. ALL DIGITAL KEYS (SHARE KEY) CLEARANCE

| Process | Procedure | Time limit (seconds) |

|---|---|---|

| 1. Start of erasure |

| - |

| 2. Get Pass-Code |

NOTICE: After obtaining the Pass-Code, do not turn off the GTS until erasure is completed. If the GTS is turned off before erasure is completed, obtain the Pass-Code once more. | - |

| 3. Confirmation of registered electrical key transmitter sub-assemblies |

HINT: When checking registered electrical key transmitter sub-assemblies, check using an electrical key transmitter sub-assembly that is registered to the Toyota Prius vehicle. | 30 |

| 4. End of erasure | Finish all digital keys (share key) clearance. | - |

Customize Parameters

CUSTOMIZE PARAMETERS

CUSTOMIZE SMART KEY SYSTEM (for Start Function)

NOTICE:

- When the customer requests a change in a function, first make sure that the function can be customized.

- Record the current settings before customizing.

HINT:

The following items can be customized.

(a) Customizing with the GTS

Click here

(b) Customizing with the multi-display

Click here

ENTRY CANCEL FUNCTION (MANUAL OPERATION)

Click here

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

- Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the suspected areas in the order they are listed. Replace parts as necessary.

- Inspect the fuses and relays related to the system before inspecting the suspected areas below.

- If the problem occurs in certain locations or times of day, the possibility of wave interference is high.

- If a malfunction occurred after optional components were installed by the dealer, check if there is wave interference from the components.

| Symptom | Suspected Area | Link |

|---|---|---|

| Power source mode does not change to ON or ACC | Smart key system (for Entry Function) |

|

| Affected by wave interference | ||

| Transmitter battery | ||

| Electrical key transmitter sub-assembly | ||

| No. 1 indoor electrical key antenna assembly (front floor) | ||

| No. 2 indoor electrical key antenna assembly (rear floor) | ||

| Power switch | ||

| Wire harness or connector | ||

| Power distribution box assembly | ||

| Certification ECU (Smart key ECU assembly) | ||

| Power source mode does not change to ON | Wire harness or connector |

|

| Relay | ||

| Power distribution box assembly | ||

| Certification ECU (Smart key ECU assembly) | ||

| Power source mode does not change to ACC | Wire harness or connector |

|

| Relay | ||

| Power distribution box assembly | ||

| Certification ECU (Smart key ECU assembly) | ||

| Power source mode does not change to ON (READY) | Hybrid control system |

|

| Immobiliser function | ||

| Wire harness or connector | ||

| Transmission floor shift assembly | ||

| Stop light switch assembly | ||

| Certification ECU (Smart key ECU assembly) | ||

| Only BA power source mode does not operate correctly . | Smart key system (for Entry Function) |

|

| Wireless door lock control system |

| |

| Power door lock system |

| |

| Power distribution box assembly |

| |

| New key cannot be registered | LIN communication system |

|

| Meter / gauge system | ||

| Reregistration | ||

| Electrical key transmitter sub-assembly | ||

| ID code box (Immobiliser code ECU) | ||

| Certification ECU (Smart key ECU assembly) | ||

| Additional key cannot be registered | Smart key system (for Start Function) |

|

| Electrical key transmitter sub-assembly | ||

| ID code box (Immobiliser code ECU) | ||

| Certification ECU (Smart key ECU assembly) | ||

| New key registration warning message is not displayed | Lighting system |

|

| Meter / gauge system | ||

| Certification ECU (Smart key ECU assembly) | ||

| Security indicator light does not blink | Wire harness or connector |

|

| Security indicator light (map light assembly) | ||

| Main body ECU (Multiplex network body ECU) | ||

| Certification ECU (Smart key ECU assembly) | ||

| Immobiliser system does not operate properly | Communication ID registration was defective |

|

| Hybrid control system | ||

| Wire harness or connector | ||

| ID code box (Immobiliser code ECU) | ||

| Hybrid Toyota Prius vehicle control ECU | ||

| System malfunction message is displayed on the multi-information display | Smart key system (for Entry Function) |

|

| Smart key system (for Start Function) | ||

| Certification ECU (Smart key ECU assembly) | ||

| Electronically controlled brake system |

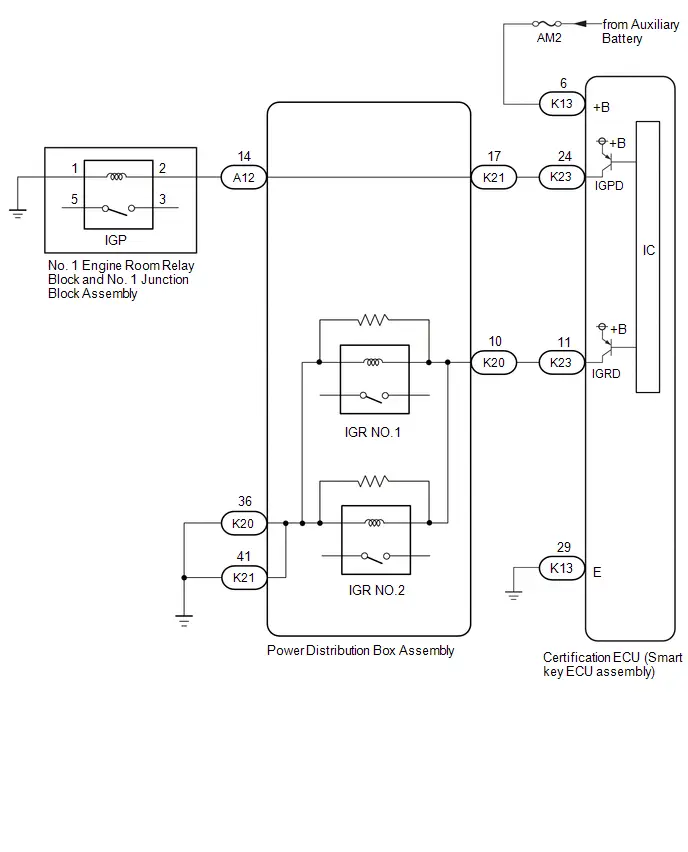

Terminals Of Ecu

TERMINALS OF ECU

NOTICE:

-

When performing an inspection, make sure that "ACC Customize" is set to "ON" using the multi-display.

