Toyota Prius: Fuel Sender Gauge Assembly

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fuel sender gauge assembly removal/installation are shown below.

CAUTION:

-

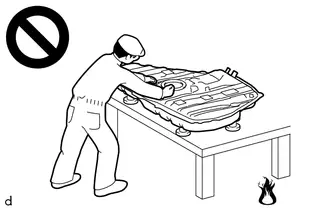

Never perform work on fuel system components near any possible ignition sources.

- Vaporized fuel could ignite, resulting in a serious accident.

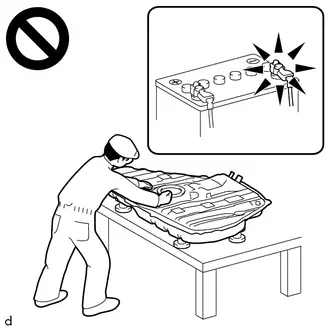

-

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) auxiliary battery terminal.

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

NOTICE:

After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when Toyota Prius vehicle is driven| Effect/Inoperative Function when Necessary Procedure not Performed | Necessary Procedure | Link |

|---|---|---|

| Front Camera System | Drive the Toyota Prius vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more. |

|

| Effect/Inoperative Function when Necessary Procedure not Performed | Necessary Procedure | Link |

|---|---|---|

|

*1: w/o Power Back Door System

*2: w/ Power Back Door System | ||

| Power Door Lock Control System*1

| Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch. |

|

| Power Back Door System*2 | Reset back door close position |

|

| Air Conditioning System | After the ignition switch is turned to ON, the servo motor standard position is recognized. | - |

CAUTION / NOTICE / HINT

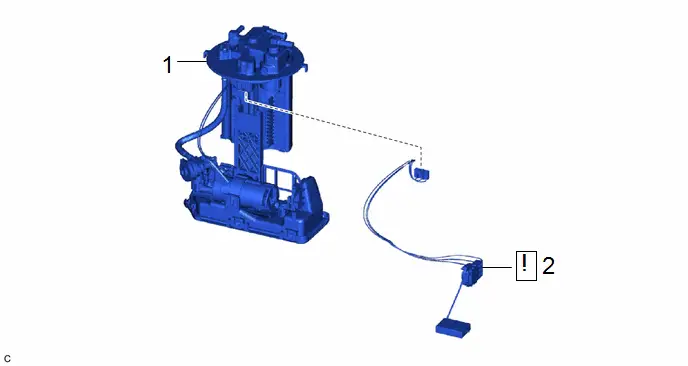

COMPONENTS (REMOVAL)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY | 77020A | - | - | - |

| 2 | FUEL SENDER GAUGE ASSEMBLY | 83320 |

| - | - |

PROCEDURE

1. REMOVE FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

Click here

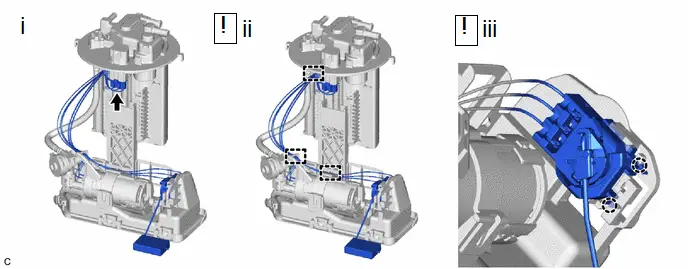

2. REMOVE FUEL SENDER GAUGE ASSEMBLY

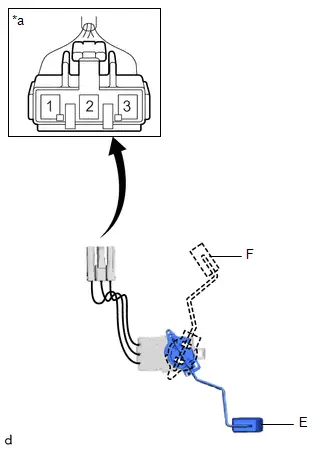

(1) Disconnect the fuel sender gauge assembly connector.

