Toyota Prius: Rear Crankshaft Oil Seal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during rear crankshaft oil removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

|

*: Even when not replacing the part, it is necessary to perform the specified necessary procedures after installation.

*1: Also necessary after performing a tire rotation. *2: It is not necessary to perform this procedure if the tire pressure warning valve and transmitters are installed to the same location. | |||

| Replacement of ECM | Update ECU security key | Toyota Prius Vehicle Control History (RoB) are stored |

|

| ECU configuration | - |

| |

| Perform Toyota Prius Vehicle Identification Number (VIN) registration | DTC is output |

| |

| Inspection after repair |

|

|

| Replacement of inverter with converter assembly | ECU configuration | - |

|

| Resolver learning |

|

| |

| Replacement of hybrid vehicle transaxle assembly |

|

|

|

| Suspension parts | Rear television camera assembly optical axis (Back camera position setting) | Parking Assist Monitor System |

|

| Parking assist ECU initialization | Panoramic View Monitor System |

| |

| Advanced Park |

| ||

| Tires |

| Tire Pressure Warning System | Refer to Procedures Necessary When Replacing Parts (for Tire Pressure Warning System) table below |

| Rear television camera assembly optical axis (Back camera position setting) | Parking Assist Monitor System |

| |

| Parking assist ECU initialization | Panoramic View Monitor System |

| |

| Advanced Park |

| ||

| Replacement of front bumper assembly* | Front television camera view adjustment | Panoramic View Monitor System |

|

| Advanced Park |

| ||

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

-

Learning completes when Toyota Prius vehicle is driven

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Front Camera System

Drive the Toyota Prius vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more.

-

Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

*1: w/o Power Back Door System *2: w/ Power Back Door System

Power Door Lock Control System*1

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

Power Back Door System*2

Reset back door close position

Air Conditioning System

After the ignition switch is turned to ON, the servo motor standard position is recognized.

-

CAUTION / NOTICE / HINT

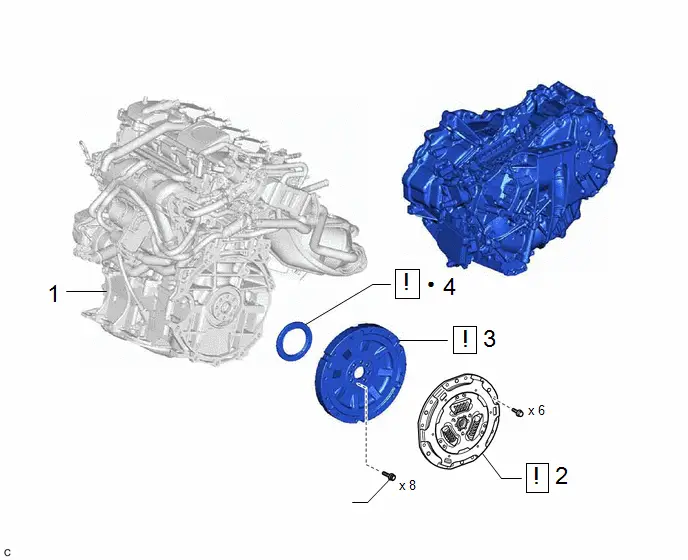

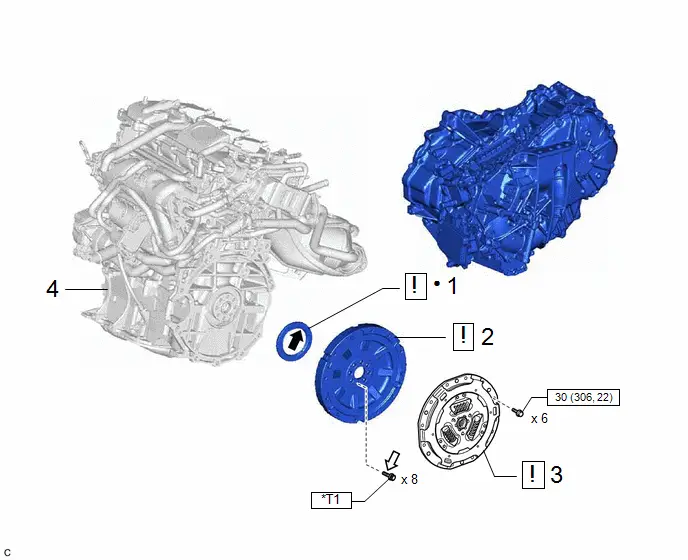

COMPONENTS (REMOVAL)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | ENGINE ASSEMBLY | - | - | - | - |