Click here

-

When "ACC Customize" is set to "ON" (ACC supply power enabled), the certification ECU (smart key ECU assembly) controls the ACC relay on and off. When "ACC Customize" is set to "OFF" (ACC supply power disabled), the certification ECU (smart key ECU assembly) and radio and display receiver assembly control the ACC relay on and off.

Therefore, inspection conditions and results may differ depending on whether "ACC customize" is set to ON or OFF when inspecting ACC related terminals.

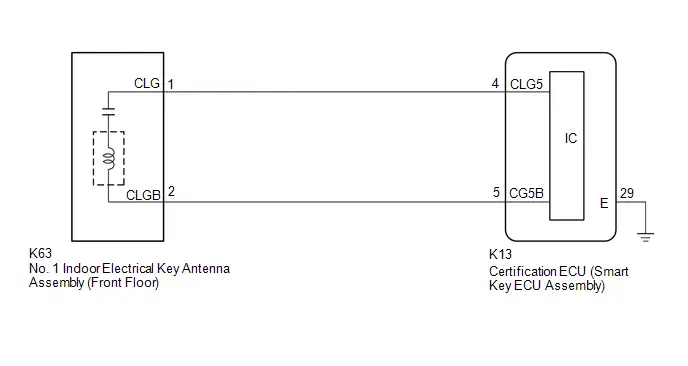

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

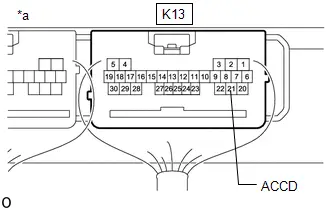

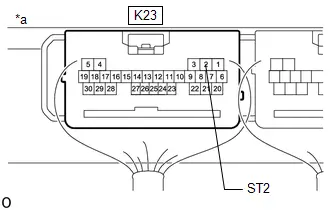

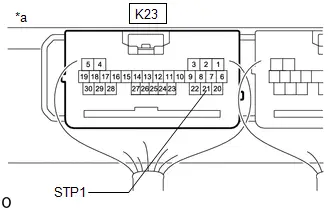

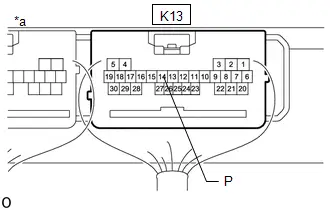

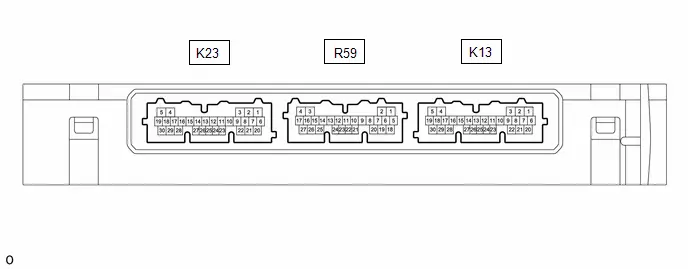

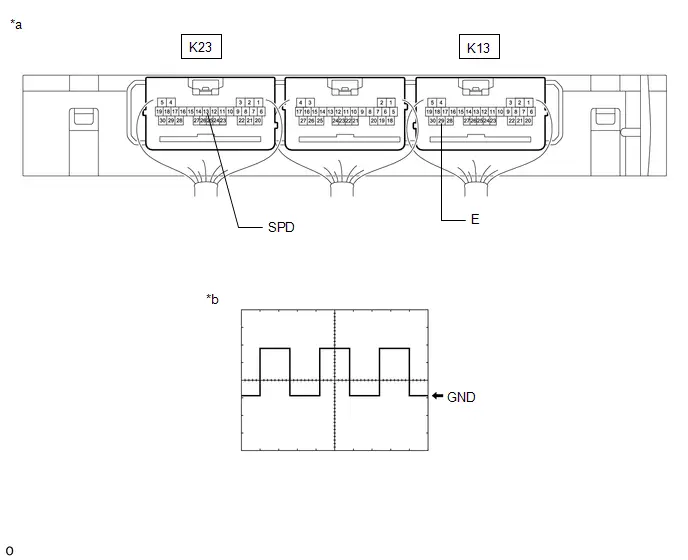

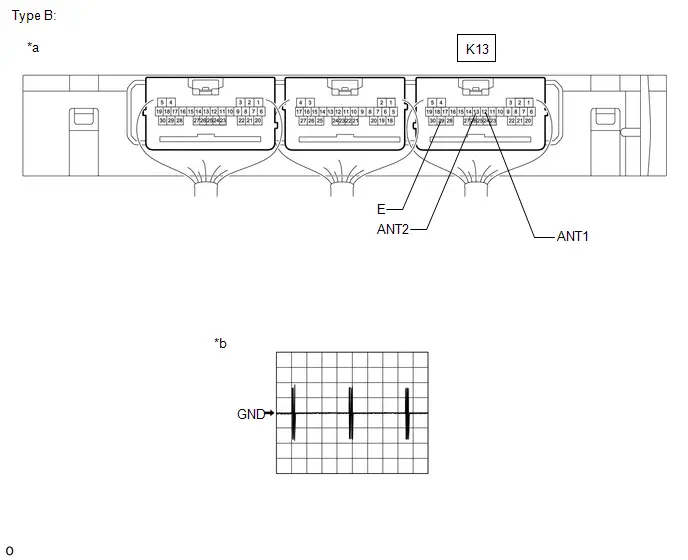

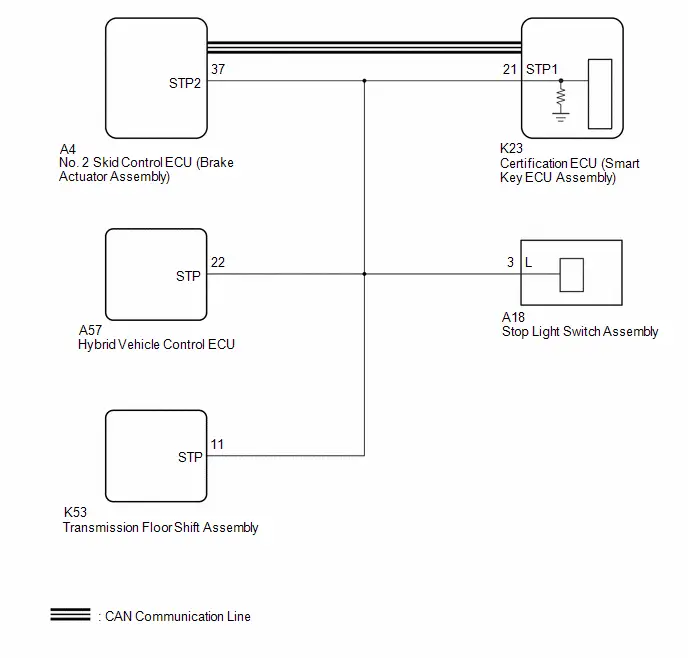

(a) Disconnect the K23 and K13 certification ECU (smart key ECU assembly) connectors.

(b) Measure the resistance and voltage according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with the connector disconnected.

| Tester Connection | Terminal Description | Condition | Specified Condition | Related Data List Item/DTC |

|---|---|---|---|---|

| K23-21 (STP1) - Body ground | Stop light switch signal | Brake pedal depressed → Brake pedal released | 9 V or higher → 1 V or less | Power Source Control

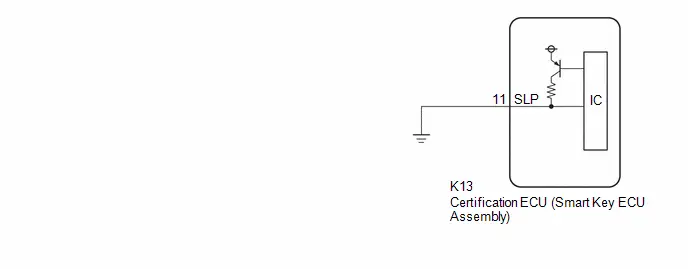

|