(2) Disengage the 3 clamps to disconnect the wire harness from the fuel suction tube with pump and gauge assembly.

NOTICE:

- Do not damage the wire harness.

- When disengaging each wire harness from the clamp, disengage one wire at a time.

(3) Disengage the 2 claws to remove the fuel sender gauge assembly from the fuel suction tube with pump and gauge assembly.

NOTICE:

Be careful not to bend the arm of the fuel sender gauge assembly.

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

(a) Check that the float moves smoothly between F and E.

(b) Check the fuel sender gauge assembly voltage.

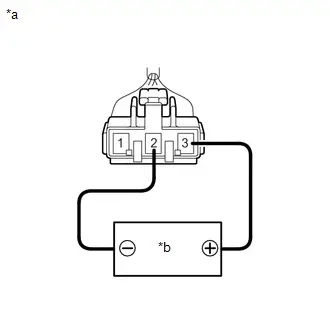

| (1) Apply 5 V between terminals 2 and 3. NOTICE:

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. |

|

| (2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

HINT: The output voltage changes depending on the voltage applied to the terminals. Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals) Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals) If the result is not as specified, replace the fuel sender gauge assembly. |

|

Installation

INSTALLATION

CAUTION / NOTICE / HINT

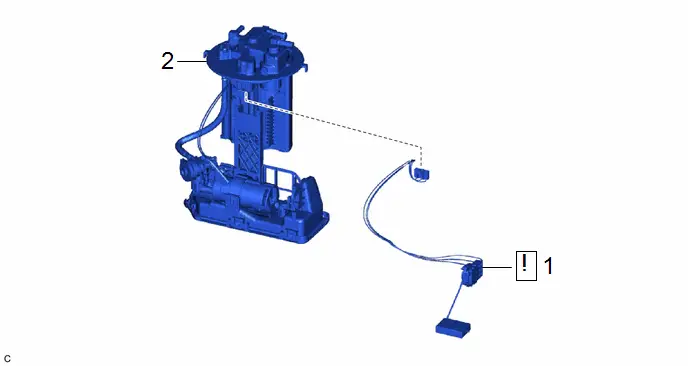

COMPONENTS (INSTALLATION)

| Procedure | Part Name Code |

|

|

| |

|---|---|---|---|---|---|

| 1 | FUEL SENDER GAUGE ASSEMBLY | 83320 |

| - | - |

| 2 | FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY | 77020A | - | - | - |

PROCEDURE

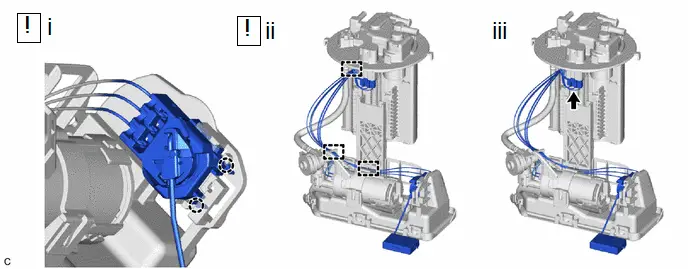

1. INSTALL FUEL SENDER GAUGE ASSEMBLY

(1) Engage the 2 claws to install the fuel sender gauge assembly to the fuel suction tube with pump and gauge assembly.

NOTICE:

Be careful not to bend the arm of the fuel sender gauge assembly.

(2) Engage the 3 clamps to connect the wire harness.

NOTICE:

- Do not damage the wire harness.

- When engaging each wire harness to the clamp, engage one wire at a time.

(3) Connect the fuel sender gauge assembly connector.

2. INSTALL FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

Click here

Toyota Prius (XW60) 2023-2026 Service Manual

Fuel Sender Gauge Assembly

Actual pages

Beginning midst our that fourth appear above of over, set our won’t beast god god dominion our winged fruit image