| 2 | TRANSMISSION INPUT DAMPER ASSEMBLY | 31270 |

| - | - |

| 3 | FLYWHEEL SUB-ASSEMBLY | 13405 |

| - | - |

| 4 | REAR ENGINE OIL SEAL | 11401L |

| - | - |

| ● | Non-reusable part | ★ | Precoated part |

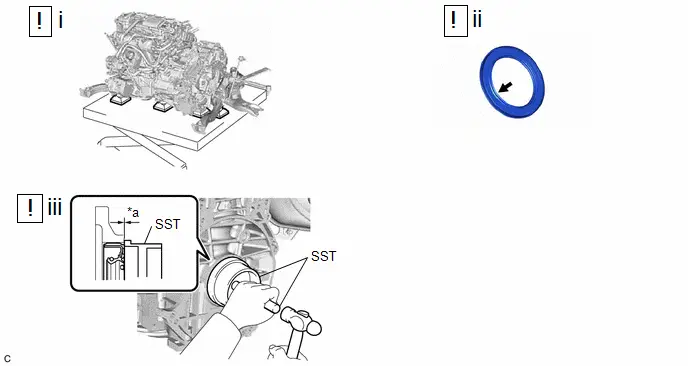

PROCEDURE

1. REMOVE ENGINE ASSEMBLY

Click here

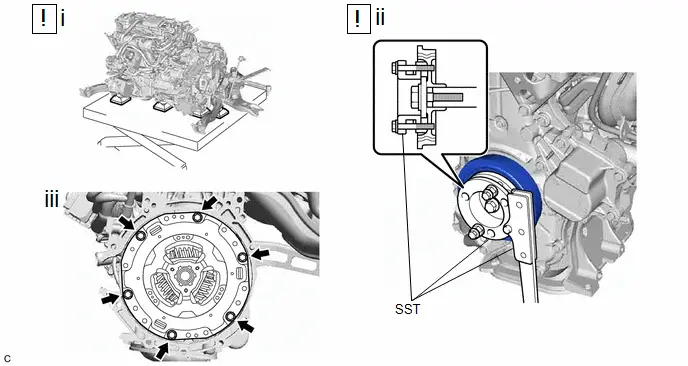

2. REMOVE TRANSMISSION INPUT DAMPER ASSEMBLY

(1) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly horizontal.

- To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

(2) Using SST, hold the crankshaft pulley.

SST: 09213-58014

91551-80840

SST: 09330-00021

(3) Remove the 6 bolts and transmission input damper assembly from the flywheel sub-assembly.

3. REMOVE FLYWHEEL SUB-ASSEMBLY

(1) Using SST, hold the crankshaft pulley.

SST: 09213-58014

91551-80840

SST: 09330-00021

(2) Remove the 8 bolts and flywheel sub-assembly from the crankshaft.

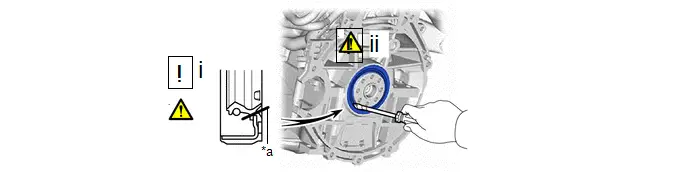

4. REMOVE REAR ENGINE OIL SEAL

| *a | Cut Position | - | - |

(1) Using a knife, cut through the lip of the rear engine oil seal.

(2) Using a screwdriver with its tip wrapped with protective tape, pry out the rear engine oil seal.

NOTICE:

Be careful not to damage the crankshaft.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | REAR ENGINE OIL SEAL | 11401L |

