Toyota Prius: Low Pressure Magnetic Valve

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during No. 3 magnet valve assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedures | Effect/Inoperative Function When Necessary Procedures are not Performed | Link |

|---|---|---|---|

| *: Even when not replacing the part, it is necessary to perform the specified necessary procedures after installation. | |||

| Front bumper assembly* | Front television camera view adjustment | Panoramic View Monitor System |

|

| Advanced Park |

| ||

CAUTION / NOTICE / HINT

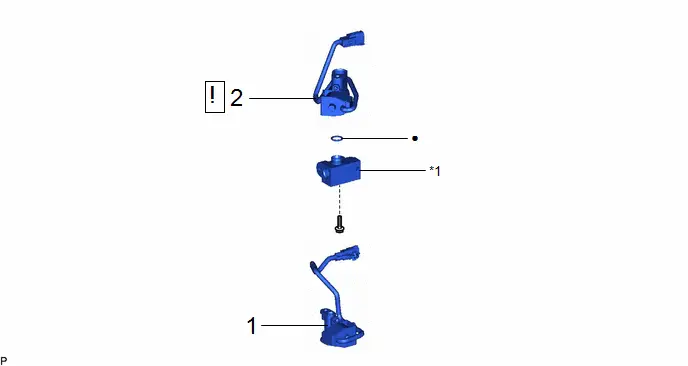

COMPONENTS (REMOVAL)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | NO. 2 MAGNET VALVE ASSEMBLY | 88690N | - | - | - |

| 2 | NO. 3 MAGNET VALVE ASSEMBLY | 88F90C |

| - | - |

| *1 | CONNECTOR TUBE | - | - |

| ● | Non-reusable part | - | - |

PROCEDURE

1. REMOVE NO. 2 MAGNET VALVE ASSEMBLY

Click here

2. REMOVE NO. 3 MAGNET VALVE ASSEMBLY

(1) Remove the bolt and No. 3 magnet valve assembly from the connector tube.

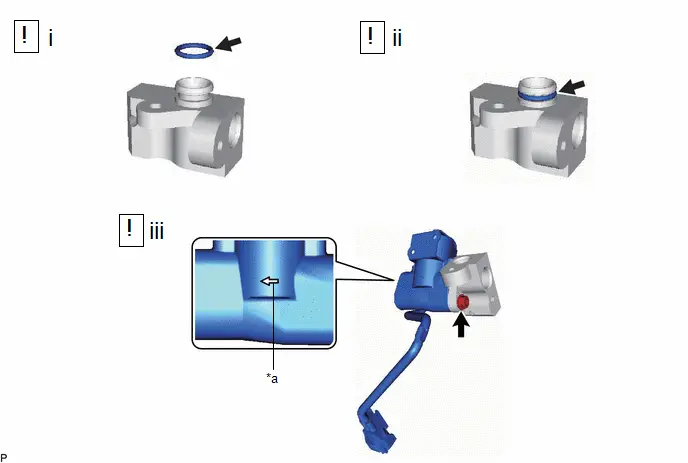

(2) Remove the O-ring from the connector tube.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

Inspection

INSPECTION

PROCEDURE

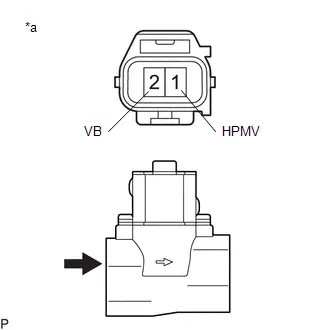

1. INSPECT NO. 3 MAGNET VALVE ASSEMBLY

| (a) Apply auxiliary battery voltage to the terminals of the connector, and check the No. 3 magnet valve assembly operates. OK:

If the result is not as specified, replace the No. 3 magnet valve assembly. |

|

Installation

INSTALLATION

CAUTION / NOTICE / HINT

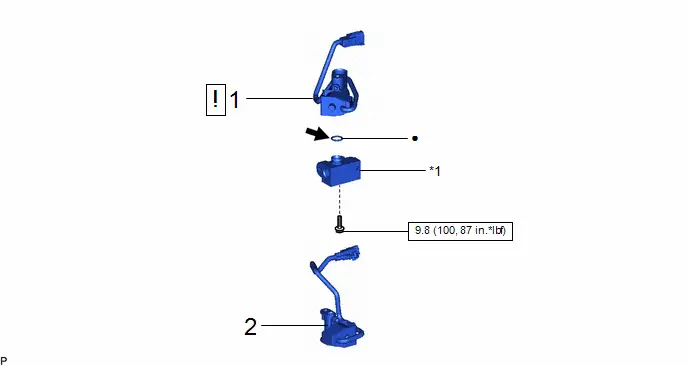

COMPONENTS (INSTALLATION)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | NO. 3 MAGNET VALVE ASSEMBLY | 88F90C |

| - | - |

| 2 | NO. 2 MAGNET VALVE ASSEMBLY | 88690N | - | - | - |

| *1 | CONNECTOR TUBE | - | - |

| N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

| Compressor oil ND-OIL 11 or equivalent | - | - |

PROCEDURE

1. INSTALL NO. 3 MAGNET VALVE ASSEMBLY

| *a | Reference Point | - | - |

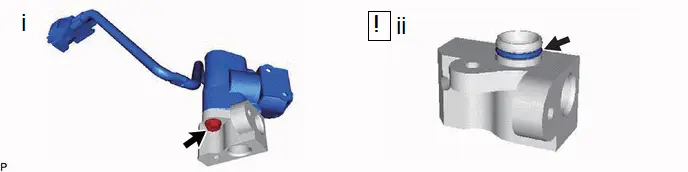

(1) Remove the vinyl tape from the connector tube and No. 3 magnet valve assembly, and sufficiently apply compressor oil to a new O-ring and the fitting surface of the connector tube.

Compressor Oil:

ND-OIL 11 or equivalent

(2) Install the O-ring to the connector tube.

NOTICE:

Keep the O-ring and O-ring fitting surface free from foreign matter.

(3) Install the No. 3 magnet valve assembly to the connector tube with the bolt.

NOTICE:

Make sure to install the No. 3 magnet valve assembly with the arrow facing the direction shown in the illustration.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

2. INSTALL NO. 2 MAGNET VALVE ASSEMBLY

Click here

Toyota Prius (XW60) 2023-2026 Service Manual

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image