| K13-6 ( B) - K13-29 (E) | Power source | Ignition switch off | 11 to 14 V | - |

| K13-14 (P) - K13-29 (E) | P position signal | Always | 30 kΩ or higher | Power Source Control

|

| K23-22 (CUTB) - Body ground | Dark current cut pin* | Ignition switch off | 11 to 14 V | - |

| K13-29 (E) - Body ground | GND | Always | Below 1 Ω | - |

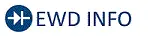

| K13-11 (SLP) - K13-29 (E) | GND | Always | Below 1 Ω | - |

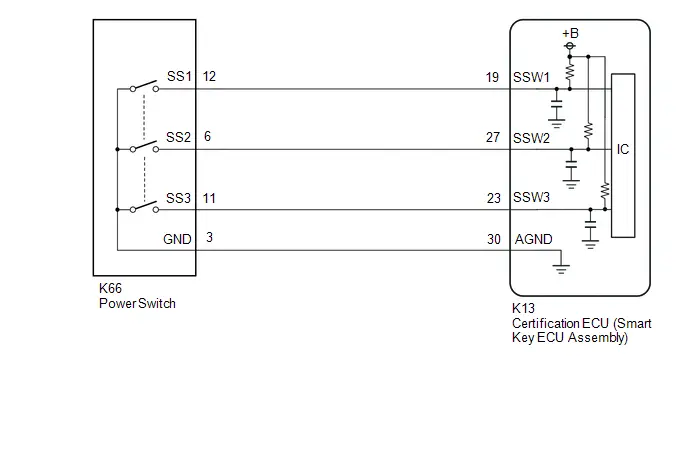

| K13-23 (SSW3) - Body ground | SSW3 contact signal | Power switch pushed → Power switch not pushed | Below 15 Ω → 10 kΩ or higher | Power Source Control

|

| K13-27 (SSW2) - Body ground | SSW2 contact signal | Power switch pushed → Power switch not pushed | Below 15 Ω → 10 kΩ or higher | Power Source Control

|

| K13-19 (SSW1) - Body ground | SSW1 contact signal | Power switch pushed → Power switch not pushed | Below 15 Ω → 10 kΩ or higher | Power Source Control

|

- *: In order to prevent the Toyota Prius vehicle auxiliary battery from being depleted when the vehicle is shipped long distances, a fuse that cuts unnecessary electrical load while the vehicle is being shipped is installed in the circuit. If the fuse is removed, the circuit becomes open. If the fuse that is between the vehicle auxiliary battery and terminal CUTB is removed and the circuit is open, the certification ECU (smart key ECU assembly) changes to a certain control mode (example: the transmission of radio waves every 0.25 seconds, which form the detection area, stops).