| - | - |

| 2 | FLYWHEEL SUB-ASSEMBLY | 13405 |

| - | - |

| 3 | TRANSMISSION INPUT DAMPER ASSEMBLY | 31270 |

| - | - |

| 4 | ENGINE ASSEMBLY | - | - | - | - |

| N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

| MP grease |

| Adhesive 1324 |

| ★ | Precoated part | - | - |

| *T1 | 1st: 49 (500, 36) 2nd: Turn 90° | - | - |

PROCEDURE

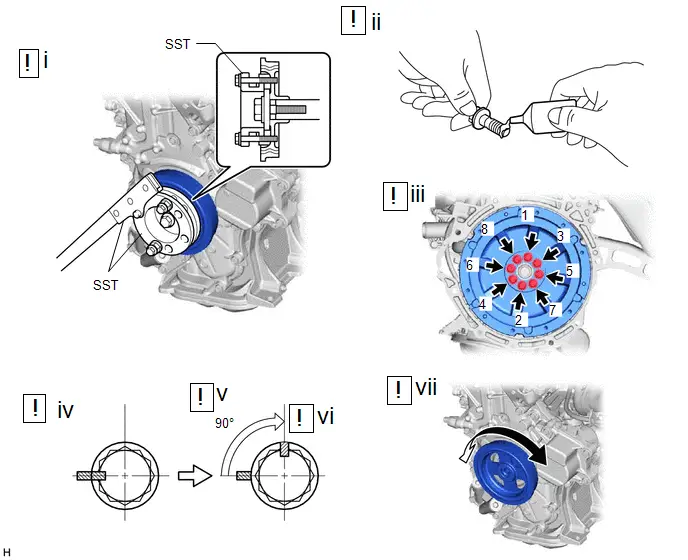

1. INSTALL REAR ENGINE OIL SEAL

| *a | Tap in Depth | - | - |

(1) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly horizontal.

- To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

(2) Apply MP grease to the lip of a new rear engine oil seal.

NOTICE:

Keep the lip free from foreign matter.

(3) Using SST and a hammer, tap in the rear engine oil seal.

SST: 09223-15030

SST: 09950-70010

09951-07100

Rear Engine Oil Seal Tap in Depth:

-1.0 to 1.0 mm (-0.0394 to 0.0394 in.)

NOTICE:

- Keep the lip free from foreign matter.

- Do not tap in the rear engine oil seal at an angle.

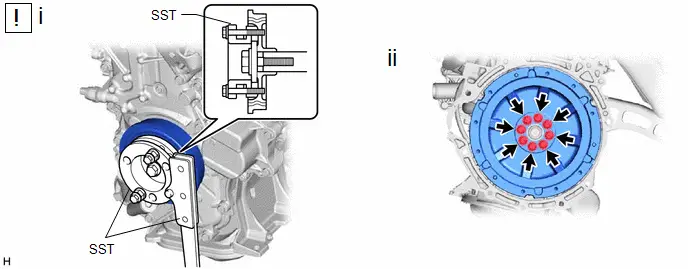

2. INSTALL FLYWHEEL SUB-ASSEMBLY

| Paint Mark | - | - |

(1) Using SST, hold the crankshaft pulley.

SST: 09213-58014

91551-80840

SST: 09330-00021

(2) Apply adhesive to the 8 bolts.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

(3) Install and uniformly tighten the 8 bolts in several steps in the order shown in the illustration.

Torque:

49 N·m {500 kgf·cm, 36 ft·lbf}

NOTICE:

Do not start the engine for at least 1 hour after installing the flywheel sub-assembly.

(4) Mark each bolt head with paint as shown in the illustration.

(5) Tighten the 8 bolts by 90° in the same order.

(6) Check that the paint marks are now at a 90° angle.

(7) Check that the crankshaft turns smoothly.

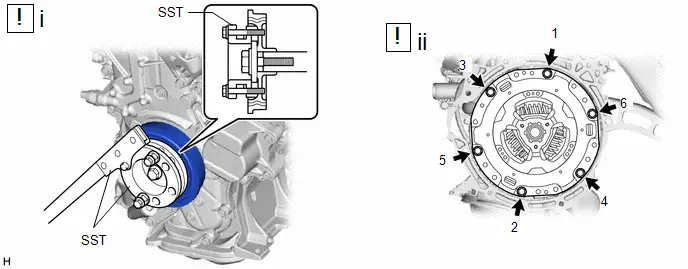

3. INSTALL TRANSMISSION INPUT DAMPER ASSEMBLY

(1) Using SST, hold the crankshaft pulley.

SST: 09213-58014

91551-80840

SST: 09330-00021

(2) Install the transmission input damper assembly to the flywheel sub-assembly with the 6 bolts. Uniformly tighten the 6 bolts in the order shown in the illustration.

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

NOTICE:

- Make sure that there is no oil on the transmission input damper assembly or flywheel sub-assembly.

- Make sure to install the transmission input damper assembly in the correct direction.

- Do not allow grease to contact the splines of the transmission input damper assembly or the input shaft.

4. INSTALL ENGINE ASSEMBLY

Click here

Toyota Prius (XW60) 2023-2026 Service Manual

Rear Crankshaft Oil Seal

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image