(c) Connect the K23 and K13 certification ECU (smart key ECU assembly) connectors.

(d) Measure the voltage and resistance, and check for pulses according to the value(s) in the table below.

| Tester Connection | Terminal Description | Condition | Specified Condition | Related Data List Item/DTC |

|---|---|---|---|---|

| K13-8 (LIN) - K13-29 (E) | LIN communication line | Ignition switch ON | Pulse generation | - |

| K13-14 (P) - K13-29 (E) | P position signal | Ignition switch ON and Shift position in P | Pulse generation (24 to 25 Hz or 30 to 31 Hz, High voltage: 9 V or more, Low voltage: below 1 V, duty ratio: 25 %) | Power Source Control

|

| Ignition switch ON and Shift position in N | Pulse generation (24 to 25 Hz or 30 to 31 Hz, High voltage: 9 V or more, Low voltage: below 1 V, duty ratio: 55 %) | |||

| Ignition switch ON and Shift position in other then P or N | Pulse generation (24 to 25 Hz or 30 to 31 Hz, High voltage: 9 V or more, Low voltage: below 1 V, duty ratio: 40 %) | |||

| K13-23 (SSW3) - K13-29 (E) | SSW3 contact signal | Power switch not pushed → Power switch pushed | 9 V or higher → 1 V or less | Power Source Control

|

| K13-27 (SSW2) - K13-29 (E) | SSW2 contact signal | Power switch not pushed → Power switch pushed | 9 V or higher → 1 V or less | Power Source Control

|

| K13-19 (SSW1) - K13-29 (E) | SSW1 contact signal | Power switch not pushed → Power switch pushed | 9 V or higher → 1 V or less | Power Source Control

|

| K13-21 (ACCD) - K13-29 (E) | ACC signal | Ignition switch off → Ignition switch ACC | 1 V or less → 8.5 V or higher | Power Source Control

|

| K23-11 (IGRD) - K13-29 (E) | IG signal | Ignition switch off → Ignition switch ON | 1 V or less → 9 V or higher | Power Source Control

|

| K23-24 (IGPD) - K13-29 (E) | IG signal | Ignition switch off → Ignition switch ON | 1 V or less → 9 V or higher | Power Source Control

|

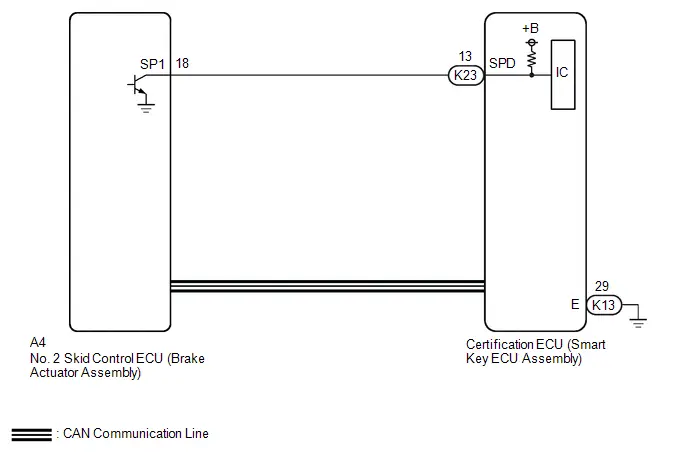

| K23-13 (SPD) - K13-29 (E) | Toyota Prius Vehicle speed signal | Vehicle being driven at approx. 5 km/h (3 mph) | Pulse generation (See waveform 1) | Power Source Control

|

| K23-2 (ST2) - K13-29 (E) | STSW signal | With the brake pedal depressed, the power switch is pressed and held → After approx. 3 sec. has elapsed, the power switch is released | 8.5 V or higher → 1 V or less | - |

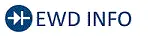

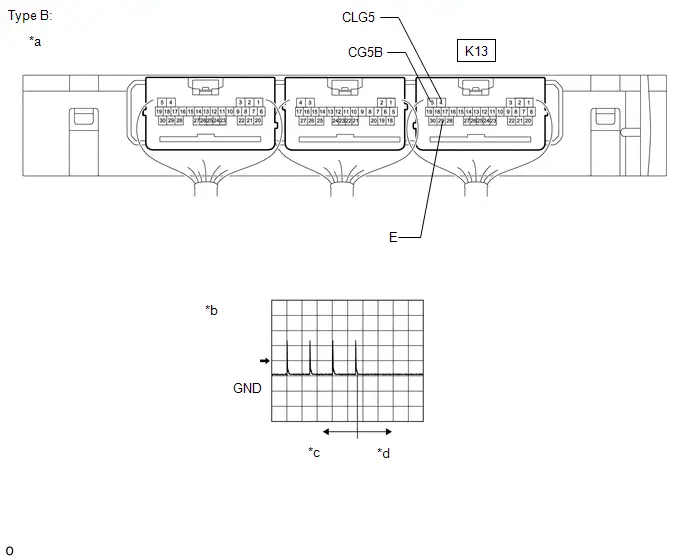

| K13-4 (CLG5) - K13-29 (E) | Output to No. 1 indoor electrical key antenna assembly (front floor) | Procedure:

| Pulse generation (See waveform 2) | - |

| K13-5 (CG5B) - K13-29 (E) | Output to No. 1 indoor electrical key antenna assembly (front floor) (terminal on opposite side of component from CLG5 output terminal) | Procedure:

| Pulse generation (See waveform 2) | - |

| R59-10 (CLG7) - K13-29 (E) | Output to No. 2 indoor electrical key antenna assembly (rear floor) | Procedure:

| Pulse generation (See waveform 2) | - |

| R59-9 (CG7B) - K13-29 (E) | Output to No. 2 indoor electrical key antenna assembly (rear floor) (terminal on opposite side of component from CLG7 output terminal) | Procedure:

| Pulse generation (See waveform 2) | - |

| K13-30 (AGND) - Body ground | Transponder key amplifier ground | Always | Below 1 Ω | - |

| K13-12 (ANT1) - K13-30 (AGND) | Signal input / output from transponder key coil (transponder key coil built into power switch) | Ignition switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of power switch pressed | Pulse generation (Type A: See waveform 3, Type B: See waveform 5) | Smart Key

|

| K13-13 (ANT2) - K13-30 (AGND) | Signal input / output from transponder key coil (transponder key coil built into power switch) | Ignition switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of power switch pressed | Pulse generation (Type A: See waveform 4, Type B: See waveform 5) | |

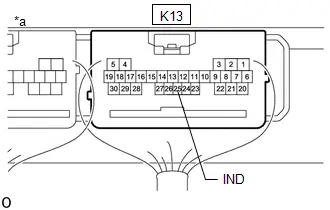

| K13-25 (IND) - K13-29 (E) | Security indicator output | Ignition switch off → ON | Pulse generation → Below 2 V | - |

| R59-20 (WCSW) - K13-29 (E)* | Wireless charger system stop signal | Procedure:

| Below 1 V → 4.5 to 6 V (For 1 second after ignition switch to ACC or ON) | - |

- *: w/ Wireless Charging System

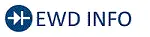

(e) Using an oscilloscope, check the waveform of the ECU.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

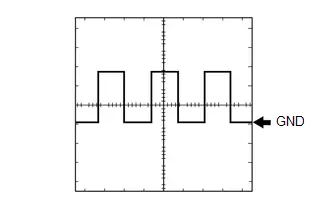

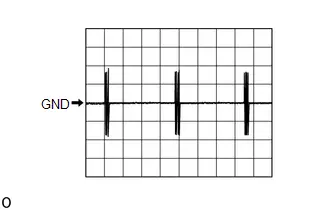

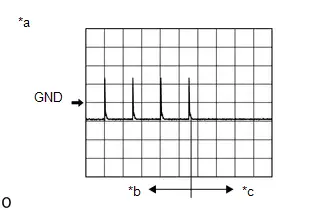

(1) Waveform 1

Measurement Condition

Measurement Condition | Item | Content |

|---|---|

| Tester Connection | K23-13 (SPD) - K13-29 (E) |

| Tool Setting | 5 V/DIV., 20 ms./DIV. |

| Condition | Toyota Prius Vehicle being driven at approx. 5 km/h (3 mph) |

HINT:

The wavelength becomes shorter as the vehicle speed increases.

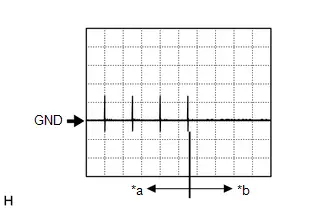

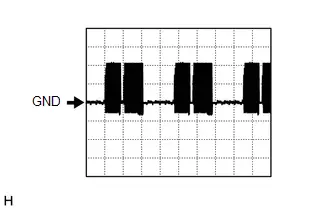

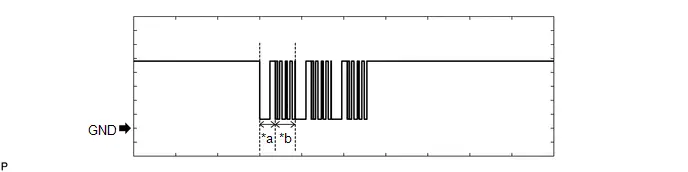

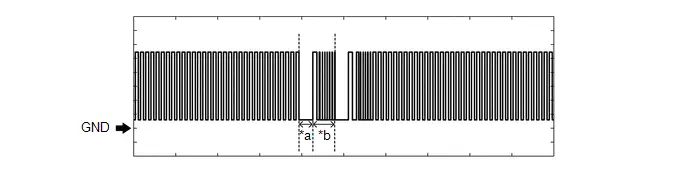

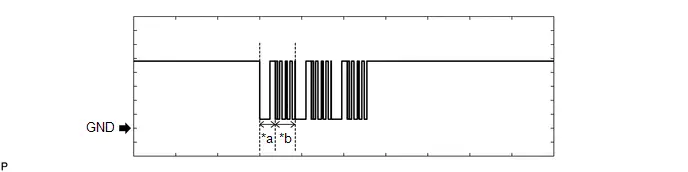

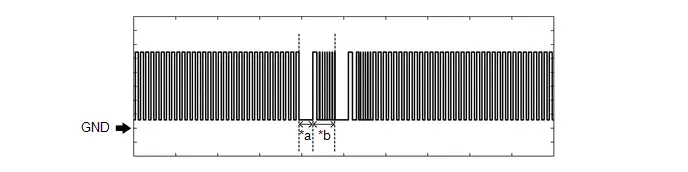

(2) Waveform 2

Type A:

| *a | For 30 seconds after any door closed |

| *b | After 30 seconds or more have elapsed since any door closed |

| Item | Content |

|---|---|

| Tester Connection | K13-4 (CLG5) - K13-29 (E) K13-5 (CG5B) - K13-29 (E) R59-10 (CLG7) - K13-29 (E) R59-9 (CG7B) - K13-29 (E) |

| Tool Setting | 5 V/DIV., 500 ms/DIV. |

| Condition | Procedure:

|

| *a | For 30 seconds after any door closed |

| *b | After 30 seconds or more have elapsed since any door closed |

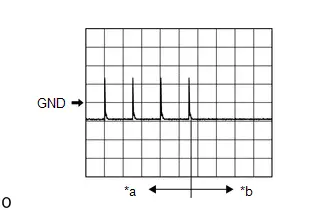

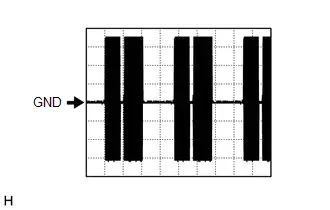

(3) Waveform 3 (Type A)

Measurement Condition

Measurement Condition | Item | Content |

|---|---|

| Tester Connection | K13-12 (ANT1) - K13-30 (AGND) |

| Tool Setting | 5 V/DIV., 200 ms./DIV. |

| Condition | Ignition switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of power switch pressed |

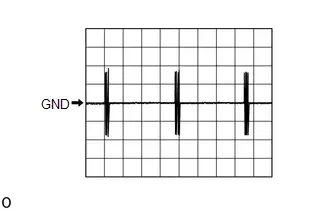

(4) Waveform 4 (Type A)

Measurement Condition

Measurement Condition | Item | Content |

|---|---|

| Tester Connection | K13-13 (ANT2) - K13-30 (AGND) |

| Tool Setting | 20 V/DIV., 200 ms/DIV. |

| Condition | Ignition switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of power switch pressed |

(5) Waveform 5 (Type B)

Measurement Condition

Measurement Condition | Item | Content |

|---|---|

| Tester Connection | K13-13 (ANT2) - K13-30 (AGND) |

| Tool Setting | 20 V/DIV., 200 ms/DIV. |

| Condition | Ignition switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of power switch pressed |

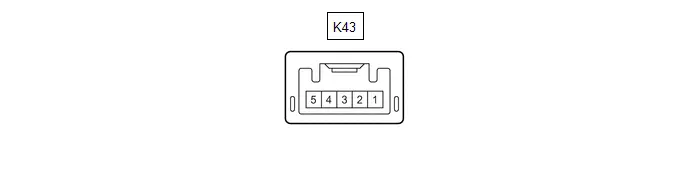

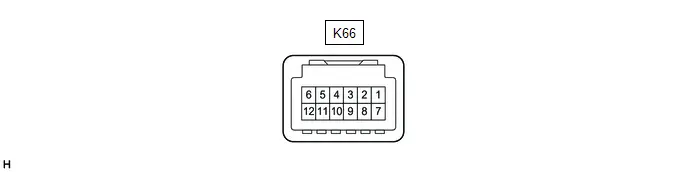

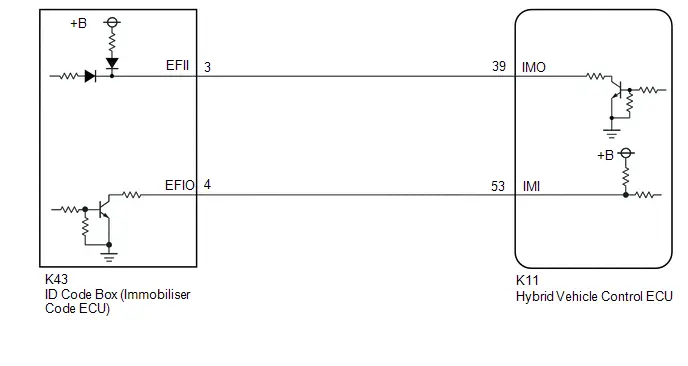

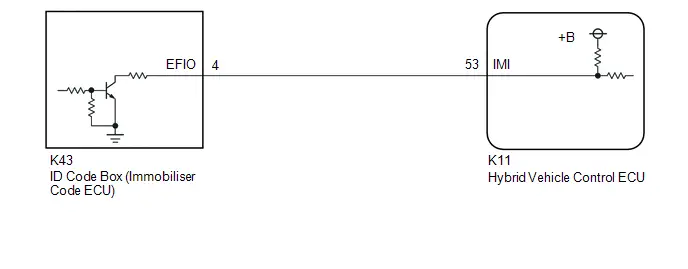

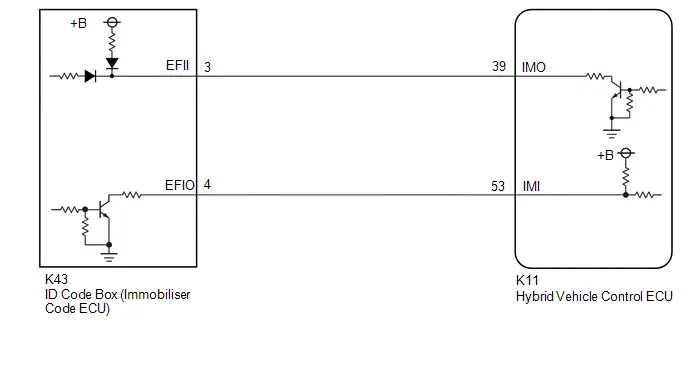

CHECK ID CODE BOX (IMMOBILISER CODE ECU)

(a) Disconnect the K43 ID code box (immobiliser code ECU) connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with the connector disconnected.

| Tester Connection | Terminal Description | Condition | Specified Condition | Related Data List Item |

|---|---|---|---|---|

| K43-1 ( B) - Body ground | Power source | Ignition switch off | 11 to 14 V | - |

| K43-5 (GND) - Body ground | Ground | Always | Below 1 Ω |

(c) Connect the K43 ID code box (immobiliser code ECU) connector.

(d) Measure the voltage and check for pulses according to the value(s) in the table below.

| Tester Connection | Terminal Description | Condition | Specified Condition | Related Data List Item |

|---|---|---|---|---|

| K43-3 (EFII) - K43-5 (GND) | EFI communication input (Signal input from hybrid Toyota Prius vehicle control ECU to ID code box (immobiliser code ECU)) | Ignition switch off | 11 to 14 V | Smart Key

|

| K43-3 (EFII) - K43-5 (GND) | EFI communication input (Signal input from hybrid Toyota Prius vehicle control ECU to ID code box (immobiliser code ECU)) | Within 3 seconds of hybrid control system start or within 3 seconds of ignition switch turned to ON after cable disconnected and reconnected to auxiliary battery | Pulse generation (See waveform 1) | |

| K43-4 (EFIO) - K43-5 (GND) | EFI communication output (Signal output from ID code box (immobiliser code ECU) to hybrid Toyota Prius vehicle control ECU) | Ignition switch off | Below 1 V | |

| K43-4 (EFIO) - K43-5 (GND) | EFI communication output (Signal output from ID code box (immobiliser code ECU) to hybrid Toyota Prius vehicle control ECU) | Within 3 seconds of hybrid control system start or within 3 seconds of ignition switch turned to ON after cable disconnected and reconnected to auxiliary battery | Pulse generation (See waveform 2) | |

| K43-2 (LIN1) - K43-5 (GND) | LIN communication line | Ignition switch ON | Pulse generation | - |

(e) Using an oscilloscope, check the waveform.

NOTICE:

The waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

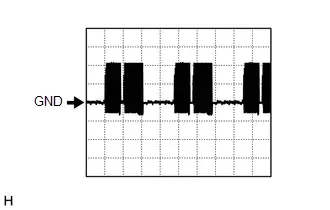

(1) Waveform 1

| *a | Approximately 160 ms. | *b | Approximately 270 ms. |

| Item | Content |

|---|---|

| Tester Connection | K43-3 (EFII) - K43-5 (GND) |

| Tool Setting | 2 V/DIV., 500 ms./DIV. |

| Condition | Within 3 seconds of hybrid control system start or within 3 seconds of ignition switch turned to ON after cable disconnected and reconnected to auxiliary battery |

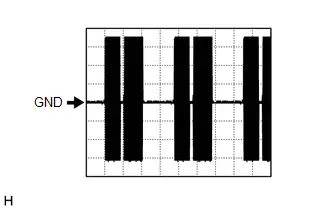

(2) Waveform 2

| *a | Approximately 160 ms. | *b | Approximately 270 ms. |

| Item | Content |

|---|---|

| Tester Connection | K43-4 (EFIO) - K43-5 (GND) |

| Tool Setting | 2 V/DIV., 500 ms./DIV. |

| Condition | Within 3 seconds of hybrid control system start or within 3 seconds of ignition switch turned to ON after cable disconnected and reconnected to auxiliary battery |

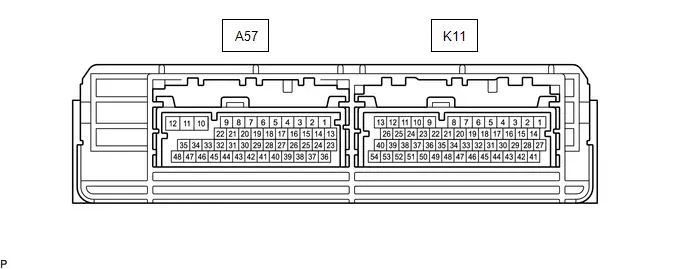

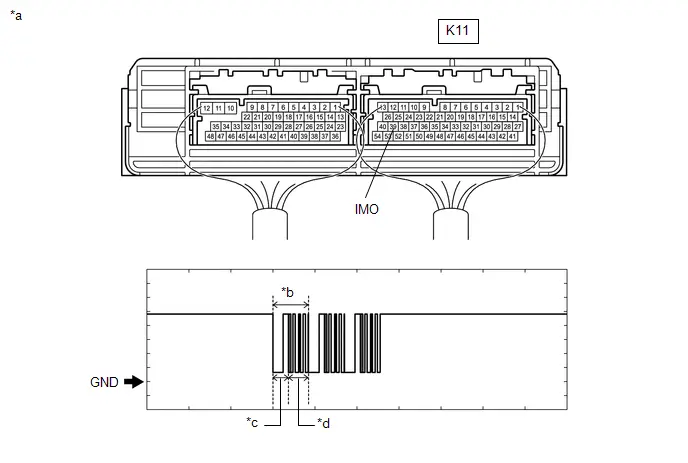

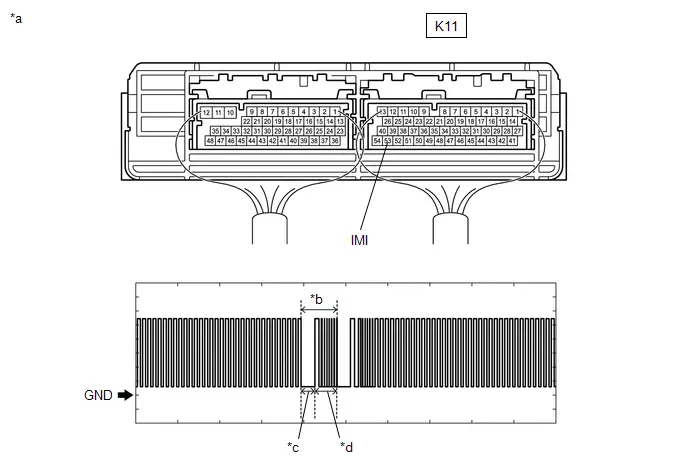

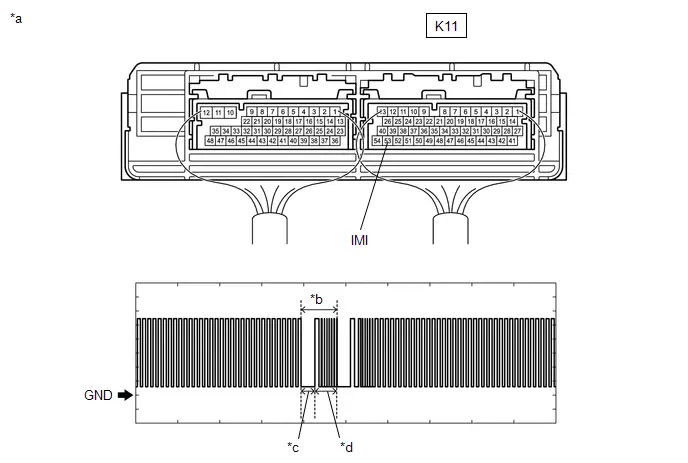

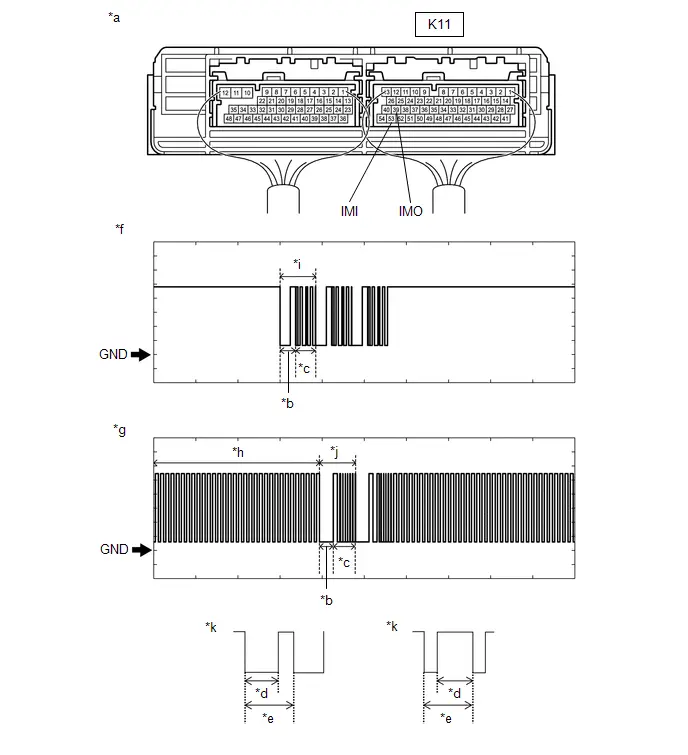

CHECK HYBRID Toyota Prius Vehicle CONTROL ECU

(a) Measure the voltage and resistance, and check for pulses according to the value(s) in the table below.

| Terminal No. (Symbol) | Terminal Description | Condition | Specified Condition | Related Data List Item/DTC |

|---|---|---|---|---|

| K11-26 (IGP) - K11-1 (E1) | Ignition power supply | Ignition switch ON | 11 to 14 V | - |

| A57-8 (IGR) - K11-1 (E1) | Ignition power supply | Ignition switch ON | 11 to 14 V | - |

| K11-1 (E1) - Body ground | Ground | Always | Below 1 Ω | - |

| K11-39 (IMO) - K11-1 (E1) | EFI communication output (Signal output from hybrid Toyota Prius vehicle control ECU to ID code box (immobiliser code ECU)) | Ignition switch off | 11 to 14 V |

|

| K11-39 (IMO) - K11-1 (E1) | EFI communication output (Signal output from hybrid Toyota Prius vehicle control ECU to ID code box (immobiliser code ECU)) | Within 3 seconds of hybrid control system start or within 3 seconds of ignition switch turned to ON after cable disconnected and reconnected to auxiliary battery | Pulse generation (See waveform 1) | |

| K11-53 (IMI) - K11-1 (E1) | EFI communication input (Signal input from ID code box (immobiliser code ECU) to hybrid Toyota Prius vehicle control ECU) | Ignition switch off | 11 to 14 V → 1 V or less | |

| K11-53 (IMI) - K11-1 (E1) | EFI communication input (Signal input from ID code box (immobiliser code ECU) to hybrid Toyota Prius vehicle control ECU) | Within 3 seconds of hybrid control system start or within 3 seconds of ignition switch turned to ON after cable disconnected and reconnected to auxiliary battery | Pulse generation (See waveform 2